- Joined

- 27 December 2005

- Messages

- 17,749

- Reaction score

- 26,371

History of the Flight

At 1345 Atlantic Daylight Time (All times are given in ADT), May 14, 1985, the Northrop F-20A prototype aircraft, GI-1001, United States of America civil registration N3986B, took off from Goose Bay Airport Runway 08 on a 5 min. practice demonstration flight in preparation for the Paris Air Show. The flight was the sixth demonstration flight flown that day on the aircraft and the fourth flown by the accident pilot The demonstration flight was to be centered at the midpoint of the runway and had been authorized by the appropriate Canadian authorities. The final maneuver sequence of the scheduled routine, which had been previously flown about 60 times by the pilot, called for a simulated head-on, low level, air to ground attack followed by a sharp 9g pull up at approximately 380 kt. This sequence was to be followed by level flight, left aileron rolls as necessary to provide adequate spacing from the runway, prior to entering a left downwind and base turn for landing.

Film taken of the mishap sequence shows that the aircraft entered an apparently normal right rolling pull up following the low level attack maneuver. The aircraft then completed 1 1/2 rolls to the left, then momentarily hesitated in the inverted position. The left roll was then continued as a barrel roll, which resulted in a descending roll out to a wings level attitude with about a 16 deg. nose low pitch attitude. The aircraft's heading was almost reciprocal to that required for the intended downwind and landing pattern. The landing gear was not extended. The aircraft continued descending, slightly increasing its nose down pitch attitude until it struck open, snow covered, fairly level terrain in an upright, slightly left wing low, nose down attitude. The aircraft was destroyed at impact, and the pilot sustained fatal injuries.

The mishap occurred less than 1 mi. north of the Goose Bay Airport Runway 08 at 53 deg. 19 min. N. Lat., 60 deg. 26 min. W. Long., at an elevation of 160 ft. above sea level. The accident occurred at 1349.

Injuries to Persons

The pilot, the only person on board, was fatally injured.

Damage to Aircraft

The aircraft was destroyed.

Other Damage

Damage was limited to ground scars in the vicinity of the accident.

Personnel Information

The pilot was qualified on the aircraft type and held valid licenses and ratings.

- Age 40.

- Pilot license--Airline Transport Pilot (USA).

- Medical expiry date--Jan. 17, 1986.

- Total flying time--5,240 hr.

- Total on type--154 hr.

- Total last 90 days--84 hr.

- Total on type last 90 days--39 hr.

- Hours on duty prior to occurrence--4 hr.

- Hours off duty prior to work period--12 hr.

Prior to his employment with the Northrop Corp., the pilot had served 15 years with the United States Air Force. He resigned his regular commission in 1981 and joined Northrop in January, 1982, as an engineering test pilot and F-20 Tigershark flight test project and demonstration pilot. He retained his commission as a major in the USAF reserve and was a current pilot on the C-141 aircraft. His military flying experience was primarily on high performance jet aircraft such as the T-38, F-4, F-15 and F-111. He had flown 120 combat missions in Southeast Asia. Immediately prior to joining Northrop, he was an instructor test pilot at the USAF Test Pilot School.

His initial military aeromedical training was conducted during February, 1967. He received additional refresher training with USAF, the last of which was conducted on Mar. 22, 1984, at Edwards AFB. His F-5/T-38 egress and parachute descent training was completed June 6, 1984. His Stencel ejection system and egress training was completed Jan. 16, 1985. There was no evidence found to indicate that he had received formal g induced loss of consciousness (GLC) training, which includes the use of a centrifuge, or that he was cognizant of the proper methods of carrying out anti-g straining maneuvers, nor was any evidence found that such training was required prior to being selected for, or participating in, high g demonstration activities. A second demonstration pilot indicated that at the time of the accident he also was unaware of many aspects of the GLC phenomenon.

