Boomerang503

ACCESS: Restricted

- Joined

- 28 November 2021

- Messages

- 11

- Reaction score

- 31

I'm very familiar with the P.1154 design with PCB, and that's why we needed an alternative for Harrier 21, just too much cross-sectional area in the middle of the aircraft causing unmanageable transonic drag rise, and no way to reduce the area there. About that AV-8C, I do know of an AV-8B that was modified with wingtip AIM-9s and zero-scarf rear (hot) nozzles, but that was a bit after I'd moved on from the group. I think the one you're referencing was a Harrier GR.1, XV798, that did some PCB work and is in the museum at Kemble now, with those nozzles still installed as far as I know.Not finding one in a quick search, what I am remembering was a harrier with "saggy tits" for the PCB nozzles with US markings on it. I'm assuming it was a singular test or demonstration type.

PCB nozzles on this were located much lower on the airframe than the cold nozzles. Where the standard Harrier cold nozzles are up in the "wingpits", the PCB nozzles were rotated down to about 30-45deg below horizontal axis of the engine/airframe, well clear of the wings and fuselage sides.

About Oct 1987 I was a member the Tandem fan team at RR Patchway. There were three other teams working simultaneously on;- PCB, Remote Augmented Lift (RALS), and ejector lift. I remember there were quite open concept comparative reviews every few months. At one of these, PCB got absolutely hammered on safety grounds, principally the critical need to maintain stable combustion in multiple places within the engine. Statistics were presented on existing engine afterburner light up reliability with the inference that given a failure for just one zone to light, would be loss of aircraft (Catastrophic). This was so bad it implied an unsustainable fleet. Although it was presented as requirement for improvement, many said anything up to a couple of years later, that it was a factor in the PCB rejection. I certainly concur that it was also said that it was not well suited to a supersonic aircraft architecture, ground erosion and hot gas recirculation.I'm very familiar with the P.1154 design with PCB, and that's why we needed an alternative for Harrier 21, just too much cross-sectional area in the middle of the aircraft causing unmanageable transonic drag rise, and no way to reduce the area there. About that AV-8C, I do know of an AV-8B that was modified with wingtip AIM-9s and zero-scarf rear (hot) nozzles, but that was a bit after I'd moved on from the group. I think the one you're referencing was a Harrier GR.1, XV798, that did some PCB work and is in the museum at Kemble now, with those nozzles still installed as far as I know.

Was that due to the newer PCB 'swirl' burners in place of the colanders? Ian Clapham and others did a lot to make the colanders work on the PCB Harrier rig and NGTE seemed happy in the end.About Oct 1987 I was a member the Tandem fan team at RR Patchway. There were three other teams working simultaneously on;- PCB, Remote Augmented Lift (RALS), and ejector lift. I remember there were quite open concept comparative reviews every few months. At one of these, PCB got absolutely hammered on safety grounds, principally the critical need to maintain stable combustion in multiple places within the engine. Statistics were presented on existing engine afterburner light up reliability with the inference that given a failure for just one zone to light, would be loss of aircraft (Catastrophic). This was so bad it implied an unsustainable fleet. Although it was presented as requirement for improvement, many said anything up to a couple of years later, that it was a factor in the PCB rejection. I certainly concur that it was also said that it was not well suited for supersonic flight aircraft architecture, ground erosion and hot gas recirculation.

During my time at RR , RALS was bleed air driven. Tandem fan expired in about 1990, ejector lift a bit earlier. The step change occurred quite quickly when RALS (shaft) was studied which killed off PCB once and for all.

All the Tandem fan work we did was cold front nozzle aimed at pre JAST studies. I briefly saw several aircraft concept architecture but can’t recall the designation… details of these were shared sparingly with the engine team especially the more junior members.Was that due to the newer PCB 'swirl' burners in place of the colanders? Ian Clapham and others did a lot to make the colanders work on the PCB Harrier rig and NGTE seemed happy in the end.

There was also a tandem fan variant with PCB for the BAe P1222. Know any more?

A GR.1 demonstrator was actually built and flown, nothing on the US side though, beyond the artwork and model.Was this an actual demonstrator or a proposed demonstrator?

