I mentioned turbo ramjets a few weeks ago being something you should keep an eye out for. Not in artwork either. Exciting times ahead in the not too distant future.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Current US hypersonic weapons projects. (General)

- Thread starter Hanse

- Start date

- Joined

- 21 April 2009

- Messages

- 13,732

- Reaction score

- 7,616

The Hypersonic Missile Debate | Aerospace Center for Space Policy and Strategy

The debate about hypersonic missiles is frequently characterized as a technological one, but it is much more nuanced than that. How should we approach this debate?

bring_it_on

I really should change my personal text

- Joined

- 4 July 2013

- Messages

- 3,637

- Reaction score

- 3,749

Air Force conducts first ARRW operational prototype missile test

Reached hypersonic speeds greater than five times the speed of sound, completed its flight path and detonated in the terminal area.

www.eglin.af.mil

Yes! Finally! Thanks for posting; been waiting for this test even more than the B-21 role out; the latter I knew was unlikely to tell us that much new.

Air Force conducts first ARRW operational prototype missile test

Reached hypersonic speeds greater than five times the speed of sound, completed its flight path and detonated in the terminal area.www.eglin.af.mil

Air Force conducts first ARRW operational prototype missile test

Reached hypersonic speeds greater than five times the speed of sound, completed its flight path and detonated in the terminal area.www.eglin.af.mil

About bloody time! I wonder when we'll get to see launch footage on YT?

La-Fuente Technologies

F-47 NEXT GENERATION AIR DOMINANCE

- Joined

- 21 November 2022

- Messages

- 369

- Reaction score

- 355

Lockheed Martin's video on the subject

Air Force conducts first ARRW operational prototype missile test

Reached hypersonic speeds greater than five times the speed of sound, completed its flight path and detonated in the terminal area.www.eglin.af.mil

Air Force conducts first ARRW operational prototype missile test

Reached hypersonic speeds greater than five times the speed of sound, completed its flight path and detonated in the terminal area.www.eglin.af.mil

About bloody time! I wonder when we'll get to see launch footage on YT?

I doubt we ever see it launched. We haven’t even seen AIM-260 yet and it is supposed to enter service next year…

bring_it_on

I really should change my personal text

- Joined

- 4 July 2013

- Messages

- 3,637

- Reaction score

- 3,749

- Joined

- 3 June 2011

- Messages

- 18,302

- Reaction score

- 12,122

Would be interesting if they showed the landing zone.Depends on what they show. They've shown ARRW launch pictures. You aren't going to chase it much beyond the launch so its not like they could show the entire sequence.

Would be interesting if they showed the landing zone.

Was it carrying the glide-vehicle though? Or was it just a test of the booster?

This was supposed to be end to end AUP round that hit the target area successfully.Would be interesting if they showed the landing zone.

Was it carrying the glide-vehicle though? Or was it just a test of the booster?

Does anyone know what other tests are scheduled? I know the USAF was angling for some kind of limited capability by the end of 2023 with whatever test articles weren't consumed.

bring_it_on

I really should change my personal text

- Joined

- 4 July 2013

- Messages

- 3,637

- Reaction score

- 3,749

This was an end to end test that included warhead detonation over the target area so yes on the question of whether the glider was used.

Switching gears, some questions about the HAWC/HACM programs: How many tests were run total (per open source)? I feel like I only heard about four tests total; two for each design. I had thought each was going to get three tests? Are more pending? On that subject was the MoHAWC extension approved?

Also is there any open source mention of what aircraft carried the demonstrators? I had assumed B-52 as usual for most large weapon types, but a statement to lawmakers from Air Force Chief of Staff Gen. CQ Brown indicated that the F-15E/EX would be the first aircraft integrated with the HACM when it enters service. This makes me wonder if perhaps HAWC and HACM aren't really suitable for regular B-52 carriage - mkellytx indicated that the B-52 struggled to get up to 49,000 feet with the X-51 stack. The B-52 might be satisfactory for testing individual weapons, but the choice of the F-15 as the initial platform makes me wonder if perhaps one of the penalties for shrinking the scramjet/booster stack down to a tactical size and having a fixed inlet/combustor scramjet only geometry means that the weapon must be launched around 50,000 feet? If it is a single stage booster to cruise speed weapon, there might not be a way of making the whole package small/light enough to be fired at 30,000 feet. The X-51 stack was 4000lbs and 24' long, and while 3D printing, smaller interstage (X-51 used a four foot long flow through design), and booster optimization will shrink that down a bit, I'd think the energy difference of 20,000 feet of altitude would be hard to overcome in similarly sized package. A fighter can reheat and get to the altitude it needs to be at; the B-21 likely will just live at 50,000 feet as it's normal cruise altitude. I wonder if the USAF didn't decide that keeping the weapon lighter and cheaper to manufacture was worth limiting the envelope to platforms with higher service ceilings?

