In almost all nuclear-power countries there was in the 1960s a hughe and sometimes very heated, if generally muffled debate within the nuclear industry on what kind of 2nd-generation power reactors to built in large numbers in the '70s and beyhond. It was especially the case in countries that had started to create a national deterrent and supposedly would need large quantities of WG fissile material and had a nascent nuclear power industry (UK, France), countries which had made the political decision to produce nuclear weapons but not yet implemented it (Switzerland), countries which were seriously considering to do it in a pre-NPT era (Sweden, Italy, Japan), and those which had hiden nuclear weapon aspirations (Spain, Argentina). Everywhere the confrontation was between:

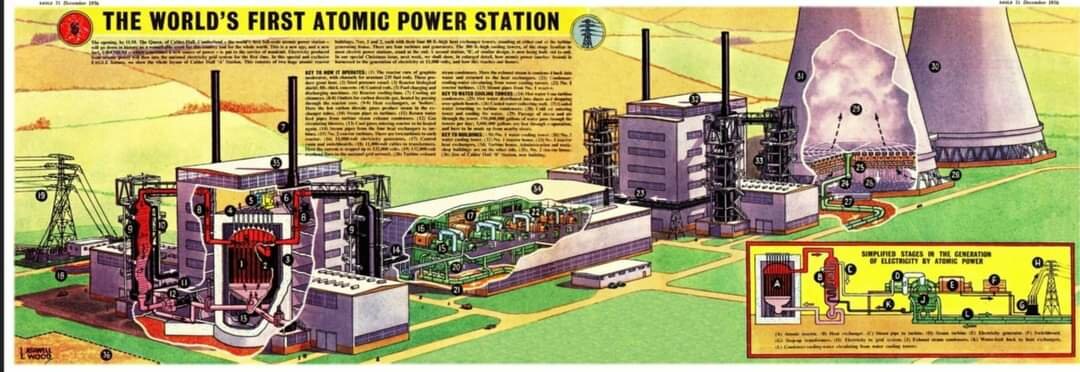

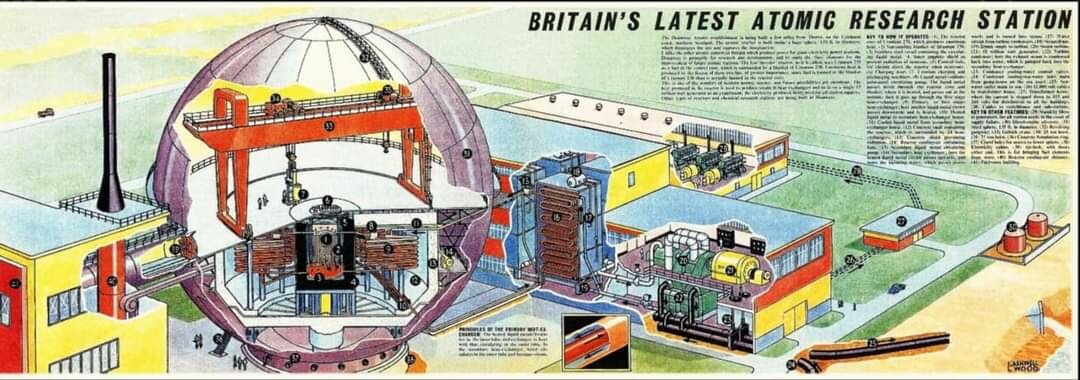

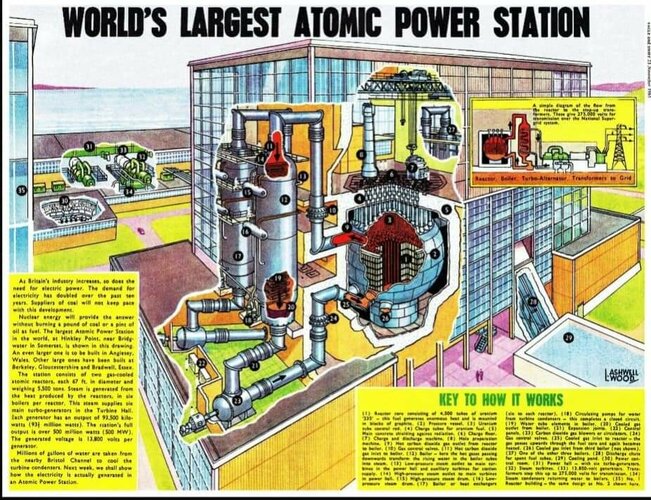

- on the one hand, the proponents of (very) large static-moderator, natural U reactors of national design, led by the atomic research authority, made of the military (interested in WG material production), radiochemistry industry, construction industry (those reactors were first and foremost large concrete structures) and mechanical industry manufacturers that had in their catalogues relatively small conventionnal steam-turbines for thermal power-stations ;

- on the other hands the proponent of (mostly) US technology LWR : utilities and power-generation companies, heavy industries able to produce large forged components (pressure vessels, steam generators) and electromechanical industry. They wanted LWR using low-enriched fuel because they were safer, could be built faster, and were less expensive, both to built and operate. Having to stop operations for refuelling was not an issue for power companies because they would need to do it anyway for maintenance, as they did with thermal plants. Refuelling under power was in fact a nuisance to them.

