Trying to dig out all the details on the 1980s reloading system, I found a reference in Marvin O. Miller's Designing the U.S. Navy's Underway Replenishment System. This dates the breadboard development to 1989, though I'm sure the images posted earlier are from a 1988 publication. By 1991, Op-03 decided there was no money to fund this capability.

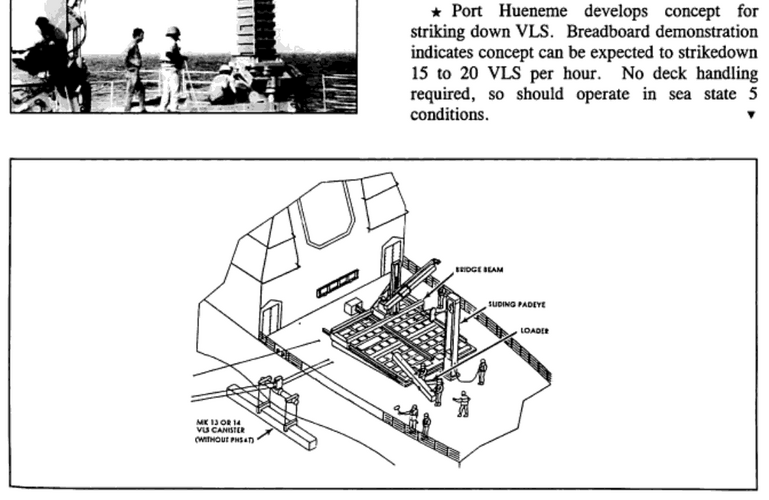

The attached diagram hopefully helps illustrate how the system works. Basically, there are longitudinal rails mounted on the deck around the VLS. The reloading rig itself rides on these rails and consists of two athwartship rails and a handling mechanism. The mechanism has two rings and a winch. It uses the rulings to grab the canister as it comes across on the high line from the supply ship, then slides both longitudinally and athwartship to position the canister at the correct cell, rotates to vertical, and winches the canister down into the cell.

The cells have to be emptied before the UNREP begins. In high-tempo operations, the spent canisters would probably be dumped overboard, or they could be crossdecked back to the supply ship for reuse. Not clear to me how the empties would be removed other than using the same rig in reverse. This is a bit of a complication, because the idea is that the mechanism is carried by the supply ship and cross-decked to the receiving ship before the UNREP proper. So you still end up spending a couple of hours alongside pulling the empty canisters, then a couple more (at least) reloading the new ones. That's a long time alongside.

View attachment 716920