You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Boom Supersonic Overture M1.8 SST

- Thread starter DrRansom

- Start date

Scott Kenny

ACCESS: USAP

- Joined

- 15 May 2023

- Messages

- 11,184

- Reaction score

- 13,563

I was thinking a CFM56 with about a 55" fan, maybe a bit smaller.Minus the burner, it might not be far off. They're going to have to be able to take off and climb out on partial engine thrust to hit the noise targets, so they might need something that big.

It could actually make sense. The older AvWeek article on Boom said they were looking at two cores -- one military and one civilian, as the possible basis for their new engine. The F101 core evolved into the CFM56, so they might be thinking about reversing that evolution, refanning a modern CFM56 core into a lower-bypass design.

Apparently, reduced boom requires an absurd anteater nose.I just came back from watching their artwork on their website and... This is the thing (at least as engineered by their marketing dept).

It seems they have lengthened the fuselage and covered it with windows all along. Looks really narrow as noted (compare the diameter of the front wheels with that of a fuselage section).

What strikes me the most is the never ending fuselage length fitted to a rear mounted small delta wing. I mean see it in terms of alpha and inertia: this thing looks twitchy to land.

I would definitively have kept the short fuselage model.

If you build the plane right to begin with, no SAS required.NO SAS was planned before that?! Doesn't it sound odd?

Nobody has had issues with titanium fires in their engines since the 1960s, because people learned just how much stretch was happening and made the appropriate allowances for it.Does anyone know if the J85 has steel LP compressor blades/staters?

I notice it was never used in any super cruise applications and typically super cruise engines will have a steel front end. This was/is because of the heat build up during sustained supersonic flight. Aluminium Alloy loses strength too quickly and Titanium has a habit of catching fire although has seen a few applications. Most supersonic aircraft such as the F5 will only be cleared for a short time at high speed measured in tens of seconds to a few single minutes. The XB1 usefulness will be significantly limited if it can’t collect sustained supersonic flight thermal flux data.

Also has anyone seen objective for time at supersonic Mach number?

No, everything I have seen about sonic boom reduction means super stretched noses and tiny wings.The demonstrator has a quite « reasonable » nose length compare to the Low Boom Flight Demonstration Aircraft or some JAXA sst research concepts. At least it doesn’t look like a Pinocchio .

Was it found these extra long noses concepts not that efficient for sonic boom reduction ?

Having worked for an aerospace company at third shift, First Shift was definitely made up of idiots and or people who were in meetings all day instead of doing productive things like working on aircraft.It's a bit frustrating to read posts that would make you believe that the workforce of aerospace companies is entirely made up of idiots.

I do like that shaping. Depending on how you set up the interior, you could make a pretty nice "executive lounge" up front where the airframe is wide and still have 1+1 seating in the back where the tube is smaller.New design from Boom Aero. Four engines now. View: https://twitter.com/AvWeekGuy/status/1549320797306716160?t=-2ln4ZQpyqvcAhABkRqitg&s=19

I was thinking about turning a CFM56 into a knockoff NK32, make the fans 55-57" in diameter.So basically GE need to remake F101 for Boom. Idk if there is money for that, but surely it will be cheaper than asking RR to develop new engine.

If in this year, the east Europe situation not happening, i will suggesting crazy idea to buy NK-32 for Boom.

Interesting, did not know that.Definitely having doubts about the Ovation configuration being able to make thrust at the 1.8M cruise point. A single stage fan, even if it looks like the 1st stage of the F119 fan, is not going to generate the fan pressure ratio needed in a mixed flow non afterburning turbofan (see the big mixer at the aft end?) to push the exhaust out fast enough to make thrust at that cruise speed. Even with modern aero design it will be hard to get the fan pressure ratio much beyond 2:1, which gets you M1 at the nozzle exit. The F119 has a 3 stage fan to get the exhaust velocity needed for positive thrust at those speeds in the F-22.

Do you think a CFM56 with a 55" diameter, 3-4 stage fan would make enough thrust for supersonic flight?

- Joined

- 15 January 2021

- Messages

- 392

- Reaction score

- 1,428

Could a CFM56 core drive a multi-stage 55”diameter fan? As the F101, an early version of that core drove a 2 stage that was approximately 45” in diameter (rated at 350 lbs /sec airflow), but was only a fan pressure ratio in the 2.2-2.5 range. The latest CFM56 core undoubtedly has higher capability than the F101 core. The latest military version of that core is the F110-GE-132 driving a 3 stage fan with 275 lbs/sec airflow at a fan pressure ratio of 3.2.

