Agility, Speed Are Keys to Survival

With today's lightweight handheld weapons, the foot soldier or the light and very mobile weapons carrier can knock out the most formidable of armored equipment.

Thus the basic rule for vehicle survival has become: Don't get hit!

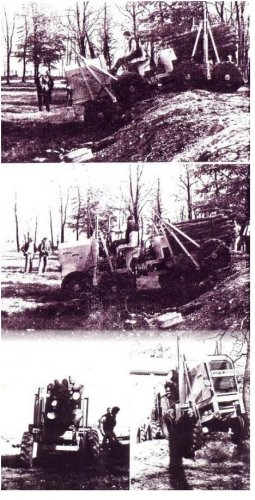

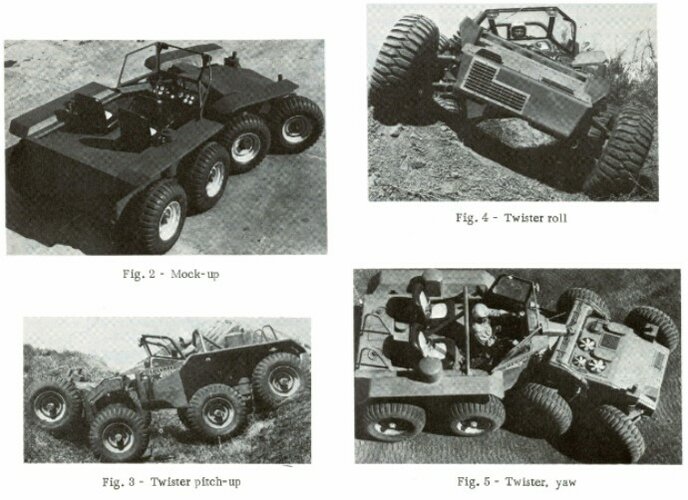

It was to increase these chances of survival that Twister was developed. High speed on and off road-ways, rapid acceleration, quick stops and short turns make Twister a fleeting target. And the vehicle maneuvers over all kinds of terrain – broken ground, snow banks, deep sand and rice paddies. Twister charges where other vehicles must crawl, it rolls through boulder-strewn fields and gullies that stop other vehicles.

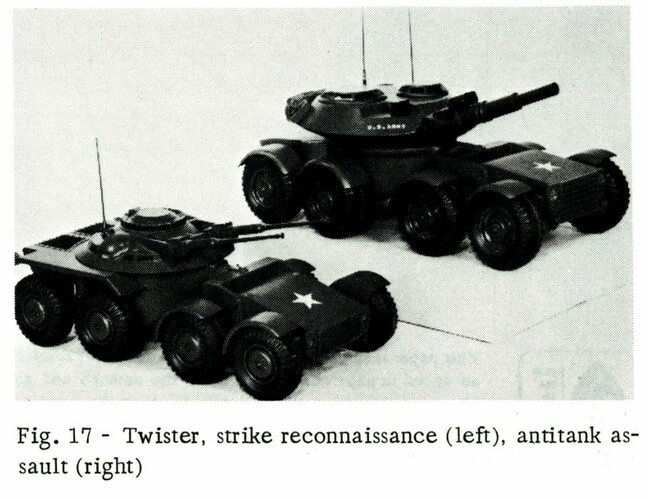

It is logical, therefore, that the first military roles proposed for Twister are those of a fighting vehicle. The first Army requirement for which Twister is a candidate is a combat vehicle that demands the ut-most in speed and agility – the Armored Reconnaissance Scout Vehicle.

Other likely military roles for vehicles with Twister’s talents are in advanced forward area air defense, anti-tank assault, mechanized infantry combat, and convoy escort. LMSC’s Ground Vehicle Systems organization has done concept work on all these kinds of vehicles and has aroused considerable Army interest in each of them.

In fighting vehicle roles, the potential pay-off of Twister is fourfold.

- First, because all Twister fighting units can move faster, larger forces can be brought to bear at critical points on the battlefield.

