You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TAI TF-X / Milli Muharip Uçak MMU Kaan

- Thread starter ocay

- Start date

Waterballoon

ACCESS: Confidential

- Joined

- 27 October 2023

- Messages

- 114

- Reaction score

- 233

No clone whatsoever.Alright, than your opinion is that Turkey has not done it already and cannot do it in the time left.

My money is on the Turkish F110-GE-132 clone by 2030.

It'll be even better but will progress in steps.

The first iteration will be all or mostly metal, non TVC, 36000lbf of thrust, with all blisk compressors with forward swept blade tips to scoop up as much air as possible.

Composite duct parts, TVC system, CMC and MMC are for later iterations bumping the thrust to 38000lbf and then to 40000lbf. All of these technologies are being researched currently through collaborations with universities and R&D projects funded by institutions such as SSB.

Many times the 17 year long EJ200 development trajectory (and for that matter the WS-15 as well) has been rejected by the CEO of TEI and the previous director of SSB. He said it multiple times it won't take that long while it won't be as short as what the previous head of TAI was pushing for (5 years!)

From an interview with the previous director of SSB in May '23:

- The engine program in terms of fielding a national engine for MMU, how far away is that? Is it realistic? Can it be done?

It is realistic but in terms of timeline it is of course... should be reasonable. We don't claim that we can have an indigenous engine in a couple of years, it will take some years we know very well experienced jet manufacturers, even if they had started it would take about 8 or 10 or 12 years so we have also targeted that kind of duration and we had already started design work and also some materials capabilities build up so within a couple of years or maybe more maybe several years but certainly not 10, much less than that.

- So much sooner than perhaps the standard jetengine...

Yes, it should be.

link

Last edited:

If you think deleting 3 stages from the HPC and deleting one turbine stage is still making it a 'quite similar' engine to the F110, then I got a bridge to sell you.

It's been done before (AL-31FM3). In fact, Salyut is an entity in a remarkably similar position to TUSAS/Turkey: they had significant experience manufacturing and assembling the base engine, as well as a certain amount of design competence from other projects. But they didn't have all the pieces and overall IP was owned by another company (Saturn, in this case). There are worse approaches to take under the circumstances, and the indigenous TS1400 turboshaft is certainly a dead ringer in concept for the LHTEC T800 it is designed to replace.

Whether that still qualifies as 'similar' is a matter of perspective and intent, I guess. Are you trying to downplay the scale of investment required (Salyut), or parade your skills (TUSAS)?

Last edited:

- Joined

- 29 November 2010

- Messages

- 1,773

- Reaction score

- 3,474

a reminder everyone, this is the thread about TAI KAAN. after several rounds of deleted posts by multiple mods, if any more off topic conversations continue, we will start escalating measures to ensure that posts remain on topic.

No ifs and buts.

No ifs and buts.

Last edited:

Waterballoon

ACCESS: Confidential

- Joined

- 27 October 2023

- Messages

- 114

- Reaction score

- 233

I wonder why people would be so disingenuous to compare '90s cutting edge turbine technology consisting of SX materials, blisks and TBC to contemporary cutting edge variable cycle technology, blings and CMC HPT blades? The Turks are aiming for the 1st and not the latter.

We are talking about a country which put 4 turbofan engined aircraft in the air within the span of 14 months, 3 of which are (V)LO, 3 of which are supersonic capable and 2 of which are unmanned.

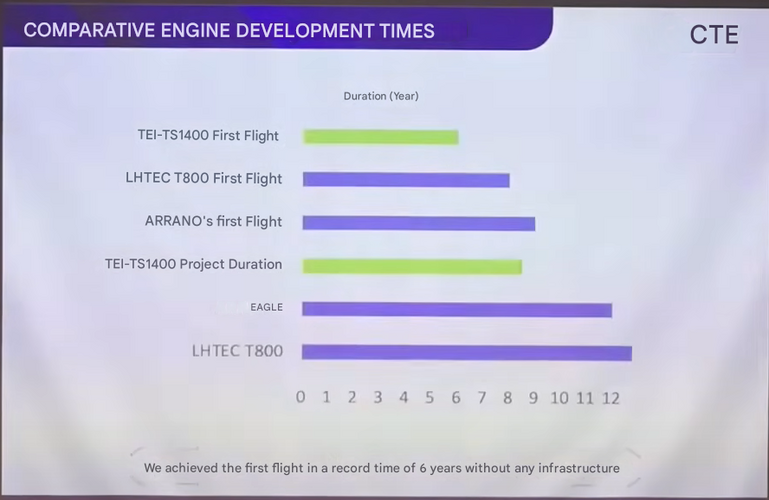

It is the same country who put their first turboshaft engine in the air from scratch, 25% to 33% faster than their modern counterparts while a pandemic was ravaging supplylines globally and locally.

