You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Turkish UAV & UCAV Developments

- Thread starter Combat-Master

- Start date

Aksungur delivery to Chad; it seems they'rebecoming a serious TAI customer with 3 different types of equipment already in service.

Source:

https://video.haber7.com/video-gale...gur-cad-hava-kuvvetlerinde-boyle-goruntulendi

Combat-Master

ACCESS: Top Secret

- Joined

- 15 July 2020

- Messages

- 1,298

- Reaction score

- 3,736

Turkey's latest E/O ASELFLIR-500 finalising qualification with AKINCI UCAV

View: https://www.youtube.com/watch?v=MdthtUl3CC8

I remember reading some news about when ASELFLIR-600 will be ready for testing but I can't remember the claim. Anyone knows? Was it this year?Turkey's latest E/O ASELFLIR-500 finalising qualification with AKINCI UCAV

View: https://www.youtube.com/watch?v=MdthtUl3CC8

Forest Green

ACCESS: Above Top Secret

- Joined

- 11 June 2019

- Messages

- 8,208

- Reaction score

- 13,878

Combat-Master

ACCESS: Top Secret

- Joined

- 15 July 2020

- Messages

- 1,298

- Reaction score

- 3,736

I remember reading some news about when ASELFLIR-600 will be ready for testing but I can't remember the claim. Anyone knows? Was it this year?

ASELFIR-600 or MEROPS 25inch gimbal was debuted in 2022, being tested at Aselsan's South African branch.

I believe it's also being touted for the mid-life E/O upgrade of the S.African Rooivalk attack helicopter

Last edited:

Forest Green

ACCESS: Above Top Secret

- Joined

- 11 June 2019

- Messages

- 8,208

- Reaction score

- 13,878

Poland receives final TB2 drone delivery from Turkey’s Baykar

The TB2 made headlines when Ukrainian forces used them against Russia early on in the war.

Combat-Master

ACCESS: Top Secret

- Joined

- 15 July 2020

- Messages

- 1,298

- Reaction score

- 3,736

A minute by minute account of AKINCI UCAV discovering the wreckage

View: https://x.com/clashreport/status/1792480578983399851

View: https://x.com/clashreport/status/1792480578983399851

alberchico

I really should change my personal text

- Joined

- 14 January 2014

- Messages

- 668

- Reaction score

- 1,374

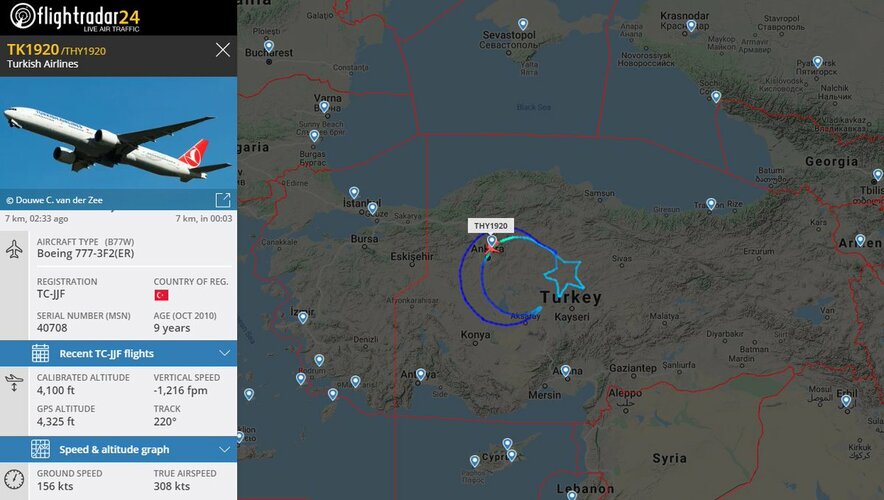

This is a screenshot taken from FlightRadar24 showing the route the drone took to undertake the SAR mission in Iran. They really did draw the star and crescent on the way back to Turkey. This is a great publicity coup for the Akcini UAV.

