- Joined

- 12 October 2009

- Messages

- 557

- Reaction score

- 213

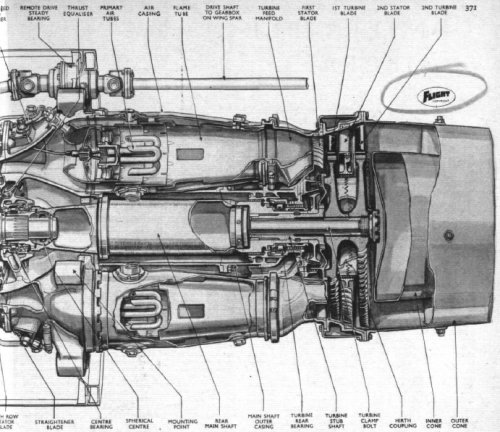

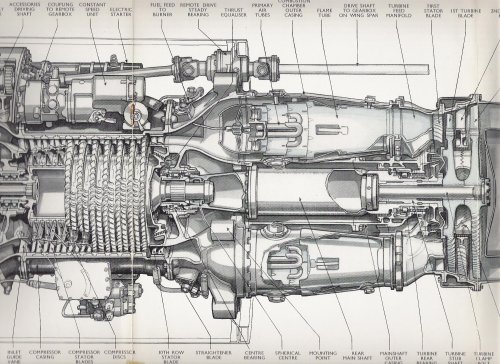

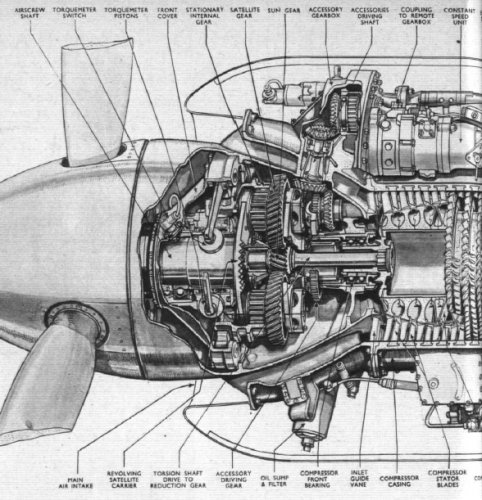

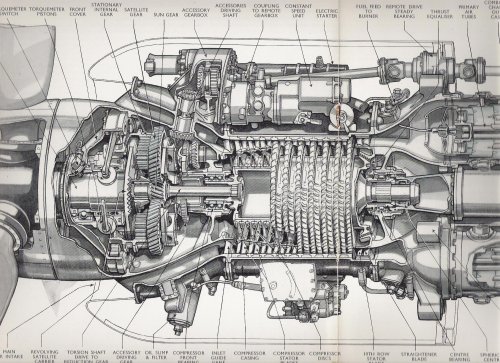

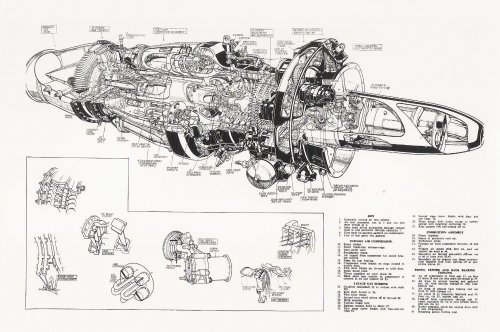

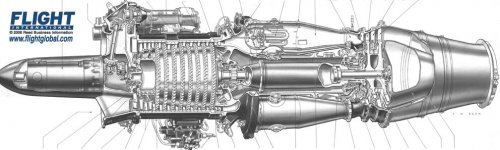

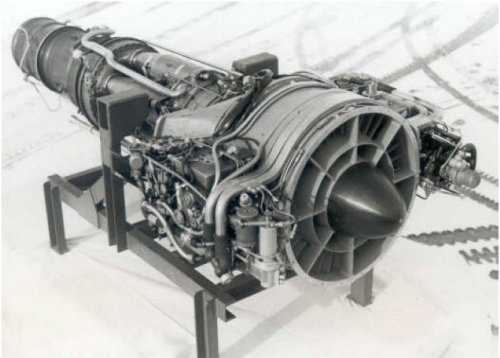