Would that configuration provide sufficient supersonic dry thrust at M1.8? Doubtful, since a clean F-16 with a F110-129 has little supercruise capability, maybe able to do M1.1 on a good day. Overture will have less supersonic drag coefficient than an F-16, but you are still a long way from M1.8.

Another issue is at M1.8 at altitude, the inlet temperature will be around 180F. Aerodynamically, an engine slows down with increasing inlet temperature, even if it is maintaining a constant physical RPM. To maintain full airflow at 180F, the fan will have to be turning 11% faster than it does on a standard day temp of 59F. Rotor speed and internal temperature limits are usually reached at much lower inlet temps, with performance dropping off as the inlet temp increases.

Would that configuration provide sufficient supersonic dry thrust at M1.8? Doubtful, since a clean F-16 with a F110-129 has little supercruise capability, maybe able to do M1.1 on a good day. Overture will have less supersonic drag coefficient than an F-16, but you are still a long way from M1.8.

Another issue is at M1.8 at altitude, the inlet temperature will be around 180F. Aerodynamically, an engine slows down with increasing inlet temperature, even if it is maintaining a constant physical RPM. To maintain full airflow at 180F, the fan will have to be turning 11% faster than it does on a standard day temp of 59F. Rotor speed and internal temperature limits are usually reached at much lower inlet temps, with performance dropping off as the inlet temp increases.

- Joined

- 27 May 2008

- Messages

- 1,178

- Reaction score

- 2,480

Zoo Tycoon said:

“Does anyone know if the J85 has steel LP compressor blades/staters?

I notice it was never used in any super cruise applications and typically super cruise engines will have a steel front end. This was/is because of the heat build up during sustained supersonic flight. Aluminium Alloy loses strength too quickly and Titanium has a habit of catching fire although has seen a few applications. Most supersonic aircraft such as the F5 will only be cleared for a short time at high speed measured in tens of seconds to a few single minutes. The XB1 usefulness will be significantly limited if it can’t collect sustained supersonic flight thermal flux data.

Also has anyone seen objective for time at supersonic Mach number?

Nobody has had issues with titanium fires in their engines since the 1960s, because people learned just how much stretch was happening and made the appropriate allowances for it.”

Scott Kenny replied;-

Nobody has had issues with titanium fires in their engines since the 1960s, because people learned just how much stretch was happening and made the appropriate allowances for it.

Zoo Tycoon

Ah no, Concorde entered service in 1976, and by 1980 had suffered two Ti compressor fires. So several Ti compressor stages were changed to steel. I understand the problem wasn’t blade stretch, but manufacture quality assurance. Remember that in the first five years of Concorde service the fleet, although small, achieved about 100 x the time at Mach 2 as the entire military previous experience. The grim reality associated with pioneering is a harsh mistress.

“Does anyone know if the J85 has steel LP compressor blades/staters?

I notice it was never used in any super cruise applications and typically super cruise engines will have a steel front end. This was/is because of the heat build up during sustained supersonic flight. Aluminium Alloy loses strength too quickly and Titanium has a habit of catching fire although has seen a few applications. Most supersonic aircraft such as the F5 will only be cleared for a short time at high speed measured in tens of seconds to a few single minutes. The XB1 usefulness will be significantly limited if it can’t collect sustained supersonic flight thermal flux data.

Also has anyone seen objective for time at supersonic Mach number?

Nobody has had issues with titanium fires in their engines since the 1960s, because people learned just how much stretch was happening and made the appropriate allowances for it.”

Scott Kenny replied;-

Nobody has had issues with titanium fires in their engines since the 1960s, because people learned just how much stretch was happening and made the appropriate allowances for it.

Zoo Tycoon

Ah no, Concorde entered service in 1976, and by 1980 had suffered two Ti compressor fires. So several Ti compressor stages were changed to steel. I understand the problem wasn’t blade stretch, but manufacture quality assurance. Remember that in the first five years of Concorde service the fleet, although small, achieved about 100 x the time at Mach 2 as the entire military previous experience. The grim reality associated with pioneering is a harsh mistress.