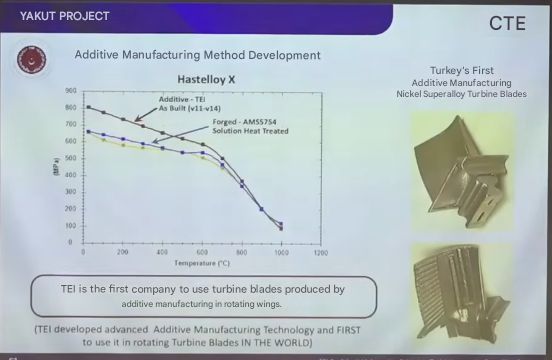

They are among the first, if not the first as claimed below to print Ni superalloy turbine blades as well (turbowizardry indeed)

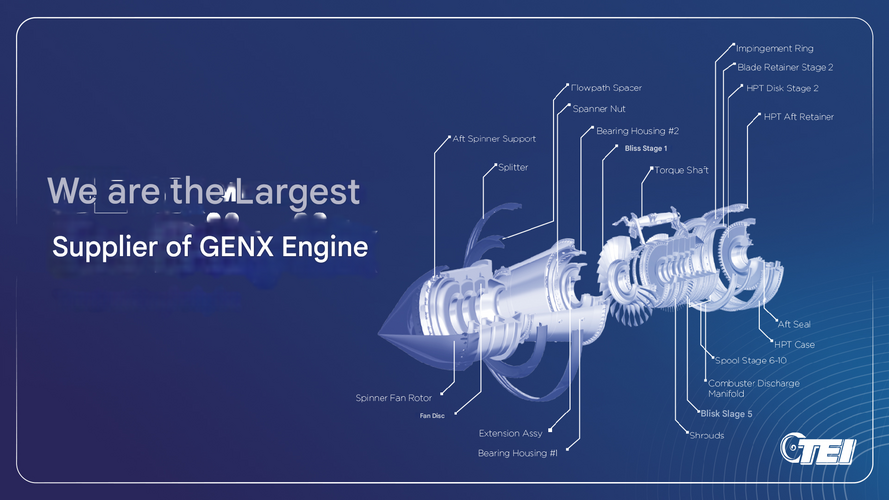

They are providing more than 1000 blisk parts every year for some of the most prolific turbofan engines in the world...

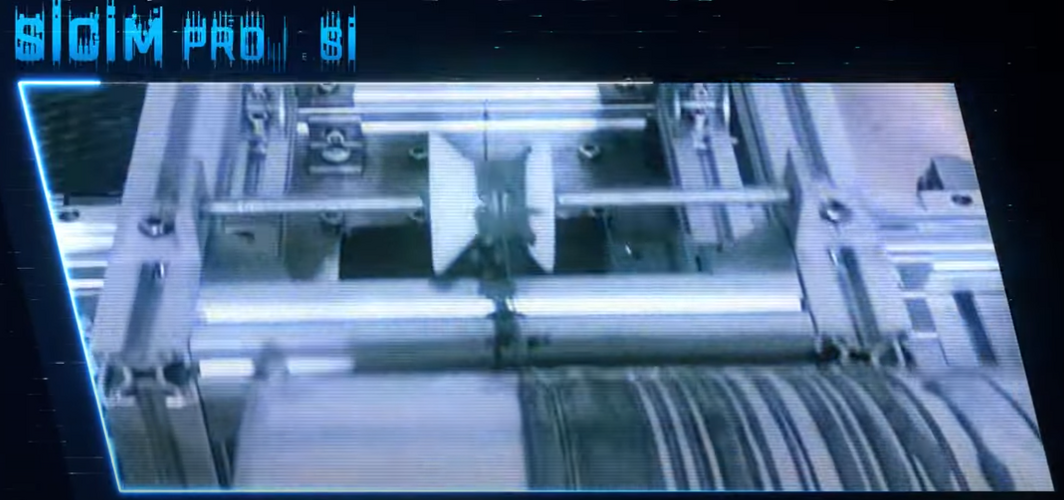

...and are able to indigenously design blisks with advanced shaping. Take note of the forwards swept blade tips. These are the technologies that enable a pressure ratio of 5 for a 3 stage fan. A 3 LPC/6 HPC stage TF36000 could reach an OPR of at least 35 easily, should there be a need.