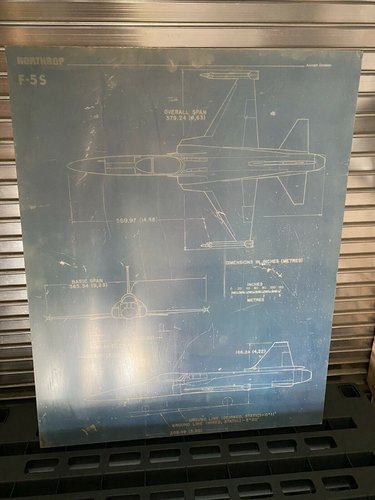

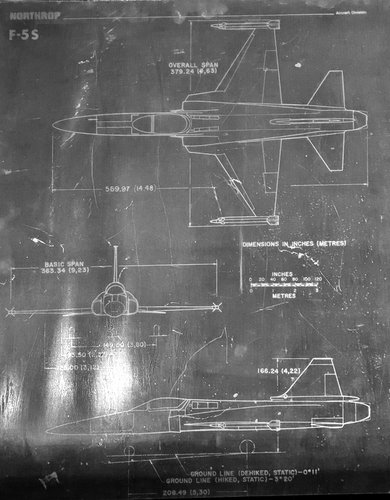

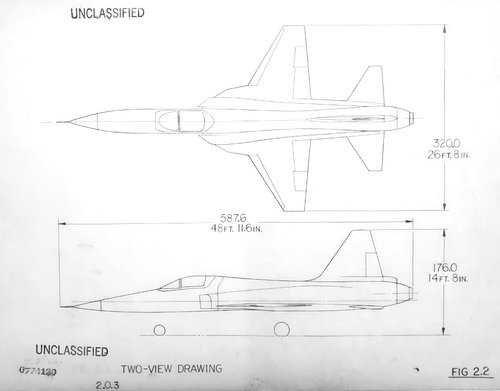

Aircraft Information

The aircraft had been serviced and maintained in accordance with United States Federal Aviation Regulations pertaining to experimental aircraft. It was on flight number 400 since manufacture. The gross weight of the aircraft at takeoff was 16,500 lb., including 2,800 Ib. of fuel. Calculated weight at impact was 14,900 Ib. The aircraft configuration was established to provide a center of gravity just forward of the 25% Mean Aerodynamic Chord position for the air show sequence. The F-20 was flight tested in this configuration prior to the air show flights. The weight and center of gravity were within the Northrop designed limits.

- Manufacturer--Northrop Corp.

- Type--Northrop F-20A Tigershark.

- Year of manufacture--1983.

- Serial number--GI-1001.

- FAA Special Airworthiness Certificate-- Valid.

- Total airframe time-- 4l0 hr.

- Engine type--General Electric YF-404-GE-100

- Maximum allowable takeoff weight-- 26,544 lb.

- Recommended fuel types--Jet A l, JP 4, JP 5, JP 8.

The F-20 flight control system (FCS) consists of a conventional hydromechanical system augmented by an electrical control augmentation system (CAS). The hydromechanical position of the FCS consists of conventional mechanical inputs to dual hydraulic actuators. Full rudder deflection and 60% of horizontal tail authority are available from the hydromechanical system. The remainder of horizontal tail authority is provided by the CAS. On this aircraft, the CAS did not provide any control to the ailerons.

The CAS is controlled by a direct current powered flight control computer. The flight control computer provides power to and receives input signals from a digital air data unit, the aircraft rate and acceleration sensors, the control column and rudder pedal position sensors, and the cockpit control panels. The flight control computer processes inputs and sends signals to CAS actuators, which together with hydromechanical actuators, position the control surfaces.

A maintenance record review indicated that, during a practice demonstration flight on the previous day (Flight 394), the CAS PITCH 1 warning light illuminated, followed by the illumination of the PITCH 2 light during the final stages of the flight. These warnings indicated that the CAS had failed, but the subsequent landing was uneventful. The problem was traced to spillage of electrolyte from the main battery onto the flight control computer unit, which was located next to the battery. Rectification included cleaning and neutralizing the battery compartment, replacing the battery, taping the battery box and replacement of the flight control computer. The area was checked after each flight for further electrolyte leaks; none were found.

Meteorological Information

The weather sequence taken at the time of the mishap was sky conditions clear, visibility unrestricted, temperature 8C, dew point 4C, altimeter 30.02 in. Hg., wind 300 deg. true at 12 kt.

Communications

The aircraft was under the positive control of the Goose Bay tower; communications were on ultrahigh frequency (UHF) 236.6 MHz. To communicate with the aircraft, Northrop company personnel operated a very high frequency (VHF) mobile communications unit at the demonstration site. During the mishap flight, all transmissions to and from the aircraft were normal. No radio transmissions were made to or from the aircraft from commencement of the final maneuver to impact.

Airport Information

The Goose Bay Airport is situated on an inlet that forms part of the northeast coast of Labrador. The airport, which is operated by Transport Canada under a public license, has two runways constructed of concrete, with an asphalt overlay. Runway 16/34 is 6,200 ft. long by 200 ft. wide; Runway 08/26 is 11,050 ft. long by 200 ft. wide. The airport reference elevation is 160 ft. asl. The other demonstration pilot practicing the air show sequence reported that the horizon provided a good reference in the areas around the airport.

Flight Recorders

The aircraft was not equipped with a flight data recorder or cockpit voice recorder, nor was either required by regulation. During the flight test program, the aircraft had been equipped with a cockpit video recorder, but this equipment was removed during reconfiguration for the Paris air show. The nonvolatile memory of flight control computer components, which were recovered from the wreck age, provided data on the function of the flight control system from take-off to impact.

Wreckage and Impact Information

The aircraft struck the ground upright in a slightly left wing low, nose down attitude. The wreckage was spread over an area approximately 1,000 ft. in length and 100 ft. in width on a general heading of 065 deg. magnetic, 4,900 ft. north of Runway 08. The wreckage area was a gently undulating stream bed. The ground at the impact point was covered with melting snow to a maximum depth of 2 ft. Just beneath lay a sandy and slushy layer 4 6 in. deep on top of frozen strata 6 8 in. thick. A wet, firm sand lay underneath.