Last edited:

Scott Kenny

ACCESS: USAP

- Joined

- 15 May 2023

- Messages

- 11,184

- Reaction score

- 13,563

I mean, it normally drives a 68-72" fan. May have to go a little smaller on the multi-stage fan, but it still needs to be bigger than 45" so we can more easily deal with noise. My goal is to be able to skip out on any afterburners, to avoid completely pissing off the neighbors.Could a CFM56 core drive a multi-stage 55”diameter fan? As the F101, an early version of that core drove a 2 stage that was approximately 45” in diameter (rated at 350 lbs /sec airflow), but was only a fan pressure ratio in the 2.2-2.5 range. The latest CFM56 core undoubtedly has higher capability than the F101 core. The latest military version of that core is the F110-GE-132 driving a 3 stage fan with 275 lbs/sec airflow at a fan pressure ratio of 3.2.

A CFM56-5C with the 72" fan pushes over 1000lb/sec. With the 68" fan, the -2 and -5s push over 800lb/sec. The small ~60" fans for the 737s push some 700lbs/sec.

We'd need to see. My numbers were based on the NK32, so we're basically turning the F101 into the NK32, 31klbs thrust without afterburner. And the big fan CFM56s can do that or a bit more. I think it's doable without a huge fan.Would that configuration provide sufficient supersonic dry thrust at M1.8? Doubtful, since a clean F-16 with a F110-129 has little supercruise capability, maybe able to do M1.1 on a good day. Overture will have less supersonic drag coefficient than an F-16, but you are still a long way from M1.8.

My other goal was to make an engine beefy enough that it wouldn't need an afterburner for takeoff.

My only suggestion there would be to have an inlet that expands enough to get the temperature down.Another issue is at M1.8 at altitude, the inlet temperature will be around 180F. Aerodynamically, an engine slows down with increasing inlet temperature, even if it is maintaining a constant physical RPM. To maintain full airflow at 180F, the fan will have to be turning 11% faster than it does on a standard day temp of 59F. Rotor speed and internal temperature limits are usually reached at much lower inlet temps, with performance dropping off as the inlet temp increases.

I ran across an very strange design for a spacecraft that could actually be stealthy. One of the tricks it used was a superexpansion nozzle, expanding so much that the exhaust temp when it left the nozzle was 3K. I dove into the math, and it only takes a 3.75x expansion to turn 600degC jet core exhaust into -40degC exhaust. And that should be 3.75x the last turbine stage area, not 3.75x the full diameter (you'd use the full diameter if you were talking about afterburner).

Inlet temp drop only needs to be from 83degC to 15degC, which is a 1.25x area increase. (math is Hot temp divided by Cold temp, using Kelvin)

And as a fun side note, a superexpansion nozzle maximizes exhaust velocity, and therefore maximizes thrust.

Scott Kenny

ACCESS: USAP

- Joined

- 15 May 2023

- Messages

- 11,184

- Reaction score

- 13,563

That's still over 40 years ago.Zoo Tycoon

Ah no, Concorde entered service in 1976, and by 1980 had suffered two Ti compressor fires. So several Ti compressor stages were changed to steel. I understand the problem wasn’t blade stretch, but manufacture quality assurance. Remember that in the first five years of Concorde service the fleet, although small, achieved about 100 x the time at Mach 2 as the entire military previous experience. The grim reality associated with pioneering is a harsh mistress.

- Joined

- 15 January 2021

- Messages

- 392

- Reaction score

- 1,428

Big single stage fans with large airflow and low pressure ratio. Great for subsonic cruise. Multistage fans with higher pressure ratio take more power to drive. All else being equal, higher pressure ratio has to be offset by smaller airflowI mean, it normally drives a 68-72" fan. May have to go a little smaller on the multi-stage fan, but it still needs to be bigger than 45" so we can more easily deal with noise. My goal is to be able to skip out on any afterburners, to avoid completely pissing off the neighbors.

A CFM56-5C with the 72" fan pushes over 1000lb/sec. With the 68" fan, the -2 and -5s push over 800lb/sec. The small ~60" fans for the 737s push some 700lbs/sec.

But it is not equal, since the CFM56 also has a low pressure compressor after the fan to push more air down the core. The bigger fans have bigger LPCs to be able to drive the bigger fan.