Everywhere, by 1970, they had won, and imposed (mainly US technology) LWR, "helped" by some minor accidents in national-technology natural-U reactors (Sweden, France) or a serious one (Switzerland, Lucens 1969: worst reactor accident in Europe before Chornobyl).

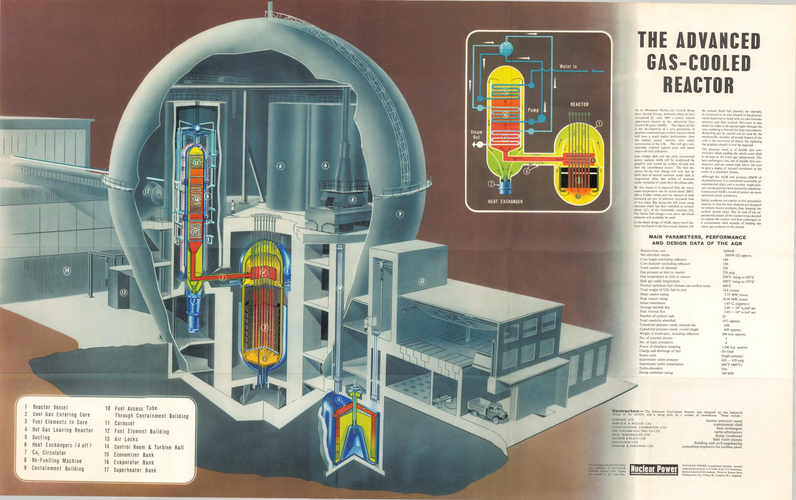

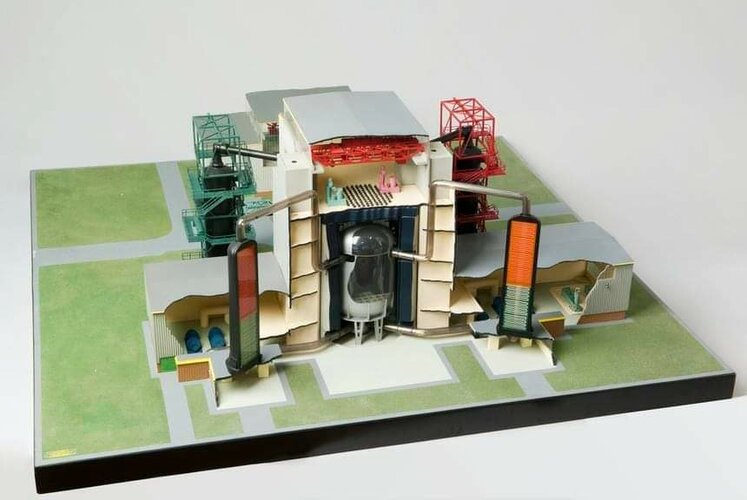

Everywhere, except in the UK, where Tony Ben overruled the CEGB, prevented LWR under US licences, imposed the AGR, and led to the demise of English nuclear industry.

In the USSR the debate was surprisingly similar, the proponents of the natural U reactor RBMK calling disparagingly the Soviet PWR, the VVER, "amerikanskii reaktor", except that in the end due to power-games in Moscow, it was decided to go ahead with both types. In communist Czecoslovakia Skoda had designed and built a national natural-U reactor. It suffered a major accident and Skoda became a VVER licensee.

The only exceptions were of course the US where AEC had decided already in 1957 that future commercial reactors would only be allowed to be LWR; Canada which had chosen CANDU in 1954 and had no industrial capability to manufacture large forged components; and of course Federal Germany. FG was the main proliferation concern of the US administration in the 60s and American pressure led to the early development of national LWR which were often superior to their US counterparts (Siemens Typ 72 BWR vs. GE BWR or KWU Konvoy PWR vs. Westinghouse "F" PWR).

PS : please note that in a CANDU reactor using the original natural U fuel, the void coefficient is indeed positive, albeit compensated by a negative temperature coefficient, and that BWRs have a single steam/water loop (hence, no "primary loop" there).