Mason’s Perspective on the X-29

Originally written in October 2007

Rev. Sept 21, 2008

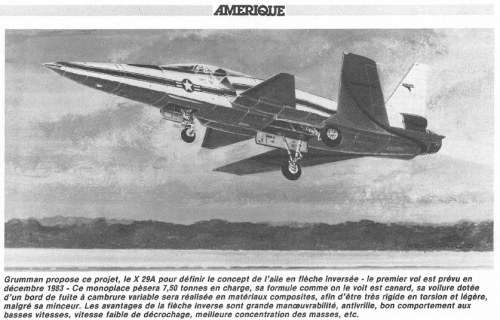

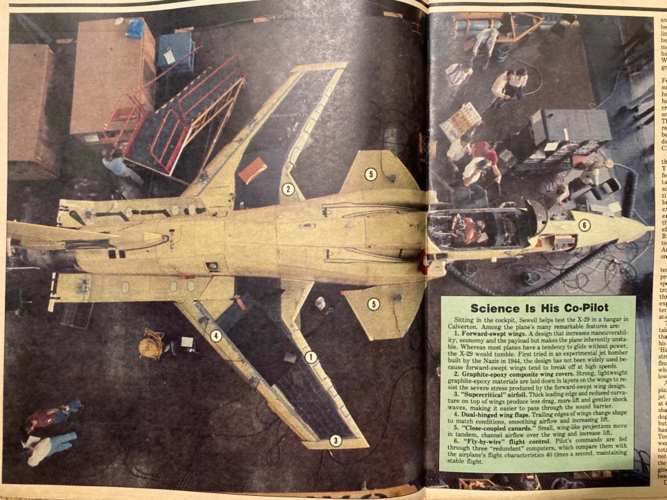

Because of the interest shown by some instructors at the Air Force Academy (USAFA) in the X-

29, I wrote up my version of the story. The first flight was in December of 1984, and the 2nd

plane flew through about 1990 or so. The second X-29 had a novel control concept, with the

pilot operating small jets that controlled the forebody vortices to enhance yaw control at high

alpha. Grumman did little to exploit the success publicly. Very few technical papers were written

by Grumman folks, but lots eventually came out of NASA Dryden and, checking the data bases,

there were also numerous papers from USAFA. Grumman didn’t get much credit for the good

things that happened in the program (unfortunately common when working with NASA,

Grumman was just “the contractor”). It seems there’s a lot of misinformation about the program.

Since the X-29 didn’t fit into NASA or Air Force plans with the F-18 HARV or the X-31, and by

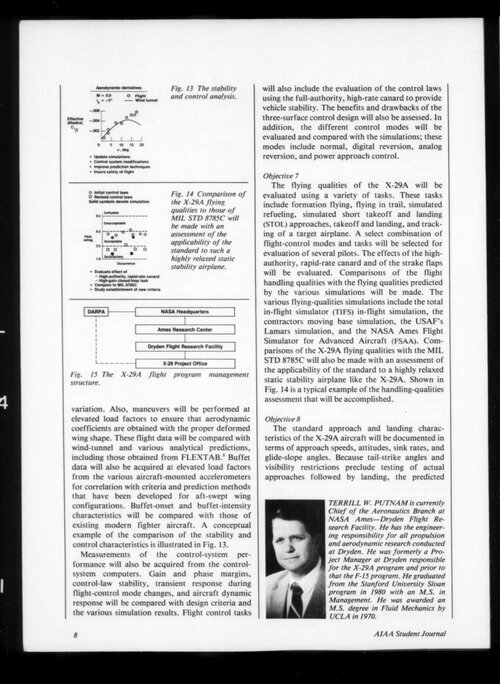

then stealth, it was mainly a curiosity. However, the program was successful. Hundreds of flights

were made, and both planes are still around in museums. Although some sources say it was an F-

5 with mods (and Grumman had hoped this would be the case), it turned out that everything

behind the cockpit was new. In addition, the use of F-16 actuators led to large “canoes” on the

wing, that resulted in lots of drag at supersonic speeds. Although never intended to demonstrate

significant supersonic capability, it has been reported that a big problem was high supersonic

drag (by the time it flew, supercruise had become a key Air Force requirement for new fighters).

Yes, supersonic drag was high, but was never considered an issue in the design. The design was

all about high sustained transonic maneuver – the classical M = 0.9 design point (corner point).

These notes provide both a description of how the plane came to be from a technical standpoint,

and also describe the company culture that surrounded events. It’s hard to separate the two.