Also is there any open source mention of what aircraft carried the demonstrators? I had assumed B-52 as usual for most large weapon types, but a statement to lawmakers from Air Force Chief of Staff Gen. CQ Brown indicated that the F-15E/EX would be the first aircraft integrated with the HACM when it enters service. This makes me wonder if perhaps HAWC and HACM aren't really suitable for regular B-52 carriage - mkellytx indicated that the B-52 struggled to get up to 49,000 feet with the X-51 stack. The B-52 might be satisfactory for testing individual weapons, but the choice of the F-15 as the initial platform makes me wonder if perhaps one of the penalties for shrinking the scramjet/booster stack down to a tactical size and having a fixed inlet/combustor scramjet only geometry means that the weapon must be launched around 50,000 feet? If it is a single stage booster to cruise speed weapon, there might not be a way of making the whole package small/light enough to be fired at 30,000 feet. The X-51 stack was 4000lbs and 24' long, and while 3D printing, smaller interstage (X-51 used a four foot long flow through design), and booster optimization will shrink that down a bit, I'd think the energy difference of 20,000 feet of altitude would be hard to overcome in similarly sized package. A fighter can reheat and get to the altitude it needs to be at; the B-21 likely will just live at 50,000 feet as it's normal cruise altitude. I wonder if the USAF didn't decide that keeping the weapon lighter and cheaper to manufacture was worth limiting the envelope to platforms with higher service ceilings?

Last edited:

bring_it_on

I really should change my personal text

- Joined

- 4 July 2013

- Messages

- 3,637

- Reaction score

- 3,749

Three More Successful All-Up ARRW Tests Required Before Production Decision | Air & Space Forces Magazine

Before the Air Force makes a production decision on the ARRW hypersonic missile, it wants three more successful flight tests.

- Joined

- 3 June 2011

- Messages

- 18,302

- Reaction score

- 12,122

"The program calls for a “leave-behind” capability of an undisclosed number of missiles that could be used in combat after the prototyping phase ends, the Air Force said."

Well that doesn't inspire confidence. Almost sounds like another case of, "our testing was a success. . .so we're killing the program now." Normally you'd have production rounds "that could be used in combat".

Well that doesn't inspire confidence. Almost sounds like another case of, "our testing was a success. . .so we're killing the program now." Normally you'd have production rounds "that could be used in combat".

bring_it_on

I really should change my personal text

- Joined

- 4 July 2013

- Messages

- 3,637

- Reaction score

- 3,749

The program always intended to do that given the limitations of 4-5 years for a Mid-Tier prototyping effort (that's a legal requirement). It was expected that testing would conclude in FY-22, and production of additional operational prototypes would take place in FY-2023 followed by the program transitioning to a formal program a year or more later. That didn't happen because of test failures as the AF did not want to procure prototypes in FY-2023 because it didn't know at the time the decision was made, whether the design issues had been resolved or not. Whatever rounds are left post testing would have always transitioned to operational availability. Now, the AF will decide on FY-2024 production decision based on remaining testing...though it and the Congress could always ask funds to be reprogrammed in FY-23. We will have to wait for some additional testing to find out either way. If the remaining test shots go fine, and the AF decides to buy additional operational prototypes in FY-2024 then there would be some gap before it receives the rounds. They could mitigate that by requesting funds be moved in FY-2023 but this thing isn't really going to be purchased in any scale until it (if) transitions to a formal program of record.

- Joined

- 21 April 2009

- Messages

- 13,732

- Reaction score

- 7,616

Hypersonics at scale: What it takes in terms of tech, manufacturing, and talent - Breaking Defense

Providing air-breathing and boost-glide hypersonics propulsion requires a holistic approach to address each system’s unique needs for speed.

- Joined

- 1 April 2006

- Messages

- 11,364

- Reaction score

- 10,149

Mayhem Hypersonic Strike-Recon Jet Contract Awarded To Leidos

The Air Force has said it wants the experimental Mayhem air vehicle to demonstrate strike and intelligence-gathering capabilities.

