Pirate Pete

ACCESS: Secret

- Joined

- 25 July 2007

- Messages

- 328

- Reaction score

- 500

I came across the following article from an old Janes Fighting Ships (1969 edition I believe)

If these vessels had been realised, what effect would they have had?

No doubt there would have been an impact on the later LHA prgramme.

Fast Deployment Logistic Ship (FDL):

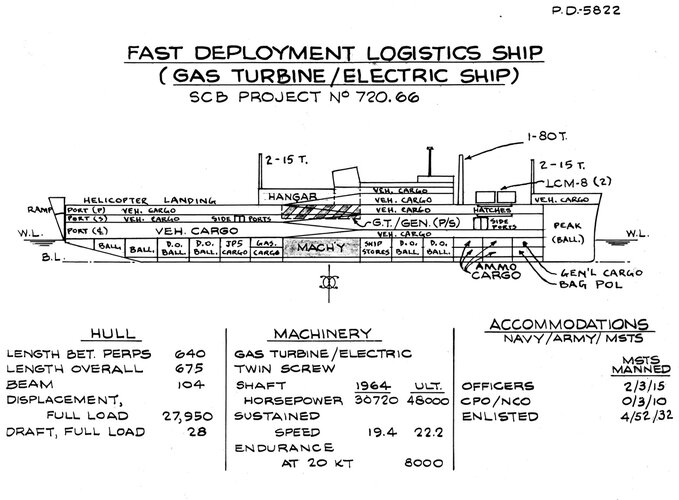

40,500 tons (FL)

855 x 104 x 28 ft

Steam Turbines – 60,000 shp

2 shafts = 24+ kts

The ships are intended to carry pre-loaded Army combat equipment to overseas areas where the equipment would be “married” to troops flown overseas. Presumably some of the ships would always be deployed overseas as floating depots. According to the Department of Defence the most cost-effective number of FDL ships necessary to meet anticipated requirements of the 1970’s would be 30 operating in conjunction with 4 squadrons of C-141 jet cargo aircraft and six squadrons of C-5 jet cargo aircraft. However, continued reluctance by the Congress to authorise the FDL programme led to a revised proposal by the D.o.D in 1968 to build on 15 FDL’s and obtain the balance of the sealift requirement through the long-term charter of up to 30 new cargo ships to be privately built according to the design criteria specified by the Navy’s Military Transportation Service.

The first FDL’s originally were requested in the Fiscal Year 1966 shipbuilding programme and each year since then, but at this writing (1969) had not been funded by Congress.

The Fiscal Year 1970 programme requests $ 187m for the construction of three ships with the remaining 12 ships planned for F.Y. 1971-73 (four ships per year). Estimated cost per ship is $ 52m.

Cargo:

Each ship could lift 11,100 tons of material including tanks, helicopters, and heavy engineering equipment. Twelve FDL’s could lift the equipment of a reinforced infantry division, a task which would otherwise require 33 C-5 merchant ships (D.o.D estimate).

Construction:

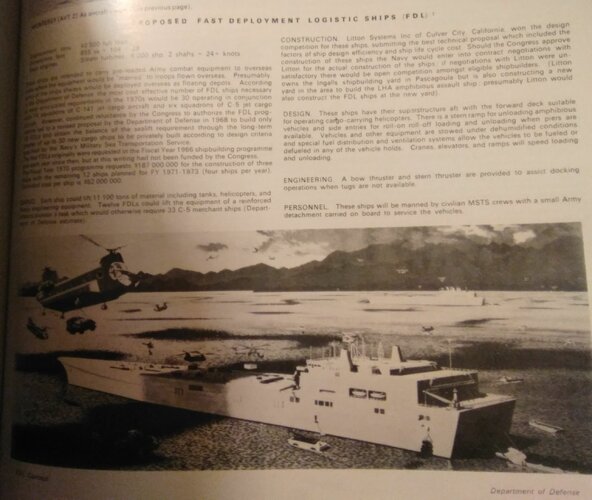

Litton Systems Inc. Of Culver City, California won the design competition for these ships, submitting the best technical proposal which included the factors of ship design efficiency and ship life-cycle cost. Should the Congress approve construction of these ships the Navy would enter in to contract negotiations with Litton for the actual construction of the ships; if negotiations with Litton were unsatisfactory there would be open competition amongst eligible shipbuilders. (Litton owns the Ingalls shipbuilding yard in Pascagoula but it is also constructing a new yard in the area to build the LHA amphibious assault ship; presumably Litton would also construct the LDL ships t this new yard).

