- Joined

- 15 July 2020

- Messages

- 1,474

- Reaction score

- 4,525

Pretty unusual to do approach today that rather than an Iron/Copper Bird on the ground and CAD for physical integration. Could argue that it lowers risk I suppose but it is much more expensive and probably makes the testing take longer. These very early air vehicles are usually 100s $m to buildStructure is designed and built airworthy, but this aircraft will be used for accelerating complicated avionics integration and ground tests,

From an inside source, I got some info about whether this aircraft is going to fly or not.

Structure is designed and built airworthy, but this aircraft will be used for accelerating complicated avionics integration and ground tests,

If TAI wants her to fly, they can make her fly, but they will just build a new prototype

Yeah sort of. According to a dude I know over at TAI, they really could strap someone in there and fly it. Although that really isn't the intention here.From an inside source, I got some info about whether this aircraft is going to fly or not.

Structure is designed and built airworthy, but this aircraft will be used for accelerating complicated avionics integration and ground tests,

If TAI wants her to fly, they can make her fly, but they will just build a new prototype

I see, so basically this is a "reference model". Kinda reminds me of Russian T-50-7 Static article. She has working systems but not really meant to fly.

Exactly, it is a full fledged aircraft that can fly, but TAI wants it betterYeah sort of. According to a dude I know over at TAI, they really could strap someone in there and fly it. Although that really isn't the intention here.From an inside source, I got some info about whether this aircraft is going to fly or not.

Structure is designed and built airworthy, but this aircraft will be used for accelerating complicated avionics integration and ground tests,

If TAI wants her to fly, they can make her fly, but they will just build a new prototype

I see, so basically this is a "reference model". Kinda reminds me of Russian T-50-7 Static article. She has working systems but not really meant to fly.

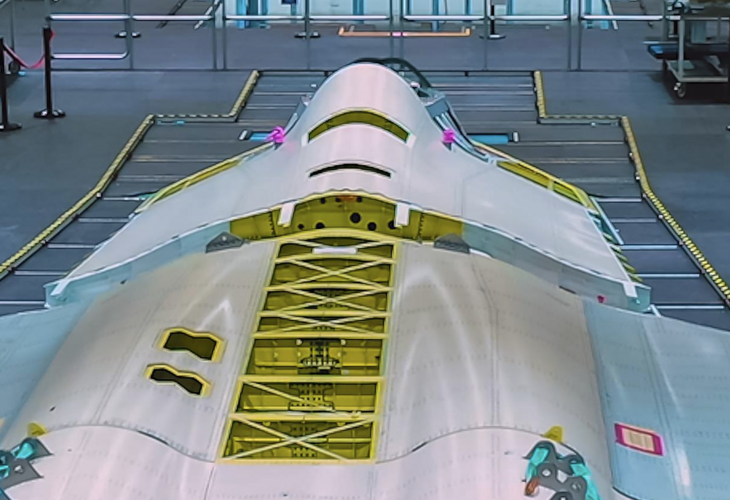

Here, you can see that Mid body-Aft connection doesn't have serration

Yes. If the join isn't going to open you can treat it with materials to bridge over the discontinuity. If the join is a panel which needs to open regularly in the air e.g landing gear or weapons bay it needs to be aligned for sure. If it opens regularly on the ground e.g. access panels, either it has to be aligned or treated before flight, which greatly increases maintenance times.

True, since they've also built an irom bird for their Hürjet trainer aircraft. Though like I've said before, you can't test the structural integrity of an aircraft with an iron bird. In that sense having a ground test vehicle built now sounds quite reasonable, as long as the FTV, which will be built after CDR, have enough similarity to the GTV structurally.Pretty unusual to do approach today that rather than an Iron/Copper Bird on the ground and CAD for physical integration. Could argue that it lowers risk I suppose but it is much more expensive and probably makes the testing take longer. These very early air vehicles are usually 100s $m to build

it is a joint, you can see it in every F-35 photo, even the flying ones (even though it is harder to see because of RAM applied over it)Here, you can see that Mid body-Aft connection doesn't have serration

Is that line in the first picture even a joint? Might as well be a tool cable for all the evidence to the contrary, and the second is too low-res to even tell anything at all.

Yes. If the join isn't going to open you can treat it with materials to bridge over the discontinuity. If the join is a panel which needs to open regularly in the air e.g landing gear or weapons bay it needs to be aligned for sure. If it opens regularly on the ground e.g. access panels, either it has to be aligned or treated before flight, which greatly increases maintenance times.

There clearly seems to be a bit more to it that that, though. Nobody is going to remove the forward fuselage from the airframe any more regularly than the rear section, yet the joint between the former and the mid fuselage is serrated on the TFX while the seam with the latter isn't. Same type of joint, completely different implementation.

