You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sikorsky S-97 Raider

- Thread starter Triton

- Start date

"Sikorsky S-97 Raider to fly this year"

Marina Malenic, Washington, DC - IHS Jane's Defence Weekly

02 October 2014

Source:

http://www.janes.com/article/44031/sikorsky-s-97-raider-to-fly-this-year

Marina Malenic, Washington, DC - IHS Jane's Defence Weekly

02 October 2014

Source:

http://www.janes.com/article/44031/sikorsky-s-97-raider-to-fly-this-year

Key Points

* Sikorsky has unveiled its coaxial rotor S-97 helicopter and will begin test flights this year.

* The company plans to initially offer the S-97 to the US Army as a replacement for the Bell OH-58D Kiowa Warrior and for special operations missions.

Sikorsky Aircraft unveiled the first of two S-97 Raider helicopter prototypes on 2 October at its facility in West Palm Beach, Florida. Test flights will begin this year, company officials said.

"Sikorsky will begin ground testing shortly and is on track for first flight this year," Steve Engebretson, Sikorsky's advanced military programmes director told IHS Jane's . "The entire flight programme will take about a year to complete."

Engebretson added that flight demonstrations will begin "after the test flight programme is complete, probably in the first quarter of 2016".

Based on Sikorsky's rigid X2 coaxial rotor design, the S-97 was designed to function as both an armed aerial scout and light assault aircraft.

The coaxial counter-rotating main rotors and pusher propeller provide cruise speeds up to 220 kt (253 mph), more than double the speed of conventional helicopters, according to Sikorsky. The aircraft is powered by a General Electric YT706 engine, a variant of the CT7.

The company plans to offer the Raider as a replacement for the US Army's Bell OH-58D Kiowa Warrior armed scout, as well as for special operations missions.

The development effort is privately funded. Sikorsky provides 75% of the investment, and its 53 principal suppliers provide the remainder, according to the company.

"Just four years ago, we announced plans to build the S-97 Raider and teamed with some of the best companies in the industry, understanding the need to ensure aircraft development would not falter as government defence budgets shrank in response to economic pressures," said Sikorsky president Mick Maurer.

Sikorsky started final assembly of the prototype in September 2013. Earlier this year, company officials said they planned to spend approximately USD200 million on the development.

Sikorsky first tested the coaxial design in 2010 on the X2 demonstrator, at which time the helicopter demonstrated a 250 kt flight speed, which is about twice that of conventional helicopters. The X2 also provided an opportunity to develop low acoustic signature technology, according to Sikorsky. Company officials have said that the Raider prototype will improve on the X2, demonstrating a capacity to conduct precision manoeuvres at low speed, as well as high- g turning manoeuvres at more than 200 kt and engage in hot-day hover performance at altitudes of up to 10,000 ft.

The S-97 offers a variety of technologies drawn from the company's X2 technology demonstrator. Its composite fuselage was developed by Aurora Flight Sciences and consists of an integrated cockpit, cabin, and tail cone. The prototype also features counter-rotating main rotor blades for lift and forward flight, and a pusher propeller for high-speed acceleration and deceleration.

Sikorsky is also using the X2 technology, along with partner Boeing, as a basis from which to develop a high-speed rotorcraft for the US Army's Joint Multi-Role Technology Demonstrator (JMR TD) programme. The JMR TD is the precursor to the army's estimated USD100 billion Future Vertical Lift (FVL) programme, which is meant to replace the army's UH-60 Black Hawk utility helicopters and AH-64 Apache attack helicopters.

F-14D said:it didn't take long...

http://www.youtube.com/watch?v=6iWlLJm3v9s

YOUTUBE VIDEO REPLACEMENT -- Original Video Deleted by Sikorsky

S-97 RAIDER "Rollout Event Highlights" HD

Published on Oct 4, 2014

Sikorsky unveiled the next generation of military rotorcraft, with capabilities and performance never seen before in our industry,” said Sikorsky President Mick Maurer. “Just four years ago, we announced plans to build the S-97 RAIDER and teamed with some of the best companies in the industry, understanding the need to ensure aircraft development would not falter as government defense budgets shrank in response to economic pressures. Sikorsky is proud of its leadership in this area, and of the leadership the S-97 RAIDER represents among the world’s military rotorcraft.”