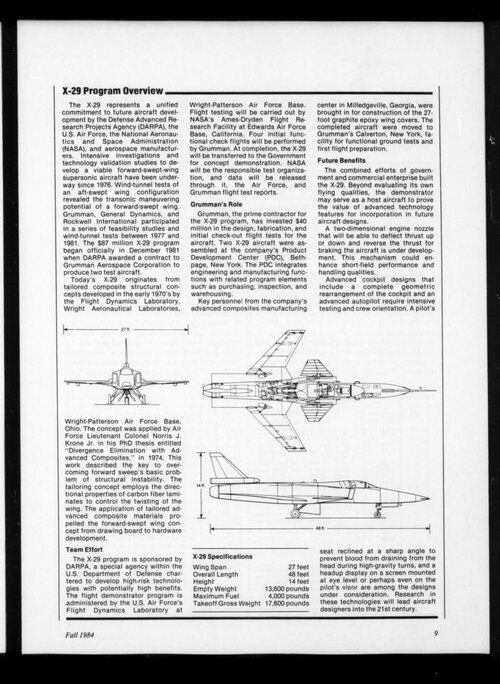

The X-29 arose accidentally. There was never any plan by any agency to build a tactical

forward swept wing airplane, the demonstrator of the technology just somehow happened.

HiMAT

Grumman competed for the NASA highly maneuverable aircraft technology (HiMAT)

program around 1973 or 1974. This program was intended to demonstrate the integration of

advanced technologies to achieve high sustained transonic maneuver capability. At that time

UAVs were called RPVs, and the idea was to build an RPV to demonstrate the technologies. The

Air Force was also a sponsor. It was assumed that the technologies would be advanced

aerodynamics, aeroelastic tailoring to achieve a passive wing design that would deform to

optimum shape at the various g loads, advanced flight controls (relaxed static stability) and thrust

vectoring. Grumman originally had a configuration similar to the one being proposed by

Rockwell, but Grumman’s evaluation was that with a similar configuration they would lose to

Rockwell. In addition, having just put the F-14 into production, there was a strong sense that a

variable sweep wing should be proposed. Essentially this was dictated by management: “no

proposal goes out the door unless the wing has a pin in it.” So Grumman’s HiMAT proposal used

a variable sweep wing with an advanced supercritical airfoil and an aeroelastically tailored wing

to obtain its sustained transonic maneuver requirement. The key was to use advanced airfoils and

nominally attached flow at the design point. Grumman was not using the vortex flow concepts

being exploited by the General Dynamics and Northrop folks with the YF-16 and YF-17.

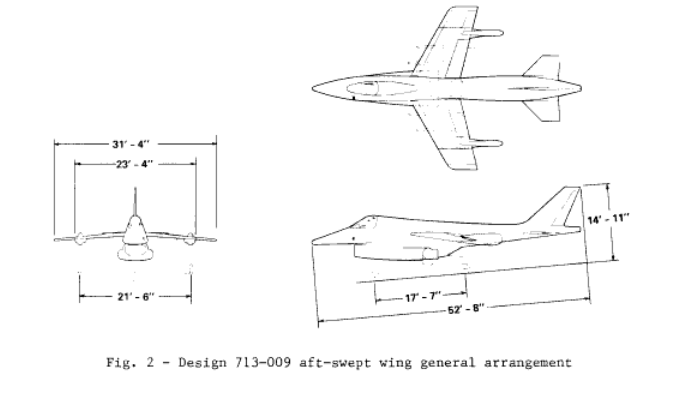

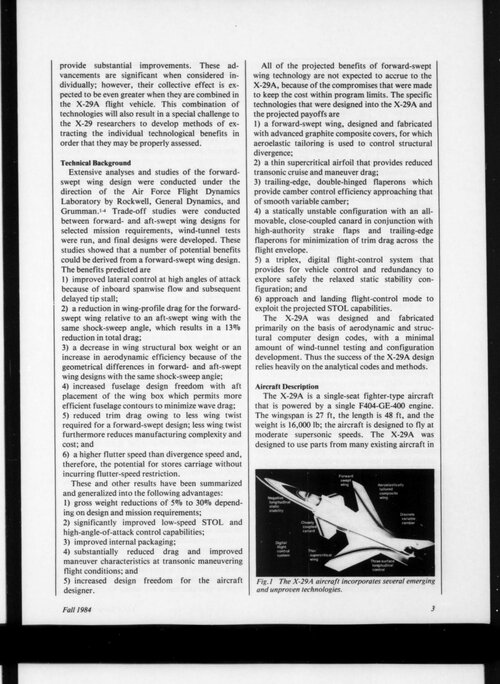

Grumman lost to Rockwell.* Figure 1 shows a sketch of the Grumman configuration, compared

to the winning Rockwell configuration in Figure 2. Note that the YF-16 and YF-17 RFPs came

out in January of 1972, so the timing of HiMAT seems a little strange, although nobody knew

how those programs were going to develop.

