The above does usefully provide rough dimensions of the versions. 100/250 are apparently 70” long, with the former being 6” and the latter supposedly 7” (though the cross section seems square rather than circular). This might allow it to roughly fill the USN MACE requirement of two per F-35 bay, though with less payload. The 500 is 13’ long and somewhat more narrow than AGM-158. It likely could fit in the F-35A/C internal bay as well.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

StandOff & PGM Weapons

- Thread starter Pit

- Start date

kqcke for you

PUMA PUMA PUMA

- Joined

- 3 November 2022

- Messages

- 1,281

- Reaction score

- 1,691

Isn't the 250 around the same size as SDB? That means in theory 4 for fitThe above does usefully provide rough dimensions of the versions. 100/250 are apparently 70” long, with the former being 6” and the latter supposedly 7” (though the cross section seems square rather than circular). This might allow it to roughly fill the USN MACE requirement of two per F-35 bay, though with less payload. The 500 is 13’ long and somewhat more narrow than AGM-158. It likely could fit in the F-35A/C internal bay as well.

Forest Green

ACCESS: Above Top Secret

- Joined

- 11 June 2019

- Messages

- 9,506

- Reaction score

- 17,393

AGM-154 Joint Standoff Weapon To Equip Ukraine’s F-16s: Report

Isn't the 250 around the same size as SDB? That means in theory 4 for fit

It looks a little too chunky for that, but possibly. SDB is 6” x 7”; if it really is 7”x7” box then it might be compatible. There certainly would be a big market for a weapon compatible with the SDB pneumatic rack. The ranges they claim to achieve with these designs make me question those sizes, although perhaps folding wings plus the very modest warhead can achieve those distances with a small turbofan. The 500 mile range for the full length -500 model seems reasonable for a full length weapon of wider diameter, especially with only 100lbs of payload. It seems roughly JSM in size but with much more volume reserved for fuel vice warhead.

This entire series definitely relies on precision delivery to make a very modest explosive content viable. An SDB 2 has the same payload as the 500 variant.

Last edited:

kqcke for you

PUMA PUMA PUMA

- Joined

- 3 November 2022

- Messages

- 1,281

- Reaction score

- 1,691

I mean If 7 Inch is the largest point in the diameter then it would fit as SDB is 70.8 in long and 7.5 in width. Even then Spear 3 is 7.1 in so it would fit.It looks a little too chunky for that, but possibly.

I mean If 7 Inch is the largest point in the diameter then it would fit as SDB is 70.8 in long and 7.5 in width. Even then Spear 3 is 7.1 in so it would fit.

I think SDB is only 6” in width, with the wings adding another inch to the vertical. But that said, it seems sized to fit on that dispenser and there is no reason to have such form factor unless you were specifically interested in that rack for internal carriage. So I suspect you are right and that this is the market they are trying to break into: F-35 users (F-15E and F-18E as well, but that’s a much smaller customer base).

Forest Green

ACCESS: Above Top Secret

- Joined

- 11 June 2019

- Messages

- 9,506

- Reaction score

- 17,393

kqcke for you

PUMA PUMA PUMA

- Joined

- 3 November 2022

- Messages

- 1,281

- Reaction score

- 1,691

Maybe its just me but Barracuda-M 250 looks like a good fit for ERAM

Maybe its just me but Barracuda-M 250 looks like a good fit for ERAM

I suspect most any of them would, though Baracuda is I think the only one we have specs for.

I idly wonder if the USAF would adopt weapons made from two or more of these test vehicles as a way to boost production.

Maybe its just me but Barracuda-M 250 looks like a good fit for ERAM

Are you referring to the SM-6?

- Joined

- 16 April 2008

- Messages

- 9,604

- Reaction score

- 14,491

Are you referring to the SM-6?

No, the Air Force Extended-Range Attack Munition, which is meant to be a 500-lb weapon with a range of 250nm.

- Joined

- 21 April 2009

- Messages

- 13,753

- Reaction score

- 7,686

Kratos Completes Significant Milestone on Cost Optimized Lim

Kratos Defense & Security Solutions, Inc. (Nasdaq: KTOS), a technology company in Defense, National Security and Global Markets, today announced that Kratos Tur

Kratos Completes Significant Milestone on Cost Optimized Lim

Kratos Defense & Security Solutions, Inc. (Nasdaq: KTOS), a technology company in Defense, National Security and Global Markets, today announced that Kratos Turwww.asdnews.com

I was wondering when some would develop something like this. It is convenient that there are off the shelf turbofans in most any size, but commercial engines are designed for long engine life hours where as for military applications, engine life can be severely truncated for missiles and even reusable UAVs. The USN and USAF are talking about CCA airframe lifetimes of hundreds of hours; a Williamsjet is going to last you thousands. Unless you are stripping out old engines and reusing them on future UAVs, it is a huge waste.

red admiral

ACCESS: Top Secret

- Joined

- 16 September 2006

- Messages

- 1,805

- Reaction score

- 2,377

Sounds a lot cheaper to pay Williams to rerate their engines for higher performance and lower life than pay a few hundred million on a new engine development

- Joined

- 9 October 2009

- Messages

- 21,969

- Reaction score

- 13,600

The paperwork alone would be likely a killer though.

Sounds a lot cheaper to pay Williams to rerate their engines for higher performance and lower life than pay a few hundred million on a new engine development

Depends on the trade offs being made. It sounds like there were also thrust improvements as part of goal, along with cheap parts and production. That is a lot more than simply asking WJ to relax their testing standards.

ETA: and more over Kratos probably wants to internalize their supply chain if possible, as well as break into a new expanding market that current engine makers do not occupy. Anduril is looking at 3D printing turbine parts for short hour life engines as well.

red admiral

ACCESS: Top Secret

- Joined

- 16 September 2006

- Messages

- 1,805

- Reaction score

- 2,377

There's also paperwork in developing a new engineThe paperwork alone would be likely a killer though.

Rerating = increased temp for lower life hot section, could also look at rpm increases etc. for this sort of application. Its not relaxing testing standards, its simple operating limit changes to get more performance but with reducing life and margin.Depends on the trade offs being made. It sounds like there were also thrust improvements as part of goal, along with cheap parts and production. That is a lot more than simply asking WJ to relax their testing standards.

The Williams engines are already cheap off the back of many years of production. Sure you could probably trim some cost with a new bespoke engine, but you need to sell a lot of engines to recoup those development costs and start saving money.

Scott Kenny

ACCESS: USAP

- Joined

- 15 May 2023

- Messages

- 11,599

- Reaction score

- 14,290

Agreed, remember that the USAF used a significantly-uprated early J52 engine designed for the A-4 Skyhawk to power their Mach 2 supercruising Hound Dog missile. They just ran it faster and hotter, for a ~3 hour expected life.Rerating = increased temp for lower life hot section, could also look at rpm increases etc. for this sort of application. Its not relaxing testing standards, its simple operating limit changes to get more performance but with reducing life and margin.

The Williams engines are already cheap off the back of many years of production. Sure you could probably trim some cost with a new bespoke engine, but you need to sell a lot of engines to recoup those development costs and start saving money.

Fair enough, you can trade thrust for engine life. But the Kratos effort seems to also attempt to trade cost for engine life as well. I think they are looking for ways to cut manufacturing costs if your engine only has to last for dozens or low hundreds of hours.

- Joined

- 23 August 2011

- Messages

- 1,610

- Reaction score

- 4,771

Agreed, remember that the USAF used a significantly-uprated early J52 engine designed for the A-4 Skyhawk to power their Mach 2 supercruising Hound Dog missile. They just ran it faster and hotter, for a ~3 hour expected life.

And in the other direction J-85 going into F-5 and Viper into Jet Provost, with both engines finding a massive number of platforms to be used in...

Forest Green

ACCESS: Above Top Secret

- Joined

- 11 June 2019

- Messages

- 9,506

- Reaction score

- 17,393

Was A Mini "Sword Bomb" Just Used To Strike A Car In Lebanon?

Damage to the car's windshield has prompted comparisons to the AGM-114R9X missile with its pop-out blades, but there are other possibilities.

TAOG

I really should change my personal text

- Joined

- 7 October 2018

- Messages

- 108

- Reaction score

- 241

According to 9/6 DIU informatuon, only three vender will conduct flight test by the end of Sep., and the last one will conduct flight test by end of Nov.

"...A spokesperson for DIU confirmed to DefenseScoop that three of the four vendors are scheduled to conduct test flights for their ETV prototypes no later than September 2024. The fourth company will fly by the end of November 2024, they added...."

Air Force secures its first Replicator system as part of second tranche

The Defense Department selected an Air Force program for inclusion in its second tranche of Replicator capabilities, DefenseScoop has learned.

Also, the winner of ETV will be the Replicator 1.2.

(Switchblade 600 is the Replicator 1.1 winner)

TAOG

I really should change my personal text

- Joined

- 7 October 2018

- Messages

- 108

- Reaction score

- 241

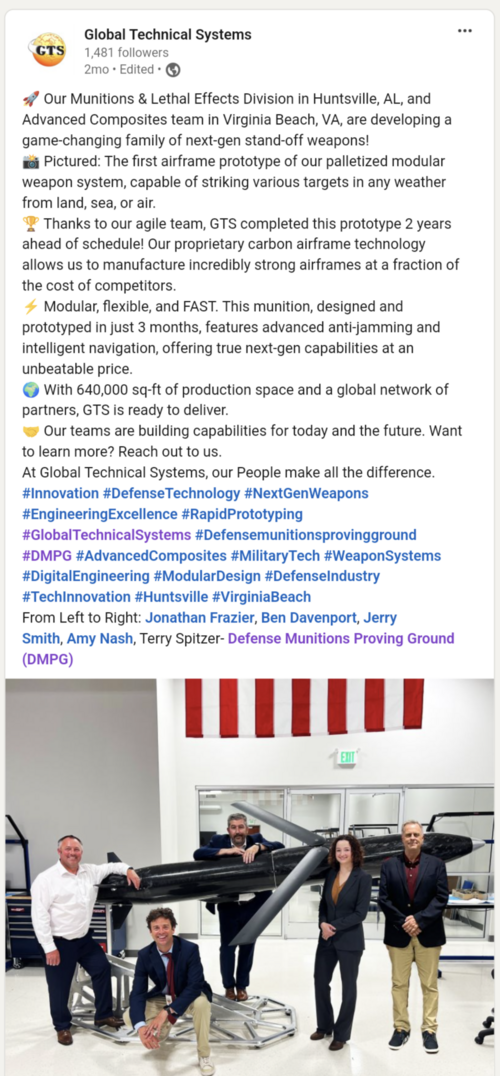

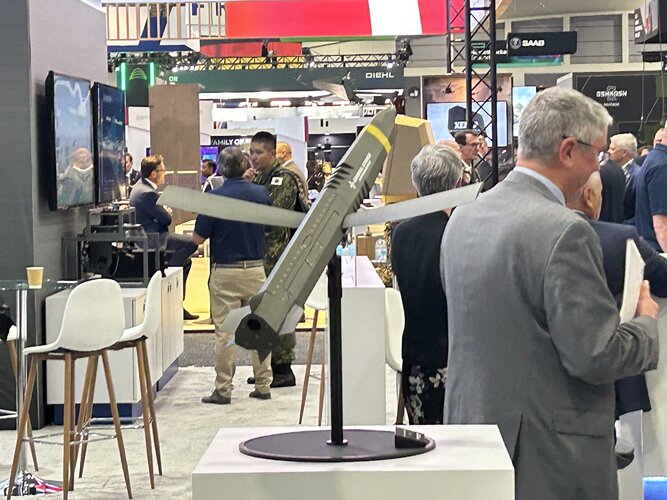

Global Technical Systems/ ACE-M (air launch)

Range: 1000nm

Total weight: 625 lb

Payload: 105 lb (anti maritime warhead)

Guidance: GPS/INS/Terminal

Comms: Dual band (S/C) wave relay with data link

Seeker: EO/IR

Cost: 150K

----------------

The cost is as same as ETV goal, but GTS is not the one along the four ETV competitor.

Update: picture 2/3 were taken on AFA 2024. (Post on Linkedin.com)

Range: 1000nm

Total weight: 625 lb

Payload: 105 lb (anti maritime warhead)

Guidance: GPS/INS/Terminal

Comms: Dual band (S/C) wave relay with data link

Seeker: EO/IR

Cost: 150K

----------------

The cost is as same as ETV goal, but GTS is not the one along the four ETV competitor.

Update: picture 2/3 were taken on AFA 2024. (Post on Linkedin.com)

Attachments

-

img-172754413429703184b1fe7c11429d737b9e8ba62141ed3147b39ea9f3c59ac15b03db834f9f5.jpg245.3 KB · Views: 48

img-172754413429703184b1fe7c11429d737b9e8ba62141ed3147b39ea9f3c59ac15b03db834f9f5.jpg245.3 KB · Views: 48 -

img-1727544136476d1b646d42d77d3bc42ade26e74c370a6b8613326f14e2232567632b42130f63d.jpg216.2 KB · Views: 40

img-1727544136476d1b646d42d77d3bc42ade26e74c370a6b8613326f14e2232567632b42130f63d.jpg216.2 KB · Views: 40 -

img-17275441386237cbd04ccf2e9b27c7f0317625e436d564d0eb10479e2741a722f84096d7f0fad.jpg301.5 KB · Views: 33

img-17275441386237cbd04ccf2e9b27c7f0317625e436d564d0eb10479e2741a722f84096d7f0fad.jpg301.5 KB · Views: 33 -

Screenshot_20240929-012800.png1.1 MB · Views: 36

Screenshot_20240929-012800.png1.1 MB · Views: 36

Last edited:

TAOG

I really should change my personal text

- Joined

- 7 October 2018

- Messages

- 108

- Reaction score

- 241

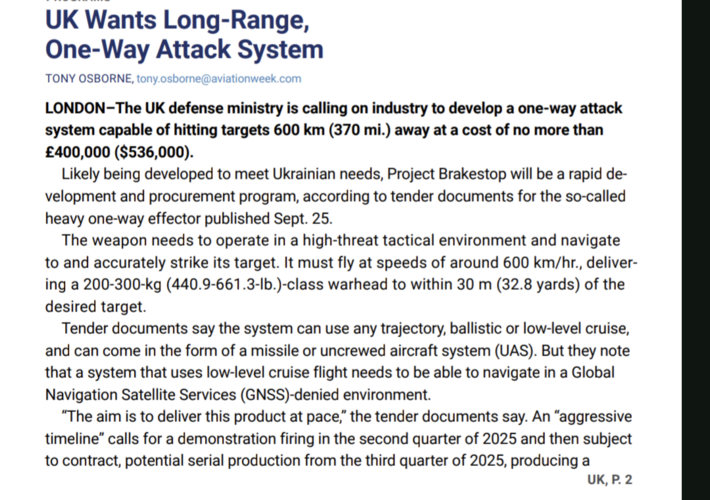

UK Brakestop project

The Ministry of Defence has not explicitly defined whether the system required under Project Brakestop will be a missile, drone, or another technology. The notice instead leaves the solution open to interpretation, stating that the One Way Effector (OWE) can be delivered via “any trajectory (ballistic or low level cruise)” and that it should be able to “navigate in a GPS denied environment”.

Demonstration firing by Q3 2025 and potential serial production from Q4 2025. “There is an aggressive timeline of a demonstration firing in Q2 2025 and, subject to contract, potential serial production from Q3 2025, producing a minimum around 20 platforms per month.”

ukdefencejournal.org.uk

ukdefencejournal.org.uk

ukdefencejournal.org.uk

----------------

ukdefencejournal.org.uk

----------------

I think it is hard to fullfill the payload/ range/ speed requirement under this low cost ($536,000).

The Ministry of Defence has not explicitly defined whether the system required under Project Brakestop will be a missile, drone, or another technology. The notice instead leaves the solution open to interpretation, stating that the One Way Effector (OWE) can be delivered via “any trajectory (ballistic or low level cruise)” and that it should be able to “navigate in a GPS denied environment”.

- Range: >500 km

- Payload: 200-300 kg (Mk 82 bomb sized payload)

- Speed: Approximately 600 km/h

- Launch: Ground-launched from a mobile platform

- Cost: Target cost of £400,000 per delivery platform (excluding VAT)

- Guidance: Operable in GPS-denied environments, resistant to EW attack.

- Accuracy: < 30m

- Scalability: Minimum production rate of 20 units per month

Demonstration firing by Q3 2025 and potential serial production from Q4 2025. “There is an aggressive timeline of a demonstration firing in Q2 2025 and, subject to contract, potential serial production from Q3 2025, producing a minimum around 20 platforms per month.”

Britain to build 20 large one way attack drones per month

The Ministry of Defence has revealed plans for a new long-range strike weapon under the codename Project Brakestop, which aims to produce a minimum of 20 units per month.

ukdefencejournal.org.uk

ukdefencejournal.org.uk

Britain developing new long range strike weapon

Project Brakestop signals the UK’s intent to develop a new long-range strike system capable of delivering precision strikes at long range in high-threat environments.

ukdefencejournal.org.uk

ukdefencejournal.org.uk

I think it is hard to fullfill the payload/ range/ speed requirement under this low cost ($536,000).

Attachments

Global Technical Systems/ ACE-M (air launch)

Range: 1000nm

Total weight: 625 lb

Payload: 105 lb (anti maritime warhead)

Guidance: GPS/INS/Terminal

Comms: Dual band (S/C) wave relay with data link

Seeker: EO/IR

Cost: 150K

----------------

The cost is as same as ETV goal, but GTS is not the one along the four ETV competitor.

That seems like an incredibly low launch weight for the payload and range. And an absurdly cheap price. They must have found a really cheap way to work with carbon fiber, IMO.

Forest Green

ACCESS: Above Top Secret

- Joined

- 11 June 2019

- Messages

- 9,506

- Reaction score

- 17,393

"Footage has been published of a Russian Su-34 fighter bomber attack, presumably with an ODAB-1500 vacuum bomb. The video was filmed in Vovchansk, Kharkiv Oblast, Ukraine. There is no official ODAB-1500 bomb, but the presence of the bomb was confirmed by Colonel General Alexei Kim in March 2024, reporting at a meeting to Russian Defense Minister Sergei Shoigu on the use of such an aerial bomb."

View: https://www.youtube.com/watch?v=6fVnxSf7bLM

TAOG

I really should change my personal text

- Joined

- 7 October 2018

- Messages

- 108

- Reaction score

- 241

Leidos low cost Black Arrow missile

I think it is the Leidos's proposal for ETV program competing.

Length: 80 inch

Diameter: 9 inch

Weight: unknown, but MQ-9 can carry eight of these missile

www.airandspaceforces.com

www.airandspaceforces.com

www.defenseone.com

www.defenseone.com

--------------------------

It is originated from SOCOM 2021 Stand-Off Precision Guided Weapon Program Cruise Missile, which request the missile have a range about 200nm-400nm, and fit in CLT.

CLT can accommodate payloads up to 42 inches in length and 5.95 inches in diameter, and has a 100-pound weight limit. But current Black Arrow missile is 80 inch in length and 9 inch in diameter, much larger than previous requested spec.

www.twz.com

www.twz.com

I think it is the Leidos's proposal for ETV program competing.

Length: 80 inch

Diameter: 9 inch

Weight: unknown, but MQ-9 can carry eight of these missile

Leidos: 'Black Arrow' Small Cruise Missile Ready for Flight Test

Leidos is about to begin flight tests with its "Black Arrow" Small Cruise Missile off an AC-130 for Air Force Special Operations Command.

New small cruise missile slated for SOCOM gunship test

Digital engineering is helping smaller companies make big leaps in missile design.

--------------------------

It is originated from SOCOM 2021 Stand-Off Precision Guided Weapon Program Cruise Missile, which request the missile have a range about 200nm-400nm, and fit in CLT.

CLT can accommodate payloads up to 42 inches in length and 5.95 inches in diameter, and has a 100-pound weight limit. But current Black Arrow missile is 80 inch in length and 9 inch in diameter, much larger than previous requested spec.

Our First Look At The Tiny Cruise Missile That Aims To Arm AC-130 Gunships

Special Operations Command sees a mini-cruise missile as a top priority that will help ensure the relevance of AC-130s and other aircraft.

Attachments

Last edited:

Forest Green

ACCESS: Above Top Secret

- Joined

- 11 June 2019

- Messages

- 9,506

- Reaction score

- 17,393

CLT = Common Launch TubeIt is originated from SOCOM 2021 Stand-Off Precision Guided Weapon Program Cruise Missile, which request the missile have a range about 200nm-400nm, and fit in CLT.

Mentioned here:

AC-130J Ghostrider Gunship Has Operated From A Highway For The First Time

Operating from highways could make AC-130J gunships more survivable and flexible, but questions remain about their role in high-end fights.

New MD Explorer Gunship Features Internal Tubes For Launching Guided Munitions And Drones

Internal launch tubes offer a big boost in firepower in a compact package and they may become far more common on armed helicopters in the future.

Forest Green

ACCESS: Above Top Secret

- Joined

- 11 June 2019

- Messages

- 9,506

- Reaction score

- 17,393

LIG Nex1 Poniard guided rocket poised to revolutionize coastal defense at KADEX 2024

Forest Green

ACCESS: Above Top Secret

- Joined

- 11 June 2019

- Messages

- 9,506

- Reaction score

- 17,393

^That's from the In Combat publication 30+ years ago.

- Joined

- 16 April 2008

- Messages

- 9,604

- Reaction score

- 14,491

No, retarded in this case means delayed or slowed down, using drag brakes or ballutes (basically parachutes) to ensure that a plane dropping them from low altitude has time to escape before they explode. Retarded bombs are not generally guided (there are exceptions, for sure, like smart submunitions that use parachutes, but they are special)

Last edited:

Forest Green

ACCESS: Above Top Secret

- Joined

- 11 June 2019

- Messages

- 9,506

- Reaction score

- 17,393

It's basically to allow aircraft to drop them at low altitude without showering the underside of their aircraft with shrapnel.

kqcke for you

PUMA PUMA PUMA

- Joined

- 3 November 2022

- Messages

- 1,281

- Reaction score

- 1,691

red admiral

ACCESS: Top Secret

- Joined

- 16 September 2006

- Messages

- 1,805

- Reaction score

- 2,377

Only the NG branding distinguishes this video from an MBDA one for SPEAR

aonestudio

I really should change my personal text

- Joined

- 11 March 2018

- Messages

- 2,964

- Reaction score

- 7,492

Northrop Grumman Releases New Details And Video Of Its Jackal Loitering Munition

Northrop Grumman is developing the Jackal, a turbojet-powered next gen missile designed for precision strikes. This versatile weapon features modular

Forest Green

ACCESS: Above Top Secret

- Joined

- 11 June 2019

- Messages

- 9,506

- Reaction score

- 17,393

Secretive Phoenix Ghost Kamikaze Drones Rushed To Ukraine Finally Come Out Of The Shadows

Phoenix Ghost was only mentioned but never seen as part of aid for Ukraine that was announced shortly after Russia's invasion began.

kqcke for you

PUMA PUMA PUMA

- Joined

- 3 November 2022

- Messages

- 1,281

- Reaction score

- 1,691

Saw this in person last week at AUSA:

Also some info here:

Also some info here:

Precision Guided Munitions

General Atomics Electromagnetic Systems (GA-EMS) precision guided munitions provide increased lethality and overmatch to the warfighter.

www.ga.com

Similar threads

-

Article Related to Some of Russian Air Launched Missile Programme

- Started by ocay

- Replies: 0

-

-

-

Air to Ground Combat Tactics: Use of PGM on night and poor visibility

- Started by Pit

- Replies: 3

-