Here is my speculation for the recently posted diesel battlecruiser study.

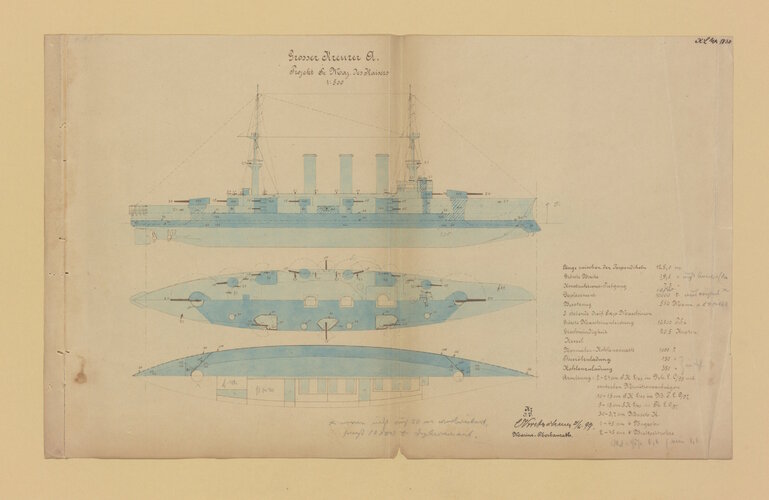

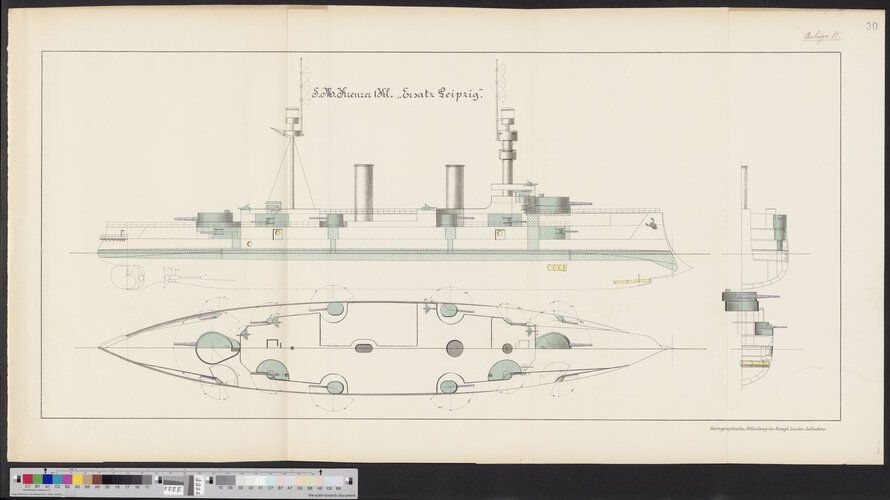

Looking at the design history of Kreuzer K (Derfflinger), one can see pretty much exactly where this design comes from in the process.

But first, as usual, diesel history:

One of the good things about Admiral Tirpitz was his strong interest in diesel engines and his insistence that they be implemented in the latest battleship and battlecruiser designs. From 1909 and until the push for them was defeated in late 1910, diesel engines played a major factor in the design process of Kreuzer K, and the Chief of Construction Department for Engine Installations had been working closely with MAN for a large marine diesel engine; and in late 1909 the RMA formed a development contract with MAN for the construction of a 6-cylinder, 12,000 hp engine. However:

"Six of the engines would be needed to produce the 70,000 hp (52,199 kW) required for the latest German battleships. Given the uncharted territory MAN was traversing, a three-cylinder engine would be built first to prove that a six-cylinder engine could meet the desired specifications. Other companies were also contracted to build competing engines."

The 3-cylinder test engine contract was formed on 28 February 1910. It was expected to produce 6,000 hp and serve as a proof-of-concept for the RMA. From this test engine a 6-cylinder engine would be produced and be capable of 12,000 hp. Of note is the other companies that were contracted, and you can see the work of companies like Junkers with their 1912 diesel battleship proposal.

