Steel is cheap. Rapid prototypying, mass production of airframes and engines, no pilot onboard... and Musk now has close from $200 billion in his pockets. He can afford it. And he will charge ahead no matter what.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SpaceX (general discussion)

- Thread starter FutureSpaceTourist

- Start date

taildragger

You can count on me - I won a contest

- Joined

- 2 November 2008

- Messages

- 403

- Reaction score

- 499

I don't think Space-X really fits into a discussion of inefficient rocket development. They've achieve revolutionary breakthroughs that eluded government agencies with much larger budgets for decades.@Moose :

I might get frustrated watching such waste of capital but I would think that logic would dictate to go back to small scale demonstrator: If the belly flop pause problem with the fuel, pump and engines, there is nothing that would be done at a smaller scale that wouldn't represent what is happening for real.

Similitudes and flows mechanics (the art of scaling down a process that would still be representative) is not sciences fictions. It has been bread and butter for aerospace since the Wright Brothers and even the Naca.

It won't prevent them to run in parallel their test for re-entry and still opening their flight domain (having an explosion diminish in effect the span of knowledge gained per flight).

My 2 cents only.

Similitudes may no longer be as useful as it was before hi-fidelity digital simulation and it was always mainly used for proving out a basic concept or configuration - I think Starship is beyond that now. There are plenty of cases where sub-scale demonstrator aircraft have turned into time-consuming distractions that have actually delayed the main project.

- Joined

- 13 August 2007

- Messages

- 8,394

- Reaction score

- 10,811

I might get frustrated watching such waste of capital...

See Atlas ICBM it was so technical new land, nobody know what could happen

Convair lost half of prototypes in explosion, stop that them ? no !

After each failure, Convair analyzed the problem, fix on next prototype put on Launch pad were explode for another reason.

What happen in Boca Chica is the same thing

Musk try to build low cost Dumb Booster, that is low cost re-usable.

he goes for cheap steel with traditionell welding, with low cost parts except the Raptor engines

rumor goes that one SN cost between 2 to 20 million dollars if that's true it really low cost production

For moment the program suffers from Issue with Raptors

like problem with combustion (see yellow discoloration of exhaust) not properly restart, one fire in Turbopump.

the Raptor is the Achilles'heel of Starship program, i hope it not become another "NK-15 under the N1 rocket"

logic would dictate to go back to small scale demonstrator:

That would make sense only if it would be cheaper. I don't believe it would be.

SpaceX believes strongly in retaining skilled workforce. They are not going to lay off or furlough the workforce at Boca while they pause to solve a problem. The workers they have at Boca cost the same regardless of what they are working on -- the raw materials basically cost nothing compared to the wages. While they are there, they might as well get more experience building starships. The other parts and fixtures that go into the SS are a similar story: they are all either built in-house by workforce with fixed costs, or they are bought externally at commodity prices. It costs ~$1 billion to run SpaceX for a year, but the marginal cost of them building a giant rocket versus not building one is probably well below a million $. The decision to run the company in this way is the main difference between them and traditional aerospace, and imho the main reason Falcon 9 beats everything else in cost so convincingly.

Any small-scale testing will then only beat blowing up starships if it 1. doesn't require any work or parts external to what the company is already doing, 2. is faster than just building another SS, including the design phase. And even if those two are true, it would cause interruption on starship manufacturing and thus hurt the lines learning curve. I don't think I could design a small-scale experiment that would beat SS, could you?

I underdtand all the concerns (or lack of) expressed here but once again, they can still build Starships and test them in parallel, avoiding the problematic of the belly flop meanwhile to concentrate on re-entry for example.

Tanks are scalable

Structure is scalable and not part of the problem hence simplified and representative or more rigid should be doable

Plumbing is scalable

Engine can be simulated at pump level (compress neutral gas) and a single raptor fitted instead of a pack of 3 (nbr of engines involved in the belly flop).

So you could make a mini-Starship with a single Raptor engine, simulated trio of engines and smaller tanks in probably a 2meter (6ft) diameter rocket per 18 meter high (based on Starship size of 9m (27ft) in diameter and 55m(60ft) length certainly in much less time and money that it takes for a full scale Starship.

That's before any similitudes techniques are applied.

