aonestudio

I really should change my personal text

- Joined

- 11 March 2018

- Messages

- 2,962

- Reaction score

- 7,468

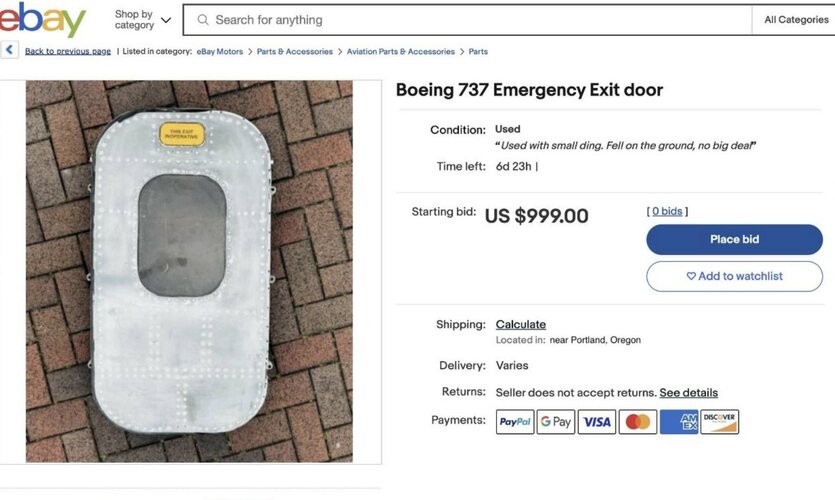

Alaska Grounds 737-9s After ‘Explosive’ In-Flight Decompression | Aviation Week Network

Alaska Airlines has grounded its Boeing 737 MAX 9 fleet for inspections after a mid-air incident forced an emergency landing.