Design:

These ships have their superstructure aft with the forward deck suitable for the operating of cargo carrying helicopters. There is a stern ramp for unloading amphibious vehicles and side entries for roll-on roll-off loading and unloading when piers are available. Vehicles and other equipment are stowed in dehumidified conditions and special fuel distribution and ventilation systems allow the vehicles to be fuelled of defueled in any of the loading holds. Cranes, elevators, and ramps will speed loading and unloading.

Engineering:

A bow thrusters and stern thrusters are provided to assist docking operations when tugs are not available.

Personnel:

These ships will be manned by civilian MSTS crews with a small Army detachment carried onboard to service the vehicles.

If these vessels had been realised, what effect would they have had?

No doubt there would have been an impact on the later LHA prgramme.

Fast Deployment Logistic Ship (FDL):

40,500 tons (FL)

855 x 104 x 28 ft

Steam Turbines – 60,000 shp

2 shafts = 24+ kts

The ships are intended to carry pre-loaded Army combat equipment to overseas areas where the equipment would be “married” to troops flown overseas. Presumably some of the ships would always be deployed overseas as floating depots. According to the Department of Defence the most cost-effective number of FDL ships necessary to meet anticipated requirements of the 1970’s would be 30 operating in conjunction with 4 squadrons of C-141 jet cargo aircraft and six squadrons of C-5 jet cargo aircraft. However, continued reluctance by the Congress to authorise the FDL programme led to a revised proposal by the D.o.D in 1968 to build on 15 FDL’s and obtain the balance of the sealift requirement through the long-term charter of up to 30 new cargo ships to be privately built according to the design criteria specified by the Navy’s Military Transportation Service.

The first FDL’s originally were requested in the Fiscal Year 1966 shipbuilding programme and each year since then, but at this writing (1969) had not been funded by Congress.

The Fiscal Year 1970 programme requests $ 187m for the construction of three ships with the remaining 12 ships planned for F.Y. 1971-73 (four ships per year). Estimated cost per ship is $ 52m.

Cargo:

Each ship could lift 11,100 tons of material including tanks, helicopters, and heavy engineering equipment. Twelve FDL’s could lift the equipment of a reinforced infantry division, a task which would otherwise require 33 C-5 merchant ships (D.o.D estimate).

Construction:

Litton Systems Inc. Of Culver City, California won the design competition for these ships, submitting the best technical proposal which included the factors of ship design efficiency and ship life-cycle cost. Should the Congress approve construction of these ships the Navy would enter in to contract negotiations with Litton for the actual construction of the ships; if negotiations with Litton were unsatisfactory there would be open competition amongst eligible shipbuilders. (Litton owns the Ingalls shipbuilding yard in Pascagoula but it is also constructing a new yard in the area to build the LHA amphibious assault ship; presumably Litton would also construct the LDL ships t this new yard).

Design:

These ships have their superstructure aft with the forward deck suitable for the operating of cargo carrying helicopters. There is a stern ramp for unloading amphibious vehicles and side entries for roll-on roll-off loading and unloading when piers are available. Vehicles and other equipment are stowed in dehumidified conditions and special fuel distribution and ventilation systems allow the vehicles to be fuelled of defueled in any of the loading holds. Cranes, elevators, and ramps will speed loading and unloading.

Engineering:

A bow thrusters and stern thrusters are provided to assist docking operations when tugs are not available.

Personnel:

These ships will be manned by civilian MSTS crews with a small Army detachment carried onboard to service the vehicles.