More descriptions of the engine:

"MAN’s design was an inline, two-stroke engine that used double-acting cylinders. Each of the closed cylinders had a combustion chamber at its top and bottom. Originally, each combustion chamber had four intake valves, four fuel valves, and two safety valves that were also used for air-starting the engine. The safety valves were located at the center of the combustion chamber. The locations of the remaining valves were split between passageways that branched off from either side of the upper combustion chamber. With the exception of the safety valves, the valves for each side of each combustion chamber were actuated by a single underhead camshaft. This configuration had a total of 20 valves for each cylinder and four camshafts for the engine. The final (seventh) combustion chamber design retained the four intake valves but had only two fuel valves and one safety valve (located in the upper combustion chamber). The changes lowered the number of valves per cylinder to 15. Exhaust ports were located in the middle of the cylinder and were covered and uncovered by the piston.

The double-headed piston was constructed of two parts. The lower part was connected to a non-articulating piston rod, and the upper part of the piston was bolted to the lower part. The piston rod was connected to the connecting rod via a cross head. The cross head slid in vertical channels on both sides of the inner crankcase. Oil was circulated through the piston to cool it. The oil flowed up through passageways in the piston rod and into the lower part of the piston. The oil then flowed to the upper part of the piston and down the center of the piston rod. The upper and lower combustion chamber sections were bolted to the center section of the cylinder, and the assembly was attached to the crankcase. A water jacket surrounded the cylinder. The center section of the cylinder and of the upper combustion chamber were made of cast iron. The crankcase, piston, lower combustion chamber, and many other components were made of cast steel. Each complete cylinder assembly was around 12 ft (3.5 m) tall, and the engine was over 24 ft 3 in (7.4 m) tall.

Each cylinder had a 33.4 in (850 mm) bore and a 41.3 in (1,050 mm) stroke. Since the piston was double-acting and there was a lower combustion chamber, each cylinder’s displacement was nearly doubled, as if it were two conventional cylinders. The upper combustion chamber displaced 36,359 cu in (595.8 L). However, the connecting rod passing through the lower combustion chamber took up around 3,021 cu in (49.5 L) of volume. Displacement for the lower combustion chamber was approximately 33,337 cu in (546.3 L). The cylinder’s total displacement was around 69,697 cu in (1,142 L). The three-cylinder test engine displaced 209,094 cu in (3,426 L), and the six-cylinder engine displaced 418,187 cu in (6,853 L). The engine drove three double-acting air pumps to scavenge the engine. Each air pump had a 52.0 in (1,320 mm) bore and a 31.5 in (800 mm) stroke."

The engines are absolutely gigantic, which explains why they can produce so much power with such a low piston number.

The 3-cylinder test engine was first run on 11 March 1911. As expected from such a technology - practically in its infancy as far as marine use goes, and especially at this size and power output - technological difficulties were encountered and subsequently there were severe delays. Worse still, an incident in January 1912 caused by a failure in the engine saw the intake manifolds explode, killing 10 workers. Further delays could be expected and this perhaps damaged the trust of the RMA in this new technology as a whole.

Unfortunately, the aforementioned Chief of Construction Department for Engine Installations (Geheimrat Veith) changed his mind by September of 1910, stating that large diesel engines were "not yet ripe" for installation aboard Kreuzer K. This was no doubt caused by the slow progress of development with the 3-cylinder engine (it had not even been run yet in Sept 1910), but Geheimrat Veith is not incorrect with his remark either. 6-cylinder engines of the required power would never be ready in time for Kreuzer K, and thus were really and truly not yet ripe. An undesirable consequence of this is that large marine diesel engines would only see limited use aboard large surface warships following this decision, ensuring the near-absolute dominance of the steam turbine in the German Navy. Tirpitz's grand beliefs and proclamations on diesel engines, that they would put them "a real leap ahead of other navies", would never see the light of day.

It would not be until June 1913 that the 3-cylinder test engine would reach the specified power output, producing 5,400 hp at 90%. Derfflinger would commission the next year. Work on the 6-cylinder engine would, regardless of the decision with Kreuzer K, follow.

So where does that leave this Study design?

