Probably more like a f-23a than anything else. Tailless is still expensive with complicated and weighty and $$$ thrust vectoring and CAN kill the rear aspect LO and diminish mission capability rate. It still needs to be a fighter which means tail. Horizontal tail.... No. Probably 7 to 8 aim260 or combo with 9x\perrigrine\cuda. Probably capable of more than 700nm range supercuise with the new engine techI think its quite possible for the NGAD to be the size of an F-111. This is just my speculation, but perhaps it may be a tailless supersonic design, powered by two adaptive cycle engines scaled from the 45,000-lbf class XA100/101. This can have substantial range and persistence, while still allowing for a reasonable level of fighter-like maneuverability with a thrust/weight ratio of ~1 and +7.33 g at combat or loaded gross weight.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

USAF/US NAVY 6th Generation Fighter Programs - F/A-XX, F-X, NGAD, PCA, ASFS news

- Thread starter Matej

- Start date

Dragon029

ACCESS: Top Secret

- Joined

- 17 March 2009

- Messages

- 881

- Reaction score

- 440

Bit late of a reply, but it's definitely not dead; the premise of the MR-X ("F-16 replacement") program is that there was a study being undertaken to look into what the USAF's future fleet should look like, and that the results of that study would inform the FY2023 budget request, which has since been released, with a lot of money going to R&D. The final decision on the MR-X program however is expected to take place in around 2028, as for now the USAF has other priorities (NGAD, B-21, AWACS, tankers, etc). The 2028 date will also give Lockheed a chance to try and enact the sustainment cost reductions that they claim can be achieved. If Lockheed gets their way the MR-X program might just turn into more F-35As.Whatever did happen to that Gen 4.5/5- idea that was floated last year? Dead on arrival, presumably?

NeilChapman

Interested 3rd party

- Joined

- 14 December 2015

- Messages

- 1,302

- Reaction score

- 536

I have been thinking about sustainment cost for NGAD, particularly cost per flight hour. How, and from whom are these numbers are calculated? Has anyone seeing a breakdown of per flight hour flying costs for F-35? All I keep seeing is a number. I would like to know how that number breaks down, and be able to compare that breakdown to other aircraft.

I'm puzzled by Lockheed Martin saying they can attain certain cost per hour by a certain date. How is that possible? Is this just a contract price that is paid?

I'm puzzled by Lockheed Martin saying they can attain certain cost per hour by a certain date. How is that possible? Is this just a contract price that is paid?

Last edited:

Dragon029

ACCESS: Top Secret

- Joined

- 17 March 2009

- Messages

- 881

- Reaction score

- 440

So first of all, there is no universal definition for cost per flight hour; there's a classic SAAB presentation for example where they claimed (around a decade ago IIRC) that the F-16C (when comparing it to the Gripen C) cost $7,000/hr. In contrast, the USAF generally claims the F-16C costs around $25,000K/hr. The vast difference between those two numbers comes from what's being included / excluded in those figures.

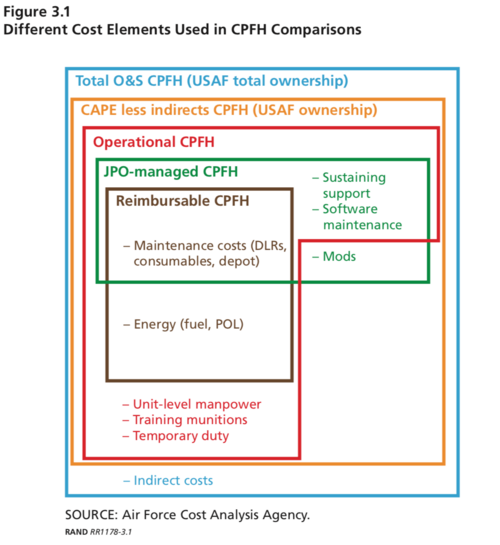

Here's a graphical comparison for example of CPFH types used with regards to the F-35; you can find a greater breakdown of these different cost elements in this CAPE document: https://www.cape.osd.mil/files/os_guide_v9_march_2014.pdf

Total ownership / total O&S can be a bit odd in that, while it does ultimately capture the total cost of operating a fleet, it includes things you might not have thought of, such as (under "Indirect costs" / "indirect support") medical support / services, initial recruit / officer training, etc.

