Some last miscellaneous info about the B1 Ter's development and related projects before moving on to other matters (or before next visit):

B1 Bis/Ter engine with ARL improvements:

Per a letter from the ARL on the 20th of April 1938, "The 300 PS Renault engine equipping the B1 Bis and B1 Ter actually delivers 285 PS at 1900 rpm on the bench when fitted with its intake and exhaust manifolds and pipes.

A power increase by 8% at least could be obtained by suitably modifying the shape of its pistons and increasing the compression ratio.

I tasked the Society to Exploit the Fleury Processes/Patents to study the modifications to apply to these pistons; it would be interesting to make 3 different batches of pistons (6 pistons + 2 spares) as fast as possible.

The development costs would be

- 25k Francs if the increase in power was below 8%

- plus an additional 20k Francs if the increase is 8%

- or an additional 30k Francs if the increase is 15%

The bonus would be given back in part or in full if the increase of power for production pistons greater than 8% was instead below 5% over 1/3rd of the production."

Subsequently, it would be noted that the "Renault engine with ARL improvements" also featured an increased normal regime of 1900 rpm instead of 1800 (in fact, even up to 1950 rpm with the new pistons), as well as a more durable exhaust manifold made in special steel and larger diameter pipes, as well as an oil cooler.

Maximum power (presumably with the exhaust manifold and pipes to make sense) was now 310 PS (7 to 10.5% power increase depending on comparison point), while specific fuel consumption dropped a little.

This was an engine tested by the ARL B1 Ter pre-production prototype, but this engine was subsequently replaced by the new Renault V12 for B1 Ters to build in 1941.

Patents of said Raymond Fleury are here:

https://patents.google.com/?invento...fter=priority:19200101&language=FRENCH&page=4

"Hybrid" B1 Bis:

While the B1 Ter program was ongoing, the matter of improving existing or production B1 Bis was not abandonned, and this was accelerated by the outbreak of WW2.

In October 1939, the following improvements were tested on B1 Bis n° 369:

- chain tensionner for the Naëder steering system

- Special belt for the fan drive

- Protective plates for the front spacer tubes (those just below the 75mm gun)

- Intercom

on B1 Bis n°251 (just as the war began) :

- modified (simplified) Naëder where the parts of the mobile generator group were modified to be interchangeable, while previously the entire group had to be replaced if a part failed. This change would have facilitated repairs.

- Aiming sight bracket

- Sound proofing

- Camouflage using the flocking process

- Misc modifications to the APX-4 turret

As of late October 1939, the idea of mounting B1 Ter assemblies to the existing B1 Bis was contemplated. The following could be easily mounted (they were in fact tested on B1 Bis n° 371):

- Intercoms

- Fuel supply circuit

- Fan drive with trapezoidal Textrope belts

- Naëder chain tensionner

- Protection of the front braces/spacers to cross antitank obstacles of the "railtrack field" type

- Move of the recovery hooks

- Provisional muzzle protection device for the 75mm gun while waiting for the device developped by the Atelier de Constructions de Bourges.

To prevent radiator clogging, it was decided on future B1 Bis (tested on n° 371) to:

- install a vent valve on the radiator of the Naëder to prevent oil splashes inside the tank

- protect the radiators with special metallic grilles that can be easily removed for cleaning.

The other modifications can't be used without deep modifications of the hull:

- cooling system

- driver's cabin

- horizontal traverse mount for the 75mm hull gun

The transmission (gearbox) and track tensionners could be mounted, but only pending results of the trials of this gearbox.