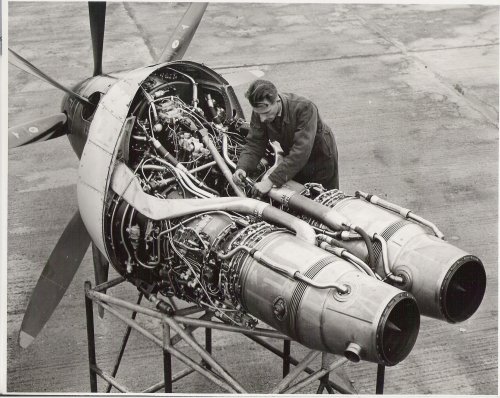

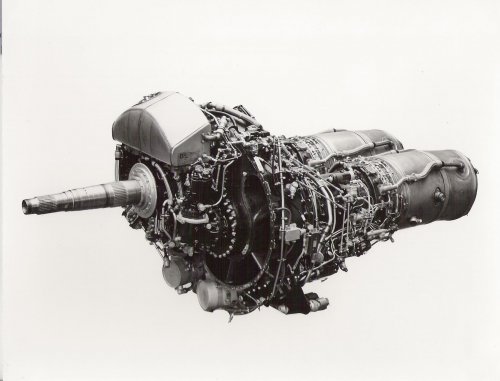

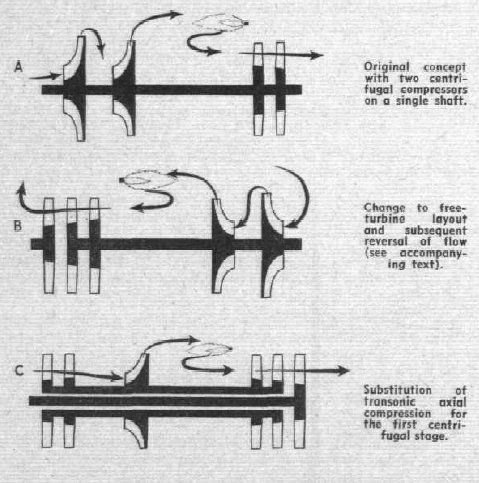

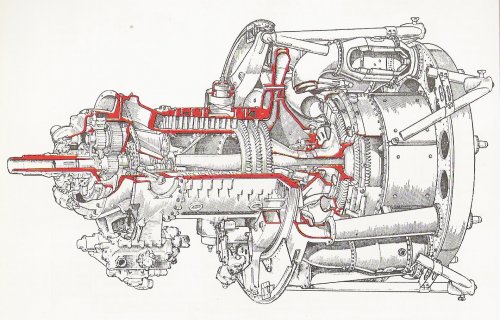

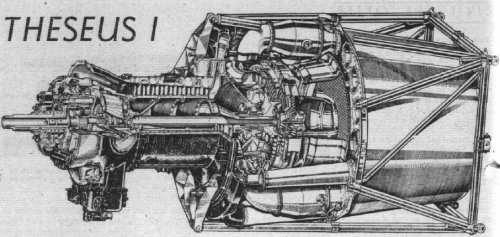

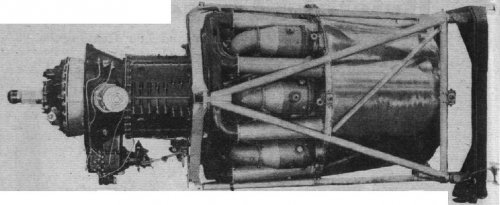

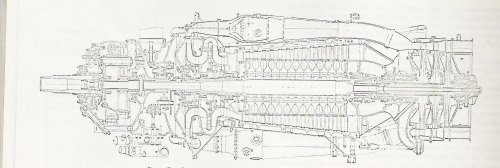

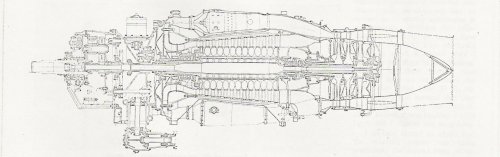

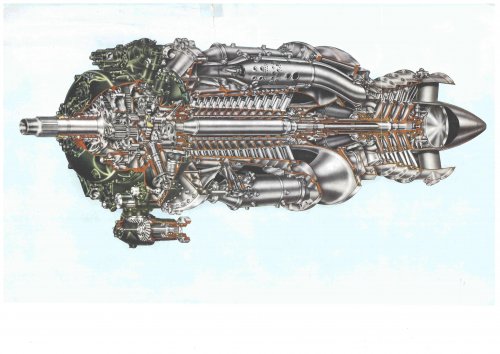