Tanks are scalable

Structure is scalable and not part of the problem hence simplified and representative or more rigid should be doable

Plumbing is scalable

Engine can be simulated at pump level (compress neutral gas) and a single raptor fitted instead of a pack of 3 (nbr of engines involved in the belly flop).

So you could make a mini-Starship with a single Raptor engine, simulated trio of engines and smaller tanks in probably a 2meter (6ft) diameter rocket per 18 meter high (based on Starship size of 9m (27ft) in diameter and 55m(60ft) length certainly in much less time and money that it takes for a full scale Starship.

That's before any similitudes techniques are applied.

Dragon029

ACCESS: Top Secret

- Joined

- 17 March 2009

- Messages

- 881

- Reaction score

- 440

To try and correctly copy and scale the ullage gas ingestion, propellant flow behaviour, including at bends and intersections, heat transfer and temperatures throughout the tanks and plumbing, etc would cost a not-insignificant amount. Producing a sub-scale vehicle would also require new tooling and new launch facilities.I underdtand all the concerns (or lack of) expressed here but once again, they can still build Starships and test them in parallel, avoiding the problematic of the belly flop meanwhile to concentrate on re-entry for example.

Tanks are scalable

Structure is scalable and not part of the problem hence simplified and representative or more rigid should be doable

Plumbing is scalable

Engine can be simulated at pump level (compress neutral gas) and a single raptor fitted instead of a pack of 3 (nbr of engines involved in the belly flop).

So you could make a mini-Starship with a single Raptor engine, simulated trio of engines and smaller tanks in probably a 2meter (6ft) diameter rocket per 18 meter high (based on Starship size of 9m (27ft) in diameter and 55m(60ft) length certainly in much less time and money that it takes for a full scale Starship.

That's before any similitudes techniques are applied.

Even after all that you still wouldn't be experiencing the same vibration modes, the same weld-quality, the same avionics complexities of having to rapidly identify engine health during the flip manoeuvre and decide which engines to shut down prior to touchdown, etc.

You'd likely wind up spending similar, if not more money, and yet still gather less data. Half the purpose of building all these Starship prototypes is just streamlining the manufacturing process as well; Musk wants to eventually be pumping out a Starship every few days to every week in order to provide massive (primarily one-way) payload transfer to Mars, so every vehicle they build helps them reach that production rate and the required production cost.

Subscale testing is useful for some things - SpaceX has built wind tunnel models of Starship for example to validate some of their bellyflop flight simulation models, and the first Raptor engine prototype they built was also a sub-scale system, but once you know that the basic concept / design is valid, you can't really continue using them to then validate your detailed engineering designs.

I understand. But we are not at day one. Structurally, Starship is sound (it survived all the flight just being blown up after hard touchdowns). So it's not about scaling it down but building a representative test model.

Also, with a single engine, it's all the plumbing that are actually installed on Starship that could be mounted on the model.

Notice that this is what earlier test were all about (Hopper).

Also, with a single engine, it's all the plumbing that are actually installed on Starship that could be mounted on the model.

Notice that this is what earlier test were all about (Hopper).

I underdtand all the concerns (or lack of) expressed here but once again, they can still build Starships and test them in parallel, avoiding the problematic of the belly flop meanwhile to concentrate on re-entry for example.

Tanks are scalable

Structure is scalable and not part of the problem hence simplified and representative or more rigid should be doable

Plumbing is scalable

Engine can be simulated at pump level (compress neutral gas) and a single raptor fitted instead of a pack of 3 (nbr of engines involved in the belly flop).

So you could make a mini-Starship with a single Raptor engine, simulated trio of engines and smaller tanks in probably a 2meter (6ft) diameter rocket per 18 meter high (based on Starship size of 9m (27ft) in diameter and 55m(60ft) length certainly in much less time and money that it takes for a full scale Starship.

That's before any similitudes techniques are applied.

They don't have tooling to make tanks of a smaller diameter. After experimenting with freely welding them, they moved to hard tooling and automatic welding for both the horizontal and vertical welds, which they would have to replicate at a smaller diameter if they wanted a tiny starship. That alone probably scuppers this idea.

