- Joined

- 15 January 2021

- Messages

- 396

- Reaction score

- 1,449

If by swept IGV you mean being angle to the rear from the OD to the nose cone, the F110 fan has a similar feature where the flow path is angled outward from the centerline, creating a bulged flow path from the outer inlet interface to the tips of the first stage fan blades. This allowed GE to fit a larger fan behind the F100 sized duct interface on the F-16. Don’t know if this has anything to do with increased fan size from the XF120 to YF120 - maybe the inlet ducts were already fixed in size before GE made this change. There may be other reasons for this feature.Its surprising how swept those guide vanes are. They almost mask the fan face but perhaps that's just how they left at after mothballing?You are correct - the static display engine is the YF120. The engines installed in this airframe PAV-1 are the YF119 engines.

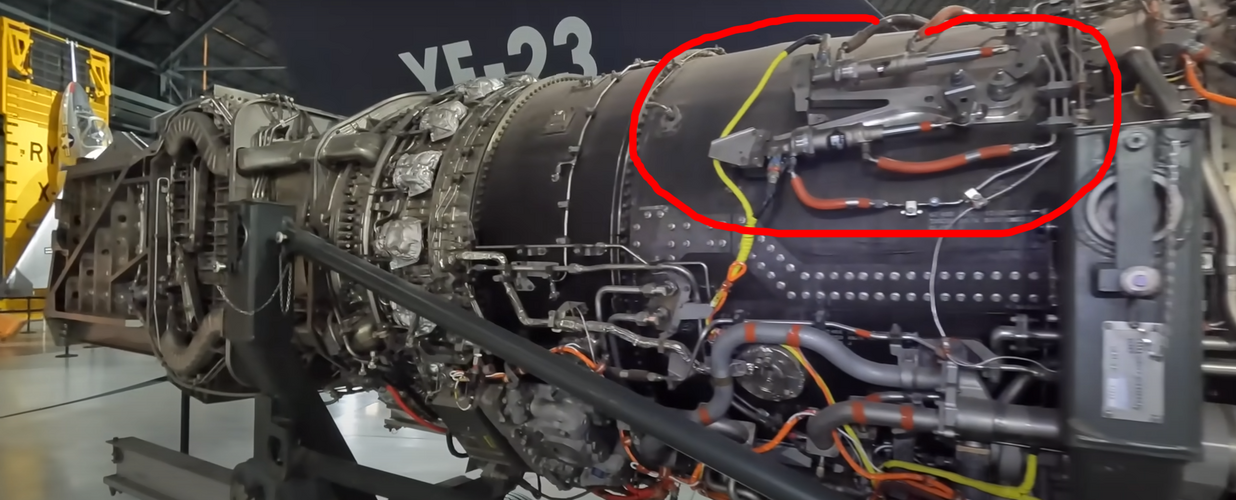

If you know anything about jet engines, at approximately 8:30 in the video on the right side of the YF120, you will see two separate variable vane actuators, instead of the single actuator that you normally see to move the core compressor variable vanes. I’m guessing that the vanes in front of the core mounted 3rd fan stage and the variable vane at the inlet of the core proper were controlled independently as part of the variable bypass control system.

Edit: Rewatching that footage the fan is quite visible. I have seen another picture of the YF120 where the fan is barely visible. WTFV

As for not being able to see the fan blades thru the IGVs, remember that there are variable trailing edge flaps behind the fixed struts that are in a cambered position at low rotor speeds and move axial at high rotor speeds. On the production F119 they implemented a feature that moved these variable flaps into a axial position during engine shutdown to facilitate fan blade inspection and repair, at the request of he YF119 flight test maintenance team.