That is a big problem. You want lots of airflow at low pressure / low exhaust velocity for quiet takeoff, but you want high pressure / high velocity for supercruise thrust. Hard to accomplish both with a moderate bypass mixed flow turbofan. You could build a big high velocity engine for supercruise, and only run it to part power for takeoff. This could give you the rotor speed / turbine temperature margin necessary for the hot inlet, but you would have a very large heavy engine all the time with lousy subsonic fuel consumption.We'd need to see. My numbers were based on the NK32, so we're basically turning the F101 into the NK32, 31klbs thrust without afterburner. And the big fan CFM56s can do that or a bit more. I think it's doable without a huge fan.

My other goal was to make an engine beefy enough that it wouldn't need an afterburner for takeoff.

Not how it works. When the aircraft is going M1.8, you have to slow the inlet air down to around M 0.6-0.7 for the fan to ingest it properly. When you slow it down perfectly, your inlet pressure at 50K ft standard day goes up from 1.68 psi to 9.13 psi, and temperature from -69.7F to 183F (using Mil-E-5007D Inlet Pressure Recovery). If your inlet is not perfect (none are), the pressure will be less and the temperature higher. You multiply the inlet recovery pressure ratio (approx 5 in this example) by the engine pressure ratio (which is slightly lower than fan pressure ratio on a mixed flow turbofan) to get Nozzle Pressure Ratio. If we can maintain an EPR of 2 the inlet temperature of 183F at M1.8, you have an NPR of 10. You want a Convergent / Divergent nozzle to perfectly expand that NPR to ambient pressure (under expand wastes thrust, over expand gives drag and flow separation). An NPR of 2 is used up getting to an exhaust velocity of M1.0 (at the average exhaust temperature), leaving you a remaining NPR of 5 for supersonic expansion in the divergent nozzle. Is this enough velocity for thrust to exceed (or at least match) drag at M1.8 ? And do you have enough supersonic thrust to accelerate to that speed through the lower Mach numbers where ram recovery is much lower (only 1.89x at M1.0) ?My only suggestion there would be to have an inlet that expands enough to get the temperature down.

I ran across an very strange design for a spacecraft that could actually be stealthy. One of the tricks it used was a superexpansion nozzle, expanding so much that the exhaust temp when it left the nozzle was 3K. I dove into the math, and it only takes a 3.75x expansion to turn 600degC jet core exhaust into -40degC exhaust. And that should be 3.75x the last turbine stage area, not 3.75x the full diameter (you'd use the full diameter if you were talking about afterburner).

Inlet temp drop only needs to be from 83degC to 15degC, which is a 1.25x area increase. (math is Hot temp divided by Cold temp, using Kelvin)

And as a fun side note, a superexpansion nozzle maximizes exhaust velocity, and therefore maximizes thrust.

Scott Kenny

ACCESS: USAP

- Joined

- 15 May 2023

- Messages

- 11,184

- Reaction score

- 13,563

Right. We'd be looking at something like 400-500lb/s mass flow, I think. And that should be doable.Big single stage fans with large airflow and low pressure ratio. Great for subsonic cruise. Multistage fans with higher pressure ratio take more power to drive. All else being equal, higher pressure ratio has to be offset by smaller airflow

May have to switch to one of the RR triple spools, so we can drive the new fan at the correct speed without overspeeding the LPC. But dang those are heavy!But it is not equal, since the CFM56 also has a low pressure compressor after the fan to push more air down the core. The bigger fans have bigger LPCs to be able to drive the bigger fan.

If you're over water by the time you have reached 10,000ft, I'd go ahead and power up to go supersonic. Frankly, I'd go supersonic as soon as the plane was over water, whatever the altitude was.That is a big problem. You want lots of airflow at low pressure / low exhaust velocity for quiet takeoff, but you want high pressure / high velocity for supercruise thrust. Hard to accomplish both with a moderate bypass mixed flow turbofan. You could build a big high velocity engine for supercruise, and only run it to part power for takeoff. This could give you the rotor speed / turbine temperature margin necessary for the hot inlet, but you would have a very large heavy engine all the time with lousy subsonic fuel consumption.

Bugger. Was afraid of that...Not how it works.

Boom - FlyBy - Q&A with Scott Powell, Senior Vice President of Symphony™

Hear from former Boeing senior engineering leader as he joins Boom to lead Symphony’s advancing engine program as Senior Vice President

Boom - Symphony

Keep the PR machine running full speed ahead ................