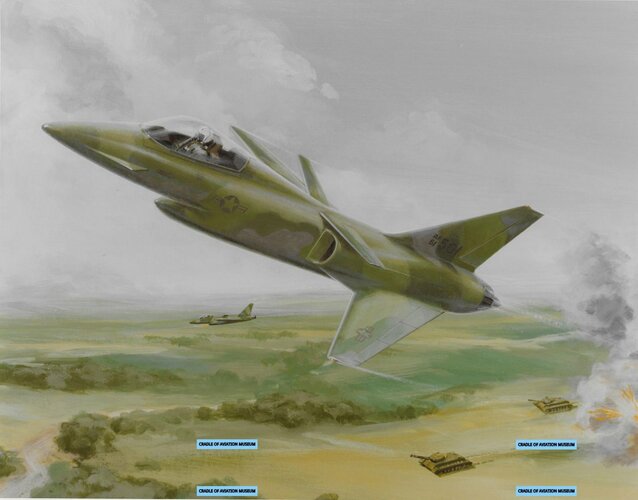

Figure 1. The Grumman proposed HiMAT configuration (unknown Grumman notes).

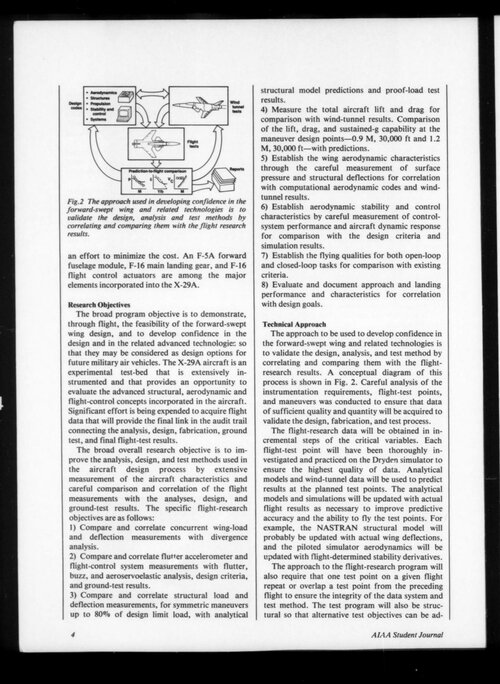

Figure 2. The winning Rockwell HiMAT configuration (AIAA 81-2433).

As part of the technical debrief, NASA said they liked the Gruman supercritical airfoil and

wing design work and offered to test the Grumman concept at Langley. The Grumman proposal

had employed an airfoil known as the Grumman “E”. However, the aero folks had been

continuing to develop airfoils, and had progressed to the “K” airfoil. The E and K airfoils had

been tested in Grumman’s transonic tunnel (a 26 inch test section blow down tunnel). I’ll say

more about the airfoils later. So a wing with the K airfoil was built and tested at Langley. Charlie

McLaughlin and Glenn Spacht were involved. The test produced a key insight.

The key observation was that a highly loaded transonic maneuver wing necessarily has a

strong shock aft on the wing. You don’t want a strong unswept shock – lots of drag! How do you

get a swept shock when it’s at 85% of the chord or more? The trailing edge needs to be swept.

To see the dilemma, consider the trailing edge sweep of the F-16 and F-18. As another

consideration, the thin (6% 2D) airfoils generate a lot of lift on the lower surface, and that seems

to be affected by the leading edge sweep, which you want to be low. Well, an aft swept wing

with inverse taper is one way to get high TE sweep – don’t laugh, Republic, about 10 miles

away, had done it with the XF-91 Thunderceptor. Or, you could propose a forward swept wing.

Looking at the test results, Glenn Spacht decided to propose a forward swept wing as the way

to integrate the high-performance “K” airfoil with the proper planform.

