ok, thanks.

"Any obstruction to direct fan flow reduces that flow."

agreed. The LS design has stators behind the fan, required to hold the centerbody with the electric motor. Beyond those, there aren't other obstructions. I think all ducted fans to date have had stators, unless they're rim motors.

"Large numbers of in serial fans adding weight and complexity while reducing reliability are an engineering lark. Four or even five sounds fine. The less the better."

It's a tradeoff. The goal is to maintain a trimmed T/W slightly greater than one in the event of one, or worse two engine/motor failures. With two motors only, in an emergency each has to be sized to provide twice the nominal hover power. So you're lugging around engines twice as big as they need to be. It's actually worse than that, because unless both motors are located at the cg, they will induce a turning moment along one of the axes. If you have four independent motors on a wing, you start being able to cope with the problem by overspeeding the good motor on the side of the failure and cutting down the power of the two motors on the other side, and each motor must provide "only" 4/3 of the nominal hover thrust. As you increase the number of motors this gets better. There's the old joke of the frustrated Cessna 152 pilot who's out of fuel, waiting to land and is told to wait because an eight-engined B-52 has lost one engine. Yeah, if you've got eight, engine out is a non-event.

I think what is missed here is that while with gas turbine or ICE engines, more units of smaller power are heavier than a single large unit of equivalent total power, with electric machines the disadvantage is not quite as bad, so you pay less of a penalty for distributed propulsion. You can also try to recoup some of the weight penalty by using the thrust differentially and getting rid of rudders, for example.

"These designs push no envelopes but are easily demonstrated which is all that is truly sought"

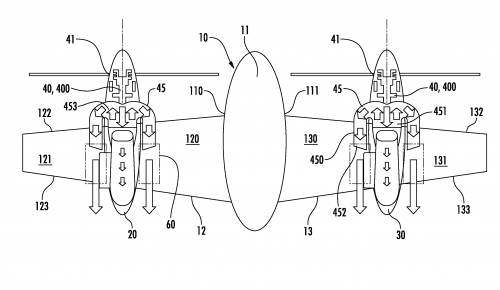

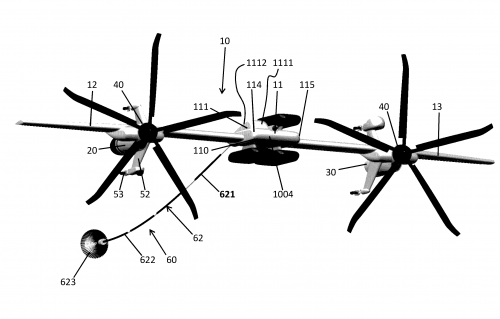

I'll respectfully disagree. I don't think there's anything easy in the aerodynamics and control laws of a distributed propulsion VTOL unlike any in the wheel of VTOL misfortune. If you look at the wing/duct units, it looks nothing like older ducted fan vehicles like, say, X-22 or Doak.

Building and flying the XV-24 will require working out the practical aspects of megaWatt class power systems on airplanes. What's the most electric power flown on aircraft today? it might be the 787, which is at least an order of magnitude less. What's learned there can be applied to increasingly electrified aviation, regardless of whether it's VTOL, commercial or military. Rolls Royce Libertyworks is one of the partners, and they're already using what they're learning in commercial offerings. Honeywell's MW flight-rated lightweight generator will come in handy as soon as the air force gets serious about lasers.