The aircraft penetrated the sandy, slushy area and rebounded into the air when it struck the frozen strata. The forward fuselage disintegrated upon initial impact and was destroyed.

The left and right wings were found in two sections left and right of the flight path, respectively. The leading edge flaps were broken loose from their attachment points and remained in the initial impact area. The left leading edge extension penetrated the frozen soil at an angle 20 30 deg. from the horizontal and was buried several feet deep in the initial impact crater, leaving only part of the spar attachment visible.

The aircraft center and aft fuselage continued down the extended flight path, further breaking up as it tumbled and contacted the ground. On the third contact, the engine broke free and separated from the aircraft. The engine was found adjacent to the vertical stabilizer, which came to rest in an upright position, 725 ft. from the initial impact point.

The remaining forward fuselage and nose landing gear came to rest furthest from the initial impact point. The ejection seat was tangled within the mass of wiring that constituted the forward fuselage and cockpit area. The landing gear selector panel indicated that the gear handle was in the up position at impact. There was no evidence of preimpact structural failure.

Medical and Pathological Information

Goose Bay is situated within the bounds of the Atlantic time zone, which is 4 hr. ahead of the time at the pilot's home base in California. The pilot departed from California on a scheduled commercial flight on May 10, 1985, four days prior to the accident. He ferried the F-20 from Andrews AFB, Md., to Goose Bay via Ottawa on May 12.

The accident pilot flew two of three planned air show practices on May 13, 1985. His first takeoff was at 1515, and he landed following the second flight at 1616. The third mission was cancelled because of the CAS problem experienced during Flight 394. In the evening, the accident pilot joined some Northrop personnel for dinner in a local restaurant. The pilot retired to his hotel room at 2230 and ate breakfast at 0730 prior to commencing flight duties on the day of the accident. He had completed two consecutive demonstration flights 2 hr. prior to the accident. His first takeoff that day was at 1115, and his second was at 1140. The pilot remained in the cockpit while aircraft refuelling took place between these two flights. This was a normal procedure used by both demonstration pilots.

The pilot landed from his second flight at 1145 and had rested and consumed a light snack before taking off at 1318 for the first of his final two consecutive flights; the contents of the light snack could not be determined. He landed at 1323 and again remained in the cockpit during refuelling. During the time on the ground, the pilot indicated in a humorous maintenance entry that he was thirsty. He took off at 1345 for his final flight, which terminated 4 min. later. The pilot's most recent U. S. Federal Aviation Administration medical examination was performed Jan. 18, 1985, by a company medical examiner. As a result of that examination, he was assessed as fit to FAA medical standards.

FAA Form 8500 8, completed immediately prior to the examination, required the pilot to declare all medical treatment received within the past five years and to certify, by signature, the truth and accuracy of such disclosure to the best of his knowledge.

Medical information gathered during the investigation established that the pilot had a history of, and received medical treatment for, ' achalasia" which was diagnosed in 1982. The pilot did not disclose this information on Form 8500 8. The pilot's supervisor was aware that the pilot had received treatment for achalasia, but he did not know that the company medical examiner was unaware of the treatment received.

Achalasia is the failure of the motor action of the lower part of the esophagus due to a deterioration of nerve function. It is an acquired neuromuscular disorder. Normally, solids and liquids are propelled down the esophagus by a wave like action, called peristalsis, which is under the control of the autonomic nerve system. In this disease, the peristaltic action stops at the affected segment of the lower part of the esophagus. This results in failure of relaxation of the functional sphincter between the esophagus and stomach during swallowing. The part of the esophagus above the lower affected segment becomes dilated, elongated and tortuous. Food can accumulate in the esophagus for some time before it passes into the stomach.

Some symptoms can include chest pains and general discomfort. Regurgitation and even vomiting can occur involuntarily during normal activities.

The probability of this reflux activity occurring would be increased substantially in flight and even more so during aerobatic maneuvers. A symptom associated with reflux activity is hypotension (low blood pressure).

The pilot had been treated by dilatation of the affected segment with a balloon device. He had had three such procedures, the first of which failed. Two were in 1983, the most recent in January, 1985, about 3 1/2 months prior to the accident. This procedure is usually at least temporarily successful. However, it occasionally leave permanent incompetence of the junction between the stomach and esophagus. More importantly, there can be reversion to relative closure of the lower end of the esophagus in two to three months.

Review of USAF annual physical examinations from 1980 to 1985 revealed no indication of pre-existing disease. It was noted, however, that several electrocardiograms (EKGs) reflected a sinus bradycardia (a relatively low heartbeat rate of 54 58 beats per min.), which USAF considered to be normal for an athletic individual.