Regards,

Boom - FlyBy - Boom Supersonic Advances Flight Preparations for XB-1

The world’s first independently developed supersonic jet, XB-1 completes key milestones and progresses towards first flight

On preparations for the Overture, Scholl says progress on the company’s 400,000-ft.2 production and test facility at Piedmont Triad International Airport near Greensboro, North Carolina, is moving slightly ahead of schedule. “We said we’d be ready next year, and it looks like it might be ready earlier next year than we thought it would be. It’s looking like a real factory now. The sidewalls are up for about half the building and it’s coming along.”

Notice that when he speaks of a factory, there is in fact not much of one. 4 walls, a roof and a slabbed floor is a light year away from a factory.... even when paced at Mach 2.

(something we have alerted the reader to remain critical when such announcement was done).

FAA Clears Boom Supersonic For XB-1 Flight Tests | Aviation Week Network

Boom Supersonic has received an FAA experimental certificate of airworthiness for its XB-1 technology demonstrator, meaning flight-testing can now get underway.

Last edited:

Boom - FlyBy - Boom Supersonic Launches Defense Advisory Group

Military leaders convene to further the development of defense variants of Boom Supersonic's Overture for the US government and its allies

Keep in the news cycle.....................

Regards,

Reaper

ACCESS: Secret

- Joined

- 31 March 2009

- Messages

- 301

- Reaction score

- 135

So what do they want to demonstrate with this? The general configuration?

Boom - FlyBy - Boom Supersonic Advances Flight Preparations for XB-1

The world’s first independently developed supersonic jet, XB-1 completes key milestones and progresses towards first flightboomsupersonic.com

View: https://youtu.be/Hg9pHnQ4zTs?si=nL8Jw9leK-rWh4Jk

- Joined

- 16 April 2008

- Messages

- 9,558

- Reaction score

- 14,341

So what do they want to demonstrate with this? The general configuration?

I think mainly validating their design tools. Does actual performance match their predictions?

Outside fighters the military has little interest in supersonic speeds, those days. Not even bombers are supersonic anymore. What I mean is: the military won't save Boom if they screw the civilian market.

Dead on the mark, they are trying everything to keep in the news cycle.Outside fighters the military has little interest in supersonic speeds, those days. Not even bombers are supersonic anymore. What I mean is: the military won't save Boom if they screw the civilian market.

The moment they lost their engine suppliers they were in trouble. the time frame for a new ground up engine is 10 yrs + easy.

Not really sure that the demonstrator is a completely different design than what they were originally going with, that design has changed a few times as well.

Looks more like a x-59?

These guys are on the bandwagon as well.

Imagining a new future for supersonic aviation — Exosonic

Imagining a new future for supersonic aviation by muting the sonic boom. Developing a Mach 1.8 airliner to fly you anywhere in half the time.

exosonic.com

exosonic.com

Regards,

aonestudio

I really should change my personal text

- Joined

- 11 March 2018

- Messages

- 2,962

- Reaction score

- 7,466

Boom signs with Latecoere for EWIS:

www.ladepeche.fr

www.ladepeche.fr

Latécoère monte à bord de l'avion supersonique du constructeur américain Boom

Boom Supersonic vient de choisir l’équipementier aéronautique toulousain pour développer l’architecture complète du système d’interconnexion du câblage électrique de son avion supersonique et de ses moteurs.

- Joined

- 16 April 2008

- Messages

- 9,558

- Reaction score

- 14,341

Ah sure, the demonstrator is sexy. Kudos to them, they have build a cool plane. Now they only have to pile a few dozens passengers inside...

Or actually fly the demonstrator. Taxi tests in early October; no flight by late November. The B-21 went from taxi to flight in a couple of weeks.

Boom signs with Latecoere for EWIS:

Latécoère monte à bord de l'avion supersonique du constructeur américain Boom

Boom Supersonic vient de choisir l’équipementier aéronautique toulousain pour développer l’architecture complète du système d’interconnexion du câblage électrique de son avion supersonique et de ses moteurs.www.ladepeche.fr

Latecoere (yes, same company as the old flying boat company) has got a contract for 103 km of wiring inside Boom SST.

Charlesferdinand

amateur theologian

- Joined

- 24 October 2013

- Messages

- 172

- Reaction score

- 272

For a minute I was hoping for a supersonic flying boatLatecoere (yes, same company as the old flying boat company) has got a contract for 103 km of wiring inside Boom SST.

Several years ago, I did some remodel work for someone that worked with Boom in Colorado. Sharing my interest in aviation, I took part in an afterhours "Investors" tour of the facility. Walked up and around the Baby Boom demonstrator and even flew the simulator (crashed short of Mojave runway). Something I won't forget!