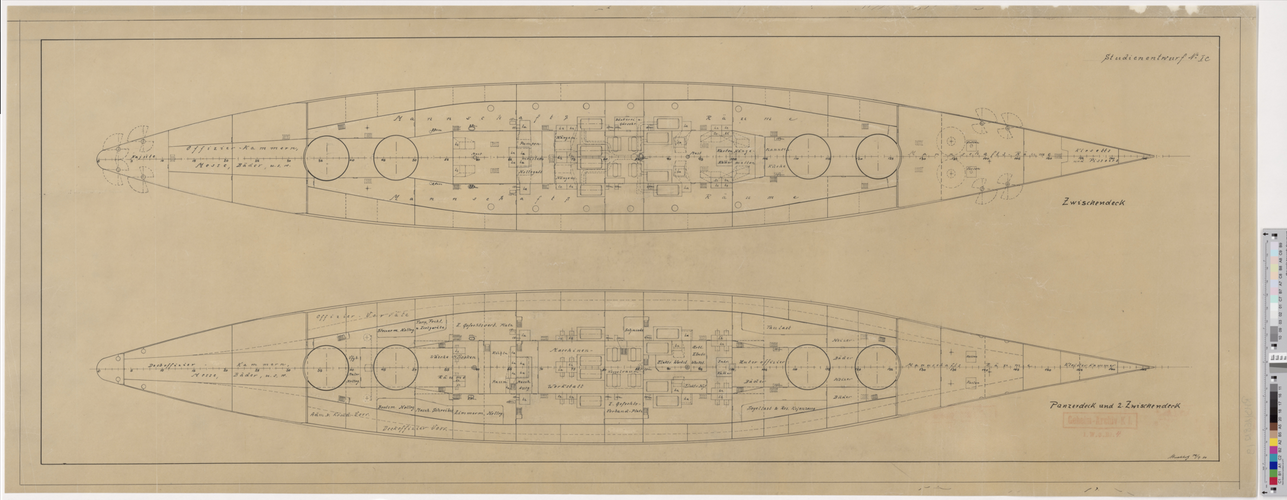

I strongly believe this is a Kreuzer K derivative, drawn up early in development and obviously is the most radical of the Kreuzer K proposals. In 1910, there was still the debate about 30.5cm vs 28cm, diesel and steam, and even whether Kreuzer K should be a sister to Kreuzer J (Seydlitz) or its own design....considerations for diesel as the main method of propulsion would no doubt have not gone beyond the initial design phase.