Forward Swept Wing Studies

Glenn Spacht came back to Bethpage and got on the phone. The aeroelastic divergence problem

was well known for forward swept wings, but aeroelastic tailoring of composite structures was a

possible solution. Glenn called Warner Lansing, the Section Head of the Dynamic Structural

Methods Section,* and asked Warner about the possibility of using aeroelastic tailoring to

propose a forward swept wing airplane with an acceptable wing weight while avoiding

divergence. Warner had just read about a PhD dissertation on aeroelastic tailoring by Norris

Krone that seemed to be directly related. He asked his secretary to get a copy. Krone was an Air

Force officer** and was possibly at AFOSR. He was somewhere around DC anyway. As I recall,

he had done the dissertation for Terry Weisshaar, who was then at Maryland. Warner’s secretary

couldn’t talk to Krone, but left a message asking if he’d send a copy of his thesis to Warner.

Apparently Warner was fairly well known in structural circles, having done some of the first

finite element structural analysis (possibly around 1950 or so). When Krone got the message, he

called Warner and asked why he wanted a copy. When Warner told him there seemed to be an

application for Krone’s work, Krone got excited, and very shortly flew up to Bethpage to see

what was going on. I heard Krone tell this story, I think at a local Long Island AIAA Section

dinner meeting. So the wheels were set in motion.

Meanwhile, some technical activities had begun. Because the Grumman HiMAT model had

variable sweep wings, it was fairly easy to make a wind tunnel model with the wings swept

forward, and they put this model in the Grumman low speed tunnel. This allowed a quick look to

see if anything terrible happened to the aerodynamic characteristics. The tests showed that there

were no obvious showstoppers.

Glenn now had a team of a designer and one aero guy working on the concept in preliminary

design, and was working with Krone to get money to do some studies. This was happening

without a formal forward swept wing concept being part of anybody’s strategic plan at

Grumman. I think the Grumman attitude was that if somebody was interested in this in the Air

Force, then they should take a look. I don’t think the Air Force had forward swept wings in the

plan either, but Krone wanted to see something come out of his PhD work, and became a

champion of forward swept wings in the Air Force. He was also working on relocating to

DARPA at about this time.

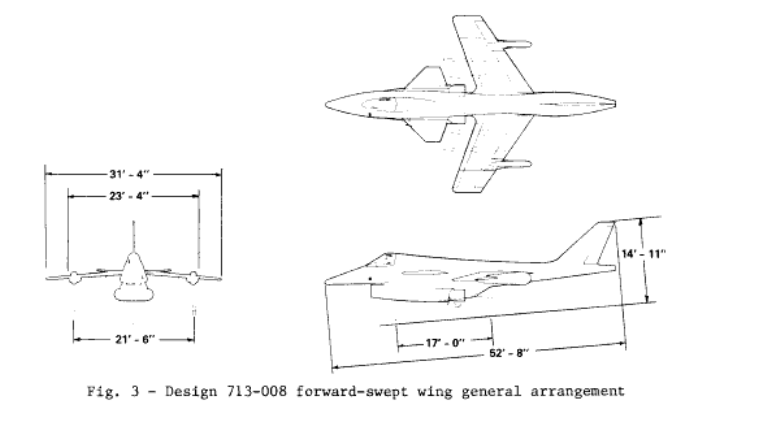

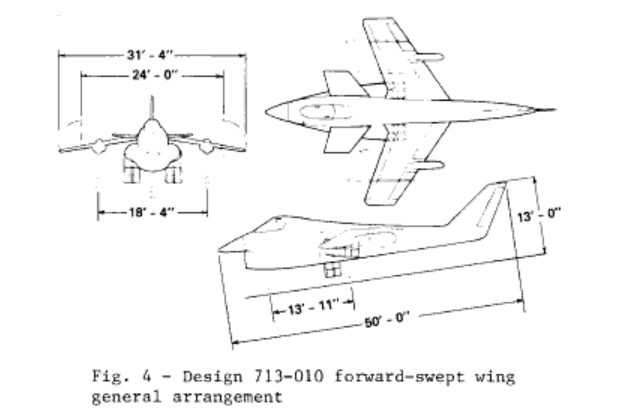

Figure 3 is a copy of a viewgraph made by Nathan Kirschbaum to establish a concept to start

development. There were some questions about how exactly this concept should be set up. The

landing gear don’t integrate as well as they do on an aft swept wing concept.