- Joined

- 3 June 2011

- Messages

- 18,307

- Reaction score

- 12,088

You mean like the kind that takes a decade to build a "new" rocket out of existing parts and not fly? That kind of "sane" engineering?They are churning them out just to be blown up like heretics thrown in the pyre during the Middle Ages...

Did they lost faith in sane engineering?

- Joined

- 3 June 2011

- Messages

- 18,307

- Reaction score

- 12,088

@Moose :

I might get frustrated watching such waste of capital

You're talking about SLS, right? RIGHT?

As noted in a few previous posts, their cost per vehicle seems so obscenely low (for rocket development) that it doesn’t seem relevant to do sub scale testing. It’s hard to argue with the success of their existing product line.

- Joined

- 3 June 2011

- Messages

- 18,307

- Reaction score

- 12,088

@sferrin : Get that. Good point.

At least it's SpaceX's dollars SpaceX is "wasting". (They can do what they want with it. If they want to put a pile of cash in a field and light it on fire that's their prerogative.) SLS is taxpayer funded.

- Joined

- 13 August 2007

- Messages

- 8,394

- Reaction score

- 10,811

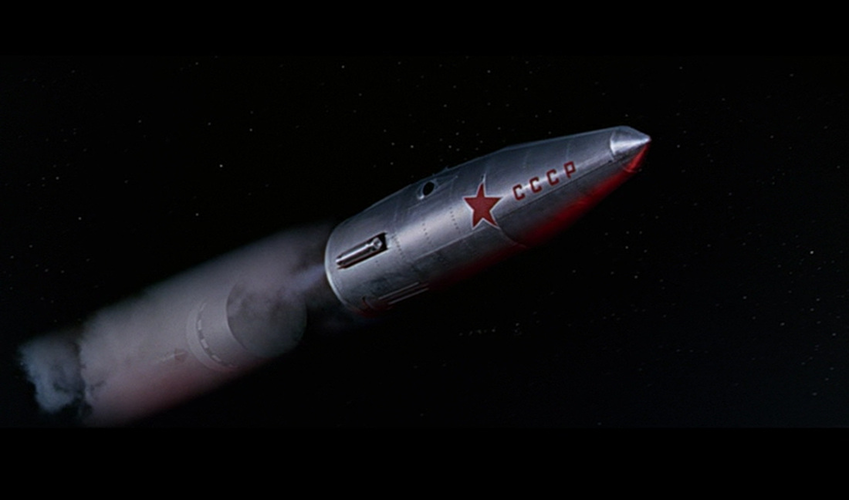

Musk is blofeld ????

So long he not become like Hugo Drax...

View: https://www.youtube.com/watch?v=xQz3-4nPwvE

So long he not become like Hugo Drax...

NeilChapman

Interested 3rd party

- Joined

- 14 December 2015

- Messages

- 1,317

- Reaction score

- 547

It seems to me the key point was made in an earlier post. This is all about scaling up production and you can't do that without producing that which you want to scale up, no?

Dragon029

ACCESS: Top Secret

- Joined

- 17 March 2009

- Messages

- 881

- Reaction score

- 440

Hopper was largely about just flight testing Raptor (I believe Starhopper's first static fire was the first time a Raptor had been operated in a vertical orientation).I understand. But we are not at day one. Structurally, Starship is sound (it survived all the flight just being blown up after hard touchdowns). So it's not about scaling it down but building a representative test model.

Also, with a single engine, it's all the plumbing that are actually installed on Starship that could be mounted on the model.

Notice that this is what earlier test were all about (Hopper).

With regards to the plumbing, I'm not sure how you could make it representative while scaling it down, without achieving very fine characterisation of the propellant and gas flows, and by the time you have that data you already have the info you would've hoped to receive from the representative test model.

Like what I'm talking about is - when Starship starts using its header tanks, and you have LOX flowing through 50m of piping from the nose of the vehicle, all the way down to the LOX manifold and engines, how far down the piping does helium or gaseous oxygen get? How does the heat transfer through the 50m of piping affect recondensing of gaseous oxygen? Down at the LOX manifold (which is ~3m wide or ~9m wide if you include all the piping attached to it), how does engine vibration affect the piping and propellant - are there resonant frequencies being achieved in the piping that cause propellant cavitation?