Based on Sikorsky’s rigid X2™ rotor coaxial design, the S-97 RAIDER helicopter features next-generation technologies in a multi-mission configuration (armed aerial scout or light assault), capable of carrying six troops and external weapons. The coaxial counter-rotating main rotors and pusher propeller provide cruise speeds up to 220 knots (253 mph), more than double the speed of conventional helicopters. Sikorsky will offer the RAIDER™ aircraft as a replacement for the U.S. Army’s OH-58D Kiowa Warrior helicopter fleet based on the Army’s future operational and financial priorities, and for the special operations platform.

“Military rotorcraft fleets need maximum performance and increased capabilities to achieve their objectives,” Maurer added. “The RAIDER delivers on that with its greatly improved maneuverability and speed, significantly improved high/hot hover performance, and greater range and endurance.”

https://youtu.be/J92WoFdHJEM

YOUTUBE VIDEO REPLACEMENT -- Original Video Deleted by Sikorsky

The Sikorsky S-97 RAIDER Unveiled HD

Published on Oct 2, 2014

From the rollout ceremony at our West Palm Beach, Florida facility. The moment the next big thing in Army aviation is introduced. The Sikorsky S-97 RAIDER

https://youtu.be/0UMKHMtHkMU

"Sikorsky rolls-out high-speed Raider rotorcraft"

By: Dan Parsons

Miami

Flightglobal.com

17:07 2 Oct 2014

Source:

http://www.flightglobal.com/news/articles/sikorsky-rolls-out-high-speed-raider-rotorcraft-404407/

By: Dan Parsons

Miami

Flightglobal.com

17:07 2 Oct 2014

Source:

http://www.flightglobal.com/news/articles/sikorsky-rolls-out-high-speed-raider-rotorcraft-404407/

Sikorsky has completed the prototype for a revolutionary rotorcraft design that could dramatically improve the speed and hover capabilities of the traditional helicopter.

After four years of internal research and development, the company on 2 October revealed the S-97 Raider, which combines dual coaxial rotor blades and a tail propeller to combine the hover capability of a helicopter with the speed of a fixed-wing aircraft.

“The rollout of a new helicopter is rare," says Sikorsky vice-president of technology and innovation research and engineering Chris Van Buiten, speaking at the company's West Palm Beach site in Florida. "The rollout of a new configuration is rarer still."

Raider has dual coaxial rotors for vertical lift and a tail propeller for forward thrust. The combination allows for flight characteristics that are physically impossible for existing rotorcraft designs.

It was designed to carry more than 4,990kg (11,000lb), or six troops plus crew. With external weapons mounted, Sikorsky says it will fly at least 220kt (407km/h). Unarmed it will fly at up to perhaps 270kt, but S-97 chief engineer Andy Bernhard will not specify how fast they intend to fly it during testing.

Raider was announced, designed and built in four years based on the company's experiences with the X2 concept demonstrator. Raider brings that aircraft's technology into a practical aircraft that can demonstrate real-world mission capabilities, says Bernhard.

Sikorsky invested $150 million for the development effort – around 70% of the total cost to produce the prototype S-92. Its 54 suppliers provided the remaining capital.

"With X2 everyone was wondering what it was, what it was supposed to do," Bernhard says. "With Raider, potential customers see it and they're talking about the size of the doors and things like that. They are already thinking up new mission sets. They get it."

Van Buiten says the aircraft can achieve 50-100% improvements in six flight characteristic measurements including speed, agility and manoeuvrability.

For one, it will be able to refuel at 200kt: much faster than current helicopters that require aerial tankers to reduce altitude and slow dramatically to transfer fuel.

Raider was initially pitched as a candidate for the US Army's armed aerial scout (AAS) programme to find a replacement for ageing Bell Helicopter OH-58D, which cruises at around 90kt.

AAS has been put on hold for fiscal reasons, but Sikorsky believes Raider could satisfy requirements like future vertical lift (FVL); the army's unofficial plan to replace all of its rotorcraft, beginning with the Sikorsky UH-60 Black Hawk.

"While armed aerial scout may be on hold for now, our commitment to the US Army is not," says Mick Maurer, president of Sikorsky. The Raider positions the company well to pursue FVL, "which is shaping up to be a winner-take-all programme," he says.