I got involved at this point. I had just finished working on a transonic CFD project for the Air

Force so it must have been 1977. It turns out that I had attended the Vortex Lattice Utilization

Workshop at Langley in 1976, where I heard John Lamar give a talk on turning his vortex lattice

analysis code into a design tool for wing-canard configurations, and the code contained the

option to trim the configuration. This was a purely subsonic method, and we already had the

code. But, we needed to consider transonic maneuver conditions, where the airfoil performance

would be an important issue, as well as the induced drag. I proposed adding transonic airfoil

section characteristics to Lamar’s induced drag calculation as a way of finding out how to

minimize induced plus profile drag for canard wing configurations. The section head of

aerodynamics didn’t think this was worthwhile and wouldn’t look for a charge number for me to

do this. I don’t exactly recall how it happened, but Glenn Spacht needed to be able to do this, and

he came up with a charge number. I think I had demonstrated how this would work by doing a

“model problem” without authorization, a somewhat time-honored way that Grumman technical

folks used to show managers the value of the work they refused to authorize. Often this approach

paid off.

Figure 3. The notional starting point for a forward swept wing airplane (Nathan Kirschbaum did

this sketch, but Russ Negri was the designer and his name is on the patent).

Next, to get to the end of the story, we need to review the airfoil work. In the early 1970s,

Whitcomb’s supercritical airfoils had generated a lot of interest in obtaining increased

performance using advanced airfoil designs. Grumman had an internal IR&D program, and had

designed some advanced airfoils. Bill Evans, who eventually became the Grumman tech rep at

Dayton when he didn’t get the Chief of Aero job, was the key proponent. They were using the

hodograph method developed at NYU as a computational tool, and hired Dave Korn from NYU

as a consultant, since the hodograph method was notoriously hard to use. Jameson had also just

developed his circle plane transonic full potential analysis code, FLO 6, and basically used that

as a resume to get another job. He joined Garabedian’s group at NYU, where he could take the

train to work and not sell his house (eventually he moved to Princeton). These airfoils required

that the boundary layer effects be included from the beginning. Before that time, boundary layers

were more closely associated with hypersonic viscous effects and heat transfer, and engineers

who knew about boundary layers had been in the Thermodynamics Section at Grumman. When

Grumman lost the space shuttle proposal to Rockwell most of these engineers were laid off.

That’s why I was brought over to the aero group, having just done a thesis on shock wave

boundary layer interaction. To include viscous effects in transonic analysis, NASA and

Grumman had Paul Bavitz spend a year at Langley, where he worked closely with Whitcomb.

Paul never quite understood why Whitcomb, a notorious loner, spent so much time with him.

Paul added a boundary layer calculation to an inviscid transonic analysis code to use in transonic

airfoil work (NASA TN-D-7718, it’s not available as a pdf). Whitcomb could now do design

work computationally rather then in the wind tunnel. Paul came back to Bethpage somewhere

around 1975. Then Charlie Boppe went down to Langley to work on a 3D transonic calculation.

Meanwhile, Whitcomb was also paying the NYU folks to make an analysis code and include

viscous effects. The so-called Bauer-Garabedian code was a very widely used code in its day.

Figure 4 shows the progression of airfoil designs at Grumman up to the HiMAT proposal.

The proposal was submitted with the “E” airfoil, although work continued. The 2D design Mach

number at that time was always M = 0.683. From simple sweep theory, this implies that for a

flight Mach number of 0.9, we were assuming a wing sweep of about 40 degrees. To get a 3D CL

of 1.0 we needed a 2D CL of 1.70, and a 2D t/c of 0.065 was used. The A airfoil came from the

hodograph method, transonic similarity scaling was used to get the right thickness (airfoil B),

and aft camber was used to increase the CL (airfoil E). The E got a CL of 1.25, so it didn’t meet

the CL requirement. Note that these plots appear to have come from the old real ink on graph

paper days of a Calcomp plotter. Charlie Boppe may have done this work.

Airfoil design work continued, and they got to airfoil “K”. Figure 5 shows this airfoil, the

pressure distribution and the drag performance. This airfoil is completely beyond any existing

airfoil performance for transonic high lift. Note the high degree of aft camber, the relatively

weak shock, and the large amount of lift carried on the lower surface because the airfoil has such

a low t/c. I’m not sure which analysis code was used to generate the predictions. Also, the

porosity of the tunnel had been adjusted to produce experimental results that matched Bavitz’s

pretest predictions (WT wall interference is always an issue with transonic resting, particularly in

2D)! The other issue with this airfoil is that every Grumman aerodynamicist felt the need to

“improve” it, so that there were many variations. I think the airfoil that was used on the X-29

was known as K-Mod 2. I’m not sure anybody can say with certainty what the actual airfoil

coordinates are. Grumman was not good with documentation.