I was being a pest in the Advanced AV-8 and V/STOL Group at the time, pushing for supersonic performance while literally everyone else was "proving" to me that a fighter could and should be subsonic, which just shows how deeply ingrained the Harrier's limitations had become in people's minds. In the end, to shut me up, the head of our Aero group did a whole series of performance calculations based on the AV-8B's geometry, ignoring the extra mess that PCB nozzles would create with cross-sectional area at the mid-fuselage, and arbitrarily adding more and more thrust. In other words, all the benefits of PCB without any of the liabilities. He proved that you could double and even triple the thrust but the basic airframe was so pudgy that you just couldn't break through the transonic drag rise. You'd need a much thinner wing and narrower fuselage to have any chance at all. The AV-8B's supercritical wing had become its major advantage (it's hard to remember those days) because it was all-composite, rare back then. Thinning it down would take away volume from its integral fuel tank, while adding PCB or any other form of afterburning would suggest that you needed more fuel, not less. The so-called "Big Wing" variant had been looked at in the UK as well as in St Louis and while it might have gained back the tank volume, it was too wide to be compatible with LPH/LHA/LHD elevators and hangar deck spaces, without adding the weight and complexity (and potential loss of fuel volume again) of a wingfold system. So there wasn't going to be any PCB-equipped Harrier variant, but then Rolls Royce came up with a repackaged Pegasus engine core that changed everything about the mid-fuselage geometry, and we were off on what became the Harrier 21.Looks like a brute-force way of puhing a first generation Harrier through the sound barrier. Basic issue was the Pegasus big fan needed big round intakes not exactly adapted to supersonic flight. This project desperately tries to go around this major issue. Was it realistic ? no idea. There are good reasons the P.1154 and P.1216 no longer looked like Harriers...

I looked everywhere but couldn't find that photo, then today, out of the clear blue, a former coworker sent me an email and attached that exact photo to it. The resolution isn't great here, but this is the photo of our ASTOVL study team at one moment in time, with the Model 4629 on the easel. I'm the 3rd standing guy to the right of the painting, the one with the beard.This looks to be the Model 4629 (as I recall it) which was what the Model 279-3 allegedly evolved into, although in fact the latter was just abandoned. I remember being amused at the traditional "evolution tree" that the ASTOVL group had put together, with top view sketches showing how the Model 279 had been gradually modified and refined in minor ways until suddenly the completely different 4629 was just tacked on at the end. The message I got was "we spent a lot of time and money trying to make the canard/delta configuration work, then realized that a traditional wing/tail design was better, so that's what we have now, at the last minute and representing relatively minimal analysis and risk reduction." Somewhere I have a photo of part of the ASTOVL engineering and design team in St Louis sitting around our big conference table. I'll see if I can find it, it has a painting of that airplane on an easel behind us.

At the time when 279-3 was about to be junked and replaced with 4629, I was still on the Advanced AV-8 and V/STOL team, working with Harrier 21, so I don't know all the issues involved with early incarnations of ASTOVL. Once MDC's corporate geniuses decided to halt H21 in favor of ASTOVL, not knowing that the latter was nothing more than a cover program for behind-the-scenes work between DARPA and Lockheed on the shaft-driven lift fan technologies, I migrated over to ASTOVL myself and worked in their Systems Engineering section on Risk Management. By then the configuration had definitely changed.Great photo. Thanks for sharing. How long had the 4629 design been going by that point? I know in 86 the UK-UK study from St Louis was expected to be the 279-3, at least on this side of the pond. There was some dismay at the 4629 being counted as vectored thrust with it's 'cactus' layout.

Hi SteveAt the time when 279-3 was about to be junked and replaced with 4629, I was still on the Advanced AV-8 and V/STOL team, working with Harrier 21, so I don't know all the issues involved with early incarnations of ASTOVL. Once MDC's corporate geniuses decided to halt H21 in favor of ASTOVL, not knowing that the latter was nothing more than a cover program for behind-the-scenes work between DARPA and Lockheed on the shaft-driven lift fan technologies, I migrated over to ASTOVL myself and worked in their Systems Engineering section on Risk Management. By then the configuration had definitely changed.