They would likely get some useful insight into their issues with a sub-scale, not-100%-representative test vehicle, but I just don't see it being worth the cost when it might not even be capable of revealing critical issues that occur at full scale.

jeffb

ACCESS: Top Secret

- Joined

- 7 October 2012

- Messages

- 1,269

- Reaction score

- 1,894

You mean like the kind that takes a decade to build a "new" rocket out of existing parts and not fly? That kind of "sane" engineering?They are churning them out just to be blown up like heretics thrown in the pyre during the Middle Ages...

Did they lost faith in sane engineering?

I don't know what the hell the SLS team's excuse is but it better be a doozy given the way that SpaceX is advancing in leaps and bounds. Very difficult not to be cynical.

- Joined

- 13 August 2007

- Messages

- 8,394

- Reaction score

- 10,811

There is point hereLike what I'm talking about is - when Starship starts using its header tanks, and you have LOX flowing through 50m of piping from the nose of the vehicle, all the way down to the LOX manifold and engines, how far down the piping does helium or gaseous oxygen get? How does the heat transfer through the 50m of piping affect recondensing of gaseous oxygen? Down at the LOX manifold (which is ~3m wide or ~9m wide if you include all the piping attached to it), how does engine vibration affect the piping and propellant - are there resonant frequencies being achieved in the piping that cause propellant cavitation?

in 50 meter long feedline from LOX header tank to Engine

it run true empty LOX and CH4 tank and on Picture inside tank, there is no Isolation on it !

it's quite possible that LOX start boil up on way to engine and

Then Turbopump get mixture of Gas and Liquid during startup, what is not good

Either the preburner or combustion chamber do not ignite or fail work continuous

Dragon029

ACCESS: Top Secret

- Joined

- 17 March 2009

- Messages

- 881

- Reaction score

- 440

It's my understanding that the LOX header feed line is already full of LOX (and probably some O2 gas) at take-off, as this feed line is also used to fill up the header tank prior to launch. Even if I'm wrong and that feed line gets drained during ascent, we do know that the LOX header tank does get opened up during the descent, which would allow for some time for gases to settle. Even if things do happen to be relatively calm during descent however, once the engines start up and the vehicle begins to flip, things get a lot more chaotic in the pipes.There is point here

in 50 meter long feedline from LOX header tank to Engine

it run true empty LOX and CH4 tank and on Picture inside tank, there is no Isolation on it !

it's quite possible that LOX start boil up on way to engine and

Then Turbopump get mixture of Gas and Liquid during startup, what is not good

Either the preburner or combustion chamber do not ignite or fail work continuous

With SN10 they had helium pressurant get into the propellant during the flip manoeuvre (maybe the CH4 plumbing, maybe the LOX plumbing, maybe both; they didn't say) and reach the engines, reducing engine performance and causing SN10 to have a hard but survivable (at least until 8 minutes later) landing.

With SN8 they were using autogenous pressurisation (CH4 propellant being heated by the engine and piped back into the CH4 tank, and vice-versa with O2 for the LOX tank), but because of sloshing they were having ullage collapse where the gaseous propellant was being cooled and losing pressure (some small amount would even probably have been condensed back into liquid).

SN15 (which is expected to be transported to the launch pad this Friday) will have a lot of changes (hundreds according to Elon), including a redesign of some of the plumbing - there is a chance that it won't fix the issue, but they seem happy about the improvements made on SN15, so we'll just have to wait and see. I do hope though that all these changes don't come with (critical) new bugs.

- Joined

- 3 June 2011

- Messages

- 18,307

- Reaction score

- 12,088

It wasn't dubbed the Senate Launch System for nothing. (Also, spends lots of money doing nothing.)You mean like the kind that takes a decade to build a "new" rocket out of existing parts and not fly? That kind of "sane" engineering?They are churning them out just to be blown up like heretics thrown in the pyre during the Middle Ages...

Did they lost faith in sane engineering?

I don't know what the hell the SLS team's excuse is but it better be a doozy given the way that SpaceX is advancing in leaps and bounds. Very difficult not to be cynical.

- Joined

- 3 June 2011

- Messages

- 18,307

- Reaction score

- 12,088

Musk is blofeld ????

So long he not become like Hugo Drax...

