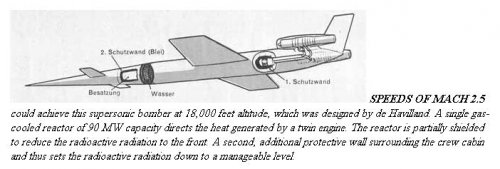

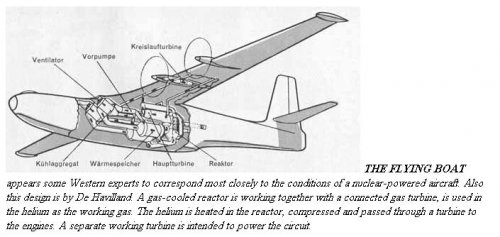

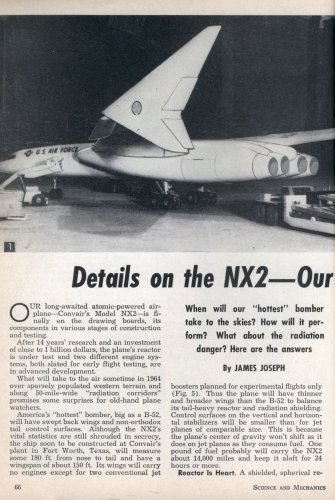

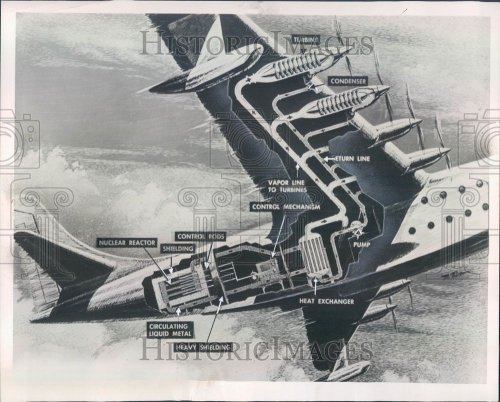

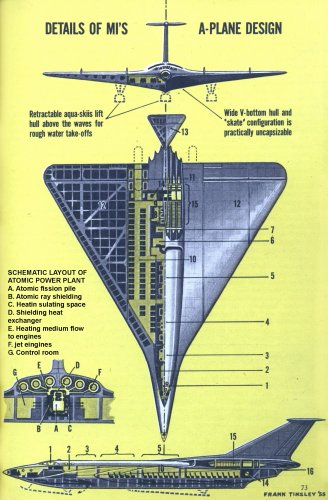

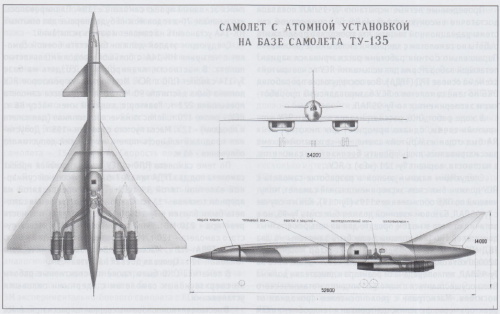

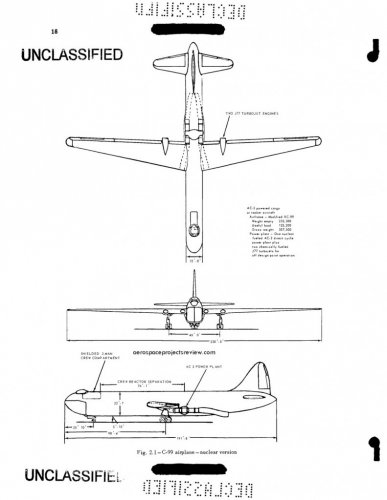

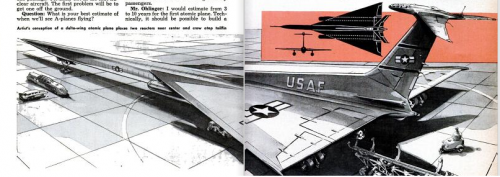

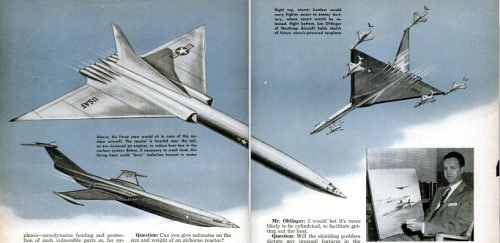

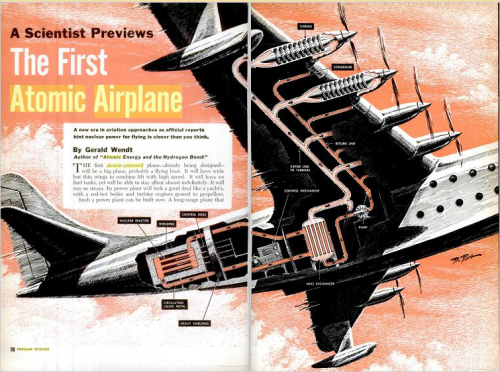

There are no fundamental technical reasons why subsonic nuclear aircraft cannot be made to fly successfully providing the aircraft is large enough. The weight of a completely shielded nuclear aircraft reactor varies about as the square root of the reactor power. Hence, the larger the aircraft the less is the weight fraction of the nuclear power system. Aircraft of 0.45 million kilograms (1 million lb) or greater are required to make the payload fraction greater than 15 percent of the gross weight. With funds drawn largely from the U.S. Air Force, the Oak Ridge Laboratory's major entrance into reactor development during the 1950s came through efforts to design a nuclear airplane. British and German development of jet engines at the end of World War II had given quick, defensive fighters an advantage over slower long-range offensive bombers. To address the imbalance, General Curtis LeMay and Colonel Donald Keirn, both of the Air Force, urged development of nuclear-powered bombers. In 1946, they persuaded General Groves to approve Air Force use of the vacated S-50 plant near the K-25 Plant in Oak Ridge to investigate whether nuclear energy could propel aircraft.

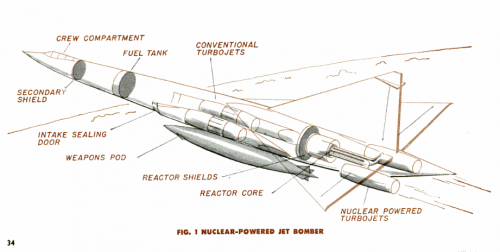

The initial concept called for a nuclear- propelled bomber that could fly at least 12,000 miles at 450 miles per hour without refueling. Such range and speed would enable nuclear weapons to be delivered via airborne bombers anywhere in the world. The aircraft, however, would require a compact reactor small enough to fit inside a bomber and powerful enough to lift the airplane into the air, complete with lightweight shielding to protect the crew from radiation.

Under Air Force contract, the Fairchild Engine and Airplane Corporation then established a task force at the S-50 plant to examine the feasibility of nuclear aircraft and arranged with Wigner to receive scientific support from the Laboratory. Initial studies conducted by the Fairchild Corporation at the S-50 plant showed promise and, in 1948, the AEC asked the Massachusetts Institute of Technology (MIT) to evaluate the feasibility of nuclear-powered flight. MIT sent scientists to Lexington, Massachusetts, for a summer's appraisal, and they reported that such flight could be achieved within 15 years if sufficient resources were applied to the effort. In September 1949, the AEC approved Laboratory participation in an aircraft nuclear propulsion project. Weinberg was made project director and Cecil Ellis coordinator. Raymond Briant, Sylvan Cromer, and Walter Jordan later served as directors of the Laboratory's Aircraft Nuclear Propulsion (ANP) project.