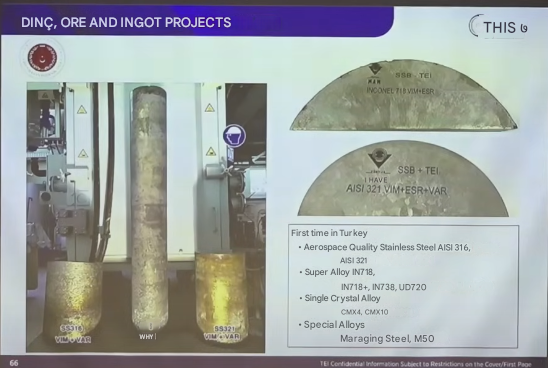

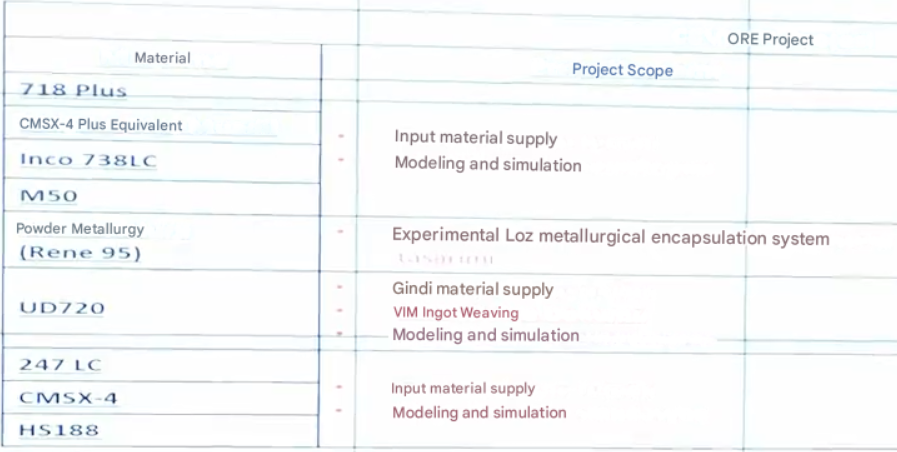

They are developing and casting themselves various alloys for turbine engines from the Incos to the CMSXs...

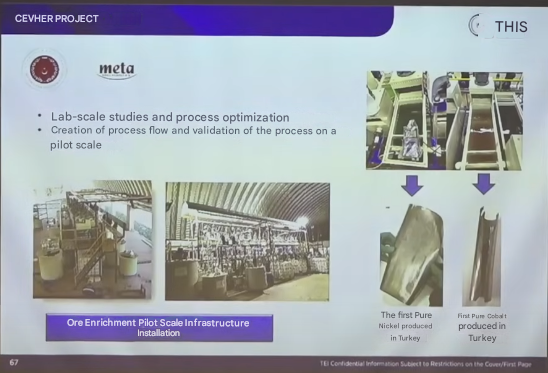

...which they are also mining themselves

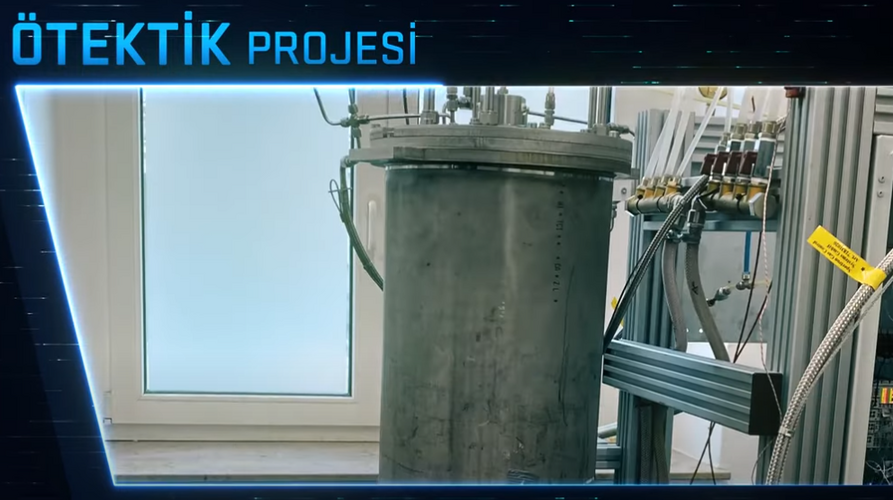

And they are funding two CMC and one MMC project, SİCİM (development of SiC fiber and SiC Matrix Composite), AMETİST (development of laser metal powder melting process for Metal Matrix Composite materials) and ÖTEKTİK (development of high temperature Eutectic Oxide Ceramic Matrix Composites).

There is more (like indigenous turbine engine design software etc.) but this should be enough to show what the Turks are capable enough. I'll try to keep it updated as much as possible.

And there is always some sturdy Soviet legacy Ivchenko-Progress support from the sides to make sure things don't go too much in the "fragile boutique" direction.

We are talking about a country which put 4 turbofan engined aircraft in the air within the span of 14 months, 3 of which are (V)LO, 3 of which are supersonic capable and 2 of which are unmanned.

It is the same country who put their first turboshaft engine in the air from scratch, 25% to 33% faster than their modern counterparts while a pandemic was ravaging supplylines globally and locally.

They are among the first, if not the first as claimed below to print Ni superalloy turbine blades as well (turbowizardry indeed)

They are providing more than 1000 blisk parts every year for some of the most prolific turbofan engines in the world...

