from

INTRODUCTION TO AERONAUTICS: A DESIGN PERSPECTIVE (see the original article for more illustrations)

CHAPTER 9: CASE STUDIES AND FUTURE AIRCRAFT DESIGNS

9.4 CASE STUDY #3: THE EVOLUTION OF THE F-16

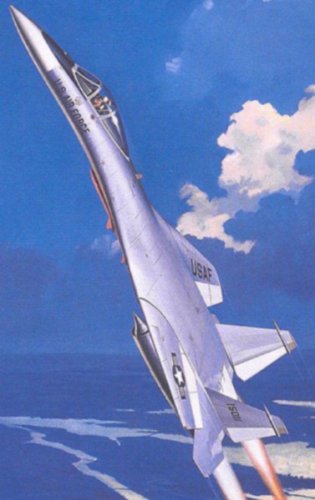

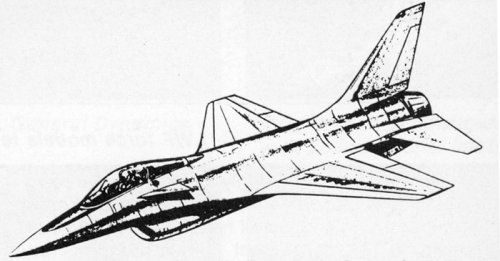

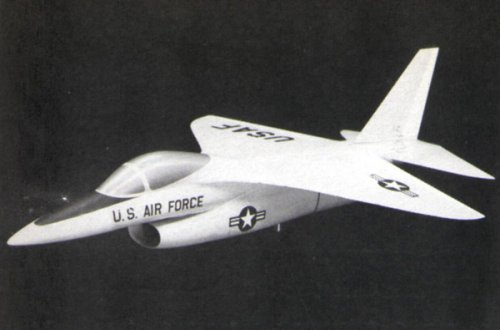

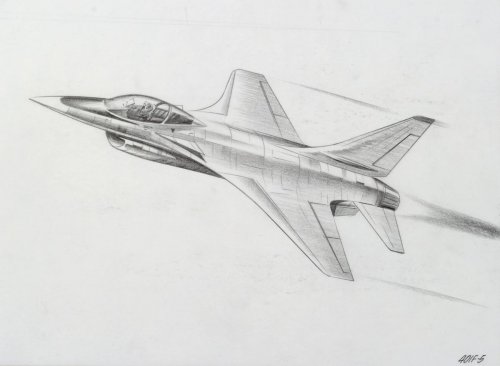

The Lockheed-Martin F-16 Fighting Falcon multi-role tactical fighter must be regarded as one of the must successful and prolific (and certainly one of the most esthetically pleasing) jet fighter aircraft of the post-Vietnam War period. Its design evolution is an interesting one, because it was developed as a light-weight air-to-air fighter (a replacement for the F-5) but went into service as a medium-weight multi-role fighter (a replacement for the F-4). Its further development into the F-16XL deep-interdiction aircraft (a replacement for the F-111) is also discussed.

As stated by Bradley 9: “ The design of tactical military aircraft presents quite a challenge to the aerodynamicist because of the vast spectrum of operational requirements encompassed by today’s military scenario. The designer is faced with a multitude of design points throughout the subsonic-supersonic flow regimes plus many off-design constraints that call for imaginative approaches and compromises. Transonic design objectives are often made more difficult by restraints imposed by subsonic and supersonic requirements. For example, wings designed for efficient transonic cruise and maneuver must also have the capability to accelerate rapidly to supersonic speeds and exhibit efficient performance in that regime.”

Bradley continues: “The design problem is further complicated by the fact that the weapon systems of today are required to fill multiple roles. For example, an aircraft designed to fill the basic air superiority role is often used for air-to-ground support, strike penetration, or intercept missions. Thus, carriage and delivery of ordinance and carriage of external fuel present additional key considerations for the aerodynamicist. The resulting aircraft flowfield environment encompasses a complex mixture of interacting flows.”

“For example, the need for rapid acceleration to supersonic flight and efficient supersonic cruise calls for thin wing sections with relatively high sweep and with camber that is designed to trim out the aft ac movement at supersonic flight. However, these requirements are contrary to those requirements for efficient transonic maneuver, where the designer would prefer to have thicker wing sections designed with camber for high CL operation and a high-aspect-ratio planform to provide a good transonic drag polar.”