As congratulatory as Sikorsky executives were at the rollout ceremony, challenges remain for Raider, which has not yet flown. The company hopes to complete ground runs in time for first flight by the end of the year.

The aircraft's software and avionics suite have been finalised and are in verification testing. Bird-strike testing at 229kt has also been successfully completed.

A transmission testbed with rotors, engine and rotorshaft has been built. It needs only a second gearbox before testing can begin on the drive system, says Mark Hammond, Raider programme manager.

"It's kind of a drag race between the testbed and the aircraft," he says. "We finished the aircraft first because it has a much longer lead times, but they'll both get going about the same time."

Raider is in component testing in anticipation of ground testing that must be completed before first flight.

Attachments

- Joined

- 3 October 2007

- Messages

- 1,960

- Reaction score

- 1,192

Triton said:S-97 Raider rollout event highlights video:

Interesting how the animation at the beginning depicts the S-97 in the configuration it had through at least the end of 2012 and not the current one ( 4 bladed rotor, tailwheel gear configuration, revised nose, etc.). Maybe they just didn't want to spend the money to update the old animation, or maybe they just thought no one would be nerdy enough to notice. ;D

yasotay said:Actually they had an extensive new video (from which the air refuel picture comes from). I suppose it will be released soon enough.

Looking forward to seeing that! Gorgeous machine!

- Joined

- 26 May 2011

- Messages

- 2,318

- Reaction score

- 3,471

'There are rollouts and there are rollouts. A rollout does not mean an aircraft is completed and ready for flight, in fact in most cases it isn't. Sort of like a ship isn't actually ready for sea when it is launched.'

I always shout at the telly when some business character or politician 'rolls' something out. I assume it's half-finished, lacks thrust and the lights don't work. Same when the term 'step up to the plate' is used in the UK. 90% of the audience haven't a clue what it means and probably think it refers to a banquet.

Chris

I always shout at the telly when some business character or politician 'rolls' something out. I assume it's half-finished, lacks thrust and the lights don't work. Same when the term 'step up to the plate' is used in the UK. 90% of the audience haven't a clue what it means and probably think it refers to a banquet.

Chris

- Joined

- 16 April 2008

- Messages

- 9,574

- Reaction score

- 14,381

malipa said:I'm actually quite interested why they covered the top beam of the landing gear... Boeing 787 problems? Radical design? 3D printed? (just random thoughts)

Could the cloth cover actually be functional, perhaps to keep debris out of the retraction mechanism?

marauder2048

"I should really just relax"

- Joined

- 19 November 2013

- Messages

- 3,157

- Reaction score

- 926

malipa said:I'm actually quite interested why they covered the top beam of the landing gear... Boeing 787 problems? Radical design? 3D printed? (just random thoughts)

Another thought: Airbus Helicopter sued Bell because the landing gear on the 429 prototypes was derived/inspired/slavishly copied from that of the EC120.

- Joined

- 18 October 2006

- Messages

- 4,203

- Reaction score

- 4,880

A fair point. The Sikorsky folks are still saying they plan to get the aircraft into the air by the end of the year. They joke that it might be one of the shortest flights on records, but they would really like to do so. My sensing is that they are really working to keep their enthusiasm in check. While the "suits" remained poker-faced at the affair, the people who have worked on the helicopter were genuinely excited at having done something different.CJGibson said:'There are rollouts and there are rollouts. A rollout does not mean an aircraft is completed and ready for flight, in fact in most cases it isn't. Sort of like a ship isn't actually ready for sea when it is launched.'

I always shout at the telly when some business character or politician 'rolls' something out. I assume it's half-finished, lacks thrust and the lights don't work. Same when the term 'step up to the plate' is used in the UK. 90% of the audience haven't a clue what it means and probably think it refers to a banquet.

Chris

yasotay said:A fair point. The Sikorsky folks are still saying they plan to get the aircraft into the air by the end of the year. They joke that it might be one of the shortest flights on records, but they would really like to do so. My sensing is that they are really working to keep their enthusiasm in check. While the "suits" remained poker-faced at the affair, the people who have worked on the helicopter were genuinely excited at having done something different.

I guess the real question is whether the Army was poker-faced at the affair. If it weren't for sequestration, would the Army have already placed orders for the S-97 Raider with Sikorsky? The other question is will sequestration continue with the next administration considering Cold War 2.0 and increased tensions with the PRC?