The autopsy was not able to rule out or confirm the effect of achalasia on the pilot. There was no evidence of any pre-existing cardiac disease. Tests for drugs and alcohol were negative with the exception of caffeine.

Fire

There was no evidence of in-flight fire or visible smoke from the aircraft. The impact-induced explosion and fire was of short duration and was contained within the impact area.

Survival Aspects

Acceleration Forces

The acceleration forces sustained when the aircraft struck the ground exceeded human tolerances. The cockpit structure was destroyed, and the injuries sustained by the pilot caused immediate death.

Escape System

The aircraft was fitted with a parachute-equipped, rocket propelled Stencel ejection seat. The Stencel system provides the pilot with a safe escape capability from zero airspeed on the ground to an airspeed of 600 kt. at 50,000 ft. The ejection system has four operating modes.

For the final trajectory of the accident flight, the system would have been operating in mode 1 at the wings level position. In this mode, the parachute opens approximately 2 sec. after ejection initiation. Examination of the Stencel ejection seat and related escape system ballistic items indicated that 19 of the 24 ballistic items had not been fired and were still live. Actuation of the five ballistic items that did fire was the result of seat and aircraft break-up during the crash sequence.

The front lower portion of the ejection seat bucket, which contains the ejection handle, had completely broken away from the seat and had actuated the right hand ejection initiator. The cable that actuates the left hand and right hand ejection initiators is continuous from the left-hand initiator through the firing handle located at the forward center of the seat bucket to the right hand initiator.

The left hand initiator did not fire because its outer sheath was sheared on the left side of the seat at impact. Only the left hand initiator provides ballistic gas from the seat to the canopy jettison system. The canopy jettison thruster was found retracted with its firing pin still intact.

Tests and Research

Inspections, teardowns, tests and analyses were conducted by the Canadian Aviation Safety Board at the accident site and the CASB Engineering Branch; General Electric Corp., Lynn, Mass.; Hamilton Standard, Farmington, Conn., and Northrop Corp. Aircraft Div., Hawthorne, Calif. Tests and analyses performed by the manufacturer and contractors were monitored and reviewed by CASB investigators.

Engine

he engine was disassembled and examined to assess the engine power level at the time of impact and to determine if there was any engine related failure. Examination of the turbomachinery indicated significant fan damage, compressor damage and a large amount of debris visible through the basic engine, back to and through the outer bypass duct.

The low pressure turbine sustained mechanical damage to all blades, with the blade tips rolled over from impact with the turbine shroud. The engine damage sustained was consistent with an engine rotating at high rpm. at the time of impact.

The main fuel control and the afterburner fuel control systems were disassembled and examined. All valves and linkages of these controls were found free and undamaged. The main fuel control examination revealed marks that coincide with mating levers when the speed shaft is positioned to command a high engine rotation speed. The position of the valve in the afterburner hydraulic actuators indicated that the afterburner was operating at an engine thrust level between 15,350 and 16,300 Ib. at impact.

Measurements of the nozzle engine diameter on the film taken of the accident flight showed that the engine remained in the afterburner range.

On several frames of the film, the glow of the afterburner was observed.

Flight Controls

The flight control computer (FCC) was recovered and examined for possible battery electrolyte contamination. No evidence of electrolyte contamination to the FCC internal components or the external case was found.

wo nonvolatile memory (NVM) boards from the Right control electronics set (FCES) were recovered from the wreckage. The nonvolatile memory is designed to record and store data on in flight failure history of the FCES and to remain intact after essential 28 v. d. c. bus electrical power loss.

Although both boards were damaged, the NVM chips were removed and installed on serviceable test boards for memory read out. Both chips produced identical results implying that both FCC channels had been cleared by the pilot prior to flight and were functional with no fault codes recorded up to 0.2 sec. prior to the loss of electrical power, which would have occurred at impact.

A total of 11 flight control hydraulic actuators were recovered and examined: two pitch servos, two speedbrake actuators, two rudder servos, two aileron servos and three control augmentation system actuators. The examination did not reveal any evidence of pre impact unserviceability to any component. Evidence derived from the pitch servo impact capture marks was consistent with a horizontal stabilizer position of 2.25 deg. Ieading edge down at impact.

This position would be a nominal automatic pitch trim setting for the flight profile immediately prior to impact.

No evidence of foreign objects (FOD) was found during the wreckage investigation.

Analysis of the movie film taken of the final maneuver (maneuver 8) indicated correct aircraft response to all flight control movements recorded throughout the mishap sequence.

Flaps

The flap selector switch was normally selected to the auto position by the pilot during the demonstration flight profile. This selection automatically cycled the flap position to suit the changing aerodynamic requirements for the flaps during flight to provide optimum aircraft performance. The main flap mixer and travel limit units were recovered and examined. The cams of both units indicated that the flaps were at the three quarter position; i. e., 18 deg. Ieading edge down, 16 deg. trailing edge down. This setting equates to an automatic mode airspeed range of 200-300 kt.