...and are able to indigenously design blisks with advanced shaping. Take note of the forwards swept blade tips. These are the technologies that enable a pressure ratio of 5 for a 3 stage fan. A 3 LPC/6 HPC stage TF36000 could reach an OPR of at least 35 easily, should there be a need.

They are developing and casting themselves various alloys for turbine engines from the Incos to the CMSXs...

...which they are also mining themselves

And they are funding two CMC and one MMC project, SİCİM (development of SiC fiber and SiC Matrix Composite), AMETİST (development of laser metal powder melting process for Metal Matrix Composite materials) and ÖTEKTİK (development of high temperature Eutectic Oxide Ceramic Matrix Composites).

There is more (like indigenous turbine engine design software etc.) but this should be enough to show what the Turks are capable enough. I'll try to keep it updated as much as possible.

And there is always some sturdy Soviet legacy Ivchenko-Progress support from the sides to make sure things don't go too much in the "fragile boutique" direction.

Last edited:

- Joined

- 27 December 2005

- Messages

- 17,742

- Reaction score

- 26,323

Have you considered posting this in a topic about Turkish jet engine development?

It would be better there than here.

It would be better there than here.

Radonislav

ACCESS: Confidential

- Joined

- 16 November 2022

- Messages

- 152

- Reaction score

- 214

That's not correct

Waterballoon

ACCESS: Confidential

- Joined

- 27 October 2023

- Messages

- 114

- Reaction score

- 233

Didn't know there was a thread on Turkish propulsion systems my apologies.Have you considered posting this in a topic about Turkish jet engine development?

It would be better there than here.

Consider it done. You want me to delete my post in this thread then?

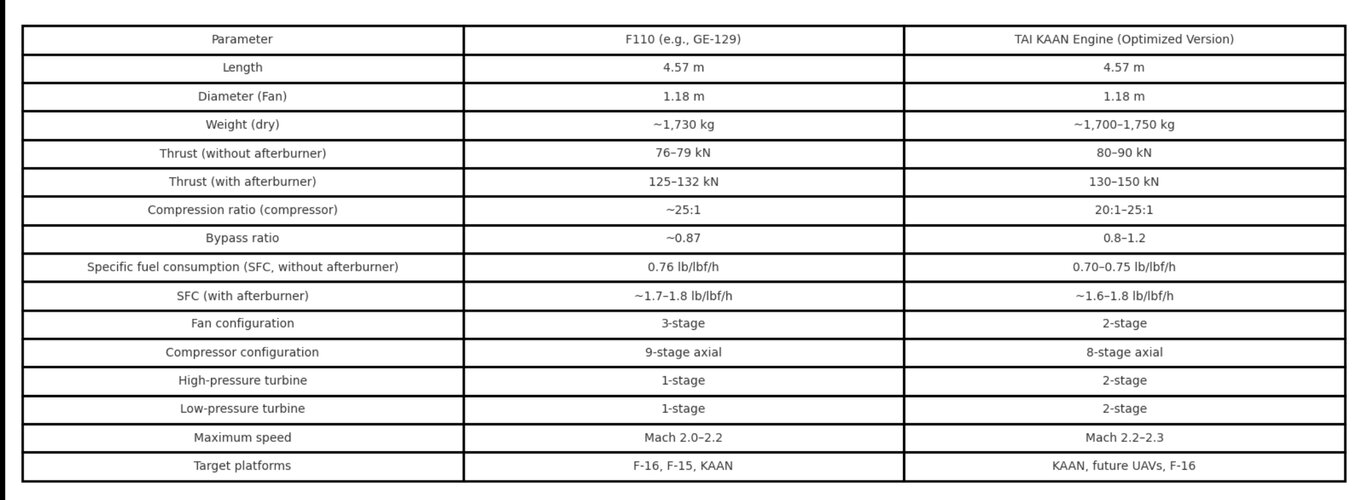

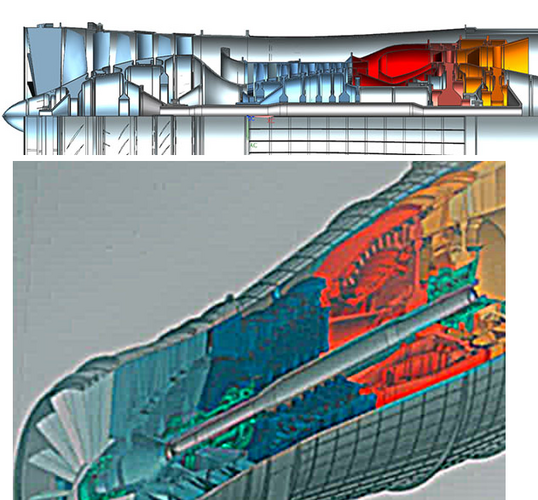

What would be the configuration of the TAI KAAN Engine?

TAI KAAN is to a certain extent bound/limited by the size of the F-110, as it will fly at least as Block 0 and 1.