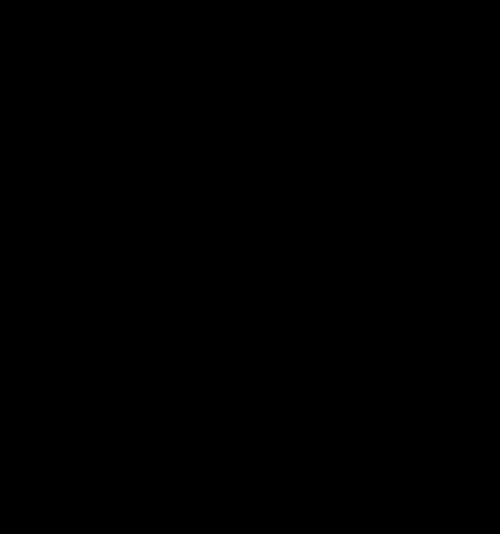

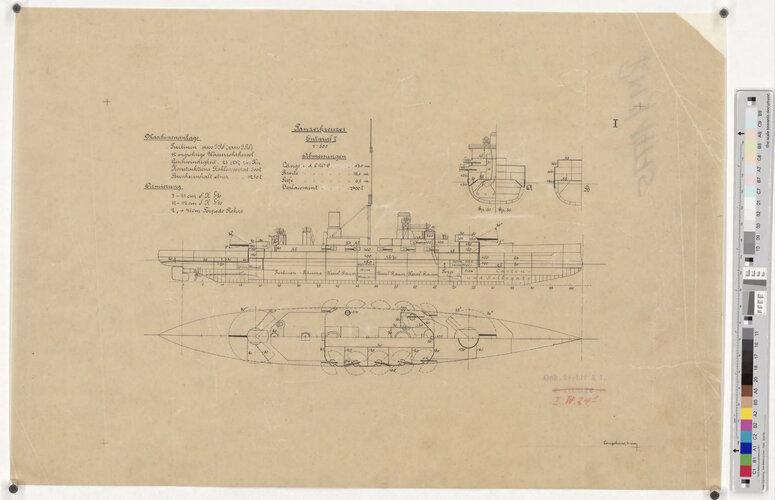

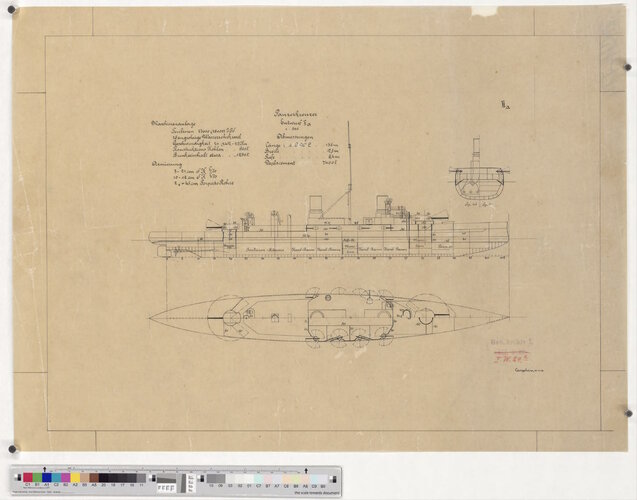

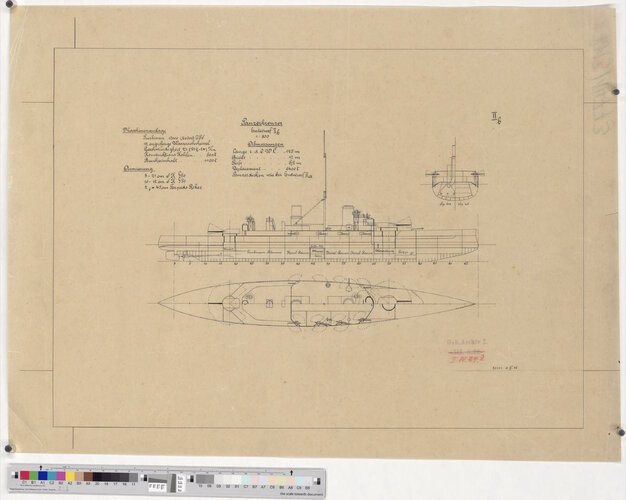

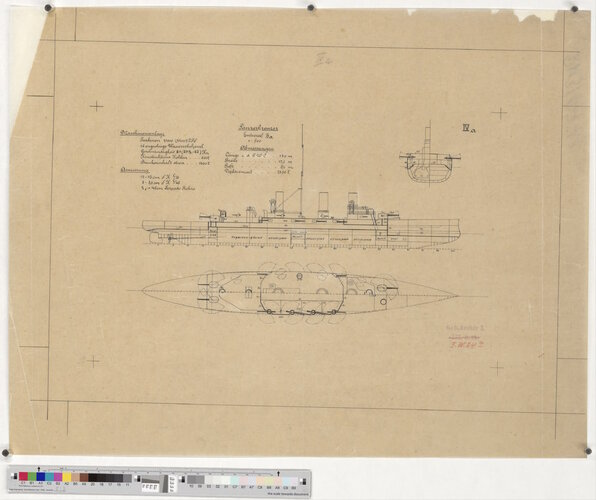

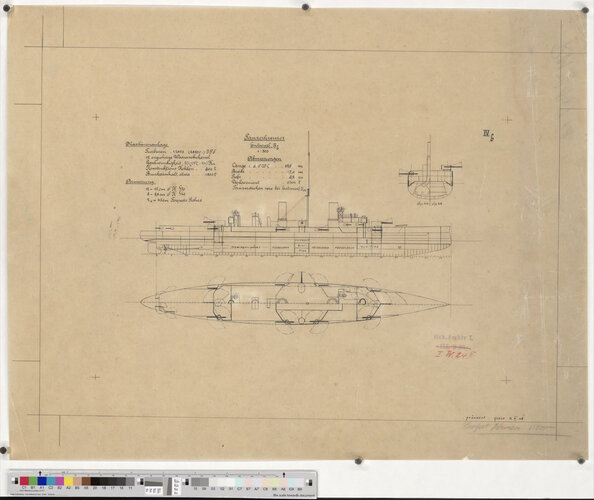

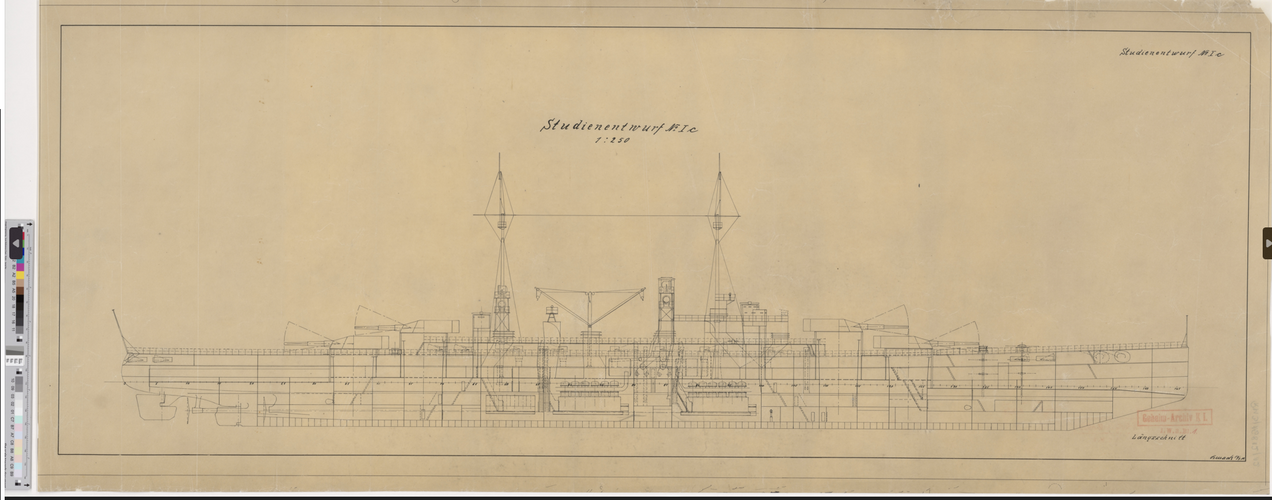

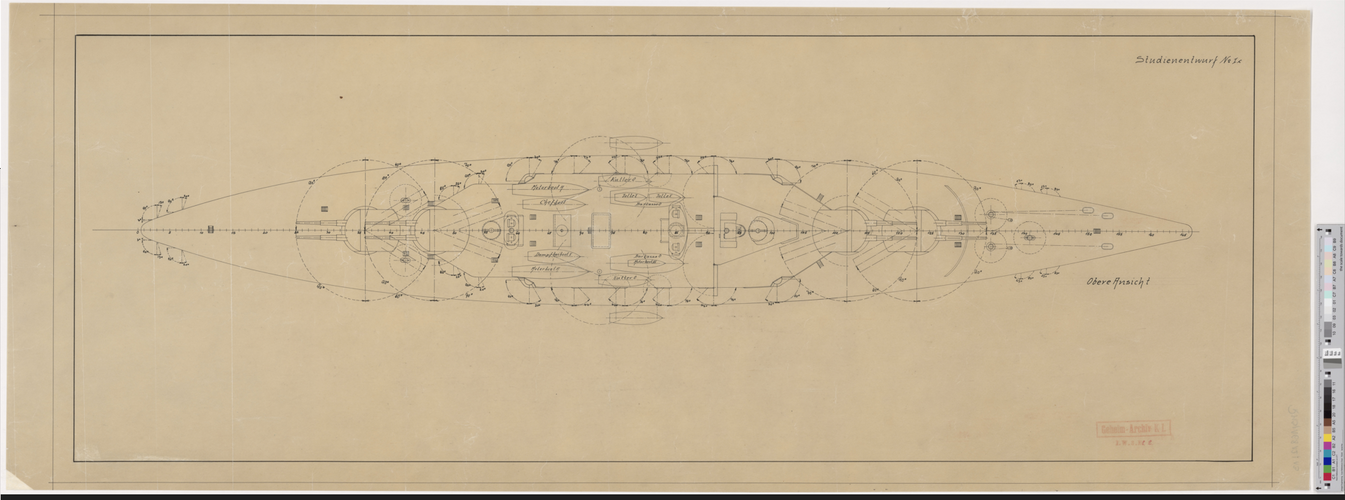

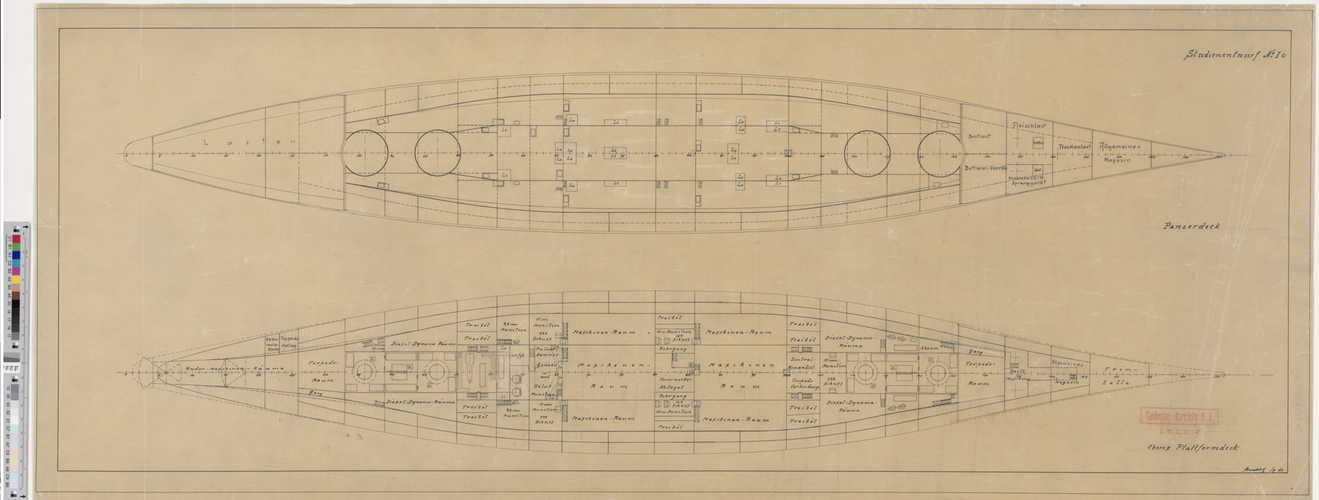

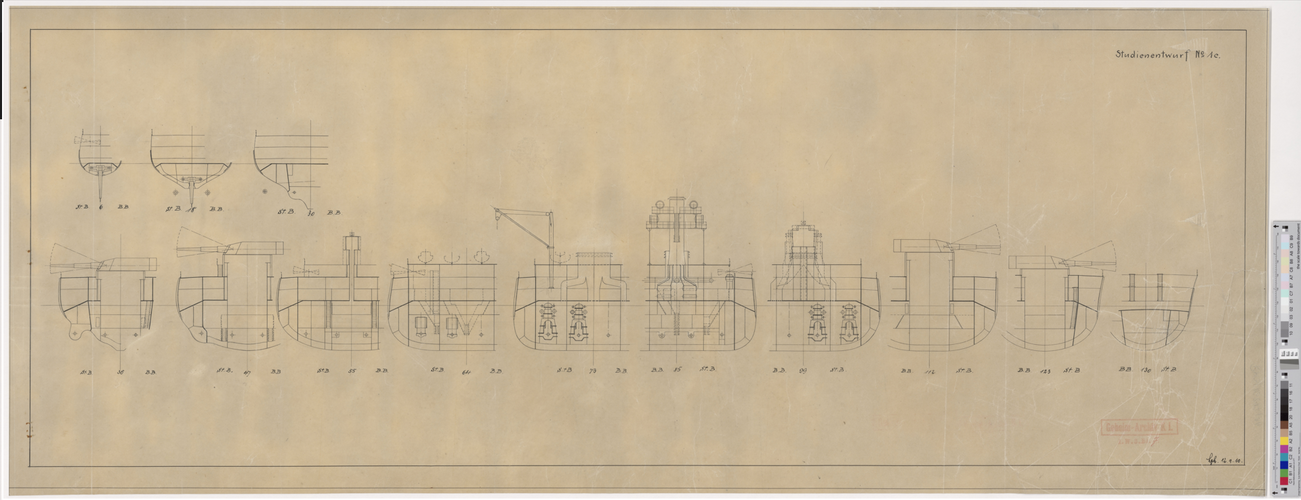

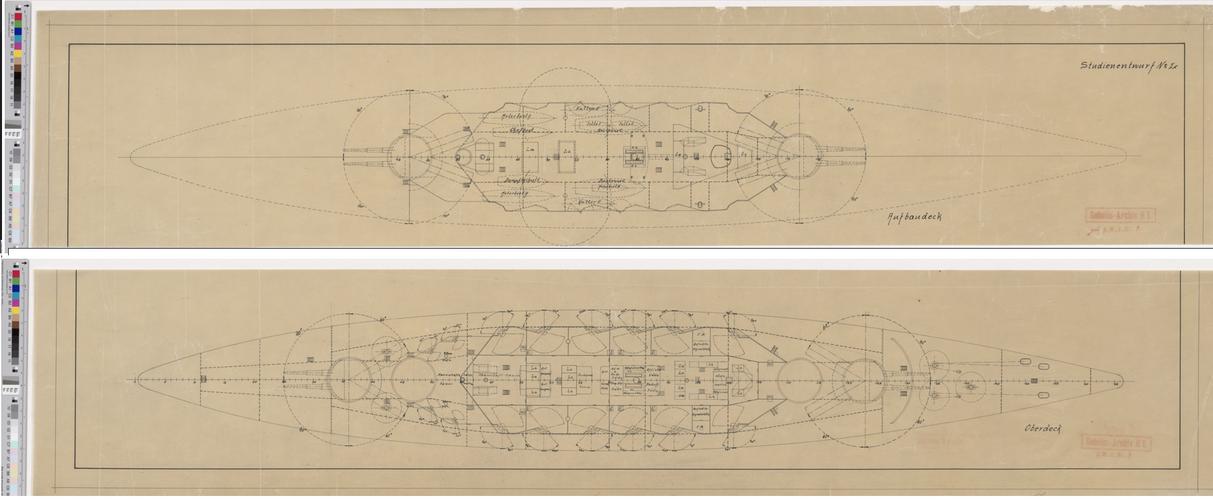

So, the chances are that this study is one of the early competing designs for Kreuzer K, or a one-off of those supposed to satisfy Tirpitz's mad desires for diesel propulsion. This one is not strictly just some derivative of Kreuzer J Design IVe given the stronger similarities to aspects of Kreuzer K Design 1 and Design 3. The official name of the study is Studientwurf No. Ic, so we might surmise that this is Design 1c and place it somewhere between Design 1 and Design 3 for Kreuzer K...which tracks given that while the casemate is recessed inboard from the hull sides like Design 3, it is still at the weather deck like Design 1, and also keeps the forward and aft hull-mounted guns as in Design 1, yet has a centerline arrangement and a declining similarity to the Kreuzer J-esque looks of Design 1...just as Design 3 does.

At the very least it exists somewhere during the development of Design 1 and 3. That much I believe.

What characteristics can we discern from the design?

That depends on a lot of factors. I would prefer to know the length and beam, which is impossible given the current image quality. I would also like to know the exact date of the design, which may even cause me to revise my entire hypothesis. This is also dashed by image quality. For now, I can play around with the machinery - arguably the most interesting part.