- Joined

- 3 June 2011

- Messages

- 18,296

- Reaction score

- 12,109

Triton said:The other question is will sequestration continue with the next administration considering Cold War 2.0 and increased tensions with the PRC?

Probably depends on if there is an "R" or a "D" next to their name.

jsport

what do you know about surfing Major? you're from-

- Joined

- 27 July 2011

- Messages

- 7,711

- Reaction score

- 5,712

A staid bureaucracy able to spend $150m on what currently would be strictly defined as an “all risk” prototype is further proof there is no hope for competitive innovation in the US. As the USG remains unwilling/able to match innovation funding to any entity which presents any alternative.

- Joined

- 3 June 2011

- Messages

- 18,296

- Reaction score

- 12,109

jsport said:A staid bureaucracy able to spend $150m on what currently would be strictly defined as an “all risk” prototype is further proof there is no hope for competitive innovation in the US. As the USG remains unwilling/able to match innovation funding to any entity which presents any alternative.

What? ???

Hunh? The two Sikorsky S-97 Raider prototypes are entirely on the nickel of Sikorsky and its suppliers. I don't quite understand what risk the United States Army, or some other entity of the United States government, is assuming. Sikorsky and its suppliers have entirely assumed the risk of the S-97 Raider and it's their responsibility to demonstrate that it works as advertised. The United States government is under no obligation to buy or fund the program. The S-97 Raider isn't JMR/FVL. If the Army wants increased speed, range, and maneuverability in its rotorcraft fleet the service needs to look beyond conventional helicopters.

- Joined

- 18 October 2006

- Messages

- 4,203

- Reaction score

- 4,880

Doubt it. However like his father before him he does go back to the old country with some regularity.Triton said:Is Sergei Sikorsky a celebrity in the Russian Federation?

Source:

http://nsk.kp.ru/photo/58584/1054675/

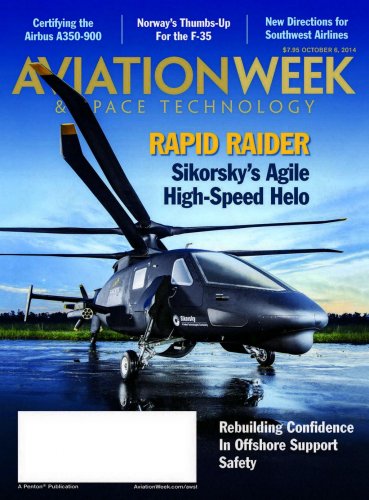

Sikorsky Talks To Customers About Potential Raider Applications

Rollout of the S-97 Raider is a second step in Sikorsky’s bid to reshape the helicopter

by Graham Warwick

Oct 6, 2014

Source:

http://aviationweek.com/defense/sikorsky-talks-customers-about-potential-raider-applications

Rollout of the S-97 Raider is a second step in Sikorsky’s bid to reshape the helicopter

by Graham Warwick

Oct 6, 2014

Source:

http://aviationweek.com/defense/sikorsky-talks-customers-about-potential-raider-applications

Sikorsky defined the modern helicopter when the VS-300, with single main and tail rotors, made its first flight in 1939. Now the manufacturer wants to redefine rotorcraft with a configuration that offers higher speed, maneuverability and hover performance, but retains the helicopter’s defining low-speed agility while enabling unique flight characteristics.

Rolled out at Sikorsky’s development test center in West Palm Beach, Florida, on Oct. 2, the S-97 Raider is the second example of the new configuration and a third is on the way. First was the X2 technology demonstrator, which exceeded 260 kt. in 2010. The third, the Sikorsky/Boeing SB.1 Defiant, is to fly in 2017 under the U.S. Army’s Joint Multi-Role (JMR) technology demonstration.

While potentially a product in its own right, the Raider constitutes a crucial step in proving that Sikorsky’s rigid coaxial-rotor compound helicopter configuration can be scaled from the 6,000-lb.-gross-weight X2 to a 30,000-lb.-class Future Vertical Lift Medium utility rotorcraft that could replace thousands of Sikorsky UH-60 Black Hawks beginning around 2035.

The industry-funded Raider program also provides an opportunity for Sikorsky to hone the rapid-prototyping processes pioneered on the company-funded X2 and now being applied to the JMR demonstrator, the cost of which is being shared by industry and the Army.