Harry Hillaker, who was the Chief Project Engineer on the YF-16 and Vice President and Deputy Program Director of the F-16, began10 the plane’s design process by clearly defining the problem and collecting data. Examination of results from air-to-air combat over Southeast Asia/Vietnam revealed that aircraft in the U. S. inventory had only marginal success over their opponents. From 1965-1968, engineers at General Dynamics in Fort Worth examined the data from the Southeast Asian conflict to determine what parameters provided an edge in air-to-air combat. Wing loadings, thrust loadings, control issues, g-tolerances for the pilot, and empty-weight fraction were identified as key parameters in air-to-air combat. Since these studies were focused on technology, there were no configuration designs.

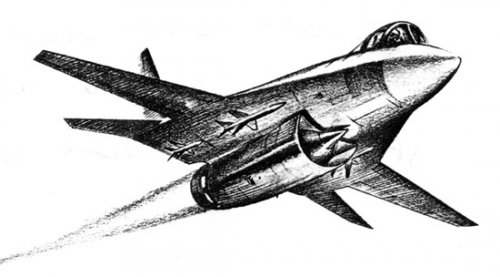

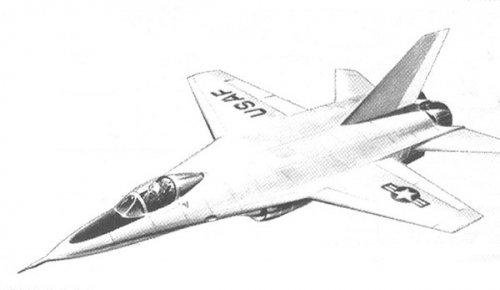