For the SAAB $7K/hr F-16C figure, they'd be talking about something akin to the Reimbursable CPFH described above (and for comparison's sake, here's the FY2021 reimbursable figures for the US services' fleets), whereas the USAF and a number of other military services around the world are generally referring to ownership or total ownership CPFH.

As for how CPFH itself is calculated, it's generally just the annual sustainment cost for a fleet, divided by the annual flight hours. The "fleet" in equation can be individual squadrons / units, but generally it's for an entire service's fleet of that aircraft type. For the F-35A CPFH figures you see it's generally just the USAF's F-35A total ownership CPFH; other F-35A operators that publicly report sustainment costs (like Australia) have had fairly similar costs, sometimes lower.

And as for how Lockheed can claim a certain CPFH by a certain date; the short answer is that they can't be 100% certain, but with the F-35 and Lockheed they were awarded a 3-year sustainment contract by the US last year, and so now Lockheed has the power to tell their suppliers that X amount of work has been secured and certain efficiencies can be gained by optimising logistics, investing in tooling and equipment, etc. However, Lockheed and its contractors / suppliers / partners do not perform all F-35 maintenance.

Out of the $33K/hr CPFH that we see for an F-35A today, Lockheed only controls around 39% of that while Pratt & Whitney (who contract to the US independently of Lockheed) owns another 11% and the US military is responsible for the other ~50%. So when Lockheed says that it's going to drop the CPFH of an F-35A from $33K to $30K by 2023, they're talking about what they can achieve by reducing their 39% of sustainment costs. In contrast, the "$25K/hr by 2025" F-35A CPFH goal that Lockheed was talking about a year or two ago is what Lockheed claims is possible, but is reliant on both P&W and the USAF reducing their F-35A sustainment costs by around 15% (from around $20K/hr [of the $33K/hr total] today to around $17K/hr [of the $25K/hr total]). Lockheed can influence USAF costs a little bit (eg: if ALIS / ODIN is less buggy then the USAF spends fewer man-hours fixing the jet and can fly the jet more frequently), but it's mostly not up to them.

Here's a graphical comparison for example of CPFH types used with regards to the F-35; you can find a greater breakdown of these different cost elements in this CAPE document: https://www.cape.osd.mil/files/os_guide_v9_march_2014.pdf

Total ownership / total O&S can be a bit odd in that, while it does ultimately capture the total cost of operating a fleet, it includes things you might not have thought of, such as (under "Indirect costs" / "indirect support") medical support / services, initial recruit / officer training, etc.

For the SAAB $7K/hr F-16C figure, they'd be talking about something akin to the Reimbursable CPFH described above (and for comparison's sake, here's the FY2021 reimbursable figures for the US services' fleets), whereas the USAF and a number of other military services around the world are generally referring to ownership or total ownership CPFH.

As for how CPFH itself is calculated, it's generally just the annual sustainment cost for a fleet, divided by the annual flight hours. The "fleet" in equation can be individual squadrons / units, but generally it's for an entire service's fleet of that aircraft type. For the F-35A CPFH figures you see it's generally just the USAF's F-35A total ownership CPFH; other F-35A operators that publicly report sustainment costs (like Australia) have had fairly similar costs, sometimes lower.

And as for how Lockheed can claim a certain CPFH by a certain date; the short answer is that they can't be 100% certain, but with the F-35 and Lockheed they were awarded a 3-year sustainment contract by the US last year, and so now Lockheed has the power to tell their suppliers that X amount of work has been secured and certain efficiencies can be gained by optimising logistics, investing in tooling and equipment, etc. However, Lockheed and its contractors / suppliers / partners do not perform all F-35 maintenance.

