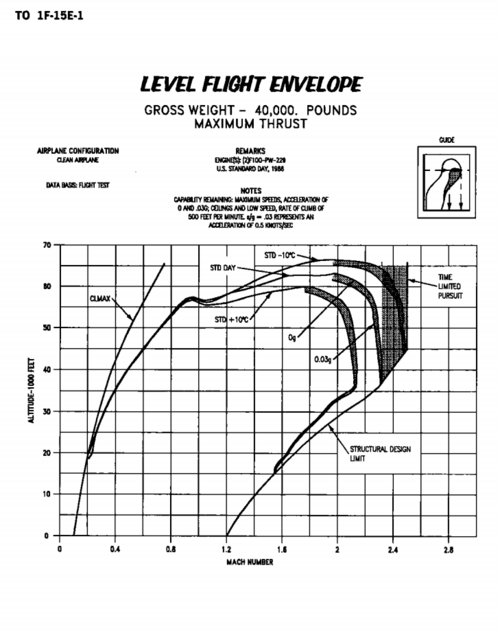

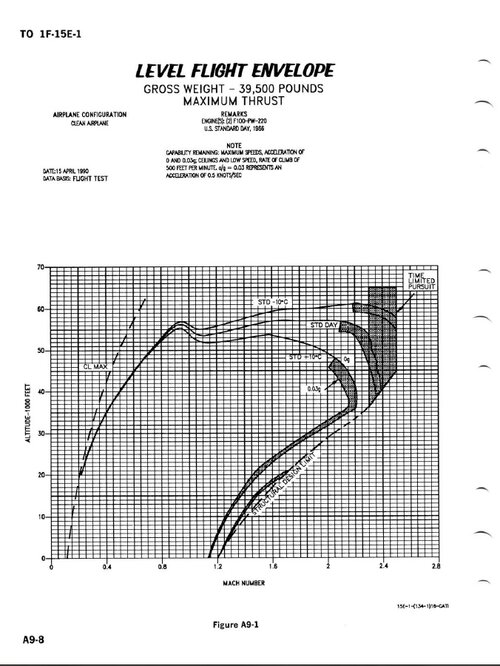

I would think that extraordinary performance under ideal conditions would be irrelevant to the required operation of an aircraft. If a stripped F-15 could graze Mach 2.5, what could it actually do at that speed, which it could only hold briefly, without weapons and radar? The question is, what is it required to do and how well does it do it compared to its rivals?

A superfast fighter would require specialised design for that superfast regime. The F-15 doesn't have it (that said, I think that it's one of the all-time classic designs). In any case, it was conceived before people were thinking about 'generations.'

Remember, it took a Hell of a lot of specialised engineering with Blackbird and a Foxbat inlet, material, structure and engine design to allow them to reach Mach 3. The Foxbat wrecked it engines with every high speed dash and every Blackbird mission was like a space launch. That just isn't apparent in an F-15. None of the published concepts for NGAD/FAXX indicate specialisation to achieve, let alone sustain extreme speed.

Nowadays, with very long cycles of development and production, each new generation of any military system strives to transcend, not merely improve upon the present state of the art. I don't think that any next-generation fighter will be just somewhat faster than its opponents; instead, it will operate in another realm where it is intended to be unreachable. That's the doctrine behind stealth and hypersonics. If NGAD were required to be faster, it would be much faster - Mach 5, say, not 3. If it's stealthy, it's extremely stealthy, if it's networked, then it's very networked and can control fleets of CCAs and even Roombas. The evidence indicates that NGAD/FAXX is not notably faster - i.e., not hypersonic - so it's something else - such as super-stealthy, super-networked, super long-ranged, super-cruise, whatever.