kqcke for you

PUMA PUMA PUMA

- Joined

- 3 November 2022

- Messages

- 1,161

- Reaction score

- 1,499

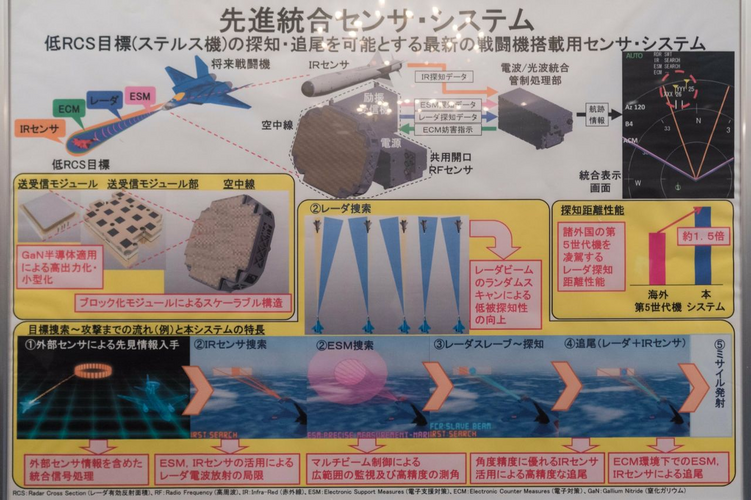

Well active flow control is already for a good time in development

that will likely lead to a massive advancement of it in AA capability and miniarturization of electronics

Not likely as France has a large share in MBDA blocked it.missile development for MBDA if the company collaborates with Mitsubishi HI

For the radar, I remember Japan working on a 3D nose mounted radar. Is that sidelined?

on wing edge to can fried electronics with short range also increase SARS so intelligence map and location, better picture area plus radar aware and scan and fire control around aircraft or drone or ground

target or missiles, ship evens submarine etc

Counter stealth on the way is exactly why stealth needs to advance as well.You don't need to be more LO than an F-22, and in any case, counter stealth capabilities are well on the way. Tailfins seem like a good compromise between full tail surfaces and no tail surfaces.

Or perhaps adopt a different approach altogether? If low RCS stops being useful because EO/IR technology advances, shaving a few mm further off the RCS is, at best, going to be a case of diminishing returns (no pun intended) and at worst a waste of time.Counter stealth on the way is exactly why stealth needs to advance as well.

Yeah. At the same time this may just be a cost matter too. Why give a "marginal" advantage which in most cases may not be needed for extra cost. But WHO knows.Or perhaps adopt a different approach altogether? If low RCS stops being useful because EO/IR technology advances, shaving a few mm further off the RCS is, at best, going to be a case of diminishing returns (no pun intended) and at worst a waste of time.

Were you able to tell northrop that before they finalized the design of the b-21?Or perhaps adopt a different approach altogether? If low RCS stops being useful because EO/IR technology advances, shaving a few mm further off the RCS is, at best, going to be a case of diminishing returns (no pun intended) and at worst a waste of time.

Not gonna lie, I'm not sure the B21 is significantly stealthier than the B2.Were you able to tell northrop that before they finalized the design of the b-21?

On a serious note, counter stealth advances in a wide spectrums including RCS, thus advancement in stealth need to do the same, again, including RCS.

To make such a bold statement that you don't need any further RCS reduction than the f-22, you gonna need some serious research and data which the US air force and industry partners have extensively done. By the shape of the b-21 it seems further RCS reduction still relevant.

I mean, even using the same techniques and materials, the B21 is physically smaller than a B2, so I'd expect it to have an equally smaller RCS just from that.We probably won't know whether the B-21 will be stealthier than the B-2 because the USAF likes to keep that information to itself for long periods of time, we still do not know just how stealthy the B-2 is even after all those years of service.

I admit it's an assumption, but IIRC the F35 has a larger RCS than the F22, despite being a smaller aircraft. But the F35 has less maintenance intensive RAM coatings.We will probably never know for sure about the newer B-21 RCS reducing materials compared to the B-2s Scott Kenny as that is an area that will be highly classified for years.

There are conflicting statements on that.I admit it's an assumption, but IIRC the F35 has a larger RCS than the F22, despite being a smaller aircraft. But the F35 has less maintenance intensive RAM coatings.

Not all things can be made with radar absorbing structure but the goal is to reduce those. Thats why F-X was to use adhesive molding for bonding materials instead of fasteners.I had thought that the manufacturers of stealth aircraft had moved away from Radar Absorbing Material to a mixture of Radar Absorbing Structure and paint? Since the RAM coatings caused no end of trouble in for the maintenance crews on the F-117 and B-2.

I'm no expert on RCS, but I remember knowledgeable members of this forum stating that RCS is not necessarily connected to physical size.I mean, even using the same techniques and materials, the B21 is physically smaller than a B2, so I'd expect it to have an equally smaller RCS just from that.

still gotta putty over any fasteners used to hold access panels on, and the F35 has an applique "sticker" layer on top of that.I had thought that the manufacturers of stealth aircraft had moved away from Radar Absorbing Material to a mixture of Radar Absorbing Structure and paint? Since the RAM coatings caused no end of trouble in for the maintenance crews on the F-117 and B-2.

Is it? There's always going to be trade offs, good old fasteners allow for ease of maintenance and production.That is crazy still using fasteners for access panels? That does not look good especially for stealth aircraft, I would have thought that the USAF would have used something better than that.

What would you use?That is crazy still using fasteners for access panels? That does not look good especially for stealth aircraft, I would have thought that the USAF would have used something better than that.

I'm not sure he would be likely to be satisfied. As an aside, the poor fellow's bad luck continues.

The Japanese are very, very good at optimizing processes.

駐日米大使「名古屋の改善はテキサスでも」戦闘機F35組み立て視察:朝日新聞

エマニュエル駐日米大使が16日、三菱重工業小牧南工場(愛知県豊山町)を訪れ、米ロッキード・マーチン社の最新鋭ステルス戦闘機F35の最終組み立ての様子を視察した。生産コストが米国内並みに低く抑えられて…www.asahi.com

While not directly GCAP related, it does bode well for when it finally enters production. Right now the assembly cost per airframe at Nagoyas F-35 plant have around the same assembly cost per airframe for the same work at the Texas F-35 plant that does 150 airframes a year. The US also wants to implement the practices done at the Nagoya plant in the US.

If Japan can pull out this efficiency for each F-35 built at such a small scale then hopefully GCAP production will be able to save a lot when it comes to production costs.

Isn't this largely down to lower Japanese labour costs for this sort of assembly?If Japan can pull out this efficiency for each F-35 built at such a small scale then hopefully GCAP production will be able to save a lot when it comes to production costs.

I don't believe so. Cost of living in Japan is high enough that they can't afford to pay peanuts.Isn't this largely down to lower Japanese labour costs for this sort of assembly?

It has been my understanding that with Japan in particular the "cost of labor" gap is much smaller than it used to be.Isn't this largely down to lower Japanese labour costs for this sort of assembly?

I don't believe so. Cost of living in Japan is high enough that they can't afford to pay peanuts.