- Joined

- 3 June 2011

- Messages

- 18,302

- Reaction score

- 12,122

"Leidos' new contract, which was awarded by the Air Force Research Laboratory (AFRL) is a "single award, indefinite-delivery/indefinite-quantity" deal with a $334 million ceiling, according to the Pentagon's daily contracting notice."

Mayhem Hypersonic Strike-Recon Jet Contract Awarded To Leidos

The Air Force has said it wants the experimental Mayhem air vehicle to demonstrate strike and intelligence-gathering capabilities.www.thedrive.com

I'd be shocked if they didn't burn through that without ever flying anything.

Forest Green

ACCESS: Above Top Secret

- Joined

- 11 June 2019

- Messages

- 9,415

- Reaction score

- 17,153

It'll fill plenty of filing cabinets though and rainforests are already wincing at the prospect."Leidos' new contract, which was awarded by the Air Force Research Laboratory (AFRL) is a "single award, indefinite-delivery/indefinite-quantity" deal with a $334 million ceiling, according to the Pentagon's daily contracting notice."

I'd be shocked if they didn't burn through that without ever flying anything.

- Joined

- 3 June 2011

- Messages

- 18,302

- Reaction score

- 12,122

Not filing cabinets. Hard drives.It'll fill plenty of filing cabinets though and rainforests are already wincing at the prospect."Leidos' new contract, which was awarded by the Air Force Research Laboratory (AFRL) is a "single award, indefinite-delivery/indefinite-quantity" deal with a $334 million ceiling, according to the Pentagon's daily contracting notice."

I'd be shocked if they didn't burn through that without ever flying anything.

Forest Green

ACCESS: Above Top Secret

- Joined

- 11 June 2019

- Messages

- 9,415

- Reaction score

- 17,153

Don't they still require paper backups and signed copied though? That was a thing even a decade ago.Not filing cabinets. Hard drives.

- Joined

- 21 April 2009

- Messages

- 13,732

- Reaction score

- 7,616

Would a contract not include test expectations of actual flights?Don't they still require paper backups and signed copied though? That was a thing even a decade ago.Not filing cabinets. Hard drives.

- Joined

- 3 June 2011

- Messages

- 18,302

- Reaction score

- 12,122

Stuff that started years ago. Most current stuff is Model Based Definition (MBD). Even work instructions are going digital. The only stuff I've signed with a pen in years are docs that require an actual signature and even those get scanned in and the hard copies shredded.Don't they still require paper backups and signed copied though? That was a thing even a decade ago.Not filing cabinets. Hard drives.

Forest Green

ACCESS: Above Top Secret

- Joined

- 11 June 2019

- Messages

- 9,415

- Reaction score

- 17,153

But typically all engineering docs require a signature from the Author, Checker and Approver?? Isn't that part of ISO 9001 or something?Stuff that started years ago. Most current stuff is Model Based Definition (MBD). Even work instructions are going digital. The only stuff I've signed with a pen in years are docs that require an actual signature and even those get scanned in and the hard copies shredded.

- Joined

- 3 June 2011

- Messages

- 18,302

- Reaction score

- 12,122

It's all digital. Instead of a classic drawing with a title block you'll have the model, a sheet for notes, and a signature sheet. All digital.But typically all engineering docs require a signature from the Author, Checker and Approver?? Isn't that part of ISO 9001 or something?Stuff that started years ago. Most current stuff is Model Based Definition (MBD). Even work instructions are going digital. The only stuff I've signed with a pen in years are docs that require an actual signature and even those get scanned in and the hard copies shredded.

Last edited:

- Joined

- 3 June 2011

- Messages

- 18,302

- Reaction score

- 12,122

One hopes. Wouldn't be the first time we've heard, "whoops, my bad. Ran out of money" though.Would a contract not include test expectations of actual flights?Don't they still require paper backups and signed copied though? That was a thing even a decade ago.Not filing cabinets. Hard drives.

bring_it_on

I really should change my personal text

- Joined

- 4 July 2013

- Messages

- 3,637

- Reaction score

- 3,749

That's a ton of money for something that is not an operational prototyping effort or a committed to weapons program like ARRW, LRHW, HACM. This shows that they are looking at beyond the first gen of boost glide or air-breathing hypersonic systems and towards future needs. I would say this is very promising.