Out of the $33K/hr CPFH that we see for an F-35A today, Lockheed only controls around 39% of that while Pratt & Whitney (who contract to the US independently of Lockheed) owns another 11% and the US military is responsible for the other ~50%. So when Lockheed says that it's going to drop the CPFH of an F-35A from $33K to $30K by 2023, they're talking about what they can achieve by reducing their 39% of sustainment costs. In contrast, the "$25K/hr by 2025" F-35A CPFH goal that Lockheed was talking about a year or two ago is what Lockheed claims is possible, but is reliant on both P&W and the USAF reducing their F-35A sustainment costs by around 15% (from around $20K/hr [of the $33K/hr total] today to around $17K/hr [of the $25K/hr total]). Lockheed can influence USAF costs a little bit (eg: if ALIS / ODIN is less buggy then the USAF spends fewer man-hours fixing the jet and can fly the jet more frequently), but it's mostly not up to them.

NeilChapman

Interested 3rd party

- Joined

- 14 December 2015

- Messages

- 1,302

- Reaction score

- 536

So first of all, there is no universal definition for cost per flight hour; there's a classic SAAB presentation for example where they claimed (around a decade ago IIRC) that the F-16C (when comparing it to the Gripen C) cost $7,000/hr. In contrast, the USAF generally claims the F-16C costs around $25,000K/hr. The vast difference between those two numbers comes from what's being included / excluded in those figures.

Here's a graphical comparison for example of CPFH types used with regards to the F-35; you can find a greater breakdown of these different cost elements in this CAPE document: https://www.cape.osd.mil/files/os_guide_v9_march_2014.pdf

Total ownership / total O&S can be a bit odd in that, while it does ultimately capture the total cost of operating a fleet, it includes things you might not have thought of, such as (under "Indirect costs" / "indirect support") medical support / services, initial recruit / officer training, etc.

View attachment 677102

For the SAAB $7K/hr F-16C figure, they'd be talking about something akin to the Reimbursable CPFH described above (and for comparison's sake, here's the FY2021 reimbursable figures for the US services' fleets), whereas the USAF and a number of other military services around the world are generally referring to ownership or total ownership CPFH.

As for how CPFH itself is calculated, it's generally just the annual sustainment cost for a fleet, divided by the annual flight hours. The "fleet" in equation can be individual squadrons / units, but generally it's for an entire service's fleet of that aircraft type. For the F-35A CPFH figures you see it's generally just the USAF's F-35A total ownership CPFH; other F-35A operators that publicly report sustainment costs (like Australia) have had fairly similar costs, sometimes lower.

And as for how Lockheed can claim a certain CPFH by a certain date; the short answer is that they can't be 100% certain, but with the F-35 and Lockheed they were awarded a 3-year sustainment contract by the US last year, and so now Lockheed has the power to tell their suppliers that X amount of work has been secured and certain efficiencies can be gained by optimising logistics, investing in tooling and equipment, etc. However, Lockheed and its contractors / suppliers / partners do not perform all F-35 maintenance.

Out of the $33K/hr CPFH that we see for an F-35A today, Lockheed only controls around 39% of that while Pratt & Whitney (who contract to the US independently of Lockheed) owns another 11% and the US military is responsible for the other ~50%. So when Lockheed says that it's going to drop the CPFH of an F-35A from $33K to $30K by 2023, they're talking about what they can achieve by reducing their 39% of sustainment costs. In contrast, the "$25K/hr by 2025" F-35A CPFH goal that Lockheed was talking about a year or two ago is what Lockheed claims is possible, but is reliant on both P&W and the USAF reducing their F-35A sustainment costs by around 15% (from around $20K/hr [of the $33K/hr total] today to around $17K/hr [of the $25K/hr total]). Lockheed can influence USAF costs a little bit (eg: if ALIS / ODIN is less buggy then the USAF spends fewer man-hours fixing the jet and can fly the jet more frequently), but it's mostly not up to them.

That, sir, was a most excellent answer. I am very appreciative of the effort you put into helping me understand some of the issues involved.

View: https://twitter.com/MIL_STD/status/1517722479615037440

Maybe that shiny coating we saw on the F-22 was actually a first hint of the surfacing we will see on the NGAD?

Maybe that shiny coating we saw on the F-22 was actually a first hint of the surfacing we will see on the NGAD?

FighterJock

ACCESS: Above Top Secret

- Joined

- 29 October 2007

- Messages

- 5,142

- Reaction score

- 5,073

View: https://twitter.com/MIL_STD/status/1517722479615037440

Maybe that shiny coating we saw on the F-22 was actually a first hint of the surfacing we will see on the NGAD?