Instruments

The primary attitude indicator from the aircraft's instrument panel was examined and found to have the off warning flag captured out of view as a result of the impact. The off flag derives its power source from the essential 28v. d. c. bus to power it out of view, indicating that the essential d. c. bus was powered to impact.

Examination of the shattered cathode ray tube (CRT) of the flight director and head up display (HUD) showed evidence of impact damage induced electrical high voltage arcing on the inner components of the tube, indicating that the a. c. bus was powered to impact.

No engine instrument data were recoverable because the instruments were liquid crystal displays.

Examination of the airspeed indicator showed an approximate impact speed of 250 kt.

Photogrammetric Information

During the demonstration practice, a company photographemrecorded the entire flight using 16 mm. movie film at 24 frames per sec.

The film, which contained footage of the mishap (flight number 400) and footage of other practice flights flown earlier in the day (flight numbers 395 to 399), was developed and examined. The film exhibited high quality images of the aircraft in all six of the flight demonstrations flown that day hlcluding the accident flight. Copies were made of the film in 16 mm. format and in l/2 in. video format for further study.

Arrangements were made with Northrop Corp. and with the USAF Aeronautical Systems Div. to carry our photogrammetric analysis of film footage of the aircraft during its final maneuver.

Analysis of the movie and of photographs of the crash site allowed a number of estimates to be made. These include the following: the amount of g force applied during the pull up; speeds at various points during the accident maneuver; construction of an accurate plot to include the camera location, and construction of an estimated ground track and final flight path .

Digital computer simulations were conducted to determine probable control inputs and the subsequent aircraft response to those inputs.

A frame by frame analysis was conducted of the total maneuver starting from the initiation of the simultaneous right turn and pull up (time zero) and continuing to the point of the last full view of the aircraft, before It passes behind the trees. The total duration for this maneuver to occur is 18.54 sec., and the first indication of fire above the trees is observed at 20.29 sec.

For maneuver number 8, the aircraft approached the camera traveling from right to left, at a speed of 361 kt. The camera was situated on the south side of Runway 08 and slightly west of the threshold. The aircraft was headhlg toward a simulated air show chalet position, situated approximately 2,000 ft. west of the Runway 08 threshold and 500 ft. south of the runway. This scenario was practiced on previous flights flown that day. As the aircraft reached the end of the runway, a right turn and a simultaneous 7.2g pull up were executed. The peak onset g level was 6.2g per sec., which was reached 1.0 sec. after the start of control application.

As a result of the right turn, the heading changed about 120-150 deg. relative to the original high speed approach heading. On completion of the pull up and right turn, the aircraft entered a left, full deflection aileron roll starting from a right wing low position, approximately 1,200 ft. agl. at a speed of 210 kt. The left rudder deflection is observed at the initiation of this left roll. The commanded left roll continues for approximately 1 l/2 rolls to essentially an inverted position as the aircraft proceeds away from the camera at a speed of 175 kt. The left roll had progressed slightly past the inverted position but was corrected back to the inverted. This inverted position (with the nose low) was maintained for about 0.9 sec. before a roll to the left was again initiated.

This stopping and starting of the roll appeared to be in response to appropriate movement of the ailerons. As the left roll continued, the aircraft was at a very nose low attitude. The nose had been raised substantially by the time the aircraft reached an upright, nose low wings level attitude, which was maintained for about 3 sec. until impact. Prior to reaching this wings level attitude, the horizontal stabilizer had been deflected, trailing edge up, by a substantial amount, possibly the full deflection of 20 deg. Just after the aircraft reached the wings level, nose low attitude, the horizontal stabilizer was observed to be deflected very little relative to an axis running through the fuselage from nose to tail. Immediately thereafter, the nose low attitude increased slightly, and the aircraft disappeared from view behind a line of trees.

During the final descent, and prior to disappearing from view, the aircraft accelerated to 258 kt. at a negative flight path angle of approximately 33 deg. and a pitch attitude of24 deg.; the angle of attack would have been 9 deg .

In an attempt to isolate any human abnormalities evident during the final maneuver of the mishap flight, all other final maneuvers flown on the same day were analyzed frameby frame. There were six flights flown that day, flights 395 to 400. The first two and last two were flown by the accident pilot. The middle two were flown by the other demonstration pilot. The maneuver entry airspeeds and speeds during the left rolls were calculated and compared as well as the roll rates and landing gear extensions. The pilots' throttle handling was also compared.

When compared with the other final maneuvers flown that day, significant differences were noted during the mishap maneuver: the stopping of the left roll in an inverted position, the lack of landing gear extension and failure to deselect the afterburner.

In addition, the aileron roll following the high g pull up and turn was not executed with authority and precision; it resembled a barrel roll, and it was not termhlated at the correct angular position As well, no significant elevator deflections or aircraft pitch attitude changes were observed during the final wings-level descent to impact.