Popular myth has it that the shaft-driven lift fan...well, I'm not going to reopen that old argument. Within the JSF/JAST/ASTOVL context, it has a rather convoluted history. As soon as the AV-8B started going into service, the Services started thinking about what might follow it in the next generation of STOVL. Putting "Advanced" up front yielded the generic acronym "ASTOVL" around 1983, but after a few years of looking at stretching existing technologies, it was apparent that there was only so much growth left in them, not nearly enough to achieve desirable goals for mission capabilities. So by 1987 the desired path forward didn't seem to have any obvious answers. At that point DARPA did a dirty thing. They approached Lockheed, and only Lockheed, in secret to see whether they might have ideas on where to go next. Lockheed said (naturally) yes, they had ideas, and so DARPA started funneling money to them to develop those technologies, chief among which was the shaft-driven lift fan. Meanwhile, to cover their tracks, DARPA pretended that it was still a wide-open game with ASTOVL, and funded a cover program as ASTOVL Phase II to preserve the false belief that there was an open competition. Lockheed took their share of that money as well, leaving everyone else drastically underfunded without realizing it. At the same time, Lockheed was also engaged in an unacknowledged technology development effort with NASA aimed at a supersonic stealth STOVL fighter, so that was another big pile of money that they had been given in secret to develop shaft-driven lift fans, while the rest of the "competitors" in ASTOVL Phase II worked away on radically less money without realizing it. This NASA-initiated program eventually became the multi-Service STOVL Strike Fighter (SSF). As the years went by, ASTOVL and SSF went through several identity iterations before eventually becoming JAST and then JSF. By then, of course, the millions of secret dollars and many years of time had given Lockheed such a lead on STOVL technologies that there was no way for anyone else to catch up. And the center core of those technologies was the shaft-driven lift fan.Hi Steve

Where did the shaft driven lift fan (RALS to us) originally come from? In the RR engine trade study at Patchway we were very much focused on bleed air powered lift fans;- there quite a few drawn up with coaxial turbines, tip turbines, geared turbines etc. I remember the shaft concept just appearing, taking centre stage and dominating very quickly. It was just about the time that I left RR for my next adventure. Years later a colleague from that time mentioned the break through was the realisation that carbon wheel brake technology could be used in a clutch which could attenuate the power off take.

Please tell more…

I imagine that P.1216 and PCB fell into that category ?Putting "Advanced" up front yielded the generic acronym "ASTOVL" around 1983, but after a few years of looking at stretching existing technologies, it was apparent that there was only so much growth left in them, not nearly enough to achieve desirable goals for mission capabilities.

Yes. Although some would say it was enough for the USMC before max stealth was added.I imagine that P.1216 and PCB fell into that category ?

It's quite the saga, I wonder what in the first place drove DARPA to go to Lockheed and nobody else. Lockheed's work on fixed-wing VTOL at that time doesn't seem to have been anything remarkable. The "go-to" guys at the time definitely would have been McDonnell Douglas who had all of that Harrier experience.Popular myth has it that the shaft-driven lift fan...well, I'm not going to reopen that old argument. Within the JSF/JAST/ASTOVL context, it has a rather convoluted history. As soon as the AV-8B started going into service, the Services started thinking about what might follow it in the next generation of STOVL. Putting "Advanced" up front yielded the generic acronym "ASTOVL" around 1983, but after a few years of looking at stretching existing technologies, it was apparent that there was only so much growth left in them, not nearly enough to achieve desirable goals for mission capabilities. So by 1987 the desired path forward didn't seem to have any obvious answers. At that point DARPA did a dirty thing. They approached Lockheed, and only Lockheed, in secret to see whether they might have ideas on where to go next. Lockheed said (naturally) yes, they had ideas, and so DARPA started funneling money to them to develop those technologies, chief among which was the shaft-driven lift fan. Meanwhile, to cover their tracks, DARPA pretended that it was still a wide-open game with ASTOVL, and funded a cover program as ASTOVL Phase II to preserve the false belief that there was an open competition. Lockheed took their share of that money as well, leaving everyone else drastically underfunded without realizing it. At the same time, Lockheed was also engaged in an unacknowledged technology development effort with NASA aimed at a supersonic stealth STOVL fighter, so that was another big pile of money that they had been given in secret to develop shaft-driven lift fans, while the rest of the "competitors" in ASTOVL Phase II worked away on radically less money without realizing it. This NASA-initiated program eventually became the multi-Service STOVL Strike Fighter (SSF). As the years went by, ASTOVL and SSF went through several identity iterations before eventually becoming JAST and then JSF. By then, of course, the millions of secret dollars and many years of time had given Lockheed such a lead on STOVL technologies that there was no way for anyone else to catch up. And the center core of those technologies was the shaft-driven lift fan.