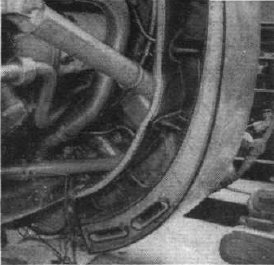

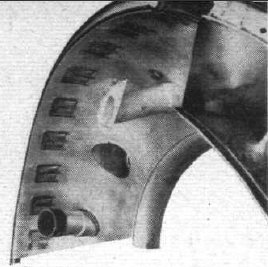

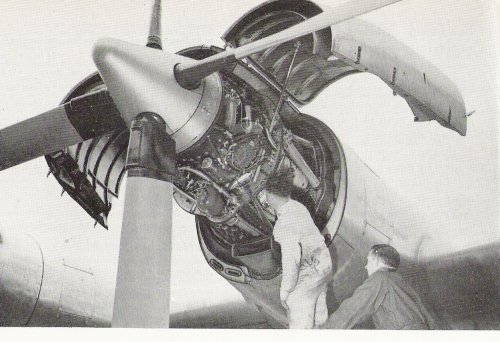

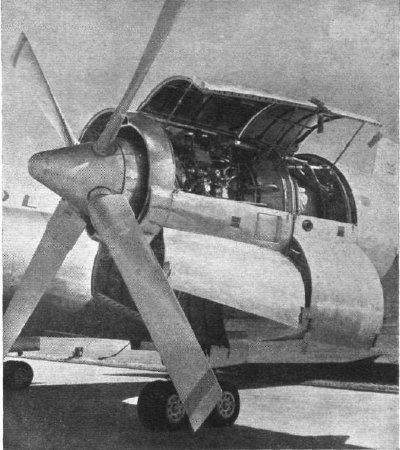

The Python has two claims to fame:

1) it influenced the layout of the engine that became the Proteus, and

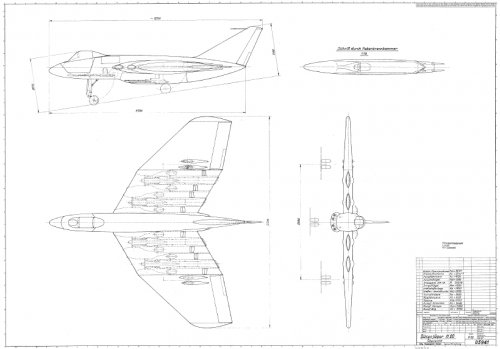

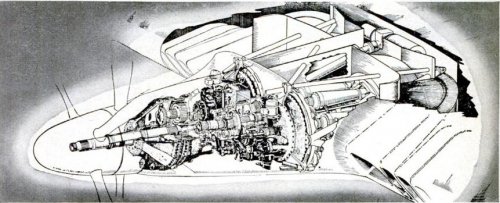

2) it powered the Westland Wyvern:

