Here’s one to send you for a mental loop:

The telescope so big that it that may allow us to find extraterrestrial life led directly to the manufacture of the display on which you’re probably reading this now.

To peer deeper than ever into space, NASA needed optics of unprecedented size; the technology to make them was later repurposed to manufacture the display you might be looking at this very moment.

www.wsj.com

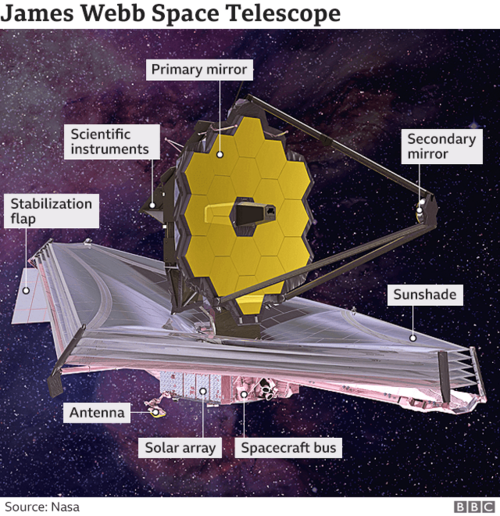

The 18, 1.32 meter-wide mirrors of the James Webb Space Telescope, to be launched into deep space this December, must all be smooth to within a few angstroms (can’t be off by more than a few atoms in thicknesss).

When NASA stipulated this 20+ years ago, it was impossible.

Tinsley optics, which had already made the corrective lenses for the Hubble Space Telescope, which then brought us decades of stunning images from deep space, bid on polishing these mirrors to a then unheard-of level of perfection.

Fast forward to 2012. Tinsley is winding down production of the James Webb telescope mirrors. But what to do with the purpose-built equipment for polishing these mirrors to unheard-of perfection?

Enter Coherent, the laser company.

Coherent, and a competitor or two, make the schoolbus-size “linebeam” systems that help make near-perfect sheets of silicon, on which OLED and some other displays are made.

They needed giant optics.

Like those on the James Webb.

So! NASA asks the impossible in order to satisfy human curiosity. (Are we alone in the universe?)

And they fund the development of the tech they need. And that leads to economical production of the phone displays we all stare at too many hours a day.

How often does this happen? How much of our modern world do we owe to NASA (and to be fair, DoD) funding “crazy” research to solve problems with no immediate commercial application?

It’s happened thousands of times.

Everything from the DustBuster to the internet are the result.

www.scientificamerican.com