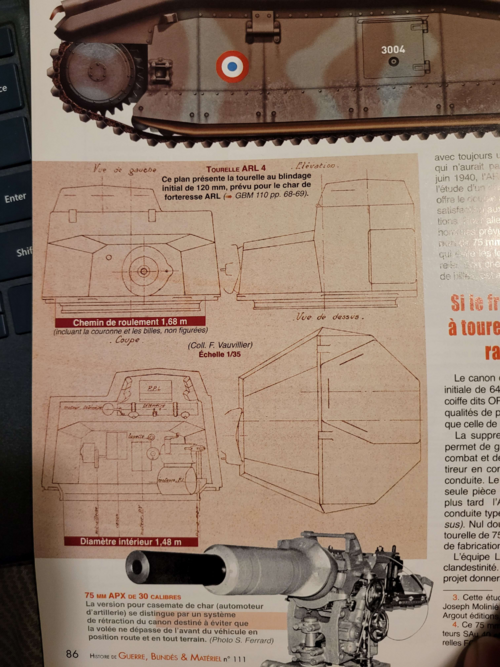

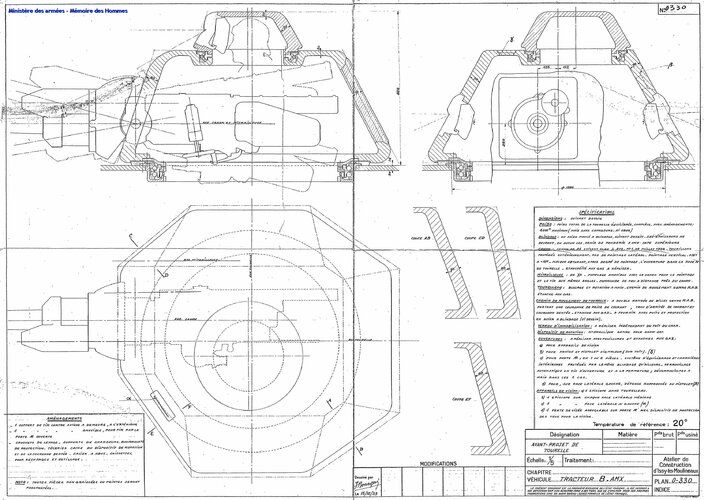

The new ARL 2 turret could be mounted by replacing the roof, moving certain accessories located on the roof, and reducing the turret thickness to 60mm. An early project for replacement of the turret was under study.

The Textrope trapezoidal fan belt system, already in use on other tanks, would be more durable than the existing BOMBYX belt. The latter stretched and worked irregularly, which degraded the operation of the fans that no longer ran at the intended speed.

Other complaints were made about:

- the dynamo, which needed to be more powerful so that the charging current remains at the maximum compatible with the battery capacity when the tank is moving.

- replacing the brakes which are too weak, wear too quickly and were easily disrupted

- bolts on the gearbox command box were too weak and thus broke too quickly, leading to pinion rupture or 2 speeds being selected at the same time

- the half-shafts on the sprockets were too weak

- improving protection of the sprockets (both B1 Bis and B1 Ter per a letter from February 1940)

Simplifications of the tank were to involve the replacement of aluminium or alpax parts with brass or steel, removal of some chamfers, simplifications of the eletrical equipment and driver's cabin.

Overall, B1 Bis upgrades were mostly focused on simplifications or reliability improvements. Only the new turret, intercom, extra fuel capacity (4*50 L reservoirs in the engine bay tunnel in emergency in June OTL, to be followed by a 200L fuel tank instead and an extra 200-250L in a rear extension) and possibly the ARL-improved Renault engine (and B1 Ter gearbox if installed) would lead to direct improvements to crew efficiency and performance.

THAV and electric transmissions or steering systems for the B1 Ter:

The THAV hydraulic steering system developped by the Baudet-Donon-Roussel (BDR) company was originally thought to be tied to the B40. It actually dates all the way back to May 1937 at least. In August, the idea to adapt it to the B1 Ter was raised.

The problem was that the new B1 Ter gearbox was shorter than the similar gearbox of the B1 Bis and B1, but the Naëder was still the same length. As a result, the clutch movement had to be transferred to the Naëder using a system of chains which had mediocre efficiency and insufficient safety. The THAV could be shorter and thus resolve the problem.

In July 1939, an electric steering device was under developpment by the SEAM/Poniatowski to potentially replace the Naëder. The advantages were:

- increased efficiency

- same size, directly replaces the Naëder

- increased force at the output of the electric transmission compared to the hydraulic system

- just as safe

- the electric system retains its characteristics while the Naëder needs to be revized after some time due to loss of efficiency over time.

- half the cost

However it is less convenient to drive (a very common criticism for WW2 tank electric transmissions).