If you want to read all the details of this shameful process of using tax dollars to favor one contractor to the severe detriment of everyone else, it was available on the Government's own jast.mil website for many years before finally being cleaned up, but it's still available on Wayback: https://web.archive.org/web/20061112005516/https://www.jsf.mil/history/his_prejast.htm

Lockheed had a way of hiring retiring Service and Government people from "relevant" places, who naturally thought of their trusted former coworkers when new business opportunities arose. They weren't shy about how they went after new business either, their strategic business strategy briefing charts were shown at conferences and were readily available online. But how and why those initial feelers were put out for VTOL technologies, I've never heard.It's quite the saga, I wonder what in the first place drove DARPA to go to Lockheed and nobody else. Lockheed's work on fixed-wing VTOL at that time doesn't seem to have been anything remarkable. The "go-to" guys at the time definitely would have been McDonnell Douglas who had all of that Harrier experience.

It's interesting that you mention industrial base support, because at that time MDC looked unstoppable. I can remember walking through Building 1 and seeing 4 different tactical aircraft in production for USAF, USN, USMC, and a bunch of foreign countries. When I first came to St Louis in 1979 there was so much going on that the MDC buildings couldn't hold all the designers and engineers. You could walk through one of the local malls and look into the glass front windows of the stores at shoes here, clothing there, and guys working over drafting boards too, designing bits and pieces for aircraft or missiles or who knew what. I wish I'd thought to take a photo. But with so much going on at MDC, while Lockheed was seemingly confined to one major tactical program, industrial base support may well have come into play. If so, it was ill advised, and late to the party after a lot of consolidation had already happened in the industry through normal business processes.Probably there was a remembrance that Convair had had a pretty good concept for a supersonic STOVL aircraft in the early 1970s... and since Convair was a division inside General Dynamics (since March 1953), and Lockheed bought the Fort Worth division of GD that built the F-16 (and which was a longstanding Convair facility) in 1993, there may well have been some engineers around Lockheed who had worked on the Convair 200 - which had the 3 bearing swivel nozzle that was the basis for the one in the F-35.

That and pure favoritism/"industrial base support considerations".

FWIW, wiki here says Lockheed got a working prototype of Yak-141 in 1993, apparently with documentation and all.which had the 3 bearing swivel nozzle that was the basis for the one in the F-35.

FWIW, wiki here says Lockheed got a working prototype of Yak-141 in 1993, apparently with documentation and all.

Russian wiki brings this link:Nothing about LM getting a functional prototype or complete documentation.

Taking a quick peek around this forum would help resolve some of your questions.Russian wiki brings this link:

The Story of How the F-35 Might Have Some Russian 'Blood'

Well, at least one of the variants of the F-35, that is.web.archive.org

and a Russian book from 2007 claims that in 1995 the government did allow Yakovlev to sell the whole set of project documentation for both Yak-38 and Yak-141 to LM. (Balakin, Zabolotsky, Soviet Aircraft Carriers).

As to the prototype you're right, it was returned to Russia after Farnborough, but the Yakovlev-LM partnership (again, according Russian wiki) span from 1991 to 1997. That's quite a lot of time and I highly doubt LM did that for charity.

Bolded by me.What I have posted above is the full scope of Yakovlev's 1995 involvement on JSF. Less than $500,000. Engineers who worked on the F-35 say the supplied data and reports were not very useful in the end. This ended further potential involvement as discussed in the above articles.

This wasn't Lockheed and Yakovlev's first alleged venture however.

DARPA ASTOVL SDLF award to LM far precedes the shenanigans with Yak. 3BSD was not a Yak invention. Most likely, what Yak was involved with is the optimization of LM's VSTOL design, as they had practical experience and could contribute their own know-hows on some of the issues LM could encounter.Basically the $10 million figure looks about the most realistic for post 1991 period, but if they actually did all the development at LM's expense from the Soviet times, it's hilarious.

That's the realistic figure, yes. Several transactions post-1991, documentation, etc. Likely exactly what happened.The money could stack up to millions, maybe.

Titanium....I am just trying to imagine that size of a contract in a bloody 1985.

Titanium....

I'd honestly expect that an engine with 3 vectoring nozzles would happen.At the same time it could be quite curious to imagine an F-35-ish Harrier evolution around the Pegasus layout, with 4 vectoring exhausts.