View: https://www.youtube.com/watch?v=xQz3-4nPwvE

It's been said Elon is one Persian cat away from being a supervillain.

- Joined

- 9 October 2009

- Messages

- 21,909

- Reaction score

- 13,479

It's been said Elon is one Persian cat away from being a supervillain.

Keep him away from the orbital death rays!

jeffb

ACCESS: Top Secret

- Joined

- 7 October 2012

- Messages

- 1,269

- Reaction score

- 1,894

- Joined

- 9 October 2009

- Messages

- 21,909

- Reaction score

- 13,479

Aieeeeee!

- Joined

- 9 October 2009

- Messages

- 21,909

- Reaction score

- 13,479

- Joined

- 13 August 2007

- Messages

- 8,394

- Reaction score

- 10,811

perfect view from 79 landing of a booster, that flew 7 times

View: https://twitter.com/Erdayastronaut/status/1379838388778450947

View: https://twitter.com/Erdayastronaut/status/1379838388778450947

Last edited:

They still produce them. They need to make a new second stage for every launch, and the production line for the MVacs is the same as the normal Merlins and the line for the second stages is the same as the first stages.Do they still produce Falcon 9 or do they intend to operate indefinitely with the existing stock?

I do believe that the production rate is slower now than it was before, as some of the workforce was reassigned to make SS-related parts. This was a problem when they had two recovery failures close to each other last year, suddenly they didn't have enough first stages to fly all the missions they wanted to when they wanted to. I believe they have more of a buffer now.

I think they have over a dozen used boosters in inventory, but I assume there are rare clients who still want new builds and there are some missions where the booster gets sacrificed. Also I think the core of the heavy has never been successfully landed to date. But I can't remember the last launch that was a first use. Probably just slipped my notice.

- Joined

- 9 October 2009

- Messages

- 21,909

- Reaction score

- 13,479

@TomcatViP It's not a waste of capital if they acquire the data and prove/improve the production system. This recent article from Teslarati puts it into perspective@Moose :

I might get frustrated watching such waste of capital but I would think that logic would dictate to go back to small scale demonstrator: If the belly flop pause problem with the fuel, pump and engines, there is nothing that would be done at a smaller scale that wouldn't represent what is happening for real.

Similitudes and flows mechanics (the art of scaling down a process that would still be representative) is not sciences fictions. It has been bread and butter for aerospace since the Wright Brothers and even the Naca.

It won't prevent them to run in parallel their test for re-entry and still opening their flight domain (having an explosion diminish in effect the span of knowledge gained per flight).

My 2 cents only.

https://www.teslarati.com/spacex-starship-launch-pad-custom-storage-tanks/

If the Raptors are in fact less than a million a pop and headed to $250,000 and the whole SS is less than $5 M, then so long as the desired objectives are met all is good. A successful landing/reuse is bonus, until that becomes the objective. If the article is to believed then $20-25 M isn't a bad spend. Heck, I've spent millions of tax payer money testing new software dropping J-series weapons... The crew dogs in the sandbox appreciated the new capabilities.

- Joined

- 2 January 2006

- Messages

- 3,806

- Reaction score

- 4,957

SN15 is out of the highbay ready to roll.

View: https://twitter.com/BocaChicaGal/status/1380172626870603780

- Joined

- 16 April 2008

- Messages

- 9,559

- Reaction score

- 14,342

With apologies to Steppenwolf:

Get your motor runnin'

Roll out of the high bay

Lookin' for adventure

And whatever comes our way

Yeah Darlin' go make it happen

Take the world in a love embrace

Fire all of your guns at once

And explode into space

- Joined

- 21 January 2015

- Messages

- 12,074

- Reaction score

- 16,133

View: https://twitter.com/ianpineapple/status/1380197565115858949

Based on this pic from Mary and another posted on the NSF Forums, looks like SN15 has 829 ties installed on its belly! By far the most we've ever seen. SN11 only had 384, and SN10 had 246.

Similar threads

-

-

-

-

McDonnell Douglas X-33 SSTO Reusable Launch Vehicle

- Started by athpilot

- Replies: 0

-

Breitbart, other conservative outlets escalate anti-SpaceX campaign

- Started by Flyaway

- Replies: 5