Scott Kenny

ACCESS: USAP

- Joined

- 15 May 2023

- Messages

- 11,553

- Reaction score

- 14,169

The case itself has 3 parts, Stainless steel case head, brass case body, and a lockwasher between the two. So there's a whole assembly step that has to happen to those stupid things before you can load the casing.Weren't they saying they had improved the manufacturing process for the hybrid-case design since the first iterations of it? That seems like a ridiculously high figure per cartridge unless the bullet has a tungsten core or it's something else that isn't standard issue ball/tracer.

All of which adds costs.

But yes, the extreme pressure round is for busting the Russian dreadnought body armor. So it's probably tungsten core if not DU. And frankly tungsten is the more expensive option there, since DU is a waste product from reactor fuel.

The only reason SIG had ludicrous pressures is because their rifle design needed a 13" barrel to come under the length limit with the suppressor on.Regardless of what happens with that, I still think it's worthwhile to continue investing in development work on the cased-telescoped ammo and small arms designs to utilize it. The True Velocity ammo has some potential but from what I read wasn't suitable for the unusually high pressures NGSW requirements sort-of necessitated.

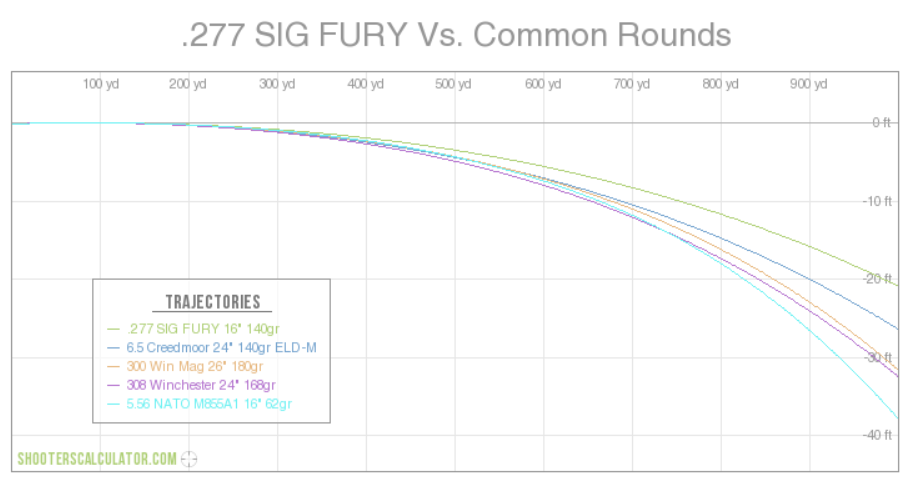

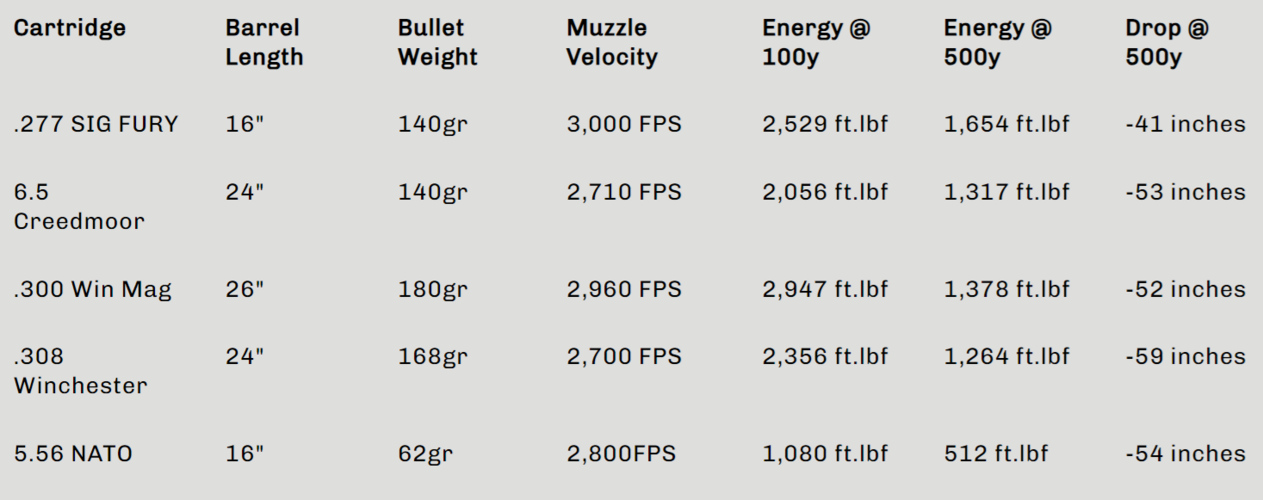

The bullpup rifle worked just fine at regular pressures, because its barrel was some 18-22" long (I forget the exact spec, want to say 20"). And the spec for the cartridge was fundamentally 140gr at 3000fps, which is .270 Winchester loads. If you can use 1950s powders to get a 150gr bullet at 2800fps out of 7.62x51 instead of x63, you can do the same thing with a .277 bullet instead.

I really hope Truevelocity can get their ammo out into the world as a more standard thing. Especially practice ammo stuff, where you want it to be as cheap as possible.

There used to be some pure-polymer shotgun ammo out there in the early 2000s, not sure whatever happened to them. Probably low number of reloading times. But they sponsored a lot of various shotgun competitions back in the day, and each loading type was color-coded on the casing (1oz of #6 shot was red, 1oz of #8 was green, etc. Think I'm right on the colors.). You'd just shovel all the empties into the appropriate color box at the end of the day.