The other issue is that for swept tapered wings, it was found that simple sweep theory

couldn’t be used to put the airfoil in the wing, and so-called “bowed” airfoil theory was used.

Our attached flow wing design work was aimed at keeping straight, well-behaved isobars. This

was similar to something employed by Northrop on the X-21 that they called “arc chord”

airfoils.* Straight isobars were critical for them because the suction slots needed to work against

a constant external pressure. Various aerodynamicists at Grumman had their own ideas of the

proper derivation of bowed airfoil theory, so that when they specified the streamwise airfoils to

the lofting group, there would have been variations on the actual streamwise contour relative to

the 2D airfoil.

Figure 4. Grumman airfoil design progression (Boppe’s internal tutorial presentation)

Figure 5. Airfoil K, as used in the Grumman X-29 (also from Boppe)

We can now describe how the X-29 forward swept wing– canard arrangement led to the airplane

being 35% unstable. Basically, The problem is to get as much attached flow lift as you can out of

the configuration. The drag penalty for a non-elliptic spanload is small compared to the penalty

from airfoil separation. This leads to a move away from elliptic spanloads to constant section CL

spanloads, with every wing station working the airfoil to its limit. The way to do this was to use

John Lamar’s existing code to minimize induced drag as a starting point. To minimize induced

drag you have a Lagrange multiplier problem that is linear, with the Lagrange multipliers being

the constraints on lift and pitching moment.* I wanted to minimize induced plus profile drag. If

you specify the airfoil section polar across the span, it amounts to adding a new term on the

diagonal and possibly something on the RHS of the equations. If the airfoil drag polars are

parabolic, then the problem is still linear. From Figure 5 you can see that the airfoil drag polar is

definitely not parabolic. After Lamar’s program was modified, the airfoil polar was input as a

table, and interpolated. This led to an iterative solution, is far from elegant, but works. You get

the minimum induced plus profile drag and also the associated spanload.*

Figure 6 shows how for a single planform the spanload changes from an elliptic spanload

concept to constant section CL concept as the design lift coefficient increases. The solution

avoids the rapid profile drag increase shown in Fig. 5. Figure 7 shows the final X-29 concept,

and Fig. 8 shows how important selecting the proper cg location is to minimize trimmed drag.

The results of the calculations make it clear that to gain an advantage for forward sweep the

plane has to be highly unstable. The aft strakes and inboard kick on the wing leading edge were

added after my initial analysis. The inboard kick was added for the structures folks. The aft

strake helped with the nose down pitching moment at high angle of attack, and led to the plane

being 32% unstable rather than the original 35% unstable, something some of the NASA folks

made into a big deal. Anyway, after trying to find other arrangements that worked without this

degree of instability, I went to Spacht and said that it looked like the forward swept wing was not

practical. He then talked to Arnold Whittaker, who unbeknownst to me had been the controls guy

on the lunar lander. Arnold told Glenn: “No problem.” So they continued on. Other work was

going on with the aeroelastic tailoring design, leading to a successful test at NASA Langley

demonstrating that a composite forward swept wing would work structurally. Thus, the

aerodynamics were pretty much set, the structural design concept was pretty much set, and the

development program transformed itself into one of flight control system design, with many

hours of overtime going to those guys. Initial discussions of making the first flights with a stable

configuration just didn’t make sense (the canard CL on stable canard configurations is very high,

not to mention the nose-wheel lift off problem), and so it always flew with the highly unstable cg

location.

The X-29 is an excellent example of how to integrate an airfoil design into a planform to

achieve the full benefit of an aft-loaded supercritical airfoil on a high-lift configuraiton. If you

have a strong aft shock, you have no other choice.

I’m writing this down after 30 years, there are some other tidbits that deserve to be noted:

- Canard-wing interaction helps wing twist on forward swept wings. On an aft swept wing canard

concept, the washin at the root has to be increased when the canard downwash unloads

the inboard wing. Just the reverse is true if the wing is swept forward because the wing twist is

down to unload the root. The canard downwash means that you don’t need to twist down as much.

- The forward swept wing configuration means that within the Mach cuts the configuration actually

“contracts”, so that the fineness ratio is effectively reduced. This is definitely not a way to get low

supersonic wave drag. I never understood Rockwell’s claim of lower supersonic wave drag.

- Effectively, the forward swept wing allowed the structural sweep to be lower than the aero sweep.

This is a big weight savings, and another big benefit of forward swept wings.