Would not surprise me skyblue, I would also think that it could also turn up on the B-21 and F-35 as well.

Forest Green

ACCESS: Above Top Secret

- Joined

- 11 June 2019

- Messages

- 8,225

- Reaction score

- 13,915

That skin looks mighty interesting, what does it do?View: https://twitter.com/MIL_STD/status/1517722479615037440

Maybe that shiny coating we saw on the F-22 was actually a first hint of the surfacing we will see on the NGAD?

NeilChapman

Interested 3rd party

- Joined

- 14 December 2015

- Messages

- 1,302

- Reaction score

- 536

That's the billion dollar question.That skin looks mighty interesting, what does it do?

Forest Green

ACCESS: Above Top Secret

- Joined

- 11 June 2019

- Messages

- 8,225

- Reaction score

- 13,915

Bends light and radio waves around the aircraft when activated. *Crosses fingers.*

Firefinder

ACCESS: Top Secret

- Joined

- 5 October 2019

- Messages

- 960

- Reaction score

- 1,734

My money on it doing something similar to Yhudia Lights.

Makes it harder for eyes and cameras to distinguish it from the sky.

Handy with how all new weapons have advanced image processors to track shit...

Makes it harder for eyes and cameras to distinguish it from the sky.

Handy with how all new weapons have advanced image processors to track shit...

Bhurki

ACCESS: Secret

- Joined

- 16 July 2020

- Messages

- 345

- Reaction score

- 381

Enough range to not need a tanker!!

Hmm..

www.airforcemag.com

www.airforcemag.com

Brown brushed that notion aside, however, saying the Next Generation Air Dominance family of systems, intended to operate inside an enemy integrated air defense system (IADS), will have “the range to go where it needs to go” and that an escort tanker is probably not needed. Brown specifically said, “I wouldn’t call [KC-Z] an escort tanker.”

Hmm..

Brown: KC-Y and KC-Z Likely Traditional Tankers; NGAD Has the Range 'to Go Where it Needs to Go' | Air & Space Forces Magazine

The Air Force probably won’t pursue some exotic approach for the KC-Y and KC-Z tranches of the service's plan to modernize its tankers.

Brown brushed that notion aside, however, saying the Next Generation Air Dominance family of systems, intended to operate inside an enemy integrated air defense system (IADS), will have “the range to go where it needs to go” and that an escort tanker is probably not needed. Brown specifically said, “I wouldn’t call [KC-Z] an escort tanker.”

Forest Green

ACCESS: Above Top Secret

- Joined

- 11 June 2019

- Messages

- 8,225

- Reaction score

- 13,915

F-22 Being Used To Test Next Generation Air Dominance 'Fighter' Tech

The F-22 is being used to test Next Generation Air Dominance (NGAD) capabilities and Raptors will also receive tech from the NGAD program.

View: https://twitter.com/PaintingSurfer/status/1514701447690031133

- Joined

- 2 August 2006

- Messages

- 3,216

- Reaction score

- 1,355

My guess is they're lights to adjust the brightness of the vehicle to match the scattered light at whatever alt it is at. AKA, active camo. The reason I think you see this being tested, and the "chrome" being tested, is they're testing active systems versus passive systems to determine which is more effective. I'm sure they're aimed at NGAD, as noted at TWZ, but wouldn't be surprised to see the tech end up on F-22s and F-35s, especially since we've seen both sporting some from of the passive variant of the camo.That skin looks mighty interesting, what does it do?View: https://twitter.com/MIL_STD/status/1517722479615037440

Maybe that shiny coating we saw on the F-22 was actually a first hint of the surfacing we will see on the NGAD?