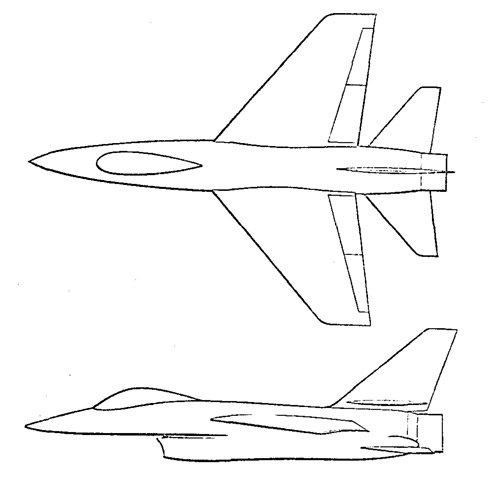

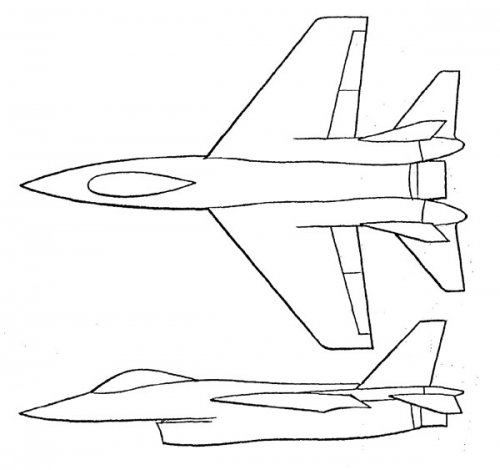

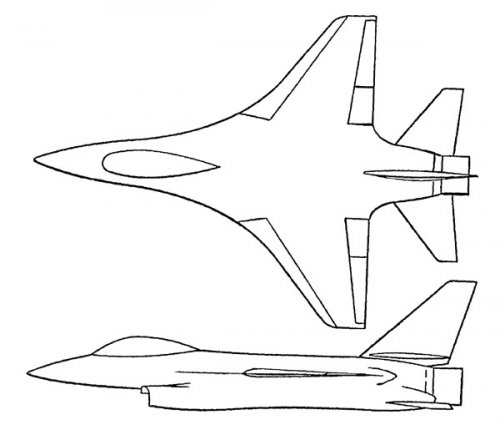

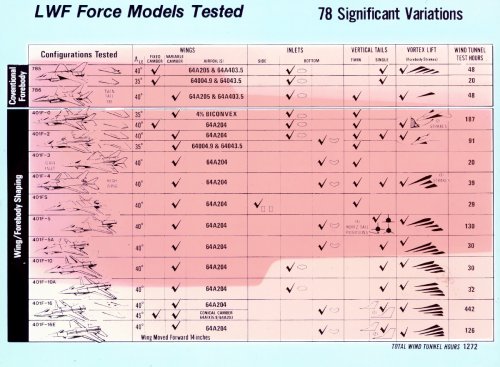

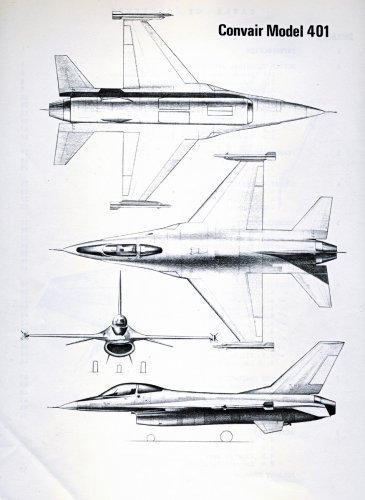

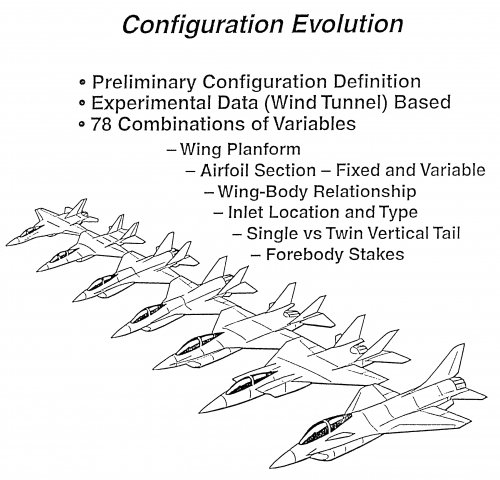

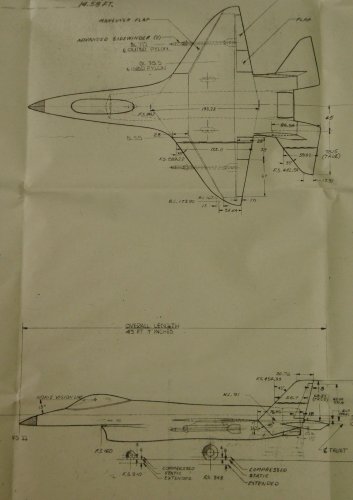

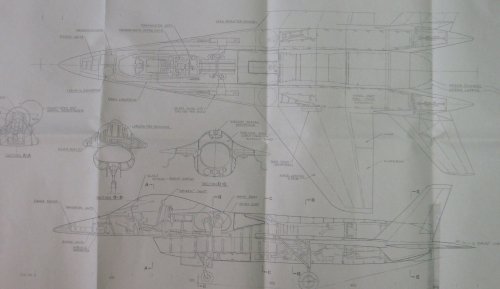

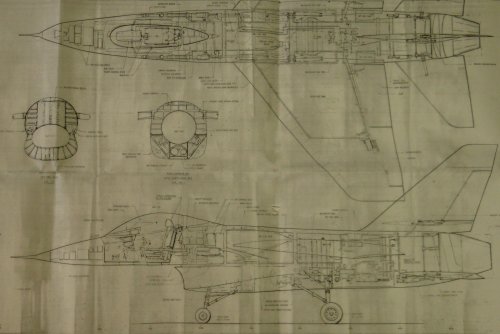

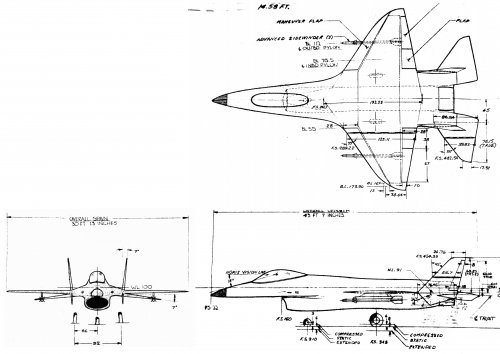

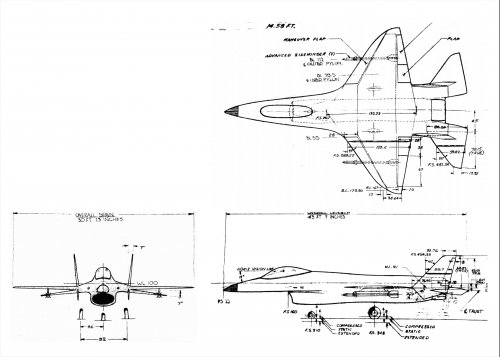

Hillaker continued: “From 1969-1971, an extensive wind-tunnel program was conducted in which data were obtained on a wide variety of configurations over a range of free-stream test conditions and angles of attack.” As shown in the sketches of Fig. 9.12, configuration variables included wing planforms, airfoil sections, wing-body relationships, inlet locations, horizontal and vertical tail configurations, and forebody strakes. Buckner et al11 reported:

“The 1969-1970 period produced technology studies in four areas very important to air combat maneuvering fighter design:

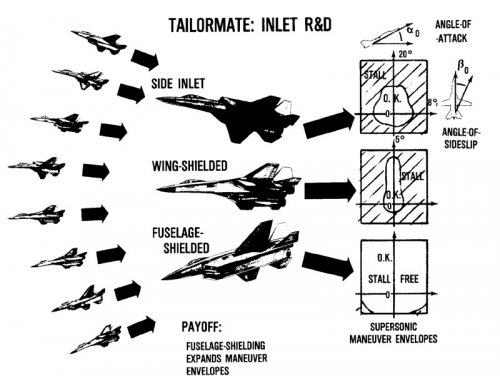

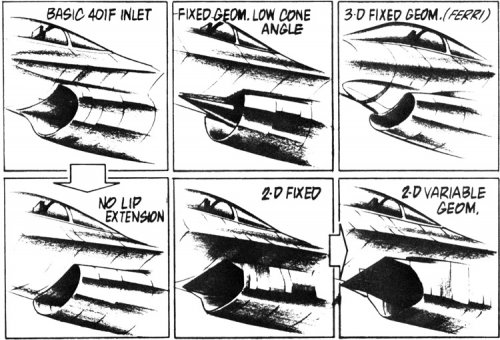

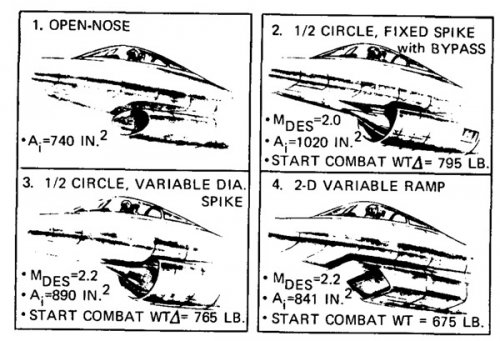

1. Project Tailormate (1969,1970) - an experimental study of a wide variety of inlet types and locations on typical fighter designs with the goal of maintaining low distortion and high-pressure recovery over wide ranges of angle of attack and sideslip. The YF-16 inlet location is largely a result of the experience gained in this work.

2. Wing Mounted Roll Control Devices for Transonic, High-Light (sic) Conditions (1969) - a study of a variety of leading- and trailing-edge devices for roll control in the combat Mach number and high-angle-of-attack range.

3. Aerodynamic Contouring of a Wing-Body Design for an Advanced Air-Superiority Fighter (1970) - an add-on to the roll-control study, which produced analytical information on a blended wing-body design. This experience was helpful in the later development of the YF-16 overall planform and blended cross-section concept.

4. Buffet Studies (1969-1970) - a series of efforts producing new knowledge and methodology on the phenomenon of increased buffet with increasing angle of attack. The methodology, in turn, allowed the YF-16 to be designed for buffet intensity to be mild enough to permit tracking at essentially any angle of attack the pilot can command in the combat arena.

The above studies produced knowledge that was brought to bear on the configuration studies, specifically for the development of a lightweight low-cost fighter, accomplished in 1970, 71.”

The lightweight, low-cost fighter configuration studies intensified when a new set of guidelines were defined for application to combat scenarios in Europe. Hillaker 10 noted: “These mission rules included a 525 nautical mile (nm) radius, four turns at 0.9M at 30,000 feet, accelerate from 0.8M to 1.6M, three turns at 1.2M at 30,000 feet, and pull a four-g sustained turn at 0.8M at 40,000 feet. Furthermore, the aircraft had to demonstrate operability both for the U. S. Air Force and its NATO allies.”

