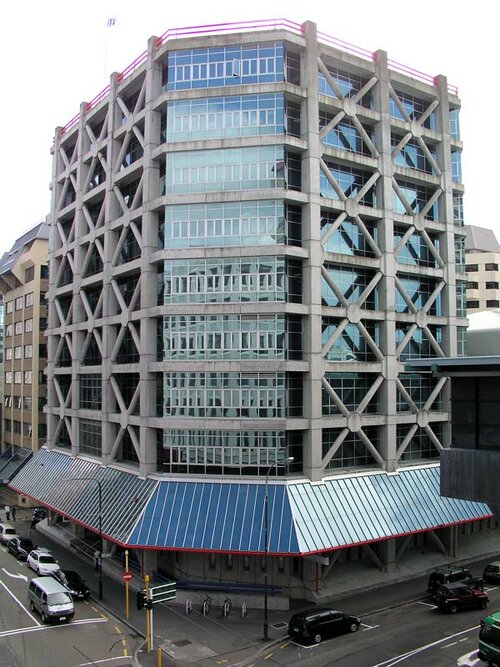

There are many X-shapes, there are 6, one every 60 degrees.

You have no analysis to support your claim that they "don't add much" or that there isn't enough.

Welding a relative thin X-shape on to a solid rectangular plate does not add much. That should be obvious. If strength was to be added they had better welded a whole plate on top of the existing one.

All that the X adds are four small triangles at the corners. Not nothing, but not much either.

Again, this design has been loaded tested to 25-50% above flight loads, so what does it matter?

So you keep saying, but where can we find the test procedure and test results?

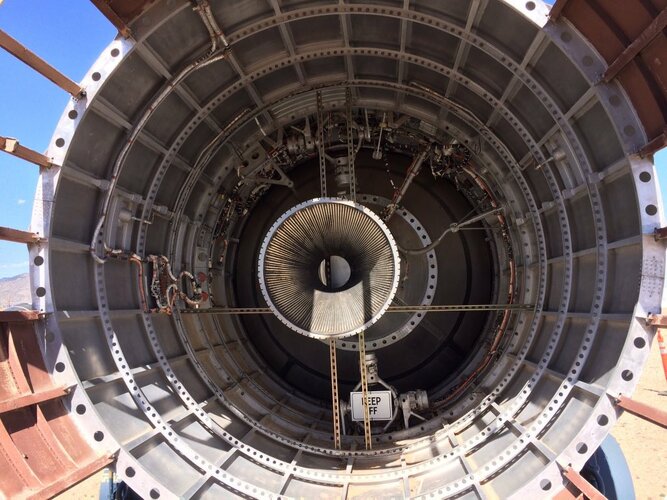

Let's do facts and not opinion. This is the Titan II interstage. There are 24 "segments" between stringers. 16 of them are open and 8 have sheet metal between the stringers. so 33% of the circumference (8/24) has a sheet metal web for shear stability.

My previous post with the photo of the Starship, the interstage has 96 "segments". The "X" web can be counted as 4 or 6 segments for covering 25% to 37.5% of the circumference. 2 of the segments on the six positions are completely enclosed by sheet metal including the "X" doubler. An additional 2-4 segments are cover by portions of the "X" "doubler". Add in the large "pedestals", there is plenty of shear support.

I love facts and will add a few more:

My eyes tell me that each of the 6 plates cover only a distance of 3 slots like between 4 vertical struts.

I count 14 slots between each of the 6 plates.

So the plates cover 3/(3 + 14) = 17.6 % of the circumference. Not 25 % or 37.5 %.

The ends of the X add small triangles at the corners of each plate. I will give some rigidity credit for that by rounding the 17.6 % up to 20 %.

The mass of a fully loaded

Starship 2nd stage is 1,450,000 kg incl. payload.

The diameter of Starship is 9.0 meter, so circumference is 28.3 m, of which 5.66 m (20 %) is actually providing resistance to shear.

Now imagine Starship is flying at an angle of say 35 degrees before stage separation:

The shear force on the Starship vented interstage would then be 1,450,000 kgf * cos(35) = 1,188,000 kgf.

That would be equivalent to 1,188,000 kgf / 5.66 m =

210,000 kgf/m.

The mass of a fully loaded

Titan II 2nd stage is 33,000 kg incl. payload.

The diameter of Titan II is 3.05 m, so circumference is 9.58 m, of which 3.19 m (33 %) is actually providing resistance to shear.

Now imagine Titan II is flying at an angle of say 35 degrees before stage separation:

The shear force on the Titan II vented interstage would then be 33,000 kgf * cos(35) = 27,000 kgf.

That would be equivalent to 27,000 kgf / 3.19 m =

8460 kgf/m.

That is a ratio of

25 at the disadvantage of Starship.

I don't know the thickness (or type) of the metal used on Starship or Titan II, so to compare I simply express the shear force in kgf/m instead of kgf/m2. It's therefor just a rough comparison but it nevertheless shows that the shear force on the Starship vented interstage is not comparable with that of Titan II.

That it held on Titan II does not prove that a similar design will hold on Starship.

Hence my concern about the present SpaceX design.