- Joined

- 24 November 2008

- Messages

- 1,413

- Reaction score

- 1,982

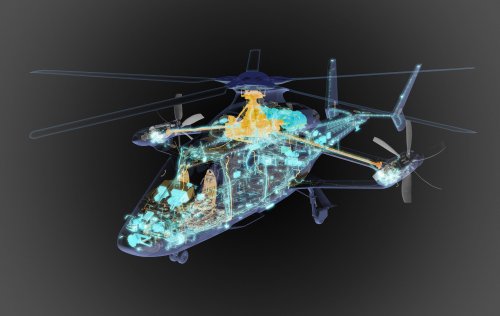

LifeRCraft = Low Impact, Fast & Efficient RotorCraft

The next step after X³

Refer to page 332 (8.7 Compound Rotorcraft Demonstration (LifeRCraft)) for further information:

http://ec.europa.eu/research/partic...l/jti/h2020-guide-techprog-cleansky-ju_en.pdf

Info about Clean Sky: http://www.cleansky.eu/fast-rotorcraft

BR Michael

...H160 derivative? :

The next step after X³

Refer to page 332 (8.7 Compound Rotorcraft Demonstration (LifeRCraft)) for further information:

http://ec.europa.eu/research/partic...l/jti/h2020-guide-techprog-cleansky-ju_en.pdf

Info about Clean Sky: http://www.cleansky.eu/fast-rotorcraft

BR Michael

...H160 derivative? :