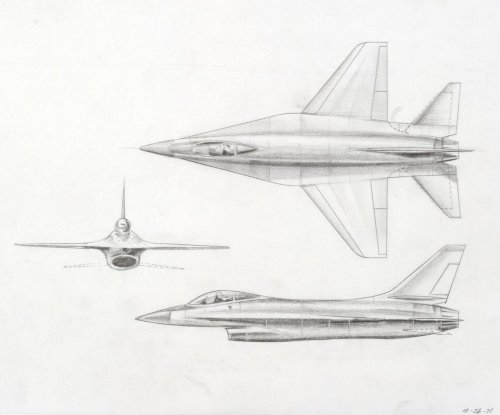

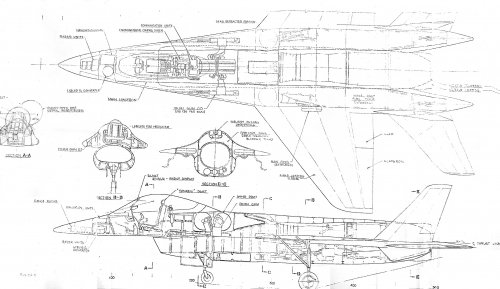

As noted by Buckner et al: “The YF-16 really got its start, then, as a result of the ‘in-house’ studies initiated in late 1970 in response to the new mission rules. .. Major emphasis was placed on achieving flight and configuration characteristics that would contribute directly to the air-to-air kill potential in the combat arena -- specifically maximizing maneuver/energy potential and eliminating aerodynamic anomalies up to the maneuver angle-of-attack limits.” Buckner and Webb 12 reported: “Examples of the ‘design to cost’ in the case of the YF-16 aerodynamic features are (1) a single engine, eliminating the complex question of what to do between the nozzles, (2) an empennage/nozzle integrated design, devoid of adverse interference, (3) a single vertical tail tucked in safely between the forebody vortices, (4) a simple underslung, open-nosed inlet with no complex moving parts, (5) a thin-wing airfoil with only slight camber, minimizing the question of Reynolds number effects on transonic shock locations, and (6) simple trailing-edge ailerons. All of these features reduced the cost through virtual elimination of design changes in the refinement stage after contract go-ahead and through simplification of the task required to fully define the vehicle aerodynamics.” In 1972, aerodynamic data were obtained over a wide range of Mach number, of Reynolds number, and of angle of attack. The ranges of these variables, as taken from Reference 9, are reproduced in Fig. 9.13.

Buckner et al.11 reported that: “From these data it is obvious that the taper ratio () should be as low as practical, consistent with reasonable tip-chord structural thickness and early tip-stall configurations. The final selection was a taper ratio of 0.227. The start combat weight is lowest at a wing aspect ratio of 3.0, the final selected value, and is relatively independent of wing sweep in the range of 35 to 40 degrees. The greater wing sweep is beneficial to the supersonic performance, giving reduced acceleration time and increased turn rate. Some penalty in aircraft size is noted as the wing sweep is increased to 45 degrees, and the higher-sweep wings are more prone to have aileron reversal because of aeroelastic effects. As a result, wind tunnel tests were limited to sweep angles between 35 and 45 degrees. Perturbation of wing thickness ratio (t/c) indicates a lighter weight airplane with a thicker wing, but supersonic maneuverability improve with thinner wings. The desire to achieve a balance in subsonic and supersonic maneuver capability dictated selection of as thin a wing as practical (t/c = 0.04), consistent with flutter and aileron reversal considerations.”

Bradley notes that: “ The tactical military aircraft design problem is made more difficult by the supersonic acceleration requirement. The wings must be as thin as structurally feasible to reduce drag, but fixed camber suitable for optimum transonic maneuver is not practical because of supersonic camber drag. An obvious solution is a smoothly varying wing camber design. However, structural and actuation system weights prove to be prohibitive for thin wings. Simple leading edge and trailing edge flaps often prove to be the most practical compromise for high-performance, multiple design point configurations.”

“The extreme possibilities are apparent. One may design a wing with optimized transonic maneuver camber and twist and attempt to decamber the wing with simple flaps for supersonic flight. On the other hand, one may design the wing with no camber or with a mild supersonic camber and attempt to obtain transonic maneuver with simple flaps.”