This is a screenshot taken from FlightRadar24 showing the route the drone took to undertake the SAR mission in Iran. They really did draw the star and crescent on the way back to Turkey. This is a great publicity coup for the Akcini UAV.

https://www.dailysabah.com/turkey/t...to-celebrate-centenary-of-parliament/news/amp

Last edited:

Forest Green

ACCESS: Above Top Secret

- Joined

- 11 June 2019

- Messages

- 8,208

- Reaction score

- 13,878

It seems almost like Iran should have invested more in a search and rescue drone rather than Shaheds.

Launching Shaheds basically forces your opponent to waste SAMs, and id they don't shoot it down they're basically risking valuable targets getting hit or people getting hurt. And even with a mediocre manufacturing base, you could easily produce tens of thousands of them annually.It seems almost like Iran should have invested more in a search and rescue drone rather than Shaheds.

Shaheds have a great ROI, the problem is that their MALE class drones are pure shit without any capable EO gimbal or SAR radar.

I reckon they could import Chinese subcomponents and assemble them locally, why they're not doing that truly baffles me.

Last edited:

Forest Green

ACCESS: Above Top Secret

- Joined

- 11 June 2019

- Messages

- 8,208

- Reaction score

- 13,878

Titra, Airbus team up to modify ALPIN drone for naval missions

The strategic cooperation agreement between the Turkish and French firms calls for collaboration in integrating Airbus’ DeckFinder positioning system with

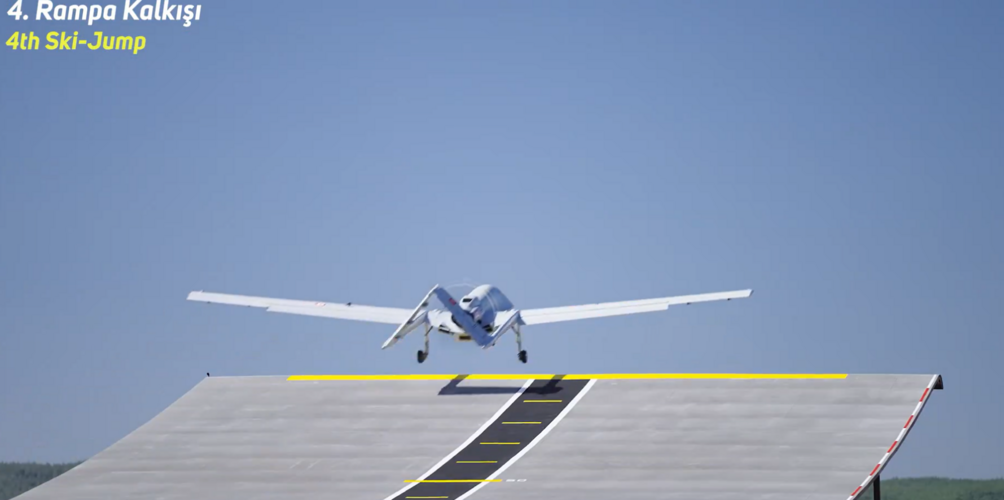

Finally what we've been waiting for: the first Ski-Jump test of TB-3. (no short landing though)