“The philosophy behind the X2 technology demonstrator is carried over: a rapid prototyping culture with a small team brokering the best in industry and innovating at the system level to create an innovative assemblage of things we know and understand that has really good traceability [to production],” says Mark Miller, vice president of research and engineering.

Sikorsky emphasizes the X2 was developed not by invention, but intelligent integration of available technologies. The company first flew the rigid coaxial-rotor compound configuration in the 1970s with the XH-59A experimental helicopter. This was fast, exceeding 260 kt., but noisy, shaky, thirsty, complex and hard to fly, requiring two pilots to manage four engines.

The X2 demonstrator applied advances in fly-by-wire flight control, rotor-hub drag reduction, integrated auxiliary propulsion, active vibration control and lightweight, stiff composite blades and structures, to overcome the drawbacks and unlock the benefits of the configuration. The result was a single-pilot, single-engine aircraft with similar vibration levels to a Black Hawk while flying twice as fast.

The X2 was a $50 million internally funded effort that took 43 months to first flight and achieved the 250-kt. level-flight speed goal in 17 test flights. From launch of the Raider in July 2010 to a first flight in December will be 49 months, and the two-prototype program is expected to cost Sikorsky and its suppliers around $200 million. The first aircraft will be used for envelope expansion and the second for customer demonstrations.

Powered by a single 2,600-shp-class General Electric YT706, the 11,500-lb.-gross-weight Raider has 34-ft.-dia. hingeless rotors each with four blades. Coaxial rotors eliminate the need for an anti-torque tailrotor. Instead, the engine also drives a 7-ft.-dia. variable-pitch propeller on the tail that provides thrust for high speed, but can be disengaged via a clutch at low speed or in hover to increase safety and reduce noise.

The Raider is designed to exceed 220 kt. in cruise, but the propulsor will also enable new modes of flight, including level-attitude acceleration and deceleration and nose-pointing for weapons employment. The Raider test program is expected to explore the utility of these new characteristics.

Key to Raider’s rapid development has been a virtual design environment in which “we build before we build, and fly before we fly,” says Miller. “We have a full system-integration laboratory, with every piece of hardware and software—sensors, generators, hydraulics—in the lab so we can shake it all out before we fly,” explains Chris Van Buiten, vice president of technology and innovation. “We started to fly on the ground a year ago, so we could find problems well in advance.”

High-fidelity modeling and simulation tools play a key role. “Our purpose here is moving risk to the left, taking time up front to eliminate or minimize discoveries that would disrupt the program,” notes Miller. “We have had basically zero discovery in assembly.” Thanks to kinematic modeling, for example, the retractable main landing gear was installed in days, not weeks, and worked first time, he adds.

“Rapid prototyping does not mean cutting things out,” says Miller. “When you push fundamental discovery into flight test, you risk the aircraft being down for months. The X2 expanded the envelope very efficiently, in 17 flights. Flying is expensive and we want to be pushing the envelope, not learning how the aircraft works,” he says. “Sure, we will have discoveries in ground test and flight test, but we won’t stumble on something we stumbled on a year ago,” adds Van Buiten.

The company also relies heavily on its 53 supplier partners. “They provide 90% of the aircraft and Sikorsky does the integration and interface control documentation. This has allowed us to go fast with a high-quality culture,” explains Van Buiten. “We have suppliers from large to small, all with different degrees of go-fast, and they are delivering parts in a time-frame they are not used to. It is exciting to watch.”

“The industry is on the road to doing business with highly sourced, high-technology content,” asserts Miller. “While we have a very extensive sup-plier network, we have strong system-level modeling tools and interface controls—the virtual design environment needs those,” he says, noting the Raider suppliers all simultaneously work with the same design model, with no latency.

The first Raider is ready to go into ground test, says Van Buiten. “All the parts are in flow for the second aircraft, and the fuselage is done. We will have a bit of time in flight on No. 1 before we assemble No. 2 so we can incorporate any changes.” A four-phase flight-test program is planned for No. 1, beginning with hover and low-speed testing, then expansion of the speed and maneuver envelope, and “pulling Gs at speed and unconventional low-speed maneuvers” with the propulsor.