Other Information

Life Support Equipment

The automatic pressure breathing oxygen regulator hose was examined. No pre impact abnormalities or evidence of deterioration was found. The pilot's oxygen mask was recovered in several pieces. The pieces were examined and analyzed by the Civil Aviation Medical Unit for possible contamination by food or stomach contents; none was found.

The pilot's USAF type anti g coverall was examined. The ''comfort zippers" were done up; all lacing in the abdomen, thigh and calf areas was done up, with loose ends of lacing correctly stowed and taped, indicating that the anti g coverall had been properly fitted to the pilot. Because of damage sustained, post accident testing of the bladder system was not possible.

Evidence from the anti g coverall hose and the aircraft high flow anti g hose connector suggests that they were connected at the time of impact.

The pilot's USAF type torso harness was examined and no abnormalities were found. All evidence indicated that the torso harness had been properly fitted to the pilot.

Air Show Maneuvers

The flight sequences being practiced at the time of the accident were developed to demonstrate the capabilities of the aircraft to potential customers. This display was to be flown at the Paris air show and had a minimum flight altititude of 500 ft. agl. The flight demonstration was intended to show the high pitch rates available to the pilot, and, as a consequence the aircraft center of gravity was kept near the aft limit to enhance the maneuvering capability. Flight tests were carried out to verify the stability and control of the aircraft at the center of gravity and speed conditions expected in the display.

The air show sequence was developed over several months and had been practiced over 60 times by both company demonstration pilots. Each practice was monitored by company personnel who debriefed the pilots following the flight. All practices were filmed by a company photographer; the presence of the photographer was a requirement for the practice.

The air show sequence included two 9g maneuvers. In the first, a 9g application was preceded by a few seconds of -lg and was followed by a series of rolls. The other 9g maneuver was the pull up that immediately preceded the accident. Normal pilot actions following the 9g pull up would include deselection of afterburner and lowering of the landing gear.

During the practices in California for the Paris air show, two unusual events occurred. Once during the -1 g to +9g maneuvers, the accident pilot allowed the aircraft to enter a steep, nose low attitude, but he was able to recover. Observers at the practice were concerned and questioned the pilot as to why the nose low attitude developed. His explanation was limited to a statement that he "buried the nose. " No further investigation took place, and no similar problems occurred with the accident pilot during the air show practices in California. The other demonstration pilot reported that, on one occasion, he had suffered physiological problems during the same -1 g to +9g maneuver. Following the 9g pull up, he realized that he was having difficulty commanding the proper roll rate. He felt that he could distinguish sky from ground but could not manage the correct control input. He stopped the roll, everything returned to normal and he was able to continue the practice.

Physiological Effects of G

The hazards associated with exposure to positive g acceleration have been recognised since the 1930s. High positive g interrupts the normal flow of blood to the brain; g induced loss of consciousness (GLC) occurs as a result of brain tissue hypoxia. Because the retinal arteries collapse at a higher eye level blood pressure and hence at a lower g level, loss of consciousness is usually preceded by "grey out'' or "black out." The "black out'' phenomenon is a complete loss of vision, but the pilot remains conscious.

The USAF now recognizes that operational GLC is not an unusual event. Up to 20%, of U. S. tactical air crew are reported to have experienced GLC. It has occurred at relatively low g (less than 4g) and during high g onset rates, without the normally expected preparatory symptoms such as grey out or black out. Even though the development of anti g equipment, such as the anti g coverall, high flow anti-g valves and high-g seat (reclined angle), and methods, such as a correctly performed M-1/L-1 straining maneuver (forced holding exhalation of breath and/or tensing of abdominal and skeletal muscles to raise thc blood pressure), physical conditioning and centrifuge training have increased man's g-tolerance , they have proven to be ineffective in the total prevention of GLC.

The physiological effects of g are a function of rate of onset g-level and the duration of g. A pilot's tolerance deteriorates over the period of exposure to both sustained and repetitive high g forces. That is to say, a pilot's ability to endure g forces is greatest when he is fresh and becomes less as a particular high g engagement progresses and as the number of engagements increases in a given day. The reason for this phenomenon is considered to be the depletion of autonomic stress hormone (c. g., adrenaline) or tissue energy stores (e. g., glycogen), or both, with time at g. Many, if not most, of the USAF GLC mishaps have occurred under circumstances of which there was evidence of pilot fatigue.

Other factors that reduce tolerance are chronic or acute hypotension, hypoglyccmia, self imposed or environmental stress, dehydration and illness. USAF centrifuge studies have also shown that, in some cases, pilots with a low heartbeat rate can have reduced g tolerance .

At the time of the accident, the U. S. military was just beginning to realize the full impact of GLC due to their recent loss of five tactical aircraft in a short space of time. All were deemed caused by GLC. Other GLC events occurred but did not result in accidents, because the aircraft altitude was sufficient to allow the pilot to recover his faculties.