I assume that the design will be based on the F-110, with modern approaches in the first revision as an Engine, it will probably be designed more moderately as an engine, but with fewer mechanically moving parts than F-110 and a little more thrust through better and modern design e.g. my example 6-8 years development time would be realistic if TUSAS, TEI and Co have been working on it since 2018 and the design does not differ significantly from the F-110.

For example:

It is just one example

TAI KAAN is to a certain extent bound/limited by the size of the F-110, as it will fly at least as Block 0 and 1.

I assume that the design will be based on the F-110, with modern approaches in the first revision as an Engine, it will probably be designed more moderately as an engine, but with fewer mechanically moving parts than F-110 and a little more thrust through better and modern design e.g. my example 6-8 years development time would be realistic if TUSAS, TEI and Co have been working on it since 2018 and the design does not differ significantly from the F-110.

For example:

It is just one example

Waterballoon

ACCESS: Confidential

- Joined

- 27 October 2023

- Messages

- 114

- Reaction score

- 233

4 turbine stages? Congratz, you designed the worlds first TurbofanshaftWhat would be the configuration of the TAI KAAM Engine?

TAI KAAN is to a certain extent bound/limited by the size of the F-110, as it will fly at least as Block 0 and 1.

I assume that the design will be based on the F-110, with modern approaches in the first revision as an Engine, it will probably be designed more moderately as an engine, but with fewer mechanically moving parts than F-110 and a little more thrust through better and modern design e.g. my example 6-8 years development time would be realistic if TUSAS, TEI and Co have been working on it since 2018 and the design does not differ significantly from the F-110.

For example:

View attachment 756911

Unless you are trying to design an engine for a VTOL like the F-35B with a liftfan, even then 3 turbine stages should be enough.

Why? I am not an expert, so I say this with great reservation?4 turbine stages? Congratz, you designed the worlds first Turbofanshaft

Unless you are trying to design an engine for a VTOL like the F-35B with a liftfan, even then 3 turbine stages should be enough.

The 1 low and 1 high pressure turbine of the F-110 has the disadvantage that the pressure is not evenly distributed and the wear is correspondingly higher.

A 2-stage system for high and low pressure turbines with a pressure ratio of 25:1 or 30:1 would allow for a better overall load and longer engine life.

It also eliminates one main fan to 2 and one compressor to 8 instead of 9, making the engine easier and cheaper to maintain. The weight will also be less than the F-110

But you have to take into account that the energy recovery would be slightly lower compared to the F-110, but this could be further compensated by the more modern approach and design optimization.

Finally, it would be 8-10% more powerful than the F-110 129.

Again I say this with great reservation, I am neither an engine engineer nor a pilot.

- Joined

- 15 July 2020

- Messages

- 1,481

- Reaction score

- 4,561

Waterballoon

ACCESS: Confidential

- Joined

- 27 October 2023

- Messages

- 114

- Reaction score

- 233

You are trying too hard. TRMotor has already shared images of the engine. It has a 3-6-2 configuration. Actually a 3-6.5-2 because there is a small stage that pushes 'cool' air into the HPT stage.Why? I am not an expert, so I say this with great reservation?

The 1 low and 1 high pressure turbine of the F-110 has the disadvantage that the pressure is not evenly distributed and the wear is correspondingly higher.

A 2-stage system for high and low pressure turbines with a pressure ratio of 25:1 or 30:1 would allow for a better overall load and longer engine life.

It also eliminates one main fan to 2 and one compressor to 8 instead of 9, making the engine easier and cheaper to maintain. The weight will also be less than the F-110

But you have to take into account that the energy recovery would be slightly lower compared to the F-110, but this could be further compensated by the more modern approach and design optimization.

Finally, it would be 8-10% more powerful than the F-110 129.

Again I say this with great reservation, I am neither an engine engineer nor a pilot.