“We will pick up where the X2 left off,” says Miller. “We’ve been doing a lot of operational analysis and putting together vignettes to show how the unique flight characteristics of the aircraft can be used to fundamentally do things differently.” Helicopter, fixed-wing and tiltrotor pilots have all flown the Raider simulator and provided feedback incorporated into the vignettes. “We plan to do some very unique demonstrations to show what it can do.”

The industry-funded Raider prototypes are representative of the aircraft Sikorsky has offered to meet the U.S. Army’s Armed Aerial Scout (AAS) requirement, which is now in limbo because of budget pressures. “It is not a production aircraft, but is much more productized,” says Miller. The prototypes are not built to military specifications, but Sikorsky is maintaining traceability to a parallel, fully productionized and military-qualified, objective aircraft design.

“Anywhere there is a difference [between the designs] we have traceability to a detailed analysis of what that item will cost [in production],” explains Miller. “We fully understand the production aircraft. There are no leaps of faith.” This process is behind Sikorsky’s confidence in its highly public declaration last year that a production Raider would have a $15 million flyaway cost—25% more than an off-the-shelf helicopter—based on building 428 aircraft to replace the Army’s Bell OH-58D Kiowa Warriors.

Although AAS is on hold, Sikorsky is discussing with potential customers what they want to see demonstrated. “We have the opportunity to do some unique missionization of Aircraft 2, and bring in other technologies in collaboration with industry and customers,” says Miller. “We are sitting down with potential customers discussing how the aircraft might be uniquely configured.”

As Sikorsky prepares to fly the Raider, it already is feeding lessons learned to the JMR program with Boeing. “It is not complete transference, but we will get a running start on JMR,” notes Miller. The virtual design environment is “robust and transferable, and we took great pains to document the rapid prototyping process so we can continue to do programs very fast,” adds Doug Shidler, director of the JMR technology demonstrator program. “What we were able to do on Raider we are seeing on JMR.”

Attachments

Published on Oct 9, 2014

Sikorsky S-97™ RAIDER™ Helicopter

Game-changing X2™ technology for future tactical missions.

Imagine a next-generation multi-mission helicopter platform so advanced that it can reach speeds of more than 220 knots, operating at 10,000 feet in 95° F of heat. The Sikorsky S-97 RAIDER™ helicopter is poised to realize this vision and revolutionize next-generation military aviation.

The S-97 RAIDER aircraft’s capabilities will meet both conventional U.S. Army and Special Operations future requirements in a variety of combat roles. Additionally, potential applications for US Air Force, US Navy, and US Marine Corp services are being explored. Sikorsky Aircraft has invested in X2™ technology to illustrate its commitment to developing future capabilities that are achievable and affordable. X2 technology is scalable to a variety of military missions including light assault, light attack, armed reconnaissance, close-air support, combat search and rescue, and unmanned applications.

http://youtu.be/cucSg6dd9a0

Sikorsky S-97™ RAIDER™ Helicopter

Game-changing X2™ technology for future tactical missions.

Imagine a next-generation multi-mission helicopter platform so advanced that it can reach speeds of more than 220 knots, operating at 10,000 feet in 95° F of heat. The Sikorsky S-97 RAIDER™ helicopter is poised to realize this vision and revolutionize next-generation military aviation.

The S-97 RAIDER aircraft’s capabilities will meet both conventional U.S. Army and Special Operations future requirements in a variety of combat roles. Additionally, potential applications for US Air Force, US Navy, and US Marine Corp services are being explored. Sikorsky Aircraft has invested in X2™ technology to illustrate its commitment to developing future capabilities that are achievable and affordable. X2 technology is scalable to a variety of military missions including light assault, light attack, armed reconnaissance, close-air support, combat search and rescue, and unmanned applications.

http://youtu.be/cucSg6dd9a0

yasotay said:hmmm.... 3:34 door seems different from the one on the stage.

Will the production rotorcraft resemble the video or the prototype? :-\

- Joined

- 16 April 2008

- Messages

- 9,574

- Reaction score

- 14,381

Triton said:yasotay said:hmmm.... 3:34 door seems different from the one on the stage.

Will the production rotorcraft resemble the video or the prototype? :-\

Neither. I'd expect changes from any current design before it gets to production (assuming it makes it at all).

- Joined

- 4 July 2010

- Messages

- 2,509

- Reaction score

- 3,075

As the AvWeek article points out, these are civspec tech demonstrators not milspec preproduction prototypes. So yes, expect plenty of changes between now and an armed scout son-of-Raider entering production.