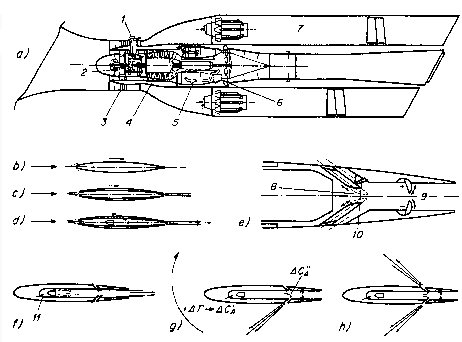

Originally intended to have the Clyde engine but with Rolls-Royce committed to other engine projects, the Armstrong-Siddeley Python was the only turboprop of the necessary size that could be used for the Wyvern. This decision added at least two years to the development cycle as the engineers struggled to create a throttle control that would allow the engine to be rapidly throttled back for a carrier landing, or rapidly throttled up to make a go-around, the solution being an inertia control unit that was unfortunately mechanically complex.

After carrier trials which started on the 21st June 1950 the Wyvern finally appeared as the S.Mk.4, which began to be delivered to RNAS Ford in May 1953 for use by 813 Squadron. and were withdrawn from service by 1958.

These aircraft did not have the definitive engine control unit and thus were not carrier-compatible until these units were installed in the summer of 1954. The first operational Wyverns went aboard HMS Albion in September 1954. The problems were not over, as there were a series of flameouts during catapult launch as a result of fuel starvation under high-g loading while the aircraft were with Albion during a Mediterranean cruise. In fact, Lt. B. D. Macfarlane made history when he successfully ejected under water after his Wyvern had ditched on launch and been cut in two by the carrier. The Wyverns were offloaded at Hal Far, Malta, and remained there until March 1955 when they returned to England. The problem was not fixed until March 1955. 813 and 827 Squadrons then embarked aboard HMS Eagle in May 1955 for a second Mediterranean cruise, which gave the Wyverns some 1,500 operating hours and 1,000 landings, after which the aircraft was considered proven.

While in service Wyverns equipped 813 Naval Air Squadron, 827 Squadron, 830 Squadron, and 831 Squadron of the Fleet Air Arm. Squadron 813 was the last Wyvern squadron to disband on the 22nd April 1958.

We will discuss the first claim to fame elsewhere.

1) it influenced the layout of the engine that became the Proteus, and

2) it powered the Westland Wyvern:

Originally intended to have the Clyde engine but with Rolls-Royce committed to other engine projects, the Armstrong-Siddeley Python was the only turboprop of the necessary size that could be used for the Wyvern. This decision added at least two years to the development cycle as the engineers struggled to create a throttle control that would allow the engine to be rapidly throttled back for a carrier landing, or rapidly throttled up to make a go-around, the solution being an inertia control unit that was unfortunately mechanically complex.

After carrier trials which started on the 21st June 1950 the Wyvern finally appeared as the S.Mk.4, which began to be delivered to RNAS Ford in May 1953 for use by 813 Squadron. and were withdrawn from service by 1958.

These aircraft did not have the definitive engine control unit and thus were not carrier-compatible until these units were installed in the summer of 1954. The first operational Wyverns went aboard HMS Albion in September 1954. The problems were not over, as there were a series of flameouts during catapult launch as a result of fuel starvation under high-g loading while the aircraft were with Albion during a Mediterranean cruise. In fact, Lt. B. D. Macfarlane made history when he successfully ejected under water after his Wyvern had ditched on launch and been cut in two by the carrier. The Wyverns were offloaded at Hal Far, Malta, and remained there until March 1955 when they returned to England. The problem was not fixed until March 1955. 813 and 827 Squadrons then embarked aboard HMS Eagle in May 1955 for a second Mediterranean cruise, which gave the Wyverns some 1,500 operating hours and 1,000 landings, after which the aircraft was considered proven.

While in service Wyverns equipped 813 Naval Air Squadron, 827 Squadron, 830 Squadron, and 831 Squadron of the Fleet Air Arm. Squadron 813 was the last Wyvern squadron to disband on the 22nd April 1958.

We will discuss the first claim to fame elsewhere.