Firefinder

ACCESS: Top Secret

- Joined

- 5 October 2019

- Messages

- 1,041

- Reaction score

- 1,888

It all digital.It's all digital. Instead of a classic drawing with a title block you'll have the model, a sheet for notes, and a signature sheet. All digital.But typically all engineering docs require a signature from the Author, Checker and Approver?? Isn't that part of ISO 9001 or something?Stuff that started years ago. Most current stuff is Model Based Definition (MBD). Even work instructions are going digital. The only stuff I've signed with a pen in years are docs that require an actual signature and even those get scanned in and the hard copies shredded.

Then it is Print out several times and stuff in several different vaults around the country.

Cause after the Snafu the Navy had with the digital Nimitiz class Blueprints sometime back where the copy they made in the mid 1990s did not work on the early 2000s programing and was only thanks to the older paper backs that nothing worse happened then a few near heartattacks. The DOD precede pushed out that all programs need to have paper back ups of an easy to read type.

OF EVERYTHING.

Cause digital corrupt from standard digital fuckouts, we all lost files on our computers due to any number of issues, to the fun incompatibility of different program versions like what happened to the Navy. Digitial files have inherent weaknesses and just dont last as long as Paper does or the near forever and a day that mircofilm does.

It since became standard practice to do so for all the big name companies as well.

Just common sense and covering you bases.

- Joined

- 3 June 2011

- Messages

- 18,302

- Reaction score

- 12,122

GuaranTEE you there aren't paper prints of the types of models I'm thinking off. There are, quite literally, no drawings to print.It all digital.It's all digital. Instead of a classic drawing with a title block you'll have the model, a sheet for notes, and a signature sheet. All digital.But typically all engineering docs require a signature from the Author, Checker and Approver?? Isn't that part of ISO 9001 or something?Stuff that started years ago. Most current stuff is Model Based Definition (MBD). Even work instructions are going digital. The only stuff I've signed with a pen in years are docs that require an actual signature and even those get scanned in and the hard copies shredded.

Then it is Print out several times and stuff in several different vaults around the country.

Cause after the Snafu the Navy had with the digital Nimitiz class Blueprints sometime back where the copy they made in the mid 1990s did not work on the early 2000s programing and was only thanks to the older paper backs that nothing worse happened then a few near heartattacks. The DOD precede pushed out that all programs need to have paper back ups of an easy to read type.

OF EVERYTHING.

Cause digital corrupt from standard digital fuckouts, we all lost files on our computers due to any number of issues, to the fun incompatibility of different program versions like what happened to the Navy. Digitial files have inherent weaknesses and just dont last as long as Paper does or the near forever and a day that mircofilm does.

It since became standard practice to do so for all the big name companies as well.

Just common sense and covering you bases.

Firefinder

ACCESS: Top Secret

- Joined

- 5 October 2019

- Messages

- 1,041

- Reaction score

- 1,888

Oh you can be surprise with what you can print out if wanted.GuaranTEE you there aren't paper prints of the types of models I'm thinking off. There are, quite literally, no drawings to print.It all digital.It's all digital. Instead of a classic drawing with a title block you'll have the model, a sheet for notes, and a signature sheet. All digital.But typically all engineering docs require a signature from the Author, Checker and Approver?? Isn't that part of ISO 9001 or something?Stuff that started years ago. Most current stuff is Model Based Definition (MBD). Even work instructions are going digital. The only stuff I've signed with a pen in years are docs that require an actual signature and even those get scanned in and the hard copies shredded.

Then it is Print out several times and stuff in several different vaults around the country.

Cause after the Snafu the Navy had with the digital Nimitiz class Blueprints sometime back where the copy they made in the mid 1990s did not work on the early 2000s programing and was only thanks to the older paper backs that nothing worse happened then a few near heartattacks. The DOD precede pushed out that all programs need to have paper back ups of an easy to read type.

OF EVERYTHING.

Cause digital corrupt from standard digital fuckouts, we all lost files on our computers due to any number of issues, to the fun incompatibility of different program versions like what happened to the Navy. Digitial files have inherent weaknesses and just dont last as long as Paper does or the near forever and a day that mircofilm does.

It since became standard practice to do so for all the big name companies as well.

Just common sense and covering you bases.

Especailly since there are HUNDREDS of programs out there to transfer CAD and 3d flow Draw and fuck knows what else = out there all made so you can put whats on the program onto paper.