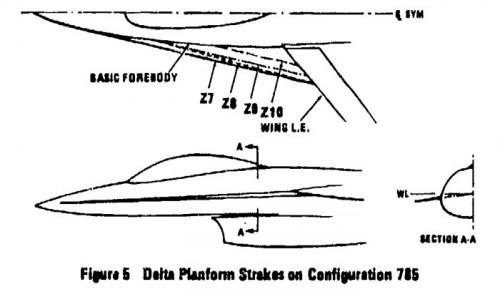

Even though the designer has worked carefully to design a wing for attached flow and to optimize its performance, there are points in the sustained and instantaneous maneuver regimes where the flowfield contains extensive regions of separated flow. The manner in which the flow separates will strongly affect the vehicle’s drag and its controllability at the higher values of the lift coefficient. For many designs, strakes or leading-edge extension devices are used to provide a controlled separated flow. Controlled vortex flow can then be integrated with the variable camber devices on the wing surface to provide satisfactory high-lift, stability and control, and buffet characteristics. The resulting flowfield is a complex one, combining attached flows over portions of the wing with the vortex flow from the strake. See Figure 9.14.

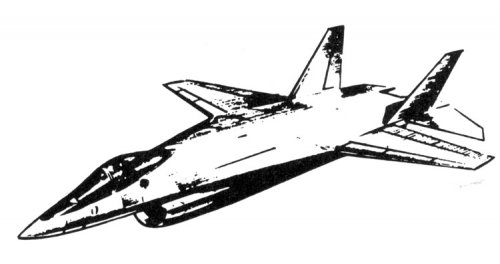

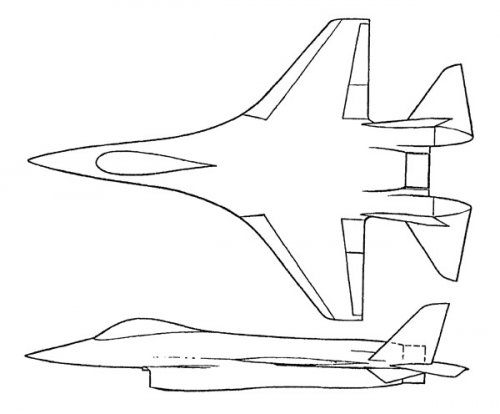

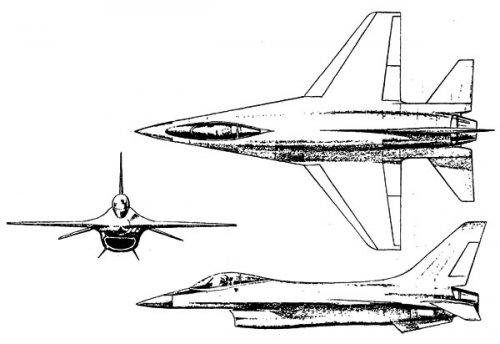

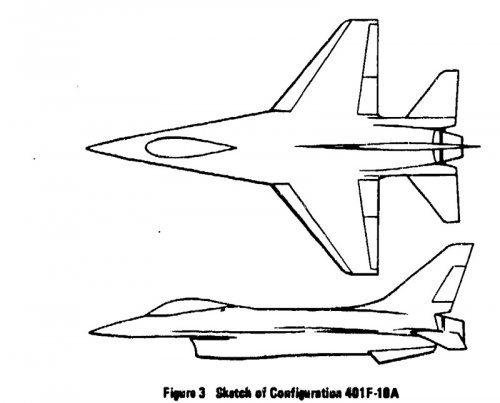

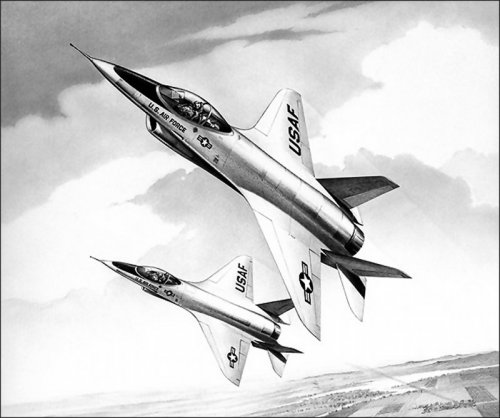

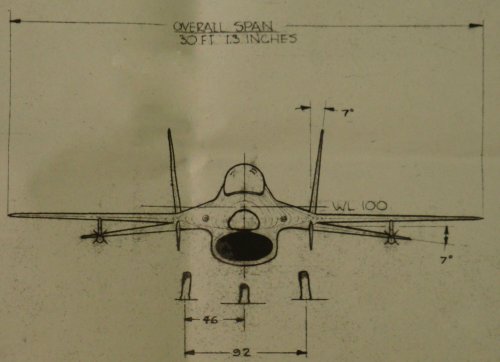

One of the questions addressed by the designers of the Lightweight Fighter was single vertical tail versus twin-tailed configurations. See Fig. 9.10. NASA data available at this time indicated advantages of the twin-tailed configurations. However, as noted by Hillaker 10, The NASA data were limited to angles of attack of 15o, or less. Buckner et al.11 noted: “To the dismay of the design team, however, the directional stability characteristics of the twin-vertical-tailed 401F-0 configuration were not as expected. In fact, a severe loss of directional stability occurred at moderate-to-high angles of attack.... Analysis of oil flow visualization photographs led to the belief that forebody flow separations and the interaction of the resulting vortices with the wing and vertical tail flow fields were major causes of the stability problem.”