Centrifuge studies have demonstrated that, once a pilot loses consciousness, a period of functional incapacitation follows. This period lasts an average of 15 sec. (the range was from 9 - 20.5 sec.). Video tapes of centrifuge subjects who experienced GLC show them moving their head and arms in an uncoordinated, haphazard manner and grunting or mumbling incoherently as if being awakened suddenly from a nightmare.

During this awakening period, the pilot is completely incapable of purposeful activity -- unable to respond to voice warning systems or radio calls, unable to pull the throttle out of the afterburner range, unable to recover from dangerously steep dives and unable to initiate ejection.

The recovery period following incapacitation lasts about 10 sec. During the recovery period, the pilot is confused and disoriented, and his performance is erratic. He may attempt to regain awareness by scanning the cockpit or grasping the flight controls. Some subjects described feelings of detachment and apathy following GLC: they stated they knew what they were supposed to do but did not care about doing it. Some described the experience as a dream like state where time seemed to move slowly. The time lapse from the pull on the control column that causes GLC until the pilot regains reasonable functional capacity ranges from 15 - 30 sec.

Another possible side effect of g exposure, and GLC is spatial disorientation. A GLC episode can temporarily destroy the visual dominance and vestibular suppression. providing all opportunity for spatial disorientation to occur during the recovery from GLC.

New generation fighter aircraft such as the F 20 are capable of developing higher g onset rates and can maintain higher sustained g loads than previous generations of fighter aircraft.

ANALYSIS

Introduction

The accident occurred on the sixth practice air show flight of the day; it was the fourth of the day for the accident pilot. The flight appeared normal until the last sequence of the air display. The aircraft deviated from the planned flight path by hesitating for approximately 1 sec. in inverted flight, following a roll that was not smoothly flown. A barrel roll type maneuver was observed, and the aircraft crashed while in a slightly left wing down attitude on a heading opposite to that expected to place the aircraft on downwind to Runway 08.

The weather at the time of the accident was suitable for the intended flight. The aircraft was clearly visible to observers throughout the demonstration flight, and at no time did it enter cloud. The terrain features provided a horizon reference in the area of the accident, eliminating the likelihood of visual illusions.

Air show displays of the type planned for the F 20 place the pilot and aircraft in situations where safety margins are reduced. Both pilot and machine are operating near their limits and a small amount of time (altitude) is available for recovery from any problem.

Aircraft Serviceability

The film of the accident flight did not reveal any evidence of failure of the aircraft structure. The aircraft appeared to have responded normally to control surface deflections. The wreckage did not reveal any evidence of failure of the aircraft or any of its systems.

Pilot Performance

The pilot's circadian rhythm would have been affected by the 4 hr. time zone difference between California and Labrador. However, because of his two day stop at Andrews Air Force Base, and the late morning start of his flight duties, the effect of circadian rhythm change would not have been significant. Prior to the mishap flight, he had received a good night's rest and had eaten breakfast and, following the first two flights, had consumed a light snack. It appears that the pilot's rest and nutritional requirements had been satisfied .

The g environment during the flight was conducive to g induced loss of consciousness (GLC), as the g level and duration were of sufficient magnitude to cause GLC. The air show was designed to display the aircraft's maneuverability, and, as a consequence, high g onset rates were generated. Although the g level targeted and possibly attained during the maneuver was 9g, even the nominal 7.2g peak estimated by film analysis is significant. Certainly, the pilot's participation in four high g demonstration flights on the day of the accident represented repetitive high g exposure, and his flying the 4 min. of flight 400 represented a moderate amount of sustained high g exposure with high onset rates.

The effect of such activity is fatigue that diminishes the ability to mount a maximal anti-g straining maneuver as well as a disinclination to do so. The achalasia condition would have reduced the ability to perform the anti g straining maneuver effectively, if the recent food ingestion had caused esophageal pain. Any reflux action present, which has the side effect of hypotension, would have reduced the pilot's g tolerance. The humorous comment entered in the maintenance log by the pilot, stating that he was thirsty, may have been an indication that the pilot was dehydrated. Dehydration lowers g tolerance. The low heartbeat rate noted in the pilot's USAF medicals indicates that the pilot may have had a reduced g tolerance. In addition, there is no indication that the pilot had obtained or had been provided with aeromedical training dealing with the GLC phenomenon to ensure that he was able to carry out a maximal Ml/L1 straining maneuver for the 9g environment of F 20 flying.

The continuation of obvious pilot induced control inputs, which continued following execution of the 7 9g pull up that may have rendered the pilot unconscious or semiconscious, can be explained. A medical opinion concludes that the pilot had practiced the maneuver so many times that, once he initiated the pull up and roll sequence, his voluntary motor activity was essentially ballistic; i. e., the roll was executed using lower (noncerebral) levels of his central nervous system without modification by conscious sensory feedback.

The absence of discrete voluntary actions involving critical conscious timing, such as afterburner deselection, landing gear lowering or efforts to save his own life by initiation of the ejection sequence, confirms that the pilot was incapacitated at least to some degree.