- The camber shown in Figure 5 was the maneuver shape. The shape was obtained using a

two-element trailing edge flap arrangement. For the uncambered cruise shape this resulted in two

non-smooth “humps”. We called this “discrete variable camber”. Ironically, because the trailing

edge was also scheduled as part of the flight control system, and the controls were “fast”, and the

maneuver deflection was “slow”, the full camber wouldn’t be achieved if the maneuvers were fairly rapid.

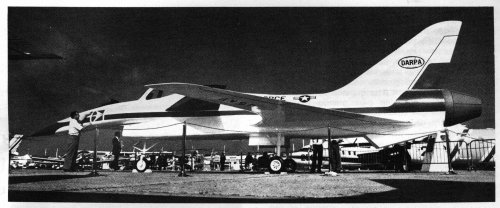

- Programatically, NASA Langley was continually negative, wanting something like a 10

year development program. DARPA wouldn’t let them do this. Although we delivered the plane

with Grumman painted on the tail, NASA took this off (eventually a smaller Grumman got back

on the plane). I made the X-series airplane chart that’s on my web site originally to show

Grumman management the long odds of converting an X-series airplane into a money maker.

Also, in the years leading up to the ATF competition some Air Force friends continually told me

that the Air Force wasn’t interested in a forward swept wing airplane. I relayed the information,

but obviously I was ignored.

- Possibly the best paper to read is by Mike Moore and Doug Frei: AIAA 83-1834. Spacht also has

a couple of papers on the AIAA web page: AIAA 80-1885 and 86-2630.

Figure 6. Single planform section minimum total drag distributions (AIAA Paper 82-0097).