Top old image, bottom newer image with enhanced sharpness

snne

ACCESS: Top Secret

- Joined

- 3 July 2022

- Messages

- 1,384

- Reaction score

- 4,495

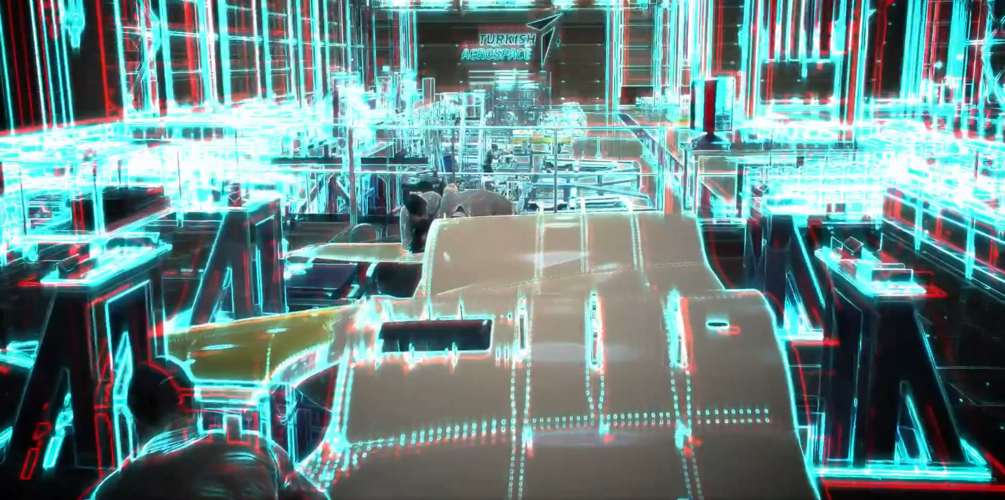

TurAF officials and defense industry representatives came together at Turkish Aerospace (TAI) facilities to evaluate the current situation of KAAN.

View: https://x.com/SavunmaSanayii/status/1884289981717614714

This probably has something to do with the completion of the CDR phase and the recently speculated addition of partner nation(s).

View: https://x.com/SavunmaSanayii/status/1884289981717614714

This probably has something to do with the completion of the CDR phase and the recently speculated addition of partner nation(s).

snne

ACCESS: Top Secret

- Joined

- 3 July 2022

- Messages

- 1,384

- Reaction score

- 4,495

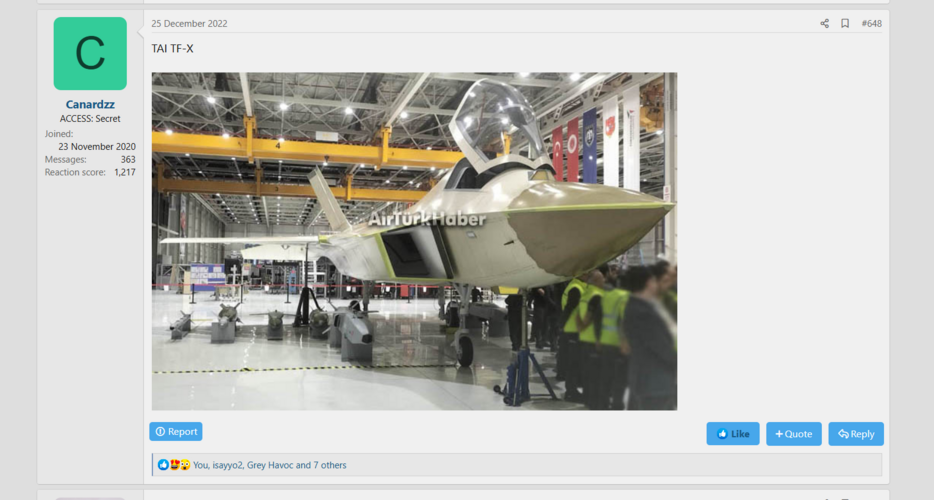

The model at the center? If so, no; that is only a scaled model of the mock-up that was revealed at Le Bourget in 2018. Hence it is quite dated.Is that the look of prototype 2? If so, indeed it looks significantly different from 1st prototype

Meanwhile, here's the latest pic of P0/GTU-0:

- Joined

- 15 July 2020

- Messages

- 1,481

- Reaction score

- 4,561

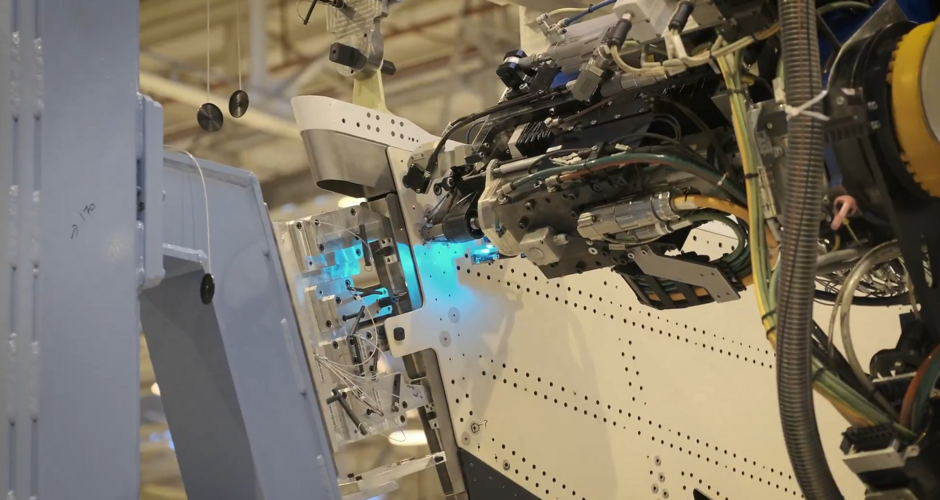

This tour given to journalist around 2 weeks ago; looks like a fresh engine on the side covered by an orange tarp - there were speculation around TF-36000 1:1 scale mock-up being test fitted to KAAN P-0 - most likely GE F110 engine