View: https://x.com/BaykarTech/status/1796891136268640455

View: https://x.com/BaykarTech/status/1796891136268640455

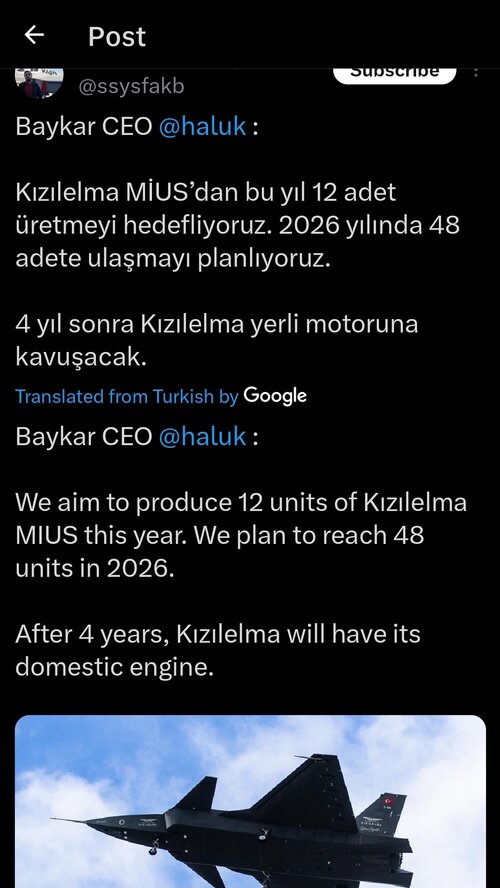

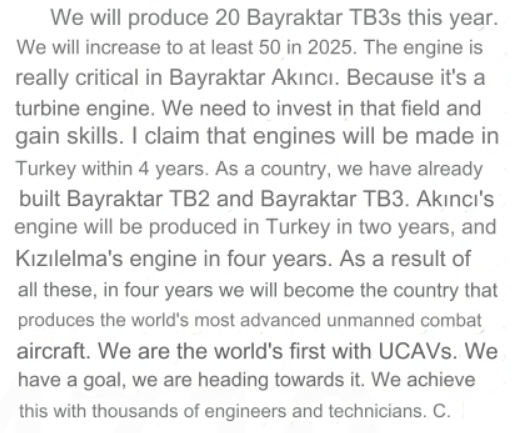

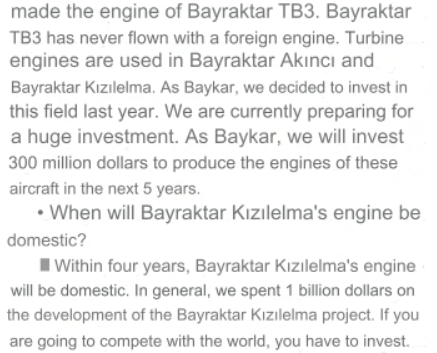

Baykar is apparently planning to develop and produce their own turbofan engines for Kizilelma.

View: https://x.com/AksanSertac/status/1797210600600170615?t=MowuAgKtsNY2vB9hUYAUCQ&s=19

I wonder how necessary this is when TEI's already testing the TF6000/10000 engine, which is intended to power Kizilelma and TAI's Anka 3.

In ~2019, IIRC, Baykar has founded a JV with Ukrspecexport to produce engines for their products but there were a lot of reports and gossips that said they were deeply unsatisfied with the Ukr side; then the War in Ukraine happened so here we are.

https://blackseashield.com/en/

Mind you, Baykar is not just a "drone company." They already produce missiles and loitering munitions and are actively developing small satellite constellations.

In short, it seems like they're moving ahead with their plans to get into the engine market.

View: https://x.com/AksanSertac/status/1797210600600170615?t=MowuAgKtsNY2vB9hUYAUCQ&s=19

I wonder how necessary this is when TEI's already testing the TF6000/10000 engine, which is intended to power Kizilelma and TAI's Anka 3.

In ~2019, IIRC, Baykar has founded a JV with Ukrspecexport to produce engines for their products but there were a lot of reports and gossips that said they were deeply unsatisfied with the Ukr side; then the War in Ukraine happened so here we are.

https://blackseashield.com/en/

Mind you, Baykar is not just a "drone company." They already produce missiles and loitering munitions and are actively developing small satellite constellations.

Selcuk Bayraktar: We aim to send 120 satellites into space by 2030 by building low orbit satellite constellations. Our goal is to build a global positioning system. Fergani also aims to develop launch vehicles to go into space.

In short, it seems like they're moving ahead with their plans to get into the engine market.