Modifications were made to delay forebody separation to higher angles of attack. Buckner et al 11 reported: “It was more difficult to make the twin-tail configurations satisfactory compared to the single vertical tail configurations (in addition, some combinations of angle of attack and sideslip produced visible buffeting of the twin tails). Beneficial effects on the directional stability derivatives were noted when relatively small highly swept ‘vortex generators’ (strakes) were located on the maximum half-breadth of the forebody.”

“At this point, NASA Langley Research Center aerodynamicists were consulted and they suggested that the lift of the wide forebody could be increased by sharpening the leading edge to strengthen the vortices rather than weaken them as our earlier attempts had done. The point was that forebody separation is inevitable at very high angle of attack; therefore, the lift advantages offered by sharp leading edges should be exploited. This also would allow the forebody vortices to dominate and stabilize the high-angle-of-attack flow field over the entire aircraft, improving, even, the flow over the outboard wing panels.”

Once the YF-16 was in the flight-test program with the YF-17, it was no longer called the Lightweight Fighter. It was called the Air Combat Fighter (ACF). Orders for the ACF, the F-16, came in 1975. The first operational units were formed in 1978. In the late 1970s, production versions of the F-16 were quickly modified to add a full radar capability, to add hard points to accommodate the ability to handle air-to-ground capability, and to increase the combat radius to 725 nautical miles. Thus, the aircraft had become a true multi-role fighter.

Bradley notes: “Perhaps the greatest irony for the tactical aircraft designer results from the fact that an aircraft designed to be the ultimate in aerodynamic efficiency throughout a performance spectrum is often used as a ‘truck’ to deliver armaments. Aircraft that are designed in a clean configuration are often used operationally to carry an assortment of pylons, racks, missiles, fuel tanks, bombs, designator seeker pods, launchers, dispensers, and antennas that are attached to the configuration at any conceivable location.”

“The carriage drag of the stores is often of the same order of magnitude as the total minimum drag of the aircraft itself. For example, the minimum drag of the F-16 aircraft is compared in Fig. 9.15 with and without the air-to-ground weapons load. It is readily seen that the store drags themselves present as large a problem to the aircraft designer as the drag of the clean configuration. Store carriage on modern tactical aircraft is extremely important, particularly as one approaches the transonic regime, where the interference effects of the stores and pylons are highest and most detrimental to performance.”

Bradley continues: “ Not only must external stores be carried efficiently by tactical aircraft, but they must release cleanly and follow a predictable trajectory through the vehicle’s flowfield. The store trajectory is governed by the highly unsteady forces and moments acting on the store produced by the nonuniform flowfield about the configuration and the aerodynamic characteristics and motions of the store itself. The problem is complicated by realistic combat requirements for jettison or launch at maneuver conditions and multiple release conditions where the weapons must not ‘fly’ into one another.”

Military aircraft of the future will have added emphasis on store carriage and release early in the design process. Some possible concepts for weapons carriage are contrasted in Table 9.4.

Bradley presented wind-tunnel measurements that compared the drag for conformal carriage versus conventional installations of MK-82 bombs. As shown in Fig. 9.16, conformal carriage permits one to carry 14 MK-82 bombs at substantially less drag than a 12 MK-82 pylon/multiple bomb rack mounting. Bradley noted: “Significant benefits for the conformal carriage approach, in addition to increased range, are realized: increased number of weapons and carriage flexibility; increased penetration speed; higher maneuver limits; and improved supersonic persistence. Lateral directional stability is actually improved with the weapons on.”

