Perry Mick's "Duckt"

The

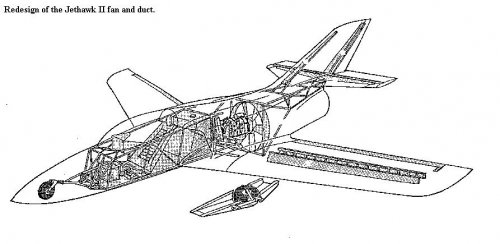

Duckt homebuilt aircraft project was started by Perry Mick in 1986 as a conventional Rutan Long-EZ. An ad by Moller International in 1994 advertising the SkyCar, which is still under development, inspired the idea to develop a ducted fan for homebuilt aircraft built around the readily available 13B rotary engine. By using a Wankel engine with only three basic moving parts, and utilizing it in a direct-drive configuration with the ducted-fan, the goal was to produce cost-effective, reliable propulsion for homebuilt aircraft.

Research into propeller and ducted fan design was begun in 1994. The basic airframe was completed in 1994. Sanding and finishing consumed more time through 1996. Installation of the rotary engine into the Long-EZ began in January 1997. Other than the engine and ducted-fan installation, the aircraft is basically stock Long-EZ, with a few minor modifications such as split forward-hinging canopies and landing lights in the strakes. However, Perry Mick decided to call the airplane "Duckt". The registration number "N7XR" ("RX7" in reverse) was obtained from the FAA.

In 1998 the first ducted fan experiments were performed. The aircraft was moved to the McMinnville, Oregon airport in June. Taxi-tests were performed for a year, from July 1998 to July of 1999, before the first flight was made. These experiments provided the knowledge to design improved ducts and fans. The early experiments that never flew were performed with Fan1 and Duct1. In the summer of 1999 the first test flights were performed with an improved duct and fan combination: Fan2 and Duct2. After about 10 hours of flight time, a lighter weight, improved fan design was built from carbon-fiber, Fan3. This fan allowed the engine to operate at slightly higher RPM, due to thinner blades and a tapered blade chord.

It was believed that the venturi-shape of Duct2 was possibly a mistake, that perhaps this shape was limiting the top-end speed of the aircraft. A new duct was designed with a venturi of 10% (air velocity in the fan plane is 10% higher than aircraft velocity), a significant reduction from Duct2 that has 30%. Duct3 was built in the Spring of 2000 and installed to the existing mounting points on the engine, and initial tests performed. The takeoff distance was increased, climb rate decreased, maximum speed about the same with Duct3. Duct3 loaded the engine more, such that the reduction in RPM offset the speed increase. Duct3 will probably be a desirable duct to use when more power is available, such as when a turbocharger is installed.

Stators were installed in June 2000. It was believed the stators would have little effect, but surprisingly, they improved climb rate by up to 50%. No effect noticed on takeoff distance or maximum speed. The current operational configuration is Duct2 with stator blades and Fan3. Mods performed in early 2003 were engine improvements. A new custom intake manifold was built from composites and relocated to the right wing-root area. This got the bulky and heavy stock manifold off the top of the engine. The big bumps were removed from the cowl, allowing more airflow into the fan and a more streamlined profile with less drag. Top speed increased 5 knots.

When it seemed like the Duckt had finally reached its ideal configuration, Perry Mick announced in February 2005 that Duckt was now ductless! It was converted from ducted fan propulsion to PSRU/prop December 2004 (still powered by a rotary engine). Mick explained that takeoff distance remained the same, climb rate was improved and cruise speed was much improved. "Ducted fans remain a viable alternative, especially for slower applications such as Light Sport Aircraft and gyrocopters. The Long-EZ, other than being a pusher, was probably not the ideal testbed to develop the ducted fan, but I did get almost 500 enjoyable flight hours in over 5 years from the configuration," said Mick.

Specifications, performance figures and more photos on my website:

http://stargazer2006.online.fr/derivatives/pages/duckt.htm