Last edited:

Combat-Master

ACCESS: Top Secret

- Joined

- 15 July 2020

- Messages

- 1,298

- Reaction score

- 3,736

CCD and SAL seeker versions of IHA-122 Supersonic Missiles tested from AKINCI UCAV

View: https://x.com/BaykarTech/status/1797737784414998907

View: https://x.com/BaykarTech/status/1797737784414998907

Scott Kenny

ACCESS: Above Top Secret

- Joined

- 15 May 2023

- Messages

- 9,155

- Reaction score

- 10,186

I was not expecting a vertical landing in that video...

That's most of the way to the DARPA TERN UAV...

In the quote he also says that they've invested a billion usd in developing Kizilelma so far.Baykar is starting to develop their own engines with USD300m investment over the next 5 years.

"Kızılelma engine will be ready ready in 4 years, Akıncı's engine will be ready in 2 years!"

"Baykar targets 12 Kızılelma to be manufactured in 2024" as LRIP, "serial production will start in 2025". 1 fighter per month at worst is impressive for LRIP! Serial production "in 2026 will have 4 fighters per month"!!!

Also also, Tb2 engine will be replaced with Baykar's in-house design BM100. They are planning to manufacture 20 of the this year.

Source: Haluk Bayraktar's interview in Capital magazine.

Baykar currently has 4500 employees with an average age of 29 years.

- Last year they invested $250 million in R&D, with the most going to AI R&D.

- Baykar allocated $1 billion for the development of Kizilelma.

- They plan to invest at least $1.5 billion in the next 5 years.

- Production rate of TB2 is 250 per year.

- Start of mass production of TB3 in this year with at least 20 build. Increase to at least 50 build next year.

- They built 12 Akinci last year and this year they plan to build 50.

- Plan to produce at least 12 Kizilelma this year, increase it exponentially (24?) in '25 and produce 48 in '26.

- They really want to produce engines on their own. The share of the TB2 engine was not even 1 % of the total added value so it wasn't necessary. They now developed the BM100 for the TB2. TB2 flies currently 250.000 hours a year which necessitates a need for 200 spare engines per year. They plan to build 20 of these engines this year. After that they'll start mass production.

- They want to produce the engines for the Akinci and Kizilelma in 2 years and 4 years respectively in Turkiye. They started investing in this since last year. In total they plan to invest $300 million for engines in 5 years (of which 1 year has passed).

- They'll continue specializing and investing in drones, satellites and AI.

Combat-Master

ACCESS: Top Secret

- Joined

- 15 July 2020

- Messages

- 1,298

- Reaction score

- 3,736

Proportions

ACCESS: Restricted

- Joined

- 22 June 2023

- Messages

- 15

- Reaction score

- 26

Good shot.IWB of Kızılelma

View attachment 699428

Combat-Master

ACCESS: Top Secret

- Joined

- 15 July 2020

- Messages

- 1,298

- Reaction score

- 3,736

Aselsan's TOLUN small diameter bomb; TOLUN is GPS/INS guided munition carried on Smart Pneumatic Quad Rack (SADAK-4T). TOLUN can be engaged against soft and hardened multiple targets simultaneously. The warhead of TOLUN is designed by Tübitak SAGE and the rest of the system is designed by ASELSAN.

Combat-Master

ACCESS: Top Secret

- Joined

- 15 July 2020

- Messages

- 1,298

- Reaction score

- 3,736

Combat-Master

ACCESS: Top Secret

- Joined

- 15 July 2020

- Messages

- 1,298

- Reaction score

- 3,736

Combat-Master

ACCESS: Top Secret

- Joined

- 15 July 2020

- Messages

- 1,298

- Reaction score

- 3,736

Combat-Master

ACCESS: Top Secret

- Joined

- 15 July 2020

- Messages

- 1,298

- Reaction score

- 3,736

IIR seeker versions of MAM-T and MAM-L series of munitions - also looks like MAM-T has folding wings now.

