Hehe

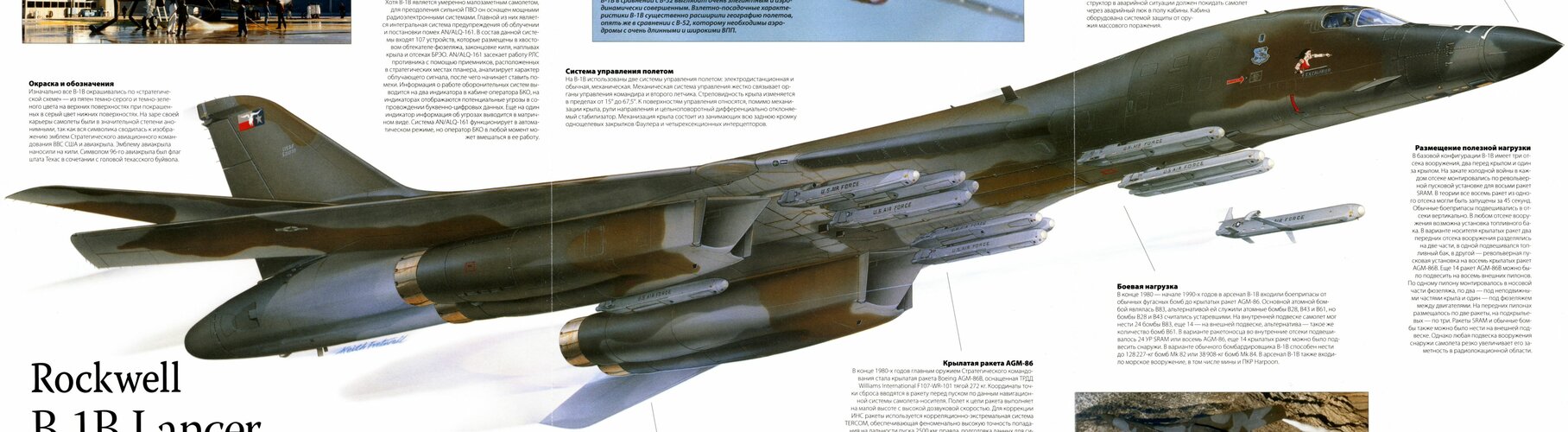

Aerospace is at the fringe of engineering.