- Joined

- 3 June 2011

- Messages

- 18,302

- Reaction score

- 12,122

There isn't any software that's going to magically convert 3D MBD models into part drawings. Sorry but you don't know what you're talking about. Sure, you can do screen renders but you aren't getting part drawings, with GD&T from those. And many curves are only defined by the splines in the model. You aren't going to be able to define them in a 2D drawing accurately.Oh you can be surprise with what you can print out if wanted.GuaranTEE you there aren't paper prints of the types of models I'm thinking off. There are, quite literally, no drawings to print.It all digital.It's all digital. Instead of a classic drawing with a title block you'll have the model, a sheet for notes, and a signature sheet. All digital.But typically all engineering docs require a signature from the Author, Checker and Approver?? Isn't that part of ISO 9001 or something?Stuff that started years ago. Most current stuff is Model Based Definition (MBD). Even work instructions are going digital. The only stuff I've signed with a pen in years are docs that require an actual signature and even those get scanned in and the hard copies shredded.

Then it is Print out several times and stuff in several different vaults around the country.

Cause after the Snafu the Navy had with the digital Nimitiz class Blueprints sometime back where the copy they made in the mid 1990s did not work on the early 2000s programing and was only thanks to the older paper backs that nothing worse happened then a few near heartattacks. The DOD precede pushed out that all programs need to have paper back ups of an easy to read type.

OF EVERYTHING.

Cause digital corrupt from standard digital fuckouts, we all lost files on our computers due to any number of issues, to the fun incompatibility of different program versions like what happened to the Navy. Digitial files have inherent weaknesses and just dont last as long as Paper does or the near forever and a day that mircofilm does.

It since became standard practice to do so for all the big name companies as well.

Just common sense and covering you bases.

Especailly since there are HUNDREDS of programs out there to transfer CAD and 3d flow Draw and fuck knows what else = out there all made so you can put whats on the program onto paper.

CWilkinson

ACCESS: Restricted

- Joined

- 29 August 2019

- Messages

- 28

- Reaction score

- 94

Modern precision aerospace manufacturing doesn't need physical drawings because there are no machinists that will read them, nor vast numbers of factory installers to use them. The construction "drawings" are digital files created on very fast computers with vast memory in 3D by engineers using proprietary software, the design of which was informed by 40 years of software development and billions in investment by the aerospace companies by people trained to understand the screw ups of the past. Access to the digital files is completely through displays, not paper. Designers that used 10-year-old software and used paper drawing set need not apply.

The software used for the machines used by our soldiers, aviators and sailors however is another separate matter. There is a major push for new, open software that can be updated on the fly in the field to avoid having our soldiers fighting old software in the field. Thats new and I'm sure there will be software screwups, but software development is so fast now that it'll be resolved even as it's in the field by satellite and even while in battle. They're teaching programming in second grade now. The pipeline of talent is only getting stronger.

You could argue that the manufacturing software has glitches and will be so outdated in 10 years that it can't be updated or accessed, or blackouts, or floor stoppages defeat the software, and so that paper drawings are a good analog backup. The software used today can be updated faster than the old software's of yore, now and in the future. The problems of the past inform the software designs now on multiple levels. Open software is the way forward. What you knew in the 90s does not exist now. Paper is dead, long live the 3D digital file.

The software used for the machines used by our soldiers, aviators and sailors however is another separate matter. There is a major push for new, open software that can be updated on the fly in the field to avoid having our soldiers fighting old software in the field. Thats new and I'm sure there will be software screwups, but software development is so fast now that it'll be resolved even as it's in the field by satellite and even while in battle. They're teaching programming in second grade now. The pipeline of talent is only getting stronger.

You could argue that the manufacturing software has glitches and will be so outdated in 10 years that it can't be updated or accessed, or blackouts, or floor stoppages defeat the software, and so that paper drawings are a good analog backup. The software used today can be updated faster than the old software's of yore, now and in the future. The problems of the past inform the software designs now on multiple levels. Open software is the way forward. What you knew in the 90s does not exist now. Paper is dead, long live the 3D digital file.

