Another Racer update from Farnborough... just hit 227 knots with room to spare!

www.flightglobal.com

www.flightglobal.com

Racer sprints to target speed within just seven flights

Just seven flights and 9h into its test campaign, Airbus Helicopters Racer technology demonstrator has already beaten its 220kt (407km/h) target speed and opened up 80% of its flight envelope since its 24 April maiden sortie.

Racer sprints to target speed within just seven flights

Just seven flights and 9h into its test campaign, Airbus Helicopters' Racer technology demonstrator has already beaten its 220kt (407km/h) target cruise speed and opened up 80% of its flight envelope since its 24 April maiden sortie.

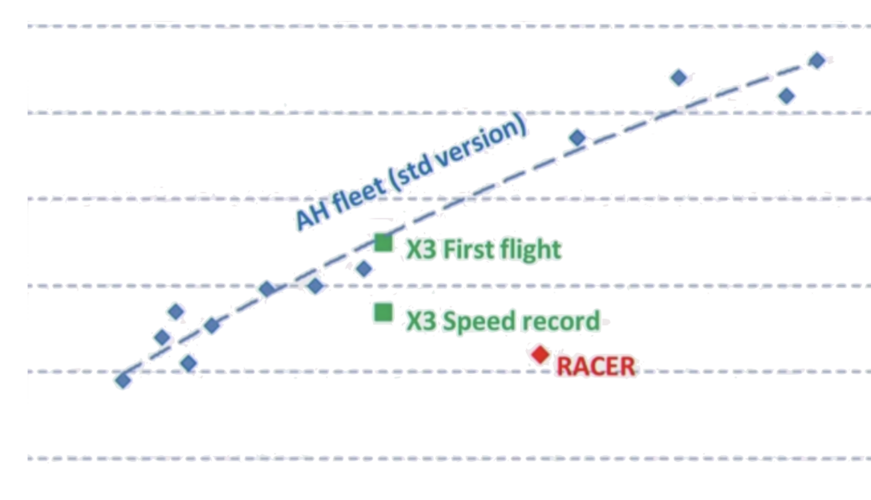

(...) The Racer beat its target speed during a test flight on 21 June, hitting 227kt in level flight, says its test pilot Herve Jammayrac. That milestone was also achieved without fairings installed on its landing gear or a highly aerodynamic main rotor cowling, as such “we believe we have additional margin for faster flight,” he adds. (...) The Racer has also been tested on more dynamic maneuvers, for example flying at a bank angle of 45° at speeds above 200kt.

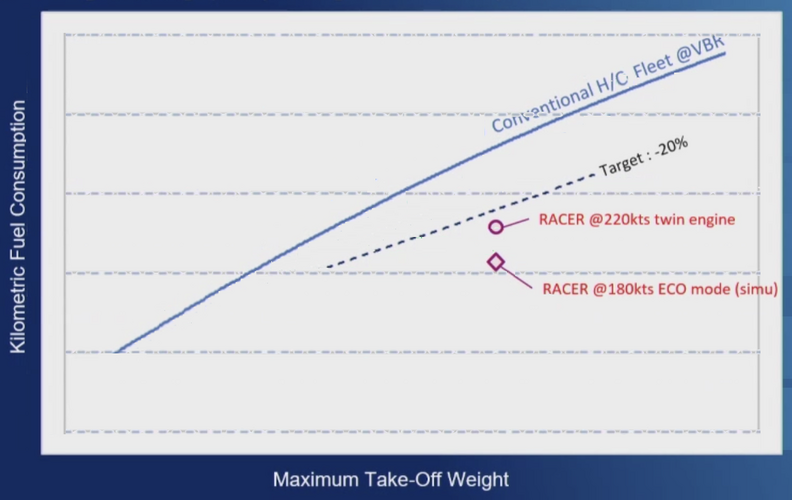

Test flights are paused for the summer and to allow routine maintenance but will resume in September as the company targets opening up the remainder of the flight envelope. A next step for the programme will be to test the ‘ecomode’ function on its twin Safran Helicopter Engines Aneto-1X powerplants. This will allow one of the engines to be shut down in cruise and then rapidly restarted – within 10s if needed – improving the efficiency of the remaining powerplant, cutting fuel burn.