Scanned this in from an old Army Magazine; this has the clearest, most detailed layout of the specs of the Army's AMS program, which included Crusader, Block III Tank, FIFV, etc.

--------

ARMY May 1991

Armor's Future: From One, Many

By Eric C, Ludvigsen

Associate Editor

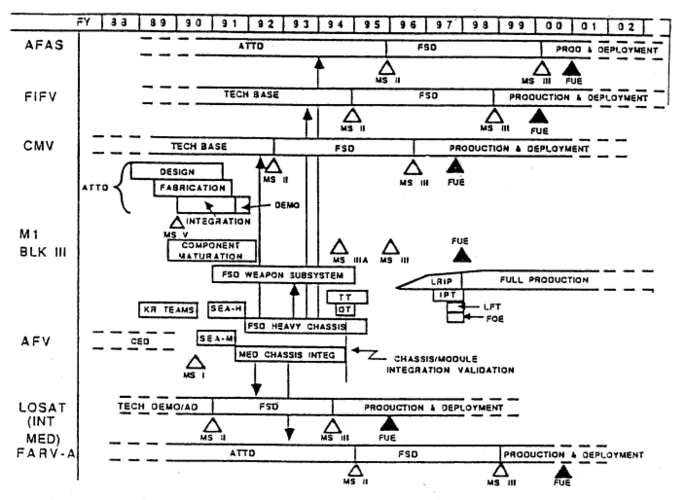

Convinced of the advantages of commonality in the development, procurement and operation of the next generation of armored vehicles, the armored systems modernization program is performing a delicate balancing act between combat capability, schedules and costs.

Despite the sterling performance of its armored vehicles in the Persian Gulf War, the Army figures that, by the turn of the century, they will begin looking like exhausted designs, much as the M60-series tanks became a technological dead end in the 1970s. The Army's ASM. (armored systems modernization) program partly rests on the idea that, in order to maintain the advantage demonstrated in Kuwait and Iraq, the service must begin now. Even as it is, first units will not be fully equipped with the ASM vehicles until late in the first decade of the new century and, as Maj. Gen. Peter M. McVey, the ASM program executive officer, says in the accompanying interview, "That is a long time to be sitting on the technology we currently have in 1991."

When ASM's predecessor programs got under way in the mid-1980s, they were looking at the problem through the other end of the telescope—American armor/antiarmor technology was thought to be behind that of the long-time cold war adversary, the Soviet Union, with a widening gap in pros-pect. That was the conclusion of the De-fense Science Board's 1985 summer study, the first to suggest that the Army might be able to catch up, get ahead and stay ahead by developing a family of heavy vehicles, using common components and based on a new main battle tank (MBT) chassis.

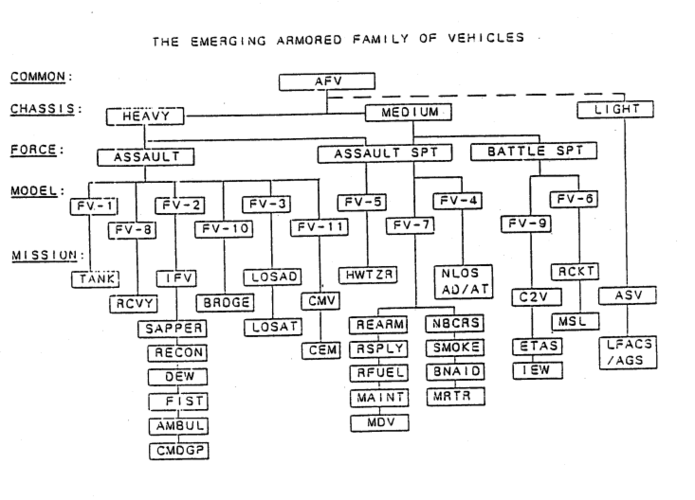

The resulting effort, the two-year armored family of vehicles (AFV) task force study, posited as many as 30 different armored vehicles for 24 missions, based on 11 variants of heavy and medium common chassis.

"The original approach was to develop these systems concurrently and then field them by battalion sets," said Walter P. Wynbelt, technical director for future systems in the ASM program executive office. "That meant that each vehicle system had to be in development at the same time, into production at the same time. You can imagine the 'bow-wave' that would create—it was totally un-affordable." Indeed, the AFV's initial 1987 cost effectiveness evaluation estimated that the cost of developing and procuring a 34,000-vehicle fleet and supporting and operating it for a 20-year life cycle would be nearly $276 billion.

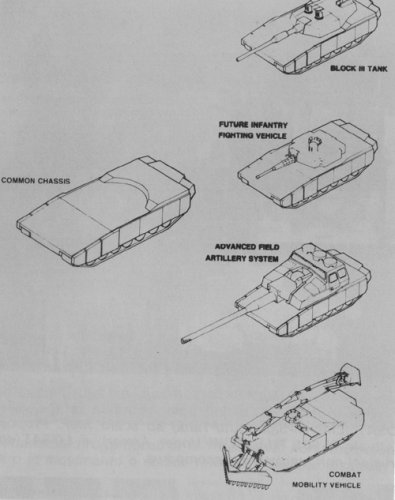

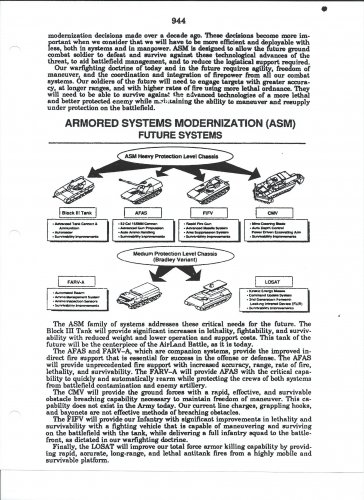

By that time, the trend was becoming evident that will reduce annual Army procurement budgets to less than 40 percent of their mid-1980s peak by fiscal 1995, so the Army rank ordered the AFV list and came up with six vehicles—four on a common heavy chassis and two on medium chassis —as an affordable program that would take maximum advantage of new technologies and also address long-neglected critical needs. "ASM was on a very short time line when it originally started," said Mr. Wynbelt of the period when the program was moving from AFV through a phase known as heavy forces modernization (HFM). "The Soviets were going to be fielding a new tank [FST-III —future Soviet tank III] before the end of the decade. The Abrams, even in its M1A2 configuration, would not be a match for that system, so there was an urgent need for a new tank. But then the