Soon after the Laboratory acquired its nuclear propulsion project, General Electric took over the work of Fairchild and relocated it from Oak Ridge to its plant in Ohio. Although some Fairchild personnel transferred to Ohio, about 180 remained in Oak Ridge to join the Laboratory's aircraft project in May 1951. Among those who decided to stay in East Tennessee were Francois Kertesz, a multilingual scientist; Edward Bettis, a computer wizard before the age of computers; William Ergen, a reactor physicist; Fred Maienschein, later the director of the Laboratory's Engineering Physics and Mathematics Division; and Don Cowen of the Laboratory's Information and Reports Division.

Much of the Oak Ridge Laboratory's initial aircraft work focused on development of lightweight shielding to protect airplane crews and aircraft rubber, plastic, and petroleum components from radiation. Knowing a nuclear aircraft would never become airborne carrying the thick walls typical of reactor shields, Everitt Blizard and his team worked two shifts daily, testing potential lightweight shielding materials in the lid tank atop the Graphite Reactor. As research progressed, however, the Graphite Reactor proved inadequate to meet the level of research activity. To continue its shielding investigations, the Laboratory added two unique nuclear reactors to its fleet.

First, in December 1950, the Laboratory completed its 2-MW Bulk Shielding Reactor at a cost of only $250,000. To build this reactor, the Laboratory modified its earlier Materials Testing Reactor design to create what became popularly known as the "swimming pool" reactor. This reactor's enriched uranium core was submerged in water for both core cooling and neutron moderation. From an overhead crane, the reactor could be moved about a concrete tank, the size of a swimming pool, to test bulk shielding in various configurations. A 10-kW nuclear assembly (named the Pool Critical Assembly) was subsequently placed in a corner of the pool to permit small-scale experiments without tying up the larger reactor.

The Laboratory standardized this inexpensive, safe, and stable design, which became a prototype for many research reactors built at universities and private laboratories around the world. Upgraded with a forced cooling system in 1963, it supplanted the Graphite Reactor (retired that year) and proved extremely useful for irradiation and study of materials at low temperatures.