About 14 years ago on some science show, they showed electro luminescent panels nearly as thin as a thick paint coat that would glow extremely bright with applied voltage... Practically any color. They showed it on a car but the implication was clear it could of would be used in aircraft..... It seems to have gone black because I cannot find hide nor hair of it online anyplace with any browser or key words. Looks like it's been applied to the raptor if I guess at what those panels are. Its the21st century project "yahooti". But they could also be just a new type of ram because those panels require a lot of wires added to the raptor which may not be feasible after the airframe is completeMy guess is they're lights to adjust the brightness of the vehicle to match the scattered light at whatever alt it is at. AKA, active camo. The reason I think you see this being tested, and the "chrome" being tested, is they're testing active systems versus passive systems to determine which is more effective. I'm sure they're aimed at NGAD, as noted at TWZ, but wouldn't be surprised to see the tech end up on F-22s and F-35s, especially since we've seen both sporting some from of the passive variant of the camo.That skin looks mighty interesting, what does it do?View: https://twitter.com/MIL_STD/status/1517722479615037440

Maybe that shiny coating we saw on the F-22 was actually a first hint of the surfacing we will see on the NGAD?

Last edited:

About 14 years ago on some science show, they showed electro luminescent panels nearly as thin as a thick paint coat that would glow extremely bright with applied voltage... Practically any color. They showed it on a car but the implication was clear it could of would be used in aircraft..... It seems to have gone black because I cannot find hide nor hair of it online anyplace with any browser or key words. Looks like it's been applied to the raptor if I guess at what those panels are. Its the21st century project "yahooti". But they could also be just a new type of ram because those panels require a lot of wires added to the raptor which may not be feasible after the airframe is completeMy guess is they're lights to adjust the brightness of the vehicle to match the scattered light at whatever alt it is at. AKA, active camo. The reason I think you see this being tested, and the "chrome" being tested, is they're testing active systems versus passive systems to determine which is more effective. I'm sure they're aimed at NGAD, as noted at TWZ, but wouldn't be surprised to see the tech end up on F-22s and F-35s, especially since we've seen both sporting some from of the passive variant of the camo.That skin looks mighty interesting, what does it do?View: https://twitter.com/MIL_STD/status/1517722479615037440

Maybe that shiny coating we saw on the F-22 was actually a first hint of the surfacing we will see on the NGAD?

BMW showed it off a few months ago.

red admiral

ACCESS: Top Secret

- Joined

- 16 September 2006

- Messages

- 1,647

- Reaction score

- 1,948

How does changing colour help vs IR sensors?

Forest Green

ACCESS: Above Top Secret

- Joined

- 11 June 2019

- Messages

- 8,225

- Reaction score

- 13,915

Maybe there's more to it than that.How does changing colour help vs IR sensors?

It doesn't really, but DIRCM is slowly becoming a thing, and that DOES helps against IR sensors. Meanwhile this might help against imaging sensors, like what Javelin uses.How does changing colour help vs IR sensors?

I suspect the coating is aimed at the IR spectrum, not the visible light spectrum. If you want to make an aircraft hard to spot in visual light all you would need is some LED white lights to drown out the background light; this was experimented with as far back as WWII.

- Joined

- 3 June 2011

- Messages

- 17,929

- Reaction score

- 11,110

About 14 years ago on some science show, they showed electro luminescent panels nearly as thin as a thick paint coat that would glow extremely bright with applied voltage... Practically any color. They showed it on a car but the implication was clear it could of would be used in aircraft..... It seems to have gone black because I cannot find hide nor hair of it online anyplace with any browser or key words. Looks like it's been applied to the raptor if I guess at what those panels are. Its the21st century project "yahooti". But they could also be just a new type of ram because those panels require a lot of wires added to the raptor which may not be feasible after the airframe is completeMy guess is they're lights to adjust the brightness of the vehicle to match the scattered light at whatever alt it is at. AKA, active camo. The reason I think you see this being tested, and the "chrome" being tested, is they're testing active systems versus passive systems to determine which is more effective. I'm sure they're aimed at NGAD, as noted at TWZ, but wouldn't be surprised to see the tech end up on F-22s and F-35s, especially since we've seen both sporting some from of the passive variant of the camo.That skin looks mighty interesting, what does it do?View: https://twitter.com/MIL_STD/status/1517722479615037440

Maybe that shiny coating we saw on the F-22 was actually a first hint of the surfacing we will see on the NGAD?

Nope, video is still there. And it's probably not what you think. It's electroluminescent PAINT. It lights up when a charge is applied but it can't change color.

