F-14ATomcat

ACCESS: Confidential

- Joined

- 26 May 2024

- Messages

- 76

- Reaction score

- 119

Safran Aircraft Engines inaugurates a new assembly line at its Querétaro plant, supporting the production of the CFM LEAP engine and generating 150 new jobs. This step reinforces its commitment to Mexico and its leadership in the aerospace industry.

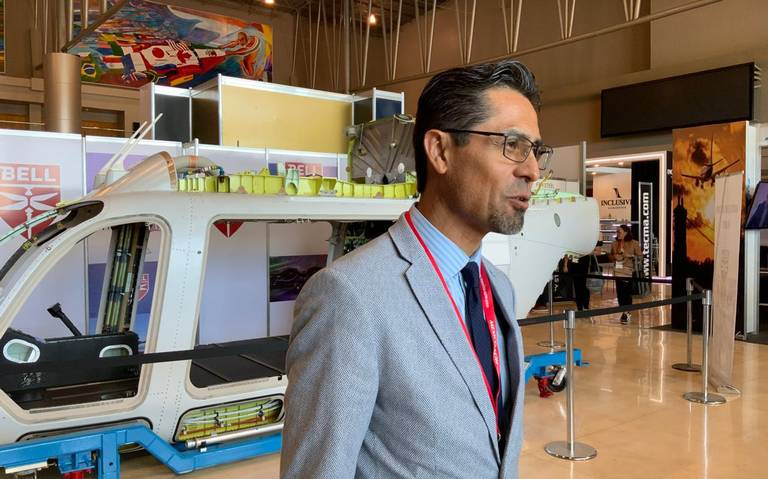

Safran Aircraft Engines, a global leader in the manufacture of aeronautical engines, inaugurated a new assembly line at its plant in Querétaro, Mexico, as part of an ambitious expansion. The event was chaired by Alejandro Cardona Seemann, President of Safran Mexico, and Marcial Suárez, General Manager of the plant, together with important personalities such as Marcelo Ebrard, Secretary of Economy; Marco del Prete Tercero, Secretary of Sustainable Development of the State of Querétaro; and Delphine Borione, Ambassador of France in Mexico.

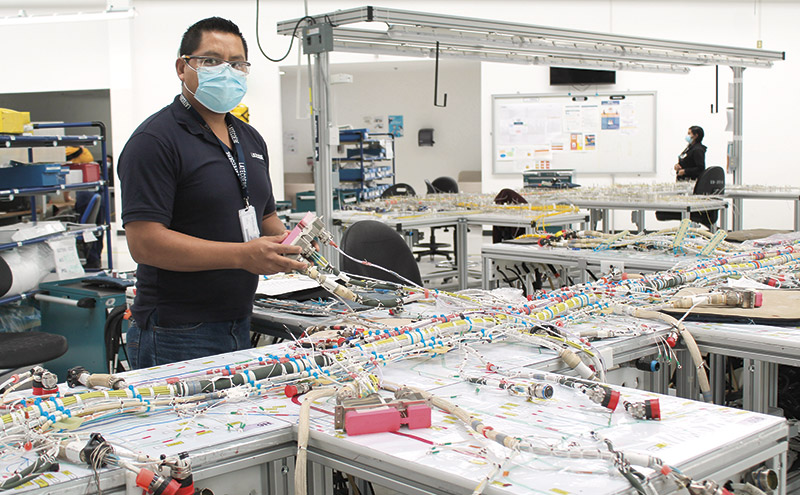

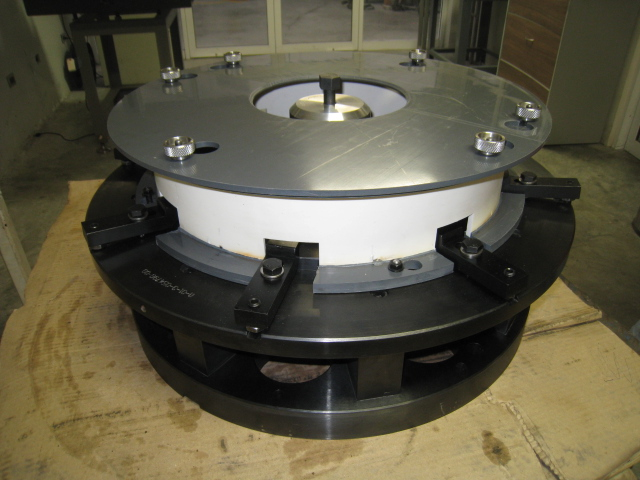

The CFM LEAP engine, one of the most successful on the market, will be the protagonist of this new stage, with the final assembly of fans and turbines. This expansion will generate 150 new jobs, bringing Safran Aircraft Engines Mexico (SAEM) to a total of 650 employees and an infrastructure of 26,000 square meters, including an additional 4,300 meters of operating space.

In addition, the plant in Querétaro is consolidated as the first final assembly site for engines for single-aisle commercial aircraft in Mexico, a milestone in the industry that reinforces Mexico's strategic position in the global aeronautical supply chain.

Jean-Paul Alary, CEO of Safran Aircraft Engines, highlighted the importance of this expansion at the Farnborough Airshow: “Mexico will position itself among the few countries capable of covering the entire engine life cycle, from parts manufacturing to maintenance and testing.”

With more than 34 years of operation in Mexico and nearly 14,000 employees in 18 facilities, Safran continues to consolidate its position as the main employer in the Mexican aerospace industry. The new assembly line in Querétaro not only strengthens the company's production capacity, but also the competitiveness and future of the aerospace industry in the region

lideresmexicanos.com

lideresmexicanos.com

Safran Aircraft Engines, a global leader in the manufacture of aeronautical engines, inaugurated a new assembly line at its plant in Querétaro, Mexico, as part of an ambitious expansion. The event was chaired by Alejandro Cardona Seemann, President of Safran Mexico, and Marcial Suárez, General Manager of the plant, together with important personalities such as Marcelo Ebrard, Secretary of Economy; Marco del Prete Tercero, Secretary of Sustainable Development of the State of Querétaro; and Delphine Borione, Ambassador of France in Mexico.

The CFM LEAP engine, one of the most successful on the market, will be the protagonist of this new stage, with the final assembly of fans and turbines. This expansion will generate 150 new jobs, bringing Safran Aircraft Engines Mexico (SAEM) to a total of 650 employees and an infrastructure of 26,000 square meters, including an additional 4,300 meters of operating space.

In addition, the plant in Querétaro is consolidated as the first final assembly site for engines for single-aisle commercial aircraft in Mexico, a milestone in the industry that reinforces Mexico's strategic position in the global aeronautical supply chain.

Jean-Paul Alary, CEO of Safran Aircraft Engines, highlighted the importance of this expansion at the Farnborough Airshow: “Mexico will position itself among the few countries capable of covering the entire engine life cycle, from parts manufacturing to maintenance and testing.”

With more than 34 years of operation in Mexico and nearly 14,000 employees in 18 facilities, Safran continues to consolidate its position as the main employer in the Mexican aerospace industry. The new assembly line in Querétaro not only strengthens the company's production capacity, but also the competitiveness and future of the aerospace industry in the region

» Safran Aircraft Engines expande su presencia en Querétaro

lideresmexicanos.com

lideresmexicanos.com