Exactly.

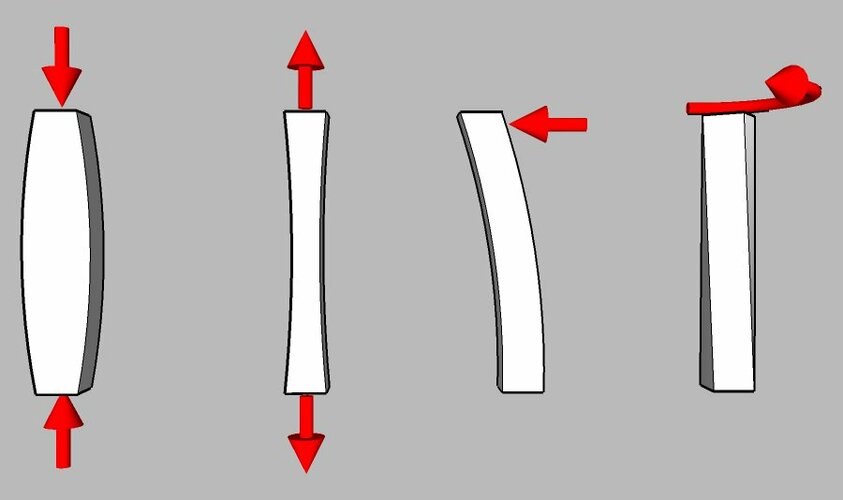

It's like he saw the very impressive tensile strength of CF and never thought to ask WHY no one was using it in submersibles, or at least not more than once.

Even after professionals who actually design submersibles sought him out to explain it using very small words ...

I agree, but with a major caveat.

I don't think it's particularly crazy to use composites in such a case. It should be the sort of thing people are interested in testing. Different patterns and materials tested at depth makes fine sense to me. Doesn't even bother me that he used out of spec commercial aviation material. Everyone after a five minute primer would understand what problems are going to likely pop up. If you want to try to find something that works in spite of that, go for it.

What

is absolutely crazy is making a

commercial diving program using the same carbon fiber elements repeatedly. If he wanted to brave the unknown testing this stuff, ignoring safety standards, then I'd give him a round of posthumous applause while looking sideways at the level of foolhardiness/madness many such explorers possess. When you start selling seats on such a venture, however, you are implying a base-level of safety that did not exist.

Go down, test the vessel over multiple trips, preferably without a crew. Drop it down on a tether. Let the weight-attachments disolve after X-hours. Recover it and pour over it. Could have done an exhaustive autopsy on the material after one dive cycle. Then two cycles. Then three. Then four, until you get a handle on what is happening to your fibres and what cracking, delam, and debonding is taking place in these cycles. But that would take money.

Should be testing it to destruction to be honest. Heaven knows how many things and components of things I've had to test to destruction.

It might be entirely possible to bond a composite section good for two or three (or even four or five or a dozen) trips to titanium or steel endcaps. It might even wind up being cheaper than a steel/titanium pressure vessel if the processes were proven and you were making enough trips to make the economies of composite section production and assembly scale up (but I doubt it). You would have to find that particular pattern and thickness that works well for your application, and whatever bonding process,

first -- and it probably isn't the combination you decided to take a SWAG on for your first batch.

I do think he was perfectly reasonable looking at the application. I think it's great, in fact. It's like the game controller. That is the least concerning thing about this. What's concerning is that he would risk his, and worse, others' lives testing an experimental vessel

in a commercial venture. But exploring the composite use case is perfectly reasonable at face value. I'd be stunned if the Navy, for instance, has not conducted many, many tests with results sitting in a file somewhere buried never to see the light of day. (I'd be stunned if they had an affordable and reuseable composite submarine pressure vessel, too, but I'm sure they've tried a hundred different ways to do it).