- Joined

- 18 October 2006

- Messages

- 4,203

- Reaction score

- 4,880

Moose said:As the AvWeek article points out, these are civspec tech demonstrators not milspec preproduction prototypes. So yes, expect plenty of changes between now and an armed scout son-of-Raider entering production.

Sikorsky made it clear at the roll out that the Raider is not a production aircraft. They do want to sell lots of them so there will likely be a number of changes for the production version.

Aeroengineer1

Engineering, not just a job, but a lifestyle :)

- Joined

- 27 January 2008

- Messages

- 122

- Reaction score

- 102

At a minimum there will be some modifications needed to remove accommodations that have been made for instrumentation.

Another screenshot from the Sikorsky promotional video for the S-97 Raider.

Source:

http://www.army-technology.com/features/featurelatest-in-defence-digital-training-ranges-sikorsky-s-97-raider-royal-navy-offshore-patrol-vessels-4412902/featurelatest-in-defence-digital-training-ranges-sikorsky-s-97-raider-royal-navy-offshore-patrol-vessels-4412902-2.html

Source:

http://www.army-technology.com/features/featurelatest-in-defence-digital-training-ranges-sikorsky-s-97-raider-royal-navy-offshore-patrol-vessels-4412902/featurelatest-in-defence-digital-training-ranges-sikorsky-s-97-raider-royal-navy-offshore-patrol-vessels-4412902-2.html

Attachments

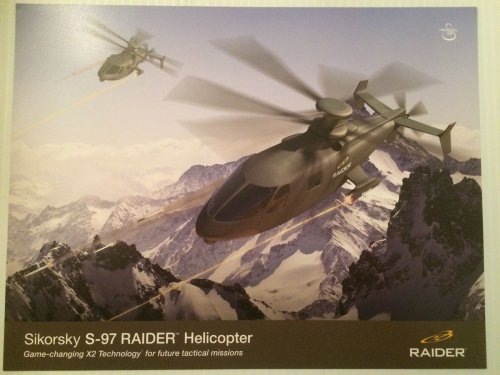

Sikorsky S-97 one-sheet flier

Sikorsky S-97 one-sheet flier found on eBay.

Source:

http://www.ebay.com/itm/Sikorsky-S-97-Raider-Helicopter-Poster-Military-Rare-X-2-Technology-/161477574605?pt=Art_Posters&hash=item2598d03fcd

Rather generous calling an 8.5" by 11" four-color one-sheet flier a poster. As you guys can probably tell, I love all things Raider and X2! Incredible machine.

Sikorsky S-97 one-sheet flier found on eBay.

Source:

http://www.ebay.com/itm/Sikorsky-S-97-Raider-Helicopter-Poster-Military-Rare-X-2-Technology-/161477574605?pt=Art_Posters&hash=item2598d03fcd

Rather generous calling an 8.5" by 11" four-color one-sheet flier a poster. As you guys can probably tell, I love all things Raider and X2! Incredible machine.

Attachments

yasotay said:Found on Twitter. Frankly I am surprised I beat Triton to this

Thank you for posting, my friend. Greatly appreciated.

Sikorsky S-97 poster

It's back...

Source:

http://www.ebay.com/itm/SIKORSKY-S-97-RAIDER-HELICOPTER-POSTER-25-X-19-H-ARMY-COPTER-INV-/400814656796?pt=Art_Posters&hash=item5d526a4d1c

It's back...

Source:

http://www.ebay.com/itm/SIKORSKY-S-97-RAIDER-HELICOPTER-POSTER-25-X-19-H-ARMY-COPTER-INV-/400814656796?pt=Art_Posters&hash=item5d526a4d1c

- Joined

- 16 April 2008

- Messages

- 9,574

- Reaction score

- 14,381

Looks like a GAU-19 .50-caliber. The picture isn't very clear; the ammunition feed isn't obvious to me.

BTW: Can you link to the source article? I'm trying to figure out why the filename is so wrong. Raider, not Defiant.

BTW: Can you link to the source article? I'm trying to figure out why the filename is so wrong. Raider, not Defiant.

Similar threads

-

-

-

-

Sikorsky Long-Range Hybrid-Electric VTOL Demonstrator (HEX)

- Started by VTOLicious

- Replies: 5

-