- Joined

- 6 September 2006

- Messages

- 4,656

- Reaction score

- 8,708

I remember there being an article in Flight International about 10 years ago about that kind of visual camouflage technology, so its certainly something that has been worked on/desired for some time (well its been the holy grail since 1915 with early transparent plastics replacing the canvas).

- Joined

- 3 June 2011

- Messages

- 17,929

- Reaction score

- 11,110

In theory you could apply that EM paint to a panel as a grid (think the RGB pixels on a monitor) and have a unique voltage controlling each "pixel". Like "digital camoflage" but one that could be changed.I remember there being an article in Flight International about 10 years ago about that kind of visual camouflage technology, so its certainly something that has been worked on/desired for some time (well its been the holy grail since 1915 with early transparent plastics replacing the canvas).

- Joined

- 6 August 2007

- Messages

- 3,461

- Reaction score

- 3,969

Reflects radar. Replaces something that is maint. intensive on existing aircraft.That skin looks mighty interesting, what does it do?View: https://twitter.com/MIL_STD/status/1517722479615037440

Maybe that shiny coating we saw on the F-22 was actually a first hint of the surfacing we will see on the NGAD?

BAE have a system in development, tested on a hawk and info on their website (admittedly its on a tank):

adativ-cloak-of-invisibility

adativ-cloak-of-invisibility

X-39

To post or not to post, that is the question

- Joined

- 20 February 2021

- Messages

- 382

- Reaction score

- 915

NGAD Price Per Tail Will More Than Double That of F-35 | Air & Space Forces Magazine

The Next-Generation Air Dominance manned platform, or NGAD, will be the most expensive fighter ever, Air Force Secretary Frank Kendall said.

The manned fighter aircraft that will form the centerpiece of the Air Force’s Next Generation Air Dominance program will cost hundreds of millions of dollars per plane, Air Force Secretary Frank Kendall told members of Congress on April 27—but the service can reduce costs in development and sustainment.

Speaking before the House Armed Services Committee on the fiscal 2023 budget request, Kendall specified that the main NGAD fighter would cost “multiple hundreds of millions of dollars … on an individual basis,” acknowledging that such a price tag “is a number that’s going to get your attention.”

F-2

ACCESS: Top Secret

- Joined

- 22 May 2020

- Messages

- 802

- Reaction score

- 1,525

I mean so was the Raptor

NGAD Price Per Tail Will More Than Double That of F-35 | Air & Space Forces Magazine

The Next-Generation Air Dominance manned platform, or NGAD, will be the most expensive fighter ever, Air Force Secretary Frank Kendall said.www.airforcemag.com

The manned fighter aircraft that will form the centerpiece of the Air Force’s Next Generation Air Dominance program will cost hundreds of millions of dollars per plane, Air Force Secretary Frank Kendall told members of Congress on April 27—but the service can reduce costs in development and sustainment.

Speaking before the House Armed Services Committee on the fiscal 2023 budget request, Kendall specified that the main NGAD fighter would cost “multiple hundreds of millions of dollars … on an individual basis,” acknowledging that such a price tag “is a number that’s going to get your attention.”

Avimimus

ACCESS: Top Secret

- Joined

- 15 December 2007

- Messages

- 2,297

- Reaction score

- 612

NGAD Price Per Tail Will More Than Double That of F-35 | Air & Space Forces Magazine

The Next-Generation Air Dominance manned platform, or NGAD, will be the most expensive fighter ever, Air Force Secretary Frank Kendall said.www.airforcemag.com

But what if we make it tailless?

X-39

To post or not to post, that is the question

- Joined

- 20 February 2021

- Messages

- 382

- Reaction score

- 915

Sounds like an individual 6th gen will cost no less than 200-300mil according to the article. Not that it hadn't been predicted in the past. https://www.defensenews.com/air/201...pensive-price-tag-for-next-air-force-fighter/I mean so was the Raptor

By comparison, the F-22 cost roughly $135 million per tail, making it the most expensive fighter the U.S. Air Force has ever developed. NGAD, according to Kendall’s estimate, will dwarf those costs

X-39

To post or not to post, that is the question

- Joined

- 20 February 2021

- Messages

- 382

- Reaction score

- 915

Piecing Together the NGAD Puzzle | Air & Space Forces Magazine

The Next-Generation Air Dominance family of systems remains highly classified. But some details are beginning to emerge.