View: https://www.youtube.com/watch?v=9tLlFxitMpM

View: https://www.youtube.com/watch?v=9tLlFxitMpM

snne

ACCESS: Top Secret

- Joined

- 3 July 2022

- Messages

- 1,384

- Reaction score

- 4,495

Yep, that's a 110 for sure. In fact, there were even more clear images of it in an another forum a while back revealing the fan and whatnot.This tour given to journalist around 2 weeks ago; looks like a fresh engine on the side covered by an orange tarp - there were speculation around TF-36000 1:1 scale mock-up being test fitted to KAAN P-0 - most likely GE F110 engine

View attachment 757839View: https://www.youtube.com/watch?v=9tLlFxitMpM

-----

So, I've found the photo and unfortunately the fan has a cover on it so you can't see it but all that detail in the aft section of the engine indicates that this is in fact an F110.

This was taken during the Saudi visit:

- Joined

- 15 July 2020

- Messages

- 1,481

- Reaction score

- 4,561

Turkish Navy Design Project Office Manager Captain Hakan Uçar stated that discussions are taking place with TUSAŞ for a possible carrier-based KAAN variant.

View: https://x.com/turdefcom/status/1892272345793843435

View: https://x.com/turdefcom/status/1892272345793843435

Maybe if they moved those damn intakes behind the cockpit and got rid of the side bays they could spend that saved weight on beefier landing gear and carrier strengthening.A carrier based variant is going to have a heavier airframe which would compromise its performance unless it also has uprated engines. too

siegecrossbow

I really should change my personal text

- Joined

- 12 March 2012

- Messages

- 707

- Reaction score

- 2,106

Maybe if they moved those damn intakes behind the cockpit and got rid of the side bays they could spend that saved weight on beefier landing gear and carrier strengthening.

That’s pretty much a new plane…

That’s pretty much a new plane…

Well they said expect the future iterations to be much different, ala YF-22 to F-22.

No way they got it right straight away with the roll out bird.

- Joined

- 2 January 2006

- Messages

- 3,824

- Reaction score

- 5,114

Well they said expect the future iterations to be much different, ala YF-22 to F-22.

No way they got it right straight away with the roll out bird.

But it makes no sense just for a projected naval variant to do it once again

Last edited:

- Joined

- 15 July 2020

- Messages

- 1,481

- Reaction score

- 4,561

Gokhan BVR Missile

View attachment 760324

It has a very strong resemblance to the Meteor LRAAM.

- Joined

- 15 July 2020

- Messages

- 1,481

- Reaction score

- 4,561

It has a very strong resemblance to the Meteor LRAAM.

Agreed, to the extent that Gokhan will also have cropped and full fin variant just like Meteor

Attachments

- Joined

- 15 July 2020

- Messages

- 1,481

- Reaction score

- 4,561

A Recap for the First Anniversary of KAANâs Maiden Flight | TURDEF

Following the maiden flight on 21 February 2024, developments regarding TUSAÅâs KAAN fighter have continued, including new prototypes and plans.

""Shortly before the second flight, TUSAŞ announced that the second prototype P1 would make its maiden flight at the end of 2025. The new prototype incorporates design changes, including size management.

The new design is notably slightly smaller, with reduced length and wingspan. TUSAŞ has published these new specifications as 20.3 m and 13.4 m, respectively, which are smaller than the values of P0. The height has also been reduced from six meters to five meters.

New test facilities will also be built for the future tests of the prototyping phase:

1-Electromagnetic compatibility in a fully anechoic environment,

2-Large-scale structural strength and fatigue test facilities,

3-Engine/APU integration and qualification test setups,

4-Hydraulic, fuel, electrical, pneumatic, and avionics integration and qualification test setups,

5-Lightning strike safety testing,

6-Climate system design and integration laboratories,

7-Near-field radar cross-section measurement,

8-Development test centres for indigenous components (e.g., avionics computers, helmets, generators, pumps, landing gear, hooks, gearboxes, oxygen/nitrogen systems, etc.).

More prototypes will be built for said tests, with the third prototype P2 under aassembly.

Aside from the prototype phase developments, TUSAŞ is drawing potential new routes for KAAN. One of these routes came to light with the Turkish Navy Design Project Office Manager Captain Hakan Uçar’s recent interview with the Sabah newspaper regarding the MUGEM aircraft carrier.

Uçar stated that the Design Project Office and TUSAŞ are discussing a possible naval variant of KAAN for use onboard the future aircraft carrier, which is planned to use an array of unmanned and manned platforms (Bayraktar TB3, Anka-III, Hürjet LCA, Kızılelma, helicopters, etc.).