Like here?I'd honestly expect that an engine with 3 vectoring nozzles would happen.

I meant more like the P.1214/P.1216, honestly. 2x Cold Nozzles up front and a single hot nozzle.

In something with the P.1216 shape? One weapons bay in each boom, kinda like the Boeing EWP proposed for the Super Hornet.How do you fit a weapons bay inside that thing?

In 1988, we at RR Patchway had a very nicely built, working scale model of a 3 bearing nozzle which was kept in a locked wooden box;- only shown to authorised employees. It wasn’t new either but I didn’t ask where it came from, just assumed it was associated with the P1214 (ie it central nozzle) a dayglo orange scale model of which was still installed in one of the gas flow recirculation rigs. I didn’t know it was the P1214 at the time, discovered that later.. if you have a three post thrust vectored architecture you really need some kinda solution for making that central stream do what you want.Probably there was a remembrance that Convair had had a pretty good concept for a supersonic STOVL aircraft in the early 1970s... and since Convair was a division inside General Dynamics (since March 1953), and Lockheed bought the Fort Worth division of GD that built the F-16 (and which was a longstanding Convair facility) in 1993, there may well have been some engineers around Lockheed who had worked on the Convair 200 - which had the 3 bearing swivel nozzle that was the basis for the one in the F-35.

That and pure favoritism/"industrial base support considerations".

In 1988, we at RR Patchway had a very nicely built, working scale model of a 3 bearing nozzle which was kept in a locked wooden box;- only shown to authorised employees. It wasn’t new either but I didn’t ask where it came from, just assumed it was associated with the P1214 (ie it central nozzle) a dayglo orange scale model of which was still installed in one of the gas flow recirculation rigs. I didn’t know it was the P1214 at the time, discovered that later.. if you have a three post thrust vectored architecture you really need some kinda solution for making that central stream do what you want.

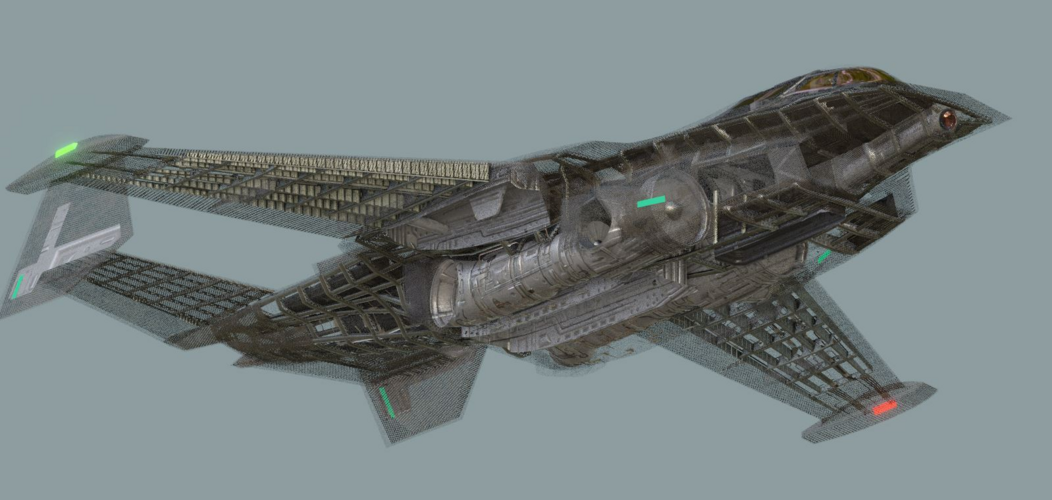

I actually found something along these lines. Mind - it's from a computer game and absolutely fictional, but - it shows how to combine the 4-exhaust layout with internal weapons bay. (sorry for the nuclear blast in the background, that's the only coherent bottom view I could find)At the same time it could be quite curious to imagine an F-35-ish Harrier evolution around the Pegasus layout, with 4 vectoring exhausts.

Ha! Twin engine STOVL on the cheap. Cross section will be gigantic however.I actually found something along these lines. Mind - it's from a computer game and absolutely fictional, but - it shows how to combine the 4-exhaust layout with internal weapons bay. (sorry for the nuclear blast in the background, that's the only coherent bottom view I could find)

View attachment 758961

View attachment 758959

You just need two engines, and put the bay between them.

Because of the nozzles?Cross section will be gigantic however.