Hmmm, is intending to give the Mig-31 a run for it's money believable in the 21st century?The primary aircraft of NGAD is likely to fly at least as high and fast as the F-22, meaning an upper ceiling of about 65,000 to 70,000 feet and a top speed of about Mach 2.8

Now retired, former Air Force Chief of Staff Gen. David L. Goldfein said in 2019 that NGAD will be comprised of “five key technologies” that would not all “come together on a single platform” and would not all mature simultaneously. Goldfein did not enumerate the five technologies, but he later alluded to them including engines, weapons, sensors, artificial intelligence, and connectivity.

Good. Keep it secret, keep it safe!NGAD is likely to remain highly classified as long as the Air Force can keep it that way. Kendall, taking a page from Cold War practice, has said he’s reluctant to share the shape and features of future combat aircraft lest the U.S. provide its opponents with a “head start” on developing countermeasures.

Last edited:

FighterJock

ACCESS: Above Top Secret

- Joined

- 29 October 2007

- Messages

- 5,142

- Reaction score

- 5,073

Let's hope that the USAF keeps the final design of the NGAD classified until it reaches IOC like they did with the F-117A.

- Joined

- 21 January 2015

- Messages

- 11,711

- Reaction score

- 15,074

The problem with this is you have to be able to match the cyber warfare capabilities of your opponents, let alone more conventional elements of spy craft. Look at Australia they literally had to cancel a whole major drone program to finance additional cyberwarfare capabilities.

Piecing Together the NGAD Puzzle | Air & Space Forces Magazine

The Next-Generation Air Dominance family of systems remains highly classified. But some details are beginning to emerge.www.airforcemag.com

Hmmm, is intending to give the Mig-31 a run for it's money believable in the 21st century?The primary aircraft of NGAD is likely to fly at least as high and fast as the F-22, meaning an upper ceiling of about 65,000 to 70,000 feet and a top speed of about Mach 2.8

Now retired, former Air Force Chief of Staff Gen. David L. Goldfein said in 2019 that NGAD will be comprised of “five key technologies” that would not all “come together on a single platform” and would not all mature simultaneously. Goldfein did not enumerate the five technologies, but he later alluded to them including engines, weapons, sensors, artificial intelligence, and connectivity.Good.NGAD is likely to remain highly classified as long as the Air Force can keep it that way. Kendall, taking a page from Cold War practice, has said he’s reluctant to share the shape and features of future combat aircraft lest the U.S. provide its opponents with a “head start” on developing countermeasures.

FighterJock

ACCESS: Above Top Secret

- Joined

- 29 October 2007

- Messages

- 5,142

- Reaction score

- 5,073

The problem with this is you have to be able to match the cyber warfare capabilities of your opponents, let alone more conventional elements of spy craft. Look at Australia they literally had to cancel a whole major drone program to finance additional cyberwarfare capabilities.

Piecing Together the NGAD Puzzle | Air & Space Forces Magazine

The Next-Generation Air Dominance family of systems remains highly classified. But some details are beginning to emerge.www.airforcemag.com

Hmmm, is intending to give the Mig-31 a run for it's money believable in the 21st century?The primary aircraft of NGAD is likely to fly at least as high and fast as the F-22, meaning an upper ceiling of about 65,000 to 70,000 feet and a top speed of about Mach 2.8

Now retired, former Air Force Chief of Staff Gen. David L. Goldfein said in 2019 that NGAD will be comprised of “five key technologies” that would not all “come together on a single platform” and would not all mature simultaneously. Goldfein did not enumerate the five technologies, but he later alluded to them including engines, weapons, sensors, artificial intelligence, and connectivity.Good.NGAD is likely to remain highly classified as long as the Air Force can keep it that way. Kendall, taking a page from Cold War practice, has said he’s reluctant to share the shape and features of future combat aircraft lest the U.S. provide its opponents with a “head start” on developing countermeasures.

The answer to that problem is not to have any computers that are involved in top secret aircraft programs connected to the internet, then any hostile country cannot gain access to that information.