And it's not just a serrated treatment covering a straight joint either. If you look at the forward edge of the upper wing skin, where the panel in front is still missing, you can see that it's the panel edge itself that is serrated.

TF-X current form (white lines) over TurAF presentation drawingView attachment 688036

Not specifically external funding, but they did look for a partner early on for the project. They've entered formal negotiations with Korea and Sweden for joint development although both negotiations fell through. SAAB was involved in preliminary design studies in the early-mid 2010s, when there were three different designs if you'd recall. It's also the time when TF-X was more of a Falcon or Super Hornet sized aircraft, not the F-15/F-22 sized fighter of today.Has TAI sought any kind of external funding for this project?

similar to how Korea received (sort of) funding from Indonesia for their KFX project?

is the TFX intended for export or primarily home market only?

I could imagine the TFX competing with the FC-31 in Pakistan, which has a history of using both Chinese and Turkish weapons

True, since they've also built an irom bird for their Hürjet trainer aircraft. Though like I've said before, you can't test the structural integrity of an aircraft with an iron bird. In that sense having a ground test vehicle built now sounds quite reasonable, as long as the FTV, which will be built after CDR, have enough similarity to the GTV structurally.Pretty unusual to do approach today that rather than an Iron/Copper Bird on the ground and CAD for physical integration. Could argue that it lowers risk I suppose but it is much more expensive and probably makes the testing take longer. These very early air vehicles are usually 100s $m to build

www.defenceturkey.com

www.defenceturkey.com

Closer look at the body work

View attachment 688124

Seems like there is a kind of non-shiny cover for the screws

Closer look at the body work

View attachment 688124

It won't likely be present on GTU-0. I'm expecting a visible slot for it on Block 0.Where does the gun go? It doesn't look very obvious from the in-build pictures

TAI Ankara project office denied this statement. They 'believe' Mr. Kotil said 2024 by mistake and confused it with the CDR. AFAIK no one was informed about this decision.TF-X's maiden flight has been moved to 2024 now!

-Landing gears have also arrived. Engines and gears will be installed on the 20th.

Happens quite frequently ngl. But yeah we will see. The rest of the statement is true tho.TAI Ankara project office denied this statement. They 'believe' Mr. Kotil said 2024 by mistake and confused it with the CDR. AFAIK no one was informed about this decision.TF-X's maiden flight has been moved to 2024 now!

-Landing gears have also arrived. Engines and gears will be installed on the 20th.

What engines?TF-X's maiden flight has been moved to 2024 now!

-Landing gears have also arrived. Engines and gears will be installed on the 20th.

What engines?TF-X's maiden flight has been moved to 2024 now!

-Landing gears have also arrived. Engines and gears will be installed on the 20th.

Are they using existing Western engines?

Is the Turkish engine effort so far along that its years away from being flyable?

Very impressive if so, considering they've never made an engine of this class before.

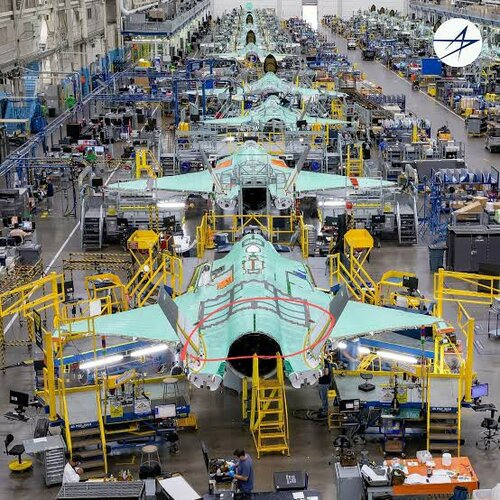

Mr Kotil: "The mid-body of MMU is a whole 4 ton piece. We decided to make this part in one piece and it was produced vertically. This is an innovation and a subject to be patented. In this way, TFX MMU consists of 4 large body parts and they are combined"

"The entire body of the MMU is composite. The frames inside are made of titanium and aluminum. The composite coating on MMU has to be produced in one piece. This composite piece is produced at the 6x12m pressure furnaces in TUSAŞ composite facility"

I guess what he actually meant was "entire skin of the body". Anyways, fancy lingos that actually doesn't mean much are to be expected.Some contradictions in that statement. It seems pretty conventional metal frames with composite skins that are made into a number of "superblocks" and then joined later? Pretty much like F-35 or Typhoon.

I guess what he actually meant was "entire skin of the body". Anyways, fancy lingos that actually doesn't mean much are to be expected.Some contradictions in that statement. It seems pretty conventional metal frames with composite skins that are made into a number of "superblocks" and then joined later? Pretty much like F-35 or Typhoon.

Speed...What benefits do they expect vertical assembly to give? Easier access to the top skin? But still have to work at height anyway given the size of the blocks

Then it ends up horizontal assembly anyway when you join the blocks