[…]

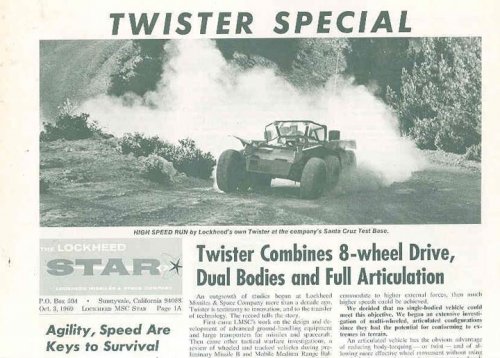

Twister Combines 8-wheel Drive, Dual Bodies and Full Articulation

An outgrowth of studies begun at Lockheed Missiles & Space Company more than a decade ago, Twister is testimony to innovation, and to the transfer of technology. The record tells the story.

First came LMSC’s work on the design and development of advanced ground-handling equipment and large transporters for missiles and spacecraft. Then came other tactical warfare investigations, a review of wheeled and tracked vehicles during preliminary Missile B and Mobile Medium Range Ballistic […] tank and tank destroyer vehicles.

The studies gave LMSC researchers and engineers a thorough understanding of vehicle limitations, performance tradeoffs, and modern tactical vehicle needs. And they especially pointed up the difficulties of achieving good cross-country speed when maintaining ride quality and platform stability at high speeds.

With these studies as background, LMSC in the early 1960’s took a searching look at the requirements and limitations of military combat vehicles. The new program was one of several in the company’s long-range plan for diversification.

This investigation, which included combat effectiveness studies, quickly showed us the Army no longer could depend on carrying the fight from behind several inches of armor plate mounted on slow moving vehicles. Weaponry had advanced too fast; individual enemy footsoldiers are now armed with inexpensive weapons whose warheads are capable of penetrating our thickest armor.

To survive and win in combat against this increased enemy firepower, it appeared that the key is higher speed and agility, together with new tactics such as the “shoot and scoot” concept, increased use of natural cover, and the ability to concentrate and disperse combat vehicle forces more rapidly.

But there’s a limit on how fast present military vehicles can move over rough terrain. The threshold of human tolerance is soon reached because of forces transmitted through the vehicle. If these transmitted forces could be reduced, and the vehicles could accommodate to higher external forces, then much higher speeds could be achieved.

We decided that no single-bodied vehicle could meet this objective. We began an extensive investigation of multi-wheeled, articulated configurations since they had the potential for conforming to extremes in terrain.

An articulated vehicle has the obvious advantage of reducing body-torquing - or twist – and of allowing more effective wheel movement without using […] dynamic loads. Further, an articulated vehicle can better keep its “feet on the ground” in rough terrain. Our designers were convinced that the effectiveness of this tire-to-ground contact would ultimately determine how well the vehicle would perform. At the same time, our designers concluded that there must be a major improvement in tire configuration.

A feasibility study was undertaken to see if we could design a vehicle that would be at least twice as good in overall military performance. From this study, our concept emerged. It incorporated:

Eight wheels, all-wheel drive; dual body joined by a unique pivot yoke that permitted three degrees of freedom (pitch, yaw, roll); a dual power supply; individual walking beam suspension with large wheel travel; coordinated Ackerman/yaw steering; and unique tire design.

The concept appeared to have a superior potential. It was decided that existing analytical methods would not be adequate to prove the design of such an unconventional vehicle. We therefore determined that a full-scale vehicle must be built and tested – both to verify our concept, and to enable a realistic evaluation by the military service.

In establishing the design criteria for the twister. […]

[…] This test data and customer comment has […] Twister’s developers to be certain that the product meets the requirements of the complex military market place. The trials of Twister began with accelerating from 0 to 40 miles an hour in 17 seconds, it also exceeded military requirements by braking to a stop from 20 miles an hour within 18 feet. Then came structural tests. With strain [], Twister dashed across 6-by-6-inch timbers at speeds up to 40 miles an hour, and across larger timbers up to 12-by-12 inches at 20 miles an hour. From this and other testing came the productive data that engineers were seeking. This information […] that its short turning radius and responsive steering were vital in keeping the vehicle moving rapidly in this hazardous test course.