A second Laboratory reactor resulting from the nuclear aircraft project was the Tower Shielding Facility, completed in 1953. Cables from steel towers could hoist a 1-MW reactor in a spherical container nearly 200 feet (60 meters) into the air. Because no shielding surrounded the reactor when suspended, it operated under television surveillance from an underground control room.

Containing uranium and aluminum fuel plates moderated and cooled by water, this reactor helped scientists answer questions about radiation from a reactor flying overhead; it also helped researchers better understand the type and amount of shielding that would be needed aboard a nuclear aircraft.

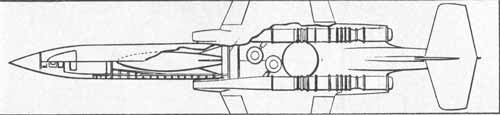

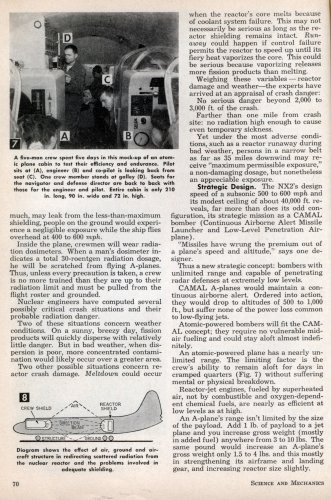

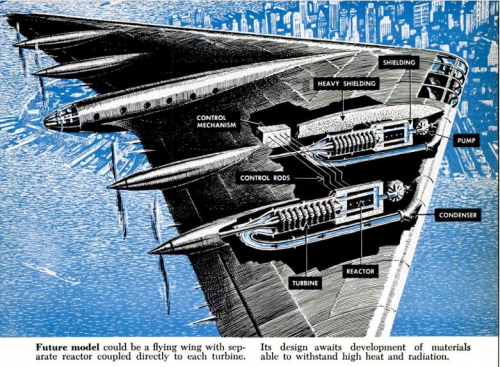

Experiments indicated that a divided shield, consisting of one section around the aircraft's reactor and another around its crew, would comprise a combined weight less than that of a single thick shield blanketing the aircraft's reactor. Researchers, however, could never devise a reactor and shielding light enough to ensure safe flight. They even considered a "tug-tow" arrangement in which the crew and controls would be in a towed glider, separated from, yet tied to, the reactor by a long umbilical cable. The Tower Shielding Facility reactor later was upgraded, and shielding experiments recently took place there in support of breeder reactor development, long after visions of a nuclear aircraft faded from memory.

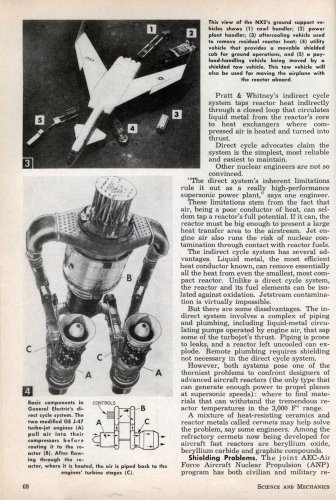

The Bulk Shielding Reactor and Tower Shielding Facility were designed to test materials that might be used on a nuclear-powered aircraft. For the U.S. Air Force, improved materials represented a means toward an end: a nuclear-powered engine that could drive long-range bombers to takeoff speeds and propel them around the world. To achieve this goal, the Laboratory designed an experimental 100-kW aircraft reactor as a demonstration.

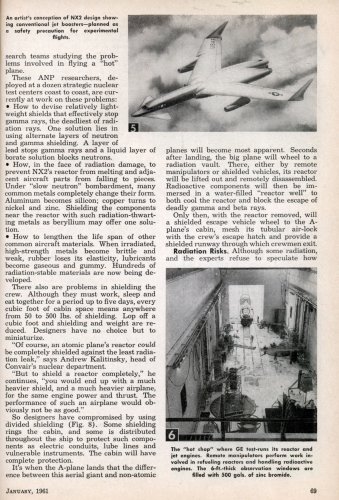

This small reactor, operating at high temperatures, used molten uranium salts as its fuel, which flowed in serpentine tubes through an 18-inch (46-centimeter) reactor core. A heat exchanger dissipated the reactor's heat into the atmosphere. In 1953, the Laboratory constructed a building to house this experimental reactor.

To contain molten salts at high temperatures within a reactor, the Laboratory used a nickel-molybdenum alloy, INOR-8, designed by Oak Ridge researchers and fabricated at the International Nickel Company. Able to resist corrosion at high temperatures while retaining acceptable welding properties, the alloy was commercialized as Hastelloy-N by private industry (an early example of technology transfer) to supply tubing, sheet, and bar stock for industrial applications. The aircraft reactor also compelled Laboratory personnel to learn how to perform welding with remote manipulators and how to remotely disassemble molten-salt pumps. In addition, Laboratory researchers also devised two salt reprocessing schemes to recover uranium and lithium-7 from spent reactor fuel.

http://www.globalsecurity.org/wmd/systems/anp.htm