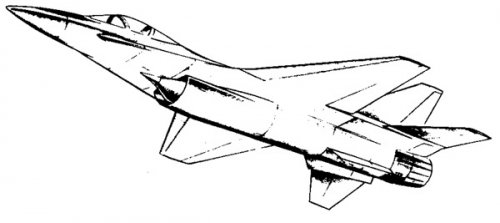

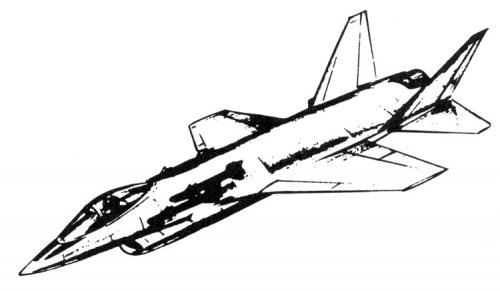

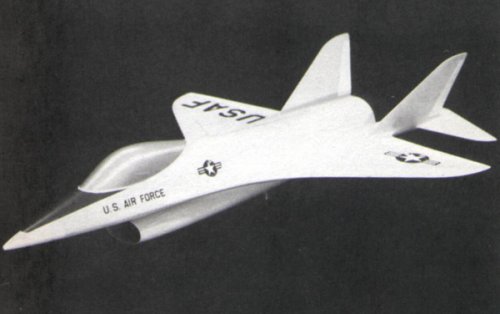

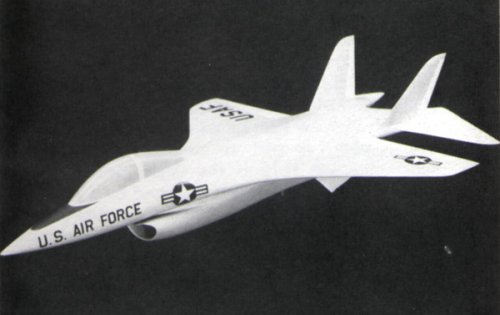

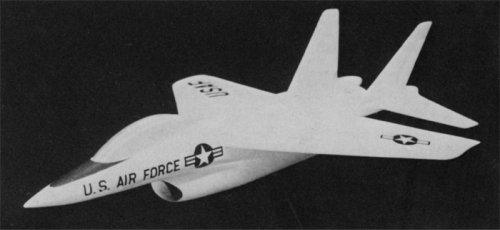

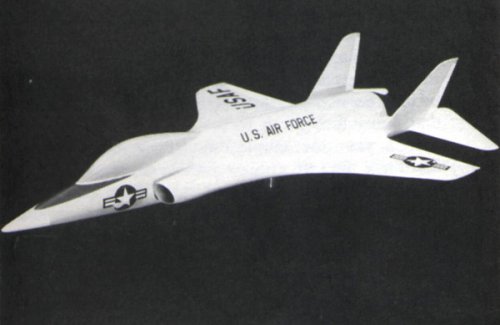

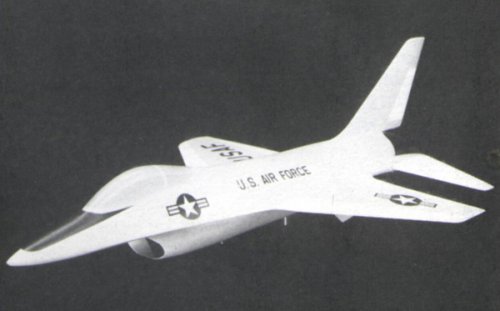

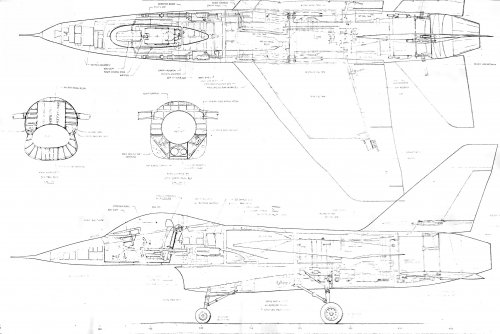

Hillaker noted that in 1974, General Dynamics embarked on a Supersonic Cruise and Maneuver Program (SCAMP) to develop a supersonic cruise derivative of the F-16. The “supercruiser” concept envisioned optimization at supersonic cruise lift conditions so that sustained cruise speeds on dry power (nonafterburner power) could be achieved in the Mach 1.2 to 1.3 speed range. Trade-offs to the aerodynamics required for supersonic cruise, subsonic cruise, and maneuvering flight were explored. The goal was to arrive at a design that would offer at least a 50% increase in the supersonic lift-to-drag ratio (L/D), that would retain a high subsonic L/D ratio, and that would provide the level of maneuverability of a fighter.