Then Twister went north to Sacramento. Here was an obstacle course consisting of fields of mature rice, three to four feet tall, […] in loose soil that was covered by six inches of water. Yet despite this slippery footing and dikes 16 to 30 inches tall – so soft that Twister’s wheels sank deep, dragging its understructure through the dikes – the Lockheed machine negotiated these areas with no difficulty.

The scene then shifted to western Nevada. There Twister pitted its off-road mobility and speed against records set by other vehicles. Running a jeep record course over nine miles of cross-country trails – which wandered through rolling, sage-covered sandy earth, ran up and down 60 per cent grades, tipped sideways into […] and slopes of more than […] per cent – Twister had no trouble. Twister cut the jeep time record in half.

Then came the snow of the Sierra. Operating at low tire pressure, Twister ran though drifts or more than nine feet at elevations of 7,000 to 9,000 feet.

In soft snow grades of 30 per cent, and snowy side slopes of 42 per cent, the story was the same Twister rolled through them all.

Twister has passed all its tests, but Ground Vehicle Systems engineers are planning to push the vehicle to even more extremes. This year, for example, Twister will face trials which include […] with tires flat; weapons firing on the move, performance […]

[…] in ride, and in stability as a weapons platform

- Extended capabilities, in many environments and operating conditions, beyond what was thought possible for wheeled vehicles.

Twister will pass harsher tests, surmount more demanding challenges. Already a top performer, this eight-wheel versatile vehicle then will be even more sharply honed – and ready to respond to the […] military requirements that can be expected in the next decade.

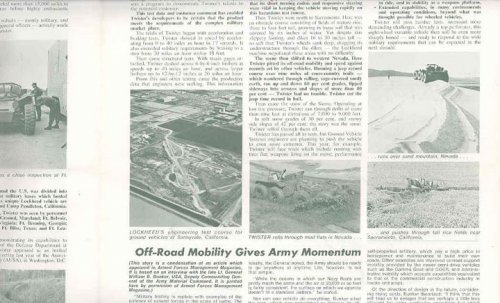

Off-Road Mobility Gives Army Momentum

(This story is condensation of an article which appeared in Armed Forces Management Magazine. It is based on an interview with the late Lt. General William B. Bunker, USA, Deputy Commanding General of the Army Material Command.)

[…]

[…] Apparently tank design and user philosophy in both the U.S. and Germany was, up to the MBT-70 era, derived more from evolution than from revolution. The computer simulation developed by LMCS helped to change this view.

LMSC’s ground vehicle systems analysis, with their first-of-a-kind computerized tank and anti-tank simulation, together with the invaluable MBT-70 study experience, see no end to the Army’s need for their services. The U.S. Army Combat Developments Command Armor Agency hired their services for over two years to help determine how many tanks and anti-tank weapons will be required on the possible post-1970 battlefields.

The analysis team is now involved in a Producibility/Cost Reduction Study of the MBT-70, a three-way joint effort with the MBG-70 developer (General Motors) and an integrating contractor (Battelle Memorial Institute). Another contract, recently completed was a study of future tank survivability, begun by DOD’s Advanced Research Projects Agency to determine what passive and active counter-measures might be developed in the 1970’s to permit today’s expensive and sophisticated tanks to live on the 1975-195 battlefields.

In 1968, a part of the Army-educated systems analysis team was set to work in a company-funded project to study new concepts, tactics and combat effectiveness of Lockheed’s own hardware – highly mobile, rough terrain, wheel vehicles such as Twister. Current emphasis is on lightweight combat vehicles for that elite branch known as “Armored Cavalry.”

The study results may never see the light of publicity, since the expected production hardware will naturally eclipse the preceding software. But LMSC’s Ground Vehicle Systems Analysis team is rewarded by the knowledge that it is an important cornerstone in a philosophical revolution that some day soon may lead to a new production line – high performance ground vehicles for military and industrial use.