- Joined

- 4 July 2010

- Messages

- 2,402

- Reaction score

- 2,725

The Next Generation Combat Vehicle program has begun to firm up its desires for the Bradley replacement, which it has now dubbed the Optionally Manned Fighting Vehicle. Similarly to MPF, the Army is accelerating this program massively and now wishes to begin fielding it in 2026 rather than in the mid-2030s as it envisioned after GCV was killed. Breaking Defense has a decently comprehensive article giving a rundown of what the Army's looking for and who the likely bidders are. Here's some highlights.

General Dynamics looks like the early favorite to replace the Army’s 1980s-vintage M2 Bradley troop carrier. That’s my personal assessment after talking at length to officers and contractors at last week’s Association of the US Army conference, where months of uncertainty finally gave way to some real clarity about both what the Army wants and what industry can offer.

In brief, GD’s Griffin III demonstrator seems to hit the sweet spot between innovative and proven technologies that the Army wants to start fielding a Next Generation Combat Vehicle (NGCV) as soon as 2026. Of the three vehicles on display at AUSA,

- BAE System’s CV90 Mark IV is the latest upgrade of a 25-year-old vehicle widely used in Europe;

- the Rheinmetall-Raytheon Lynx is an all-new design, although individual components have a good track record;

- but the General Dynamics Griffin III is in the middle, combining a new gun and new electronics with the time-tested chassis from the European ASCOD family.

Schirmer offered more specifics. “We have a pretty challenging test schedule… very similar to MPF, (so) we really can’t afford a clean sheet design,” he said. The more mature the component technologies, the better, he said, but what’s best is that those individual components have been proven as an integrated system.

Specifically, Schirmer said, “for the Bradley replacement, we are going to be buying vehicles that are based on a mature architecture — powertrain, track, suspension — that’s already in service somewhere in the world.”

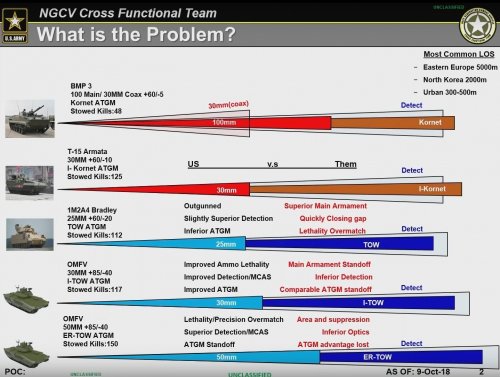

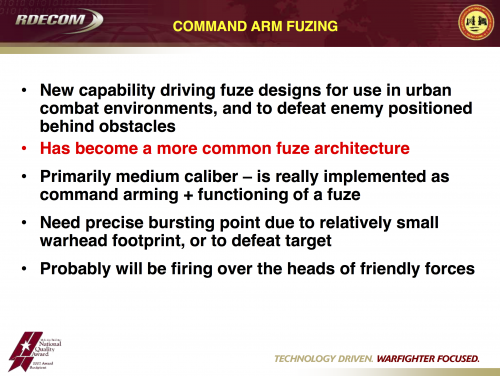

While the Army wants a proven hull, however, Schirmer says there is one area where technology is advancing fast enough for it be worth taking some risk: lethality, i.e. the gun and sensors. In particular, while the Bradley has a 25mm chaingun, the Army really wants NGCV to have a 50mm cannon — firing shells about four times as big — that’s now in development at the service’s Ammunition Research, Development, & Engineering Center (ARDEC).

That gun, the XM913, is currently integrated on just one competitor, the Griffin, although both the Lynx and CV90 turrets could accommodate it. All three vehicles, like the Bradley, also have room in the turret to mount anti-tank missiles of various types. The Griffin on the show floor also mounts a launcher for AeroVironment Shrike mini-drones, while the Lynx will have the option to launch Raytheon’s Coyote: Both mini-drones can be configured either with sensors to scout or with warheads to destroy.

Besides gun caliber, the other easily measured aspect of an armored vehicle is its weight, which is very much a two-edged sword. There’s been no breakthrough in armor materials since the 1980s and none on the horizon, so the only way to get better armor is to make it thicker. So a heavier vehicle is probably better protected, but it also burns more fuel, wears out more spare parts, and has more trouble getting places: Bridges and transport aircraft in particular can only take so much weight.

“Having just left Poland…and traveled to Korea and elsewhere, the infrastructure doesn’t support a heavy vehicle,” Coffman said. “At this stage, before the RFP is written, we’re looking at everything as options, (but) the idea is we have a smaller vehicle that is lighter, but survivable.”

Even as the Army tries to maximize the number of passengers the Bradley replacement can carry, it’s trying to minimize the number of crew required to operate it. In fact, while NGCV is still the name of the overall program, which also includes unmanned Robotic Combat Vehicles, the Bradley replacement specifically is now officially known as the Optionally Manned Fighting Vehicle (OMFV). That’s because the Army foresees future advances in automation making it possible to conduct at least some missions by remote control, starting with simpler tasks like convoys but expanding over time.

But even when the human crew is aboard, the Army wants a limited Artificial Intelligence to help them out. The machine might find its own way around obstacles to reach a destination set by the crew, for instance, so they can rest or focus on scanning for danger. Or it might pull together sensor data to pinpoint threats: heat and sound might warn of an approaching enemy tank, for instance, or reveal where an hidden anti-tank missile team just fired from.

Last edited: