Sikorsky's X2 helicopter programme has a mixed R&D heritage, and could be the model for the next generation of rotorcraft designs

Along with broadening the realm of vertical lift, first flight of Sikorsky's internally funded X2 compound helicopter demonstrator in the fourth quarter this year will also spotlight what may become the best model for introducing new civil and military rotorcraft designs - do it yourself.

DIY models could become widespread in the US rotorcraft industry, with limited amounts of government funding available for research and development and demonstrator vehicles that showcase transformational technologies.

The US government continues to invest in the basic and applied research that helps manufacturers create breakthrough aircraft. However, the prime focus for most funding has become results-oriented incremental component or operational efficiency improvements to aid the US military on the battlefield.

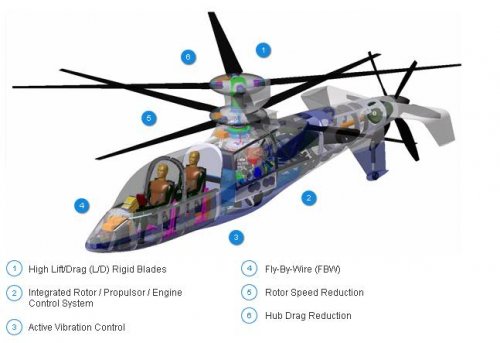

Though the X2 concept is the result of much of that government-funded R&D, the demonstrator itself is 100% Sikorsky funded, and features a frugality and simplicity that reflects who is paying the bill. The aircraft is being built from numerous off-the-shelf components scavenged from near and far to keep costs low so much so that Peter Grant, Sikorsky advanced programmes manager, affectionately refers to the two-seater as a "mongrel". It uses dual rigid counter-rotating coaxial main rotors and a pusher propeller to reach cruise speeds of 250kt (462km/h), well beyond the 170kt maximum speed for conventional helicopters.

The X2 has a mixed heritage of government and industry R&D in rotor systems, propulsion, aerodynamics and controls technologies that will help it meet performance goals of high speed and "low" vibration - about the same vibration level as a traditional helicopter at its top speed of 140kt.

The X2's chief predecessor, the XH-59A advancing blade concept (ABC) helicopter, was built by Sikorsky and funded by the US Army, NASA, Sikorsky and others. Two vehicles were built and readied in two years, starting in 1971, a time when the US government funded such experimental aircraft.

The goal was to test the premise that rigid counter-rotating main rotors, where the advancing blade on each side produces lift while both retreated blades are feathered, could be used reduce drag and tip velocities to allow for cruise speeds well above the norm for helicopters. During testing from 1973 to 1977, Sikorsky pilots reached 240kt with the help of two fuel-thirsty auxiliary turbojets.

Though it was successful, the flight-test programme proved that the concept was ahead of its time because the technologies needed to solve key issues - high vibration levels, tedious mechanical control mechanisms and inefficient power management - have only recently become available. [Emphasis mine]

"We believe it now makes this configuration feasible for next generation helicopter flight," says Grant.

The maturation was due in large part to government-funded research on military contracts, among them the Boeing-Sikorsky Comanche advanced light attack helicopter, cancelled by the US military in 2004, and its precursor, the Shadow programme, an S-76 with fly-by-wire (FBW) flight controls. Both provided the knowledge base for the X2's flight controls.

The means to control vibrations came partly from the military-funded UH-60M Black Hawk upgrade programme. Coaxial rotor design expertise came partly from the Cypher programme, a vertical takeoff and landing unmanned air vehicle demonstrator that Sikorsky developed under a US Marine Corps contract.

Solving specific problem areas through directed research, rather than funding whole demonstrator aircraft, continues to be the R&D focus for the US government. Its research is largely provided by the US Army and NASA for basic and applied research, and the Defence Advanced Research and Projects Agency (DARPA) for long-term, high-risk and potentially lucrative projects.

NASA's civil programme

NASA is planning to spend more than $40 million a year for the next four years on rotorcraft research as part of its fundamental aeronautics programme, which has a budget of $890 million.

"We're doing a host of fundamental research geared towards improved utility of civil helicopters," says Juan Alonso, programme director at NASA.

The research includes a programme to reduce rotor tip speed at cruise by 50% from hover to boost speed and reduce noise. NASA is also developing advanced control system design tools, creating new structures that reduce interior noise and vibration, and developing new tools to validate and assess helicopter capabilities and predict behaviour.

US Army investment

The US Army is investing approximately $100 million annually in R&D. This is split between its research labs, and aviation and missile Research, Development and Engineering Center (RDEC). It is focusing most of its funds on applied technologies. The army's primary R&D areas for rotorcraft include mission systems, power and drives, operations support and sustainment, and systems concepts and analysis.

Given the continued conflict in Afghanistan and Iraq, the army is naturally placing a premium on R&D that can lower the operating costs and improve the performance and safety of its helicopters. Projects within RDEC include efforts to reduce blade erosion from sand and preventing brown-out accidents through new cockpit technologies, a project the army is working on with DARPA.

The RDEC is involved in longer term projects as well, including an individual blade control (IBC) programme with Sikorsky to boost future helicopter performance, and decrease noise and vibration. Testing of a full size UH-60 blade with IBC will begin in August at the National Full-Scale Aerodynamics Complex (NFAC) at NASA's Ames Research Centre, a windtunnel facility the army and air force now operate after NASA reduced its testing infrastructure in 2002.

When the IBC testing is finished in the autumn, the army will begin experimenting with a Boeing-built "smart" rotor that uses active flaps on the blade to control vibration and noise, says Barry Lakinsmith, acting director of the RDEC's Aeroflightdynamics directorate. Though progress is being made, Lakinsmith says active rotor control research in the USA lags behind that being done abroad.

"Europe's being more aggressive on full scale active rotors. It's been difficult for us to match that given the war fight," he says.

At the US Army Research Laboratory (ARL), research is more open-ended, and can be applied to helicopters as well as ground vehicles or missiles. The big driver within ARL's vehicle technology directorate (VTD) is the Joint Heavy Lift (JHL) programme, says Mark Nixon, VTD director.

JHL, on which the military recently completed a study phase by four vendors, including Sikorsky, calls for a range of vehicles that can lift as much as 26t of Future Combat System equipment, in some cases at high speeds.

Nixon's team of 80 employees working at two NASA centres has been focusing on the ultra lightweight but protective composite structures that such an aircraft would need to provide safe travel for troops as well as increased performance. The army says it might fund a demonstrator version of the JHL in the 2015 timeframe.

Rotorcraft industry advocates have said the R&D needed to realise the development of the JHL is underfunded by about a factor of 10. Most vocal has been Rhett Flater, executive director of the American Helicopter Society, who says a sustained investment of $2 billion a year for the next five to seven years is needed for basic research.

Nixon does not necessarily agree. "I can't say we're so under-funded we just won't get there," he says, noting that the required R&D will depend on the aircraft the military chooses. An entrant like Bell's quad tiltrotor JHL candidate, for example, should not require as much research as other candidates as much of the R&D work has already been accomplished on the V-22 Osprey programme, he says.

X2 joint heavylift

Many key foundation technologies for Sikorsky's JHL entrant, a much larger version of the X2, will be tested when the X2 demonstrator takes flight later this year. Included are active vibration control centralised around the transmission, a method designed to "short circuit vibrations at their origin", says Grant. Sikorsky currently uses distributed active vibration damping systems for its production helicopters.

Once first flight is completed, Grant says his goal will be to get to high speed flight as quickly as possible. The company plans four phases of flight tests, beginning with hover and low-speed work later this year, followed by phases 2 to 4 throughout next year.

For Sikorsky, the benefits of DIY would appear to outweigh the financial risks of going it alone.

"Early on, we wanted to do this independently," says Grant. "It's best for allowing it to proceed that much more quickly."

There's another advantage to 100% internal funding: "If it's important for Sikorsky's future, we want to keep it within the company," adds Grant.