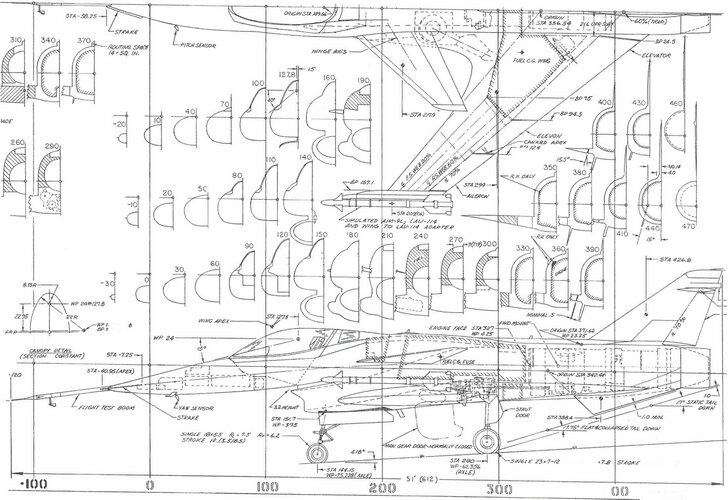

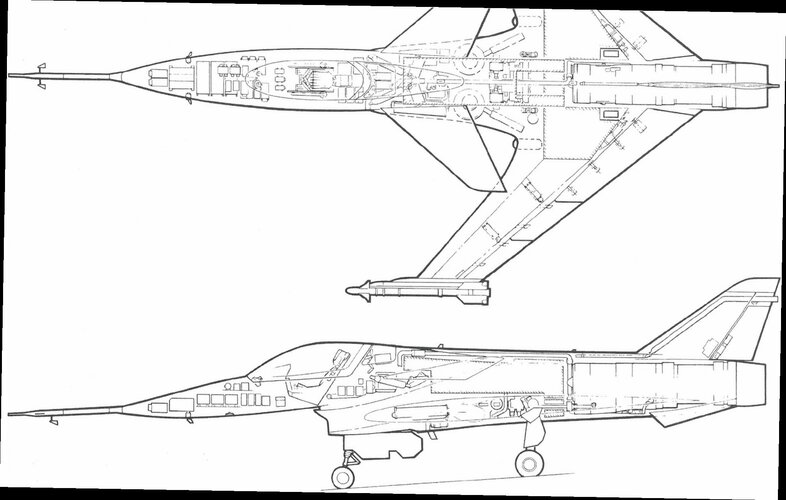

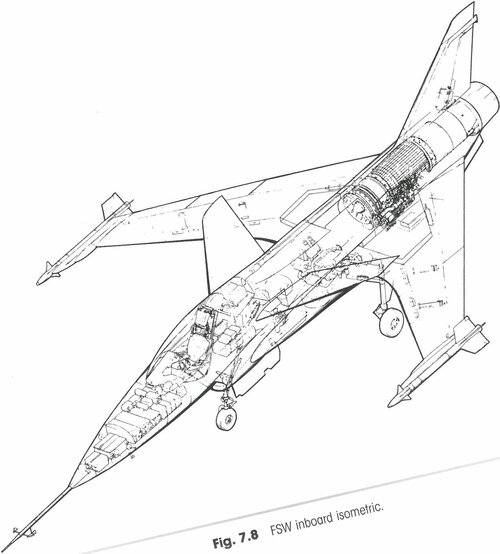

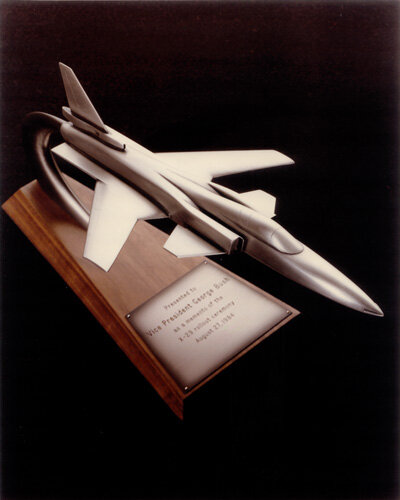

Figure 7. The final X-29 concept. (from Jay Miller’ X-series book). Note the nose strakes to suppress high alpha asymmetries.

There are plenty of other parts to the story, but this is the part I was involved in, and can tell. Not

long after I finished this work, I was pulled off the forward swept wing project to work on a

concept called SuperCritical Conical Camber, or SC3, intended to apply transonic concepts to

supersonic maneuver. This was definitely an aft swept wing concept. Grumman’s chief of aero

never thought Krone would find the money to build the forward swept wing airplane. He thought

the canard wing concept shown in Fig. 9 was what the company should be pursuing. SC3 is

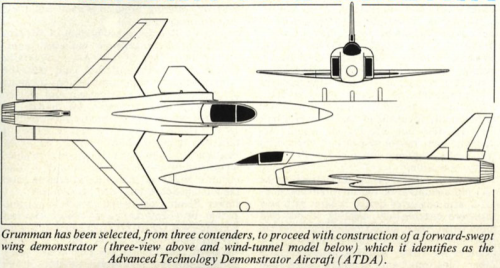

another story (AIAA Paper 83-1858). The company went on to win a competition that included

Rockwell and General Dynamics to build the X-29. They completely ignored stealth during this

time, simply paying lip service to it, but not really thinking it was real. Charlie McLaughlin

became the project aero on Grumman’s VTX proposal. This was the program that led to the T-46

Goshawk. We had a team of Beech and the Link Trainer folks, and thought this was a real “mom

and apple pie” team for the navy. A story that may or may not be true is that Reagan and

Thatcher got together and decided to modify the Hawk for the Navy trainer. At any rate, this loss

was really the end for Grumman as prime airframer, although it took many more years for

everything to play out.

Figure 8. Total drag variation with static margin – why the X-29 had to be highly unstable.

(AIAA 82-0097 and my COMSAC Paper in NASA/CP2004-213028/PT1)

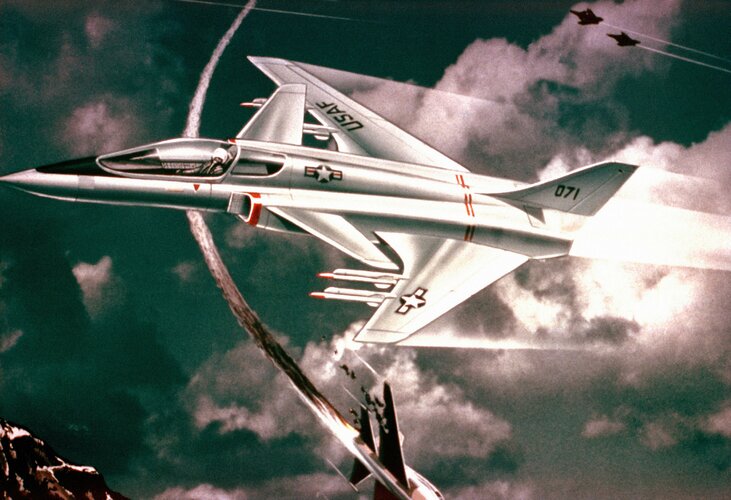

Figure 9. The Grumman Research Fighter Configuration (RFC), a joint program with NASA

Langley, it had its own problems. The NTF model cost $600K and was never tested!