The issue in Australia with the reallocation of funds from AIR 7003 Ph1 MQ-9B SkyGuardian buy for Project REDSPICE is more to do with the Govt over-committing themselves on multiple fronts. It is also not necessarily a done deal yet given there is an election underway.Look at Australia they literally had to cancel a whole major drone program to finance additional cyberwarfare capabilities.

- Joined

- 21 January 2015

- Messages

- 11,711

- Reaction score

- 15,074

Problem is I am not sure even air gaping computers these days means you can be free of espionage.The problem with this is you have to be able to match the cyber warfare capabilities of your opponents, let alone more conventional elements of spy craft. Look at Australia they literally had to cancel a whole major drone program to finance additional cyberwarfare capabilities.

Piecing Together the NGAD Puzzle | Air & Space Forces Magazine

The Next-Generation Air Dominance family of systems remains highly classified. But some details are beginning to emerge.www.airforcemag.com

Hmmm, is intending to give the Mig-31 a run for it's money believable in the 21st century?The primary aircraft of NGAD is likely to fly at least as high and fast as the F-22, meaning an upper ceiling of about 65,000 to 70,000 feet and a top speed of about Mach 2.8

Now retired, former Air Force Chief of Staff Gen. David L. Goldfein said in 2019 that NGAD will be comprised of “five key technologies” that would not all “come together on a single platform” and would not all mature simultaneously. Goldfein did not enumerate the five technologies, but he later alluded to them including engines, weapons, sensors, artificial intelligence, and connectivity.Good.NGAD is likely to remain highly classified as long as the Air Force can keep it that way. Kendall, taking a page from Cold War practice, has said he’s reluctant to share the shape and features of future combat aircraft lest the U.S. provide its opponents with a “head start” on developing countermeasures.

The answer to that problem is not to have any computers that are involved in top secret aircraft programs connected to the internet, then any hostile country cannot gain access to that information.

FighterJock

ACCESS: Above Top Secret

- Joined

- 29 October 2007

- Messages

- 5,142

- Reaction score

- 5,073

Problem is I am not sure even air gaping computers these days means you can be free of espionage.The problem with this is you have to be able to match the cyber warfare capabilities of your opponents, let alone more conventional elements of spy craft. Look at Australia they literally had to cancel a whole major drone program to finance additional cyberwarfare capabilities.

Piecing Together the NGAD Puzzle | Air & Space Forces Magazine

The Next-Generation Air Dominance family of systems remains highly classified. But some details are beginning to emerge.www.airforcemag.com

Hmmm, is intending to give the Mig-31 a run for it's money believable in the 21st century?The primary aircraft of NGAD is likely to fly at least as high and fast as the F-22, meaning an upper ceiling of about 65,000 to 70,000 feet and a top speed of about Mach 2.8

Now retired, former Air Force Chief of Staff Gen. David L. Goldfein said in 2019 that NGAD will be comprised of “five key technologies” that would not all “come together on a single platform” and would not all mature simultaneously. Goldfein did not enumerate the five technologies, but he later alluded to them including engines, weapons, sensors, artificial intelligence, and connectivity.Good.NGAD is likely to remain highly classified as long as the Air Force can keep it that way. Kendall, taking a page from Cold War practice, has said he’s reluctant to share the shape and features of future combat aircraft lest the U.S. provide its opponents with a “head start” on developing countermeasures.

The answer to that problem is not to have any computers that are involved in top secret aircraft programs connected to the internet, then any hostile country cannot gain access to that information.

To stop espionage these day's they should check potential employees political backgrounds thoroughly with a fine tooth comb and ban them from working on sensitive programs for good if they find anything suspicious, problem solved.

FighterJock

ACCESS: Above Top Secret

- Joined

- 29 October 2007

- Messages

- 5,142

- Reaction score

- 5,073

You're saying we should do background investigations for people with security clearances?

I should have said before they got security clearances.

Similar threads

-

Japanese next generation fighter studies (aka i3, F-3)

- Started by bobbymike

- Replies: 573

-

Russian 6th Generation Fighter News

- Started by bobbymike

- Replies: 37

-

CNO Greenert Warns Congress of Fighter Shortfall, Hornet Line to Close 2017

- Started by Triton

- Replies: 1

-

-