- Joined

- 3 June 2011

- Messages

- 18,302

- Reaction score

- 12,122

I wouldn't go that far.Modern precision aerospace manufacturing doesn't need physical drawings because there are no machinists that will read them, nor vast numbers of factory installers to use them. The construction "drawings" are digital files created on very fast computers with vast memory in

- Joined

- 21 April 2009

- Messages

- 13,732

- Reaction score

- 7,616

Successful sounding rocket campaign advances hypersonic weapon tech for Navy, Army

The vehicle spent about one minute above Mach 9 in a relevant altitude band, an unprecedented accomplishment for a sounding rocket.

www.sandia.gov

aonestudio

I really should change my personal text

- Joined

- 11 March 2018

- Messages

- 2,962

- Reaction score

- 7,475

DARPA Operational Fires (OpFires)

View: https://www.youtube.com/watch?v=fQ1yQONC8mU

www.lockheedmartin.com

www.lockheedmartin.com

Lockheed Martin’s Hypersonic OpFires Missile Has Medium Range Covered

In early 2020, Lockheed Martin began work on Operational Fires (OpFires) weapon system integration under a Defense Advanced Research Projects Agency (DARPA) contract. OpFires is an innovative ground-launched system that enables a hypersonic boost glide missile system to penetrate modern enemy...

Last edited:

What puzzles me is the delay b/w the turbojet regime and ramjet. Mostly because they are running this from a static container with no forced airflow like you would have in a wind tunnel.

At one time, they speak about "energetics". I sometimes wonder if they are not using reactive material to build pressure during the transition. This would explain the safe shutdown of the turbojet, the slight delay and then the ramjet blowing exhaust at full, quickly stable, regime.

I haven't seen yet any precooler. I would appreciate if anyone can direct me to where that is identifiable.

At one time, they speak about "energetics". I sometimes wonder if they are not using reactive material to build pressure during the transition. This would explain the safe shutdown of the turbojet, the slight delay and then the ramjet blowing exhaust at full, quickly stable, regime.

I haven't seen yet any precooler. I would appreciate if anyone can direct me to where that is identifiable.

CWilkinson

ACCESS: Restricted

- Joined

- 29 August 2019

- Messages

- 28

- Reaction score

- 94

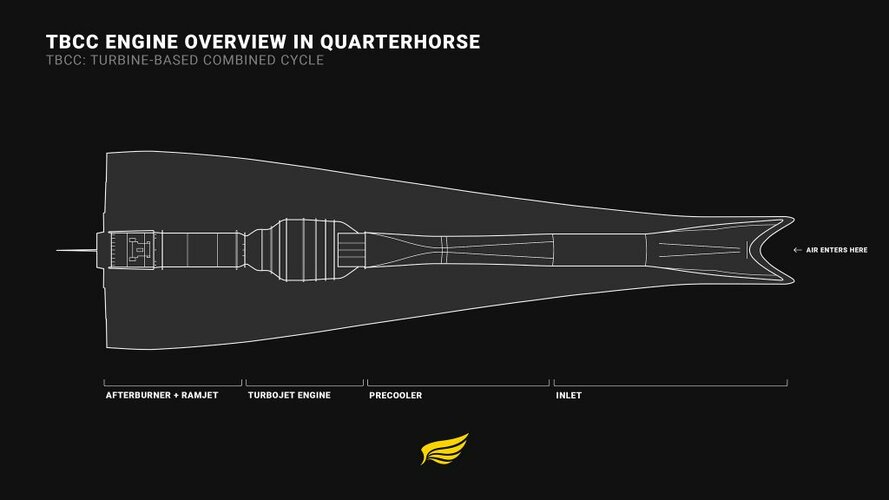

The precooler is shown on the Hermeus diagram for Quarterhorse attached here. The delay is puzzling between the turbojet and ramjet operation. I wondered if the design has a mechanical process that prevents back pressure onto the turbine section of the turbojet associated before ramjet operation. I'm not familiar with the J58 to know if this was a problem during the transition to and from the turbojet operation.What puzzles me is the delay b/w the turbojet regime and ramjet. Mostly because they are running this from a static container with no forced airflow like you would have in a wind tunnel.

At one time, they speak about "energetics". I sometimes wonder if they are not using reactive material to build pressure during the transition. This would explain the safe shutdown of the turbojet, the slight delay and then the ramjet blowing exhaust at full, quickly stable, regime.

I haven't seen yet any precooler. I would appreciate if anyone can direct me to where that is identifiable.

The Chimera engine test was conducted at Notre Dame Turbomachinery Laboratory test stand that produced the M4 airflow for the engine test.

Attachments

Similar threads

-

Lockheed Martin AGM-183 Air-Launched Rapid Response Weapon (ARRW)

- Started by Moose

- Replies: 667

-

-

China DF-17 hypersonic boost-glide missile carrier

- Started by antigravite

- Replies: 41

-

-