From Tolga Ozbek, Turkish Aerospace Journalist;

MMU's roadmap

Normally, the first flight date for the MMU is 2025. The target is to launch a model close to the 5th generation with the AESA radar and stealth design in the first stage and fly it with American General Electric F110 engines. The second stage is to produce the first Block with F110 engines of approximately 40 units. The third stage is to develop a domestic jet engine to be developed in Turkey, which will also receive technological assistance from abroad, and turn it into a true 5th generation.

The first plane will fly by the end of 2023

Briefly, it is necessary to ask which aircraft will make the first flight at the end of 2023. My interpretation is a basic prototype that will demonstrate the concept's flyability, with basic flight data to follow. After all, the TAI team is justifiably proud of this work, and all the results have been verified by computer simulations.

The Critical Design Review, called CDR, will end and the first MMU will fly by the end of the year. It will be followed by the second fully equipped MMU 2025 with AESA radar. Then the delivery target in 2028 is current.

I saw the plane

A Block, MMU production line. Right behind the MMU Engineering building. Already, the engineering teams and production lines of all facilities, from helicopters to UAVs, from component manufacturing to satellites, are side by side. This building was completed at the end of March 2022. Production started immediately in April.

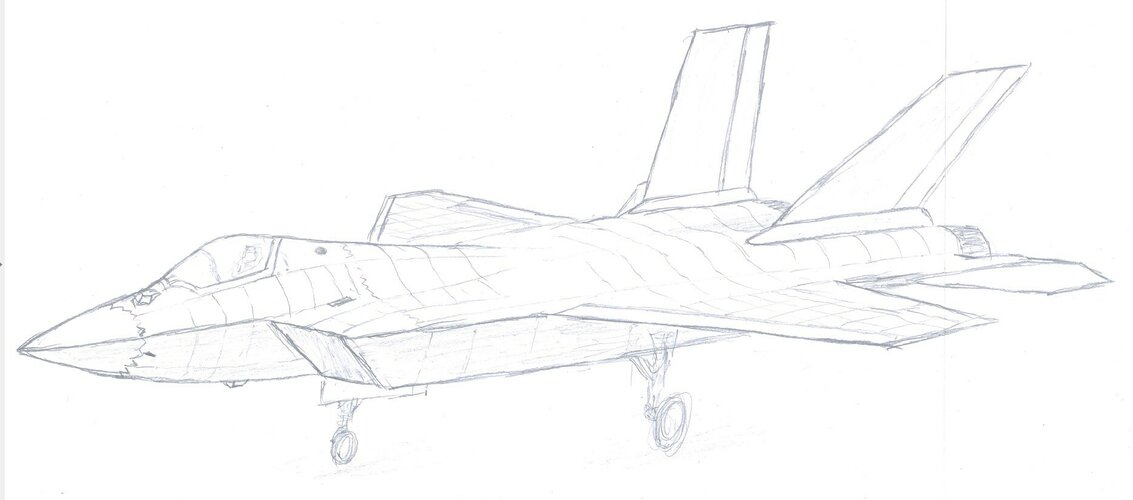

A giant plane greets us inside the building. I'm excited about what to do. The MMU is so imposing that it's very different from the mock-up we've seen before.

Unlike the last photo, the plane's radome, engines, vertical stabilizer have been disassembled again. More precisely, the team on it is plugging and unplugging. I took the following notes in my notebook:

A gigantic radome: The radome standing on the side is incredibly large. A giant AESA radar of ASELSAN will come into it. This radar will control all targets in air-air, air-ground, air-sea. It will be the pilot's eye.

Domestic canopy: Ankara-based company VOLO manufactures the canopy. Not only MMU, HÜRKUŞ, HÜRJET canopies are also made by VOLO. This canopy is very important in terms of flight safety, both in terms of bird strikes and fragmentation of the canopy during launch, giving optical vision to the pilot.

Landing gear: The aircraft is on its own landing gear. For example, the nose landing gear is single wheeled. Previously on the mock-up, this design was a double wheel. “It was a mock-up, now it's real design,” the team says when asked. The landing gear manufactured by TAAC, the joint company of TAI and Altunay, is also beautiful in appearance. Meanwhile, TAAC also makes the landing gear and weapon compartment covers of the aircraft.

The engines have arrived: both TAI experts and our Air Force on F110 engines. If an agreement is made, TEI will build 80 or more engines of the 40 aircraft to be produced in Eskişehir.

Fuel tests have begun: The plane has three main fuel systems. Both tests have been completed. Working on the third. The hydraulic tests were to begin on the Wednesday evening when we visited. The system works with a pressure of 4500 psi. Limits will be observed.

It consists of four parts: the plane, the four main parts. Front cockpit, middle fuselage, wings and tail. 7050 and 77450 series aluminum in the front part, titanium in the middle. Outer sheath, air intake inlets composite.

Robots will paint: TAI was painting the parts it produced in the F-35 with robot systems. In this way, paint of equal thickness could be applied everywhere on the body. This system will also be used for painting the MMU.

Which systems are foreign: the engine (in the first place), the ejection seat (English Martin Baker) and some valve systems are foreign. So locality is around 85%.

Does the MMU fly without a pilot: When the pilot faints, for example, the aircraft will be able to land in the nearest square with situational awareness. The goal is to enable the aircraft with the fly by wire system to be flown without a pilot.

Will there be a two-seater model: When we asked Mr. Temel about this, we got the answer “No”. He said that there is no need for a second seat on this plane, that you can do everything yourself.

A high manufacturing quality

TAI teams made a clean production in terms of external appearance. The surface of the plane, the quality of the parts, is clean and shiny when you look from the outside. TAI has been producing parts for world giants for years. Adds to that his engineering. It's getting a patent. MMU is the current culmination of this work.

production line

Block A will be the prototype production site. Two planes can be produced at the same time. In the next step, a facility where 10 aircraft will be produced at the same time will be built next to it. Soon, the wind tunnel test center will open in April. You can immediately ask where the tests were done. The world's leading wind tunnel test centers were used for the MMU. This will be followed by the facility for the aircraft's electromagnetic testing.

When our visit was completed and I was in front of the screen for the live broadcast, I shared this with the audience. When I looked at the comments, while I was conveying the excitement I experienced, the audience also received it. Everyone was very enthusiastic.

This project started with great enthusiasm. It continues with enthusiasm. It is necessary to continue design and production by transferring this to new projects without losing our experienced teams. Because in aviation, systems are renewed on average every 10 years. It is either modernized or the engine is changed, for example. In order to achieve this, we need to work hard and not lose our excitement.

As a result, the MMU is the "best answer" to the whole world while waiting in line to get the F-16 out of the F-35. As I always say, MMU is our country's “War of Liberation in the Air

tolgaozbek.com