Post 126 - MRA4 -What went wrong - upon re-reading it, I’ve corrected a bit of my poor English and added some extra narrative for clarification.

1- In late 94, BAESYSTEMS preferred RMPA solution was lost with the do not proceed decision on A400m , but only after MOD had agreed to launch a Nimrod replacement program. The Nimrod re-engine proposal was hastily conceived and grew rapidly without an appropriate pre study.

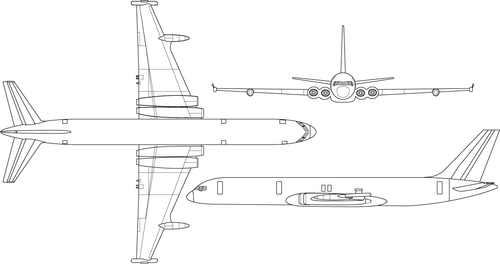

2 -The RAF/BAESYSTEMS couldn’t see beyond wanting a Nimrod to replace a Nimrod, they concluded that the air vehicle fundamentally had to be 100tons max take off weight and four engines.... there was nothing else adaptable and HMG wouldn’t approve an entirely new design.

3 - (not so) Smart Procurement (introduced by political decree;- a ruthless race to the bottom)- delivered a commercially non feasible contract. It contained excessively optimistic assumptions, which were known to both parties.

4 - The first optimistic assumptions to go bad was the required engineering ramp up, it would never have worked, so via the Force Majeure contract clause, a one year slip was agreed in the exchange for reducing the number of airframes delivered from 21 to 18, to cover 1year of extra incurred costs. The actual engineering ramp up, particularly at Farnborough took two years. (So CDR closure scheduled for September 98 slips to Dec 2000, but in real terms was even a bit later than that)

5 - A poor engineering decision during wing structure optimisation adds a further 6 months. i. The original wing proposal, under estimated its weight because it was not based on the wing structure optimisation process assumed in the planned timescale, so the wing weight increased but ii. An over estimated drag drove unnecessary additional design time to reduce its weight, perceived to be essential to achieve the performance spec. A result of (not so) Smart Procurement and lack of pre studies.

6.- As a consequence of the above ie late issuing of drawings, the production lull prior to Typhoon ramp up, vital to securing early parts delivery to Woodford, was completely missed. At the same time it was realised many parts expected to be retained would require new fabrication thus further overload the production organisation.

7 - The build of the first 3 prototypes experiences paralysing part shortages. This turns a planned 18 month build time into a 48 month actual.

8 - By 2002, it became evident to both parties the original fixed price contract was maxed out, having delivered nothing but becoming politically too big to fall. The original contract was replaced by a more traditional version but only for nine production aircraft, (The Russian submarine fleet has seen massive reductions since project conception in the early 90’s) but this aircraft fleet was well below the threshold of commercial viablity to support.

9 - when PA1 flys (Aug 2004) it’s ailerons control forces are unacceptable, as is its yaw stability. These issues take 3 years to resolve and remember a large part of the flight testing can only be completed with the control system at its final design standard. A flight test program originally scheduled at 24 months, takes nearly 60 months. The aileron issue was due to the insistence on using old technology “tug by wire” because fly by wire was known to expensive. This poor decision making (Both BAE and MOD agreed, see <not so> Smart Procurement ) forced a lengthy re-learning of old design methods. The last clean sheet “tug by wire” ailerons system for a large wing was the A310 in the mid 70’s and the guys that had all the deep learning from A300, 146, VC10, Trident werel long retired. FBW ailerons might have had a degree of greater upfront cost but could have saved 36months together with the massive cost incurred by the delay.

10 - Due to delays on MR4, the MR2 was been pushed too hard with insufficient support, ref Hadden Cave.

11 - it’s was then discovered that part of MRA4 safety case for Air to Air refuelling was based on the flawed case of MR2 which fixing would lead to yet more delays. Furthermore part of the “tug by wire” aileron control cables was exposed to bird strike when the bomb doors are open..... Again more fixes required.

12 - a cash strapped government trying to sort thing out after the great market crash of 2008 finally pulls the plug