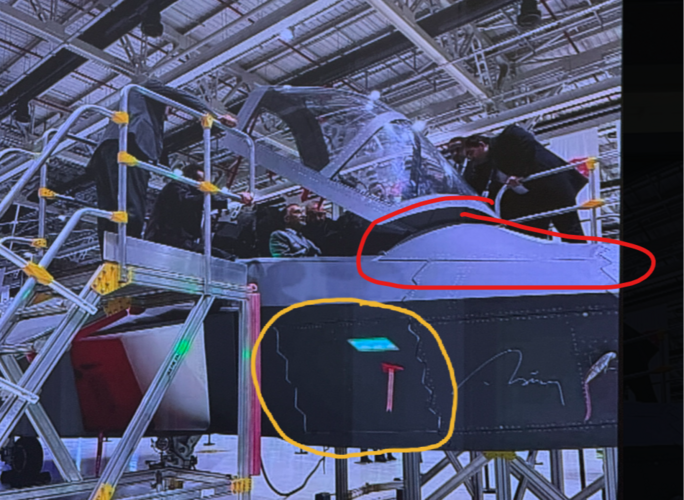

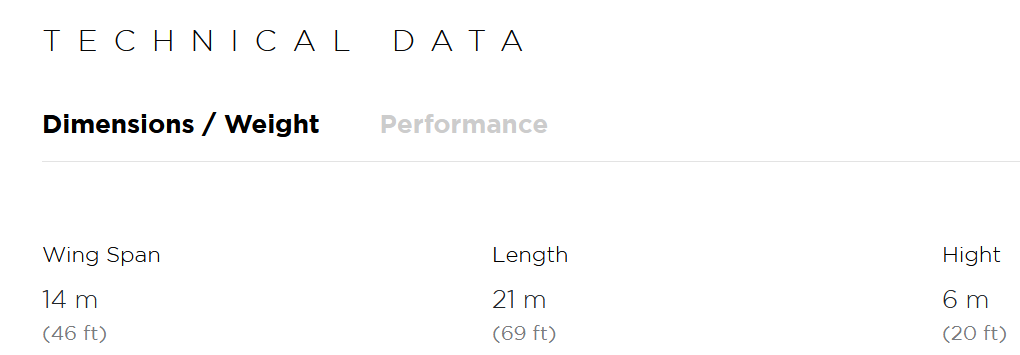

"Kaan's new brochure shows new dimensions of aircraft. According to brochure, the length has shortened by 0.7m, the wingspan by 0.6m and the height by 1m."

View: https://x.com/T_Nblty/status/1879202535472566766

------------

DIMENSIONS / WEIGHT

Wing Span 13.4 m

Wing Area 71.6 m2

Length 20.3 m

Height 5 m (20 ft)

Maximum Take Off Weight 60,000 lb

Engine Thrust Class 2 x 29,000 lb

Maximum Speed 1.8 Mach (at 40,000 ft)

Service Ceiling 55,000 ft

Positive / Negative G Limit +9g / -3.5g

FEATURES

Multirole (Air-to-Air & Air-to-Ground)

Super Cruise Capability

High Maneuverability

Low Observability with Weapon Bays

Extended Combat Radius

Interoperable with Current & Future Assets

High Situational Awareness

Optimized Pilot Work Load

with Decision Support Capability

Within & Beyond Visual Range Missiles Employment

Precision Strike

New Generation Avionics

• Integrated Radio Frequency System

• Integrated Electro Optical System

• Integrated Communication Navigation Identifi cation System

• Integrated Modular Avionics

• Large Area Display

• Helmet Mounted Display