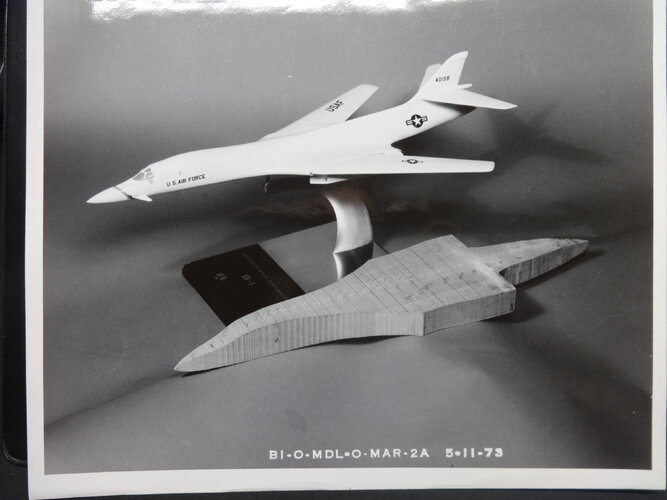

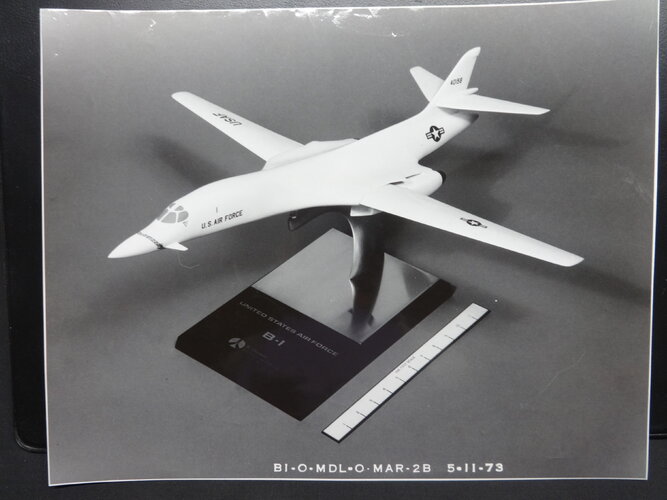

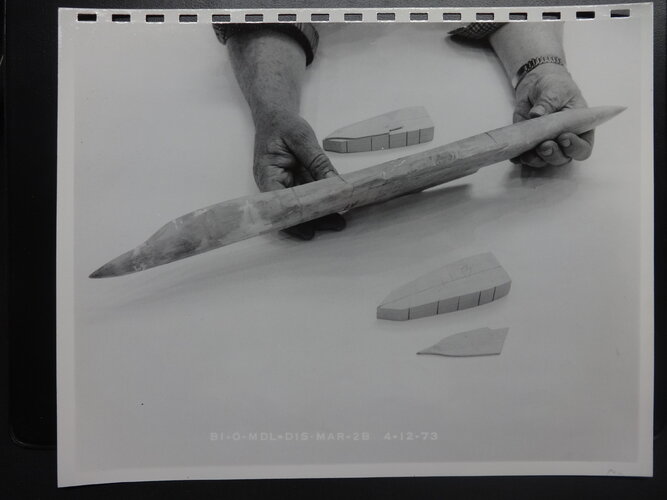

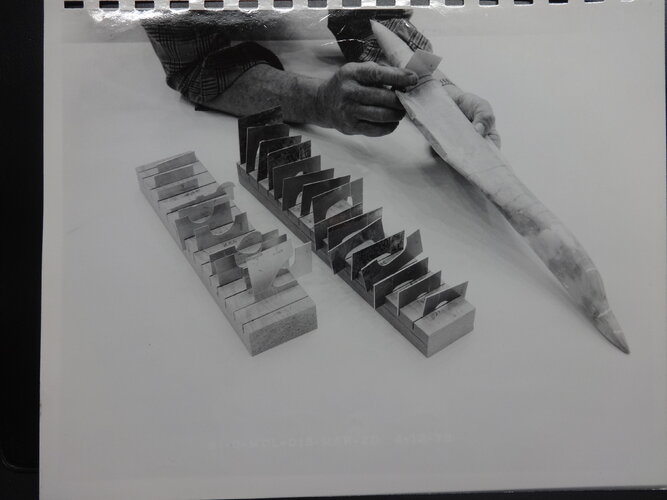

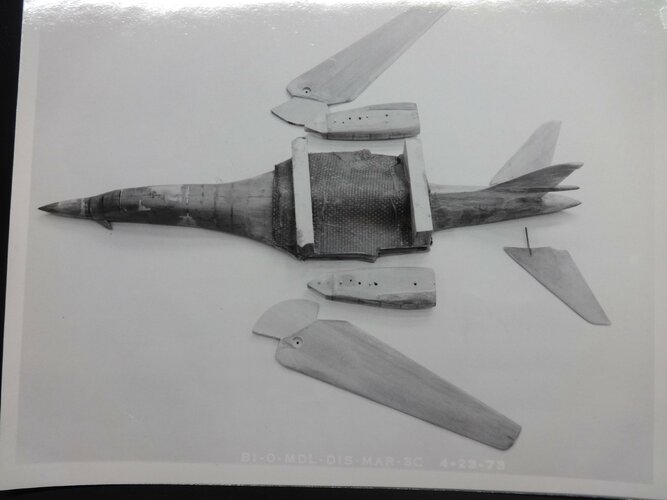

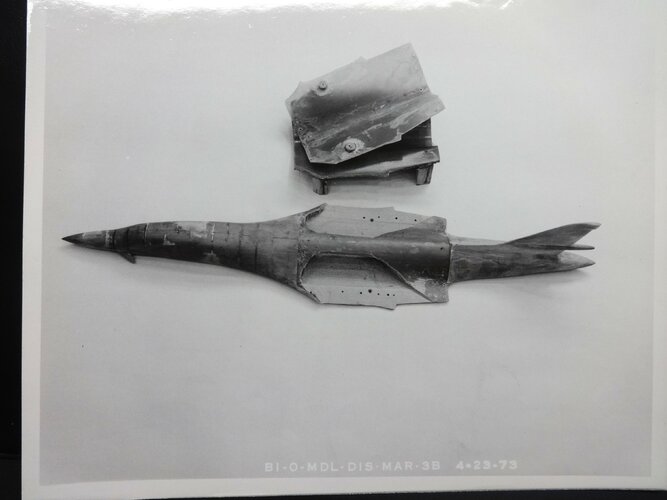

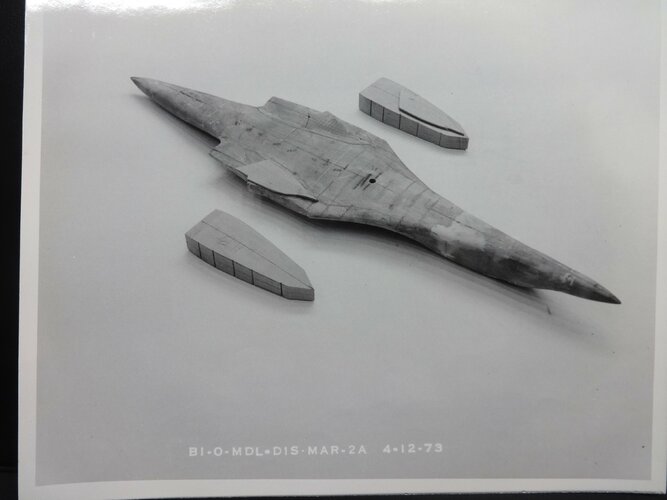

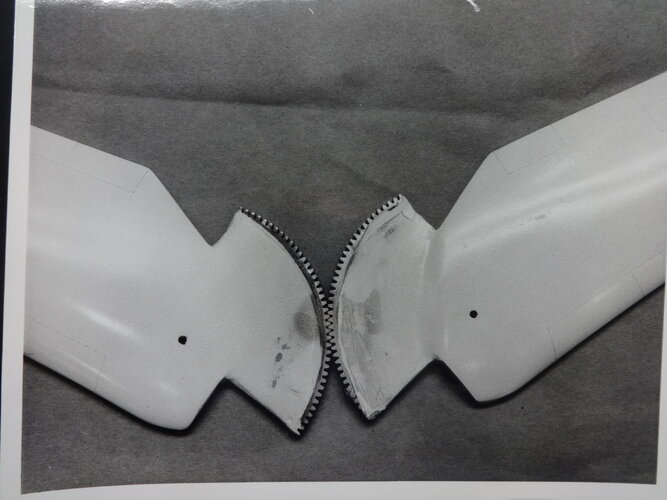

Remember that we did not have 3D at the time, meaning that everything, mostly, was 2D projected.

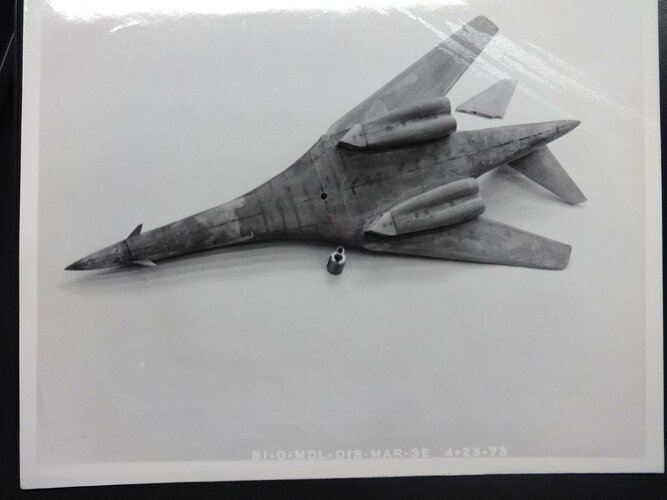

With often complex body curvature (yes, Aerospace is the sexy branch of engineering!), parts real shapes are sometime not perfectly reflected in the manufuring drawings and instructions. Yes. You read it correctly.

Then, what happens when you loose the experienced mechanics, welder or men in charge of hot shaping, cold bend a complex part, casted or not? You can loose the knowhow. Loose the mold, that were often hand trimmed or rectified with experience from the assembly lines, and it's even worst!

That's where the fun start for very experienced engineers with good mathematics and academics (I insist). Like that Belgian detective, you have to rebuild a manufacturing chain, often from scratch, that it can be rebuilt accurately. That's what the kids here are offered to do (with some instructor). It's a hell lot of fun where you learn at every step of the way like few of your colleagues will ever have the opportunity to experience.

Highly recommended!