Attachments

djfawcett

With Enough Power, Anything Will Fly

- Joined

- 16 December 2012

- Messages

- 268

- Reaction score

- 388

Not quite right..........the Air Force initiated contact to pursue their perceived requirements.Outside fighters the military has little interest in supersonic speeds, those days. Not even bombers are supersonic anymore. What I mean is: the military won't save Boom if they screw the civilian market.

aonestudio

I really should change my personal text

- Joined

- 11 March 2018

- Messages

- 2,962

- Reaction score

- 7,466

Scott Kenny

ACCESS: USAP

- Joined

- 15 May 2023

- Messages

- 11,184

- Reaction score

- 13,563

I'm pretty sure there's a desire for an ability to throw a dozen Delta/Green Berets (and all their gear) at a problem from halfway around the world. Call it a couple dozen people and 10 tons of stuff.Outside fighters the military has little interest in supersonic speeds, those days. Not even bombers are supersonic anymore. What I mean is: the military won't save Boom if they screw the civilian market.

- Joined

- 1 April 2006

- Messages

- 11,348

- Reaction score

- 10,036

Attachments

alberchico

I really should change my personal text

- Joined

- 14 January 2014

- Messages

- 704

- Reaction score

- 1,506

XB-1 met all of its test objectives, including safely and successfully achieving an altitude of 7,120 feet and speeds up to 238 knots (273 mph).

"Everyone on the XB-1 team should be incredibly proud of this achievement," said Bill "Doc" Shoemaker, Chief Test Pilot for Boom Supersonic. "It has been a privilege to share this journey with so many dedicated and talented professionals. The experience we have gained in reaching this milestone will be invaluable to Boom's revival of supersonic travel."

Boom’s first test flight could signal the return of supersonic air travel

Could supersonic air travel make a comeback?

Last edited:

The loyal opposition

techxplore.com

techxplore.com

Could supersonic flights be the next big thing in air travel? This flight expert isn't so sure

If you could fly from New York to London in half the time, would you? With a renewed interest and investment in commercial supersonic flight, that's what some companies hope to achieve.

Scott Kenny

ACCESS: USAP

- Joined

- 15 May 2023

- Messages

- 11,184

- Reaction score

- 13,563

Yes, they really should be proud of getting their subscale demonstrator up and flying!

Boom’s first test flight could signal the return of supersonic air travel

Could supersonic air travel make a comeback?www.theverge.com

They've just made it farther than any other of the supersonic startups!

Helicoprion

Aircraft enthusiast and Aerospace Machinist

- Joined

- 23 July 2023

- Messages

- 27

- Reaction score

- 57

O/T

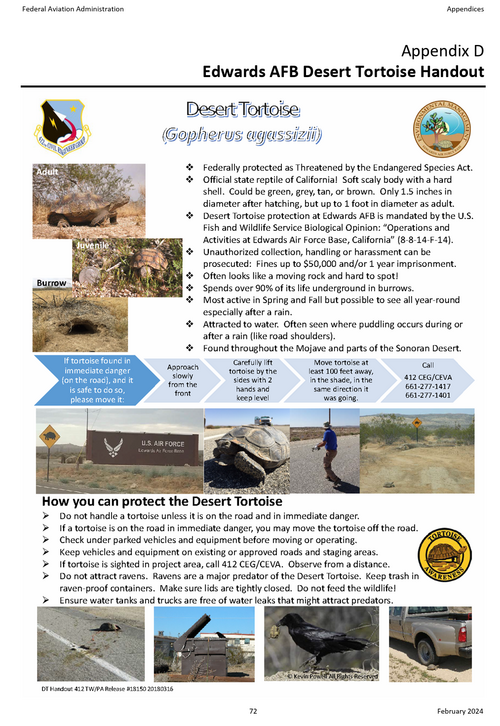

I foster a desert tortoise, and this brings me great joy here’s a shot of “Panzer” for you.

Attachments

- Joined

- 28 January 2008

- Messages

- 994

- Reaction score

- 2,130

Help, there's something coming tortoise!!!

Similar threads

-

-

-

-

50 years ago Air Force Magazine - A Mach 3 transport?

- Started by bobbymike

- Replies: 1

-

US Army's 1990s Armored Systems Modernization (ASM) Program (FIFV, Block III Tank, Crusader)

- Started by RyanC

- Replies: 77