Trials results of the B1 Ter prototype:

In December 1937

- exhaust seals were deteriorated and the batteries were emptied

Maximum speed on flat ground: 30 kph

Average speed (removal of time spent stopped): 26 kph

Average speed on a 80 km trail: 19 kph

Oil temperature reached 100°C, requiring an impoved cooling system.

In early 1939:

- after the needle bearings broke, it was finally decided to replace them by other types of bearings in the gearbox

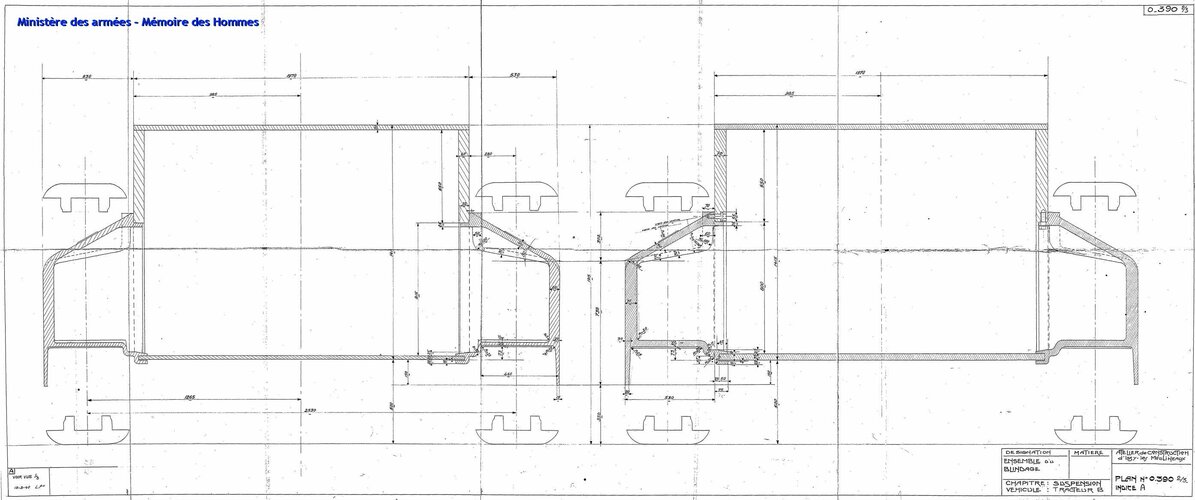

- the suspension should be reinforced (it was following/heeling too much)

Timing of the 3 pre-production prototypes and evolution of the original prototype:

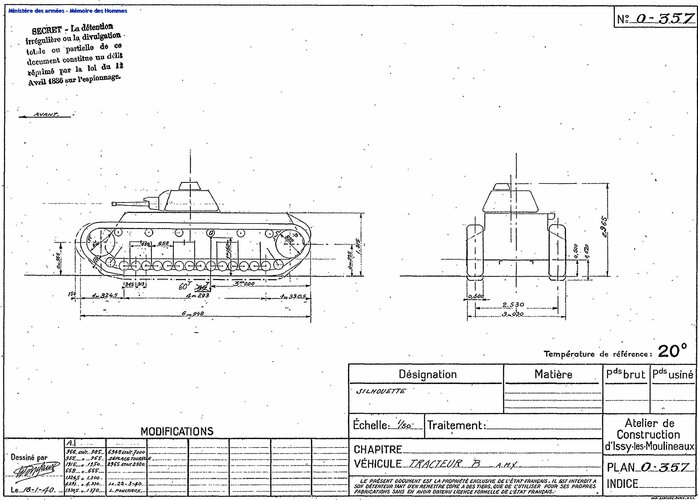

Originally, it was contemplated to order the 7th batallion of B1 tanks as B1 Ter. The decision had to be taken in May 1938, which required rushing trials of the prototype. This battalion would not start being delivered unil November 1939. In the end, it was deemed preferable to build this battalion with B1 Bis, but it was envisionned to build 3 B1 Ters as part of it. This would allow preparation of the drawings, tooling, future studies and production processes for the B1 Ter, and the establishment of production in manufacturers outside of the current Char B consortium. Originally, it was BDR and not Five-Lilles which was intended to build the 2nd preproduction prototype.