To sum everything up, the first year has been fruitful for KAAN; with the first prototype close to its third flight, the second prototype P1 being fleshed out towards the end of 2024, the third prototype entering production, and discussions for a naval version to be used onboard the MUGEM aircraft carrier taking place.""

snne

ACCESS: Top Secret

- Joined

- 3 July 2022

- Messages

- 1,384

- Reaction score

- 4,495

snne

ACCESS: Top Secret

- Joined

- 3 July 2022

- Messages

- 1,384

- Reaction score

- 4,495

Gokhan BVR Missile

View attachment 760324

Full view

For those of you who remember, this presentation with mock-ups was made back in December 2022 to a delegation of officials from the Gulf. This means that they hid the mock-up of the new BVRAAM from us for two years...

Last edited:

siegecrossbow

I really should change my personal text

- Joined

- 12 March 2012

- Messages

- 707

- Reaction score

- 2,106

Full view

View attachment 760383

For those of you who remember, this presentation with mock-ups was made back in December 2022 to a delegation of officials from the Gulf. This means that they hid the mock-up of the new BVRAAM from us for two years...

View attachment 760385

I just realized one unique characteristic of KAAN not seen on other fifth gen fighter aircraft — the vertical slabs are not mounted on booms in the tail section but on top of the engine nacelles. Pretty sure someone else might have commented on this in this thread but I’m not digging through 3500 posts…

snne

ACCESS: Top Secret

- Joined

- 3 July 2022

- Messages

- 1,384

- Reaction score

- 4,495

Yeah I hate this detail...I just realized one unique characteristic of KAAN not seen on other fifth gen fighter aircraft — the vertical slabs are not mounted on booms in the tail section but on top of the engine nacelles. Pretty sure someone else might have commented on this in this thread but I’m not digging through 3500 posts…

I'm sure that it wasn't purely an aesthetical design choice and that they had to make those compromises but I hope they can mask the engines in the production version for better IR/Radar Low Observability.

- Joined

- 15 July 2020

- Messages

- 1,481

- Reaction score

- 4,561

I just realized one unique characteristic of KAAN not seen on other fifth gen fighter aircraft — the vertical slabs are not mounted on booms in the tail section but on top of the engine nacelles. Pretty sure someone else might have commented on this in this thread but I’m not digging through 3500 posts…

There's a significant change in height between the P0 and P1, perhaps the reduction means the vertical slabs have shifted to the tail section

How do you know the dimensions of the P1?There's a significant change in height between the P0 and P1, perhaps the reduction means the vertical slabs have shifted to the tail section

donnage99

ACCESS: Top Secret

- Joined

- 16 June 2008

- Messages

- 1,355

- Reaction score

- 861

I know placement of twin tails can potentially have large drag implication, also could interfere with vortex flow off the forebody. Anyone can theorize what possibly be reason why the tails move from positions that enclose the engines from the side to on top of the engine?

- Joined

- 15 July 2020

- Messages

- 1,481

- Reaction score

- 4,561

How do you know the dimensions of the P1?

Loading…

www.secretprojects.co.uk

Why are we assuming that those are not the dimensions of the P0 but of the P1?Loading…

www.secretprojects.co.uk

Do you think the round figures(6m height, 14m wingspan etc.) they shared some years back represents P0?

- Joined

- 15 July 2020

- Messages

- 1,481

- Reaction score

- 4,561

Why are we assuming that those are not the dimensions of the P0 but of the P1?

Do you think the round figures(6m height, 14m wingspan etc.) they shared some years back represents P0?

Just like how the Hurjet dimensions have changed with the introduction of the P2 prototype, where we can see the visual differences. Same is expected with KAAN, officials have also said first/second prototype will be more compact then the P0 tech demonstrator - so yes, it coincides.

These do not make those figures belong to P1. It could also well be that the P1 will have smaller dimensions than those you shared. Many people with 3d modeling skills calculated the size of P0 to be smaller than those old round numbers shared by TAI.Just like how the Hurjet dimensions have changed with the introduction of the P2 prototype, where we can see the visual differences. Same is expected with KAAN, officials have also said first/second prototype will be more compact then the P0 tech demonstrator - so yes, it coincides.

Waterballoon

ACCESS: Confidential

- Joined

- 27 October 2023

- Messages

- 114

- Reaction score

- 233

The 21x14x6m specs for the Kaan where most likely either carelessness or counterintel which I fell for, just like the Hurjets initial 35m2 wing area which was more obvious to me to be BS.

And the MTOW of 60.000lbs for Kaan is still BS for now and should be discarded. MTOW should be 75.000lbs with the indigenous engines.

And the MTOW of 60.000lbs for Kaan is still BS for now and should be discarded. MTOW should be 75.000lbs with the indigenous engines.

Similar threads

-

-

-

Combat use of F-16s in Mideast spurs fresh demand: Lockheed

- Started by Triton

- Replies: 1

-

Aerospace Cooperation Opportunities Between Europe and Turkey

- Started by snne

- Replies: 20

-