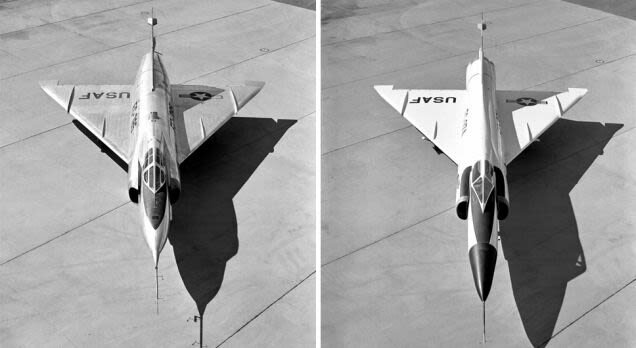

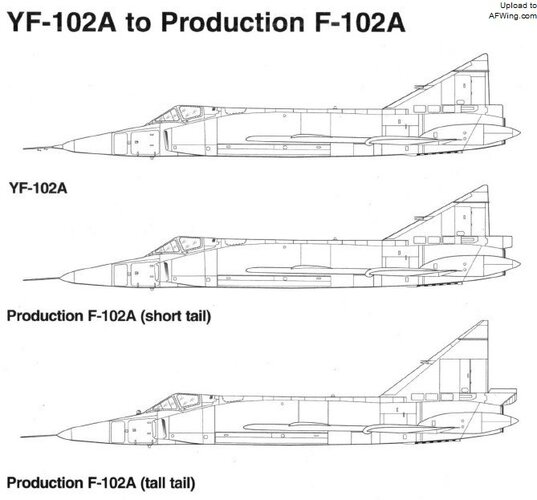

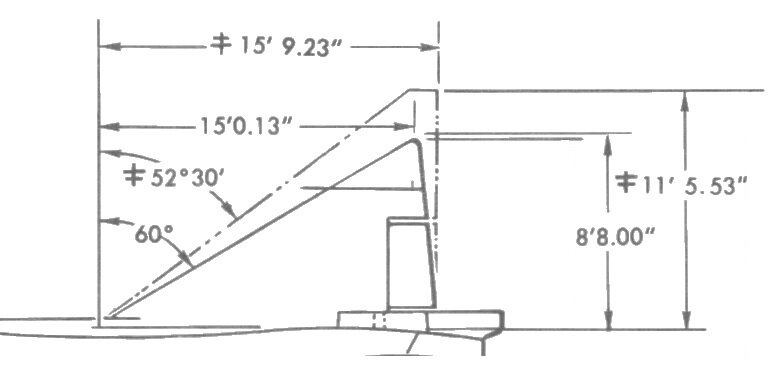

The salvation of the project turned out to be in the "area rule" devised by NACA scientist Richard Whitcomb. According to the area rule, the total cross sectional area along the direction of flight should be a constant in order to achieve minimum transonic drag. In order to achieve this, it was required that the fuselage be narrowed down in the region where the wing roots were attached, then broadened back out again when the wing trailing edge was reached. This gave the aircraft fuselage a characteristic "wasp-waist" or "Coke-bottle" shape. In order to achieve this, the length of the fuselage was increased by 11 feet, and a pair of aerodynamic tail fairings were added aft of the trailing edge, these fairings extending beyond the end of the afterburner tailpipe in a pair of characteristic protrusions. These tail fairings were for purely aerodynamic purposes and had no other function. A new cockpit canopy with a sharper leading edge was fitted, although it had an adverse effect on overall visibility. Cambered leading edges were fitted to the thin delta wings to improve the behavior of the thin airfoil at high angles of attack, and the wingtips were given wash-in.

A J57-P-23 engine was fitted, which was considerably lighter and more powerful than the previous J57-P-11. The J57-P-23 engine was rated at 11,700 lb.s.t. dry and 17,200 lb.s.t. with afterburning. The aircraft was lightened by reducing excess structures no longer required by the lighter engine. The new aircraft was given the designation YF-102A.

Designated Model 8-90, the first of four YF-102As (53-1787/1790) was rolled out at San Diego just 117 days after redesign had started. It was trucked out to Edwards AFB and took off on its maiden flight on December 20, 1954. On the next day, Mach 1 was easily exceeded, fully confirming the predictions of the area rule. It soon reached a top speed of Mach 1.2 in level flight. In addition, the aircraft could still keep on climbing after reaching 51,600 feet.

A milestone was reached on July 8, 1955, when a YF-102A fired six Falcon missiles and 24 unguided rockets in less than 10 seconds.

The retooling required by the changes in the YF-102A played havoc with the Cook-Craigie plan for early production. Fully two-thirds of the 30,000 tools that had been purchased had to be thrown out and new ones acquired. Following the costly re-tooling procedure, full production of the F-102A began at the Convair plant in San Diego. The first production Model 8-10 or F-102A (53-1791) flew on June 24, 1955 and was delivered to the Air Force five days later. It had a J57-P-23 engine.

In the full production F-102A, the wings were moved aft, and fuselage length was increased by more than 16 feet over the original YF-102. The wingspan was increased from 37 feet to 38 feet 1 1/2 inches, the wing area increased from 661 square feet to 695 square feet, and the gross weight increased from 26,404 pounds to 28,150 pounds.