MAM-T IIR Technical specifications:

Weight: 100kg

Warhead weight: 70kg

Diameter: 230mm

Range: 50+ km

Guidance: IIR (Imaging infrared seeker), RF data link (Man-in-the-Loop)

Warhead type: Particle effect and thermobaric

MAM-L IIR Technical specifications:

Weight: 23kg

Warhead weight: 10kg

Diameter: 160mm

Range: 25+ km

Guidance: IIR (Imaging infrared seeker), RF data link (Man-in-the-Loop)

Warhead type: Multi-purpose (anti-tank and particle effective) and thermobaric

Both expected to enter inventory of Turkish armed forces this year.

MAM-T IIR Technical specifications:

Weight: 100kg

Warhead weight: 70kg

Diameter: 230mm

Range: 50+ km

Guidance: IIR (Imaging infrared seeker), RF data link (Man-in-the-Loop)

Warhead type: Particle effect and thermobaric

MAM-L IIR Technical specifications:

Weight: 23kg

Warhead weight: 10kg

Diameter: 160mm

Range: 25+ km

Guidance: IIR (Imaging infrared seeker), RF data link (Man-in-the-Loop)

Warhead type: Multi-purpose (anti-tank and particle effective) and thermobaric

Both expected to enter inventory of Turkish armed forces this year.

Last edited:

Combat-Master

ACCESS: Top Secret

- Joined

- 15 July 2020

- Messages

- 1,298

- Reaction score

- 3,736

General capabilities:

*Radar electronic support

*Radar electronic attack

*Communication electronic support

*Communication electronic attack

AKINCI UAV mounted ASOJ 234-U loitering duration of 18 hours.

First prototype is expected to be delivered in 2026.

WatcherZero

ACCESS: Top Secret

- Joined

- 22 May 2023

- Messages

- 686

- Reaction score

- 1,488

Interesting comments from the French Army Chief of Staff General Pierre Schill, he says after early war dominance Bayraktar aren't flown at all in Ukraine anymore because they are extremely susceptible to EW jamming. At the moment he says cheap fragile FPV suicide drones 'the sword' are dominant accounting for around 80% of air to ground kills but he expects this to be a blip in in eternal struggle between sword and shield and due to improvements in air defences they wont be around at all in 10 years time, already 75% of small drones are being lost on the battlefield due to electronic warfare and he expects the pendulum to swing back towards more complex and larger medium altitude drones.

www.defensenews.com

www.defensenews.com

Small drones will soon lose combat advantage, French Army chief says

He cited the example of the Bayraktar drone, “the king of the war” at the start of the conflict in Ukraine, that is no longer being used.

It seems Baykar is seriously developing an in-house engine for Kizilelma. It seems they want to use their own products for all of their drones, including the TB-2.

Haluk Bayraktar: Bayraktar KIZILELMA's engine will be indigenous in four years

View: https://x.com/SavunmaTR/status/1803733994199990342BAYKAR ( @BaykarTech ) General Manager Haluk Bayraktar ( @haluk ): "BAYKAR has spent 1 billion dollars for KIZILELMA so far with only its own resources.

The company currently produces 250 Bayraktar TB2 and 50 Bayraktar AKINCI per year.

The third prototype of KIZILELMA is in the production phase.

A domestic engine named BM100 was developed for Bayraktar TB2.

BAYKAR will invest 300 million dollars for aircraft engines in the next five years."

Combat-Master

ACCESS: Top Secret

- Joined

- 15 July 2020

- Messages

- 1,298

- Reaction score

- 3,736

By domestic, does he mean Ukrainian engines built in Turkey or clean sheet engines developed in Turkey ?

I don't think licensing Ukranian engines and producing them would take 4 years when the plant is almost ready, thus it should be a brand new, in-house engine design.By domestic, does he mean Ukrainian engines built in Turkey or clean sheet engines developed in Turkey ?

Similar threads

-

-

-

"Lockheed" Penetrating High Altitude Endurance (PHAE)

- Started by quellish

- Replies: 31

-

Long-range surveillance and target tracking balloons/blimps (JLENS, etc)

- Started by Maro.Kyo

- Replies: 0

-