- Joined

- 28 January 2008

- Messages

- 1,015

- Reaction score

- 2,196

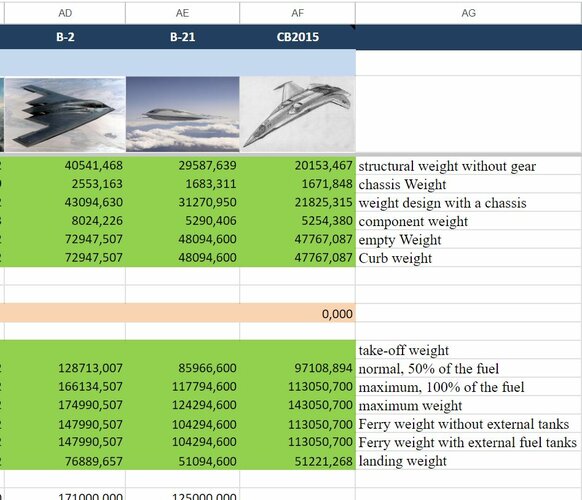

B-21 is following the B-2 path, production tooling, six FSD aircraft but with an accelerated LRIP phase. Should see the second 21 first flight soon. B-21 moving somewhat quicker due to the B-21 being more than likely a "180" derivative, safe guess.