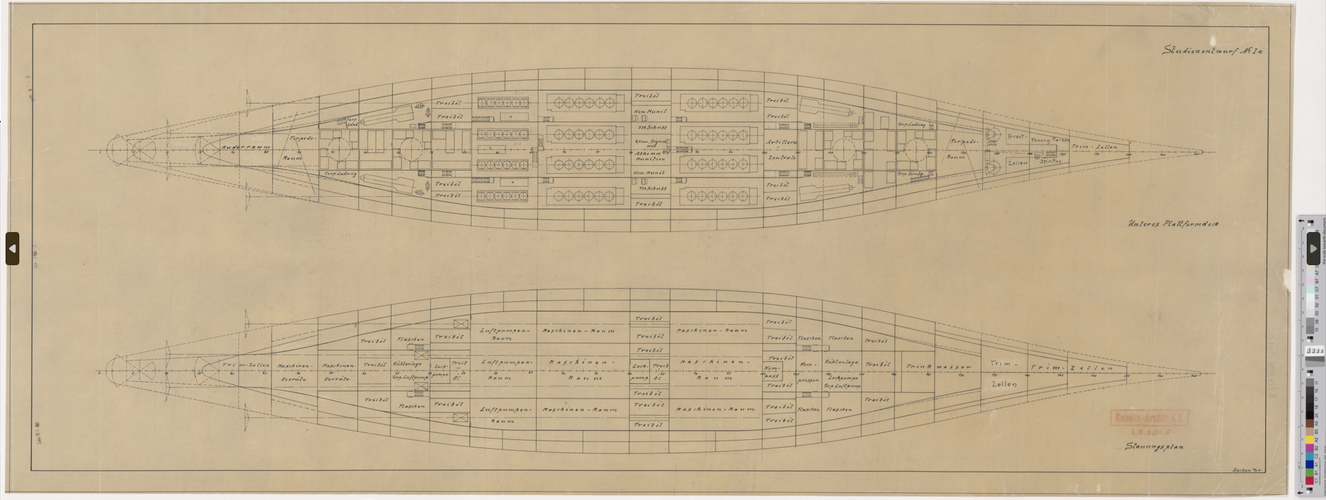

While 6 6-cylinder engines were required to power new German battleships, this design has 8. 12,000 hp was expected from the get-go, and by April 1917 this had been achieved:

"On 24 March 1917, the six-cylinder engine produced 12,200 hp (9,098 kW) at 135 rpm for 12 hours. In April 1917, the engine passed its five-day acceptance test, running at 90% power and producing 10,800 hp (8,054 kW) at 130 rpm."

In 1914, things had been slightly different:

"The six-cylinder engine was first run on 23 February 1914. By September 1914, the engine was producing 10,000 hp (7,457 kW) at 130 rpm."

Shifting priorities caused by the outbreak of war in 1914 saw the development of MAN's 6-cylinder project decline rapidly, and more so as priority again shifted to U-Boat warfare in 1916. Although the Bayern-class battleship Sachsen (and her sister Wurttemburg) had been slated for one of these engines, it was not to be.

Assuming some miracle (typically found in the form of money) allowed the 6-cylinder's progress to progress far more rapidly that it had in this universe, one could expect to see 96,000 hp from these 8 engines. This is not an overload power, but a continuous output...at least for a few days, depending on maintenance/the condition of the engines and a billion other factors. Given that the HSF operated only by short sorties, I see no issue. At worst (10,000 hp 100% output), that is still 80,000 hp - more than what was initially expected for Derfflinger either way.

I'm glad that this design was found. A interesting and unique piece to the history of marine diesel engines overall.

Perhaps they might have been ready for Hindenburg, in a candid world.

Sources:

German Battlecruisers of World War One (Gary Staff)

Dieselmotoren fur funf Deutsche Marinen (Eberhard Moller/Werner Brack)

In the first half of the 20th century, MAN (Maschinenfabrik Augsburg-Nürnberg) developed a number of double-acting, two-stroke, diesel, marine engines, including a V-24 that displaced 224,957 cu in…

oldmachinepress.com