As of December 1938, they were expected for late 1939. In November 1939, they were expected for January, February and March 1940.

In October 1938, the prototype was modified:

- revized gearbox

- new compressed air braking system

- new slides for the suspension in cemented steel on one side to compare it to ordinary steel

- reinforced track links

- improved aiming system

- the radiator and fan were modified and laid out horizontally to improve cooling and faciliate access to the tunnel next to the engine. The mass flow rate of the fans was increased.

In April 1939, the original prototype was modified:

- the needle bearings were replaced with ball or roller bearings

Its lubrication system was replaced by a splash lubrication system. This also allowed the deletion of many external lubrication pipes.

- the compressed air brakes were moderated in progressiveness.

- the suspension's leaf springs were reinforced.

- a wooden uninflammable floor was installed for the crew instead of the flocked aluminium floor. This new floor was much more convenient in every way (less cold, safer to handle).

- the oil cooler was replaced with a smaller one.

The preproduction prototypes were to feature the following improvements which could only be tested as mockups:

- reduced size of the radio

- increased battery capacity

- new driver's cabin

- ARL 2 or 37 FCM turret

- increased fuel capacity (possibly just to the 500 L we know about)

- increased ammo capacity

During testing, the following items could be added:

- an engine with an extra 5% power and 8% lower specific fuel consumption (this is in line with the engine with ARL improvements)

- automatic opening of the case ejection port

- special exhaust manifold replacing the current pipes.

The gearbox in use on the pre-production prototypes and potential tanks built in 1939/40 couldn't allow the use of the new 350 PS engine (Renault V12) beyond 2000 rpm. A new mechanism was ordered on June 1939 which would allow the full use of the potential of this engine for tanks made in 1941.

In practice, since production of the B1 Ter was relegated to 1941 at the earliest, only the new transmission would be used. A complete transmission with sprockets suitable for 400 PS was ordered.

Intercom:

The Bronzavia intercom, identical to aircraft types, allowed:

- intercommunication between all crew members

- the radio operator and tank commander both could connect instantly to the radio receptor (previously, only the radio operator could listen IIRC)

This greatly facilitated command of the tank and in turn improved crew safety and reduced fatigue.

Driver's cabin:

All directions relative to the driver.

The old cabin used on the prototype featured:

- a cast steel body including one front face, one left face and the roof which was an access hatch

- behind the slit of each face, a PPL RX 160 episcope, the upper part of which is protected. Fields of vision were 23° vertically and 60° horizontally

- a panoramic Gundlach periscope on the roof

Due to the tall gun mount at the game, the driver could also use this periscope to see to the right.

A new model, showcased in September 1938, featured:

- welded 70mm rolled plates with one front face, 2 lateral faces and a roof acting as access hatch.

Vision was set up as such:

I°) Front face:

a) a window of double the dimensions of the B1 Bis window, equilibrated, that can be opened. This is analogous to what you might see on the Churchill tank, but it opens upwards.

b) On said window, a PPL RX 180 P episcope with a 68° horizontal field of view and a 27° field of view (5° over and 22° under the horizon)

c) an auxiliary vision slit under the window which is obturated by an armor block as long as the PPL is in use.

2°) Left face:

An identical PPL RX 180 P. The upper track cover limits vision to 18° below the horizon.

3°) Right face:

Identical PPL RX 180 P. The setup of the plate, slit of the PPL and gun mount permits relatively interesting vision to the right: 45° horizontally, +5 to -10 ° vertically in spite of the gun and track covers.

4°) Panoramic periscope with an instantaneous field of view of 10°, that can rotate 360°.

The access hatch is of the same dimensions as the B1 Ter prototype but is lighter, less vulnerable and the work to do on the cam to elevate the gun is reduced.

It is possible to see the ground:

1) 3.75m in front of the tracks (same as old cabin)

2) 5.5m from the left flank instead of 9.8m before

3) 10m from the right flank instead of it being impossible.

Observation is better accross the board, the panoramic periscope allows observation when stopped.