The final roll of the aircraft to an upright wings level, albeit nose low attitude, which was maintained to impact, could have been a chance result of involuntary, uncontrolled, control column movements by an unconscious or barely conscious pilot. This roll to upright occurred about 15 - 17 sec. after the high g portion of the pull up maneuver and ground impact was approximately 3 sec. later. U. S. military experience with GLC events has shown that it is possible that the pilot would not have been capable of functioning normally within the 20 sec. available from the g application to ground impact. Involuntary pilot movements are commonly seen during GLC events. At best, the aircraft motions were a manifestation of a primitive righting reflex, a subconscious response by the pilot to threatening vestibular and/or ambient visual stimulation.

Another possible physiological effect of the air show display would be spatial disorientation, either as a result of the combined g and rolling forces on the vestibular system or as a consequence of a GLC episode. The disorientation experience encountered by the other F-20 demonstration pilot, during a similar high g rolling maneuver, shows that such an event can occur. The nose low event experienced by the accident pilot during an air show practice in California shows that the flight profile leading to the accident was not an isolated event.

The structural and performance capability of new generation fighter aircraft, such as the F-20, F-18 and F-16, is far superior to their predecessors. These aircraft are capable of developing higher g onset rates and higher sustained g loads; this increases the risk of GLC.

Survivability

The accident was nonsurvivable because of the magnitude of the impact forces. The ejection sequence was not initiated by the pilot likely as a result of incapacitation. Based on the 2 sec. parachute deployment time of the ejection system, a successful ejection could have been possible if it had been initiated immediately following commencement of the final wings level descent.

CONCLUSIONS

Cause Related Findings

Other Findings

- The pilot became incapacitated during or following the final high g pull up maneuver and did not recover sufficiently to prevent the aircraft from striking the ground.

- The low altitude used in the flight demonstration reduced the time available to regain control of the aircraft following a temporary incapacitation of the pilot.

- The pilot suffered from achalasia, which reduced his g tolerance, and this condition was not disclosed to his examining physician.

- The pilot's ability to achieve a maximal anti g straining maneuver could have been impaired by his undisclosed medical condition.

- The pilot had not received formal aeromedical training pertaining to the GLC phenomenon, and no evidence was found that GLC training was required prior to participation in high g demonstration flights.

- In the 2 l/2 hr. prior to the accident, the pilot participated in four high g demonstration flights requiring repetitive, rapid onset, high g exposure in addition to sustained moderate g exposure, which lowered his g tolerance.

SAFETY ACTION

- There was no evidence of any failure or malfunction of the aircraft or its systems.

- The close proximity of the aircraft battery and the flight control computer (FCC) made the FCC vulnerable to damage from electrolyte fluid leaks.

- The pilot was qualified to conduct the flight in accordance with existing regulations.

- The aircraft was certified, equipped and maintained in accordance with existing regulations and approved procedures.

- The aircraft weight and center of gravity were within the prescribed limits.

- A cockpit video recorder had been removed prior to the demonstration flights.

- The aircraft was not equipped with a cockpit voice recorder or a flight data recorder, and neither was required by regulation.

Action Taken:

The Canadian Aviation Safety Board (CASB) notes the following action taken by the aircraft manufacturer as a consequence of this occurrence and the subsequent investigation:

The CASB recognizes that these efforts have contributed to a better understanding of GLC by the manufacturer, its foreign customers and the USAF. It is also understood that parallel efforts within the Canadian Department of National Defense have been under way for some time. In an effort to further improve awareness of the GLC phenomenon, copies of this occurrence report are being made available to the Canadian Department of National Defense.

- Cooperative research has been undertaken by the manufacturer and the USAF School of Aerospace Medicine into GLC.

- The manufacturer has requested that the United States Air Force School of Aerospace Medicine allow company test pilots to undergo centrifuge familiarization and testing under high g conditions.

- Information briefings on the GLC phenomenon have been given to the manufacturer's foreign customers, as well as Northrop and USAF test pilots and engineers. These briefings have been supported by audio visual presentations on actual GLC occurrences in flight and during centrifuge experiments.

Action Required

Awareness of the GLC Phenomenon

The CASB notes that the GLC phenomenon can be caused by sustained high g loads and also by rapid g onset rates. It is recognized that due to performance limitations, civilian aerobatic aircraft are not able to sustain high g loads for as long as military type high performance aircraft. However, acceleration rates for both positive and negative g loads are comparable for these two types of aircraft.

Based on discussions with Canadian civil aerobatic pilots and their representative organization, Aerobatics Canada, the CASB believes that there is a lack of current knowledge regarding the GLC phenomenon.

Therefore, the CASB recommends that the Dept. of Transport disseminate information regarding g loss of consciousness to the civilian aerobatic pilot community.

F-20A GI-1001 Crash Investigation Report

F-20A GI-1001 Crash Investigation Report space project projects programme program programmes programs spaceflight astronaut cosmonaut biography rocket spacecraft satellite exploration launch vehicle history

web.archive.org