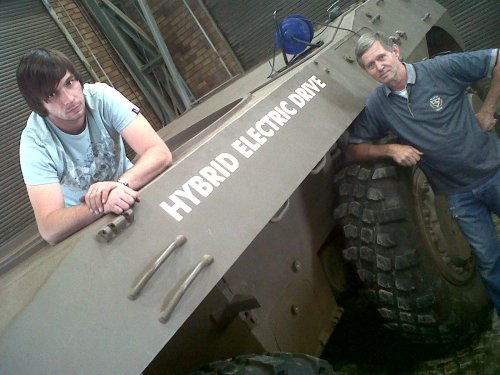

IN stealth mode, the hybrid Rooikat can tiptoe its 25-ton bulk so quietly

over desert sand that the gunner’s breathing will sound louder in the turret

than the soft whine of the hub motors.

Parked in peace time, the gun’s batteries hold enough charge to

provide power to a small suburb for a night. And when it comes to efficiency,

the old gun can teach the Nissan Leaf and Toyota Prius a thing or 400 about

recycling.

In braking mode, the Rooikat’s hub motors return up to 400 kW per

motor back into the system, as the heavy gun slows it down.

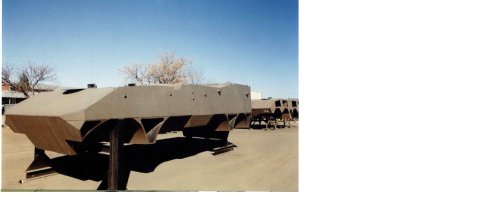

Despite its age, the hybrid Rooikat is still seen by all in the

know as a brilliant achievement — and all of it is now gathering dust in a hired

hangar at the Gerotek testing terrain west of Pretoria.

When we visited, the man who managed the development of the

e-drive technology in the Rooikat, Wynand Avenant, was preparing to mothball

the hybrid gun for its last resting place. It was to go to the South African

Armour Corps Museum in Bloemfontein.

Since then, Avenant has informed us that the gun is to stay at

Gerotek for the time being. There was, at the time of printing, no clarity

about what will happen to the old gun, which dates back to the nineties, when

the world’s generals wondered how to apply hybrid drives to army vehicles.

The technology in the Rooikat was first tested in a truck and was

then, as it is now, neither the newest nor the most powerful.

Trains use the same system, with a diesel engine driving an

alternator to turn the axles, while giant mining trucks have, since the late

sixties, been using much higher-powered electric motors to inch up steep

inclines in open-cast mines.

But the system in the hybrid Rooikat represents an experiment by

some of the finest minds then contracted to the SA National Defence Force, to

see just how far they could push the envelope on electric propulsion. The system

they perfected has, these past seven years, been a source of quiet pride for

its designers and still garners respect from those who know their Ohms from

Amperes.

Avenant said his system is powered by an old

diesel engine that has been tuned to sip diesel, and mapped to push its work

rate up to 450 kW and lower its torque in order to drive the alternator at a

constant high speed. The alternator generates the electric current that turns

eight permanent magnet motors, one in each of the one-metre hubs of the Rooikat.

Each hub motor has as much power as a small car (80 kW) and can

handle up to one megawatt of current. To get the bulk of the gun moving in thick

sand is no problem either, as each motor turns with 2 200 N/m of torque from

zero km/h, with the two-speed hydraulic transmissions in low range.

But all this was too late for the Cold War and is still too early

for a world addicted to crude oil.

The hybrid Rooikat has never fired a shot in anger and at the

last armament show, where it was displayed, the world’s buyers showed little

interest.

Avenant has good news, however, as all this benchmark-setting

technology need not be lost to transporters. For the technical wizardry that

drives it has roots that stretch all the way to the Westville campus of the

University of KZN, where the electric propulsion experiments started on a Ford

bakkie in the mid-eighties.

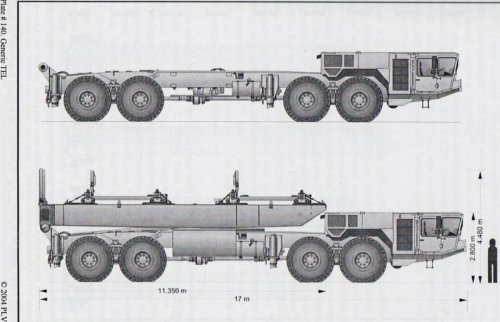

Avenant said Armscor then progressed to test the first electric

truck in 1996.

The truck was driven up Mpumalanga’s steep escarpments, in the

Namib Desert’s shifting sands and in the depths of a snowy winter in Germany.

The system finally proved itself as a tow truck for the 19-ton Ratel. The big

question now is whether transporters can afford Avenant’s gas.

Bearing in mind that thousands of trucks trundle up and down the

N3 each day, burning on average almost a litre of diesel for every kilometre on

the 600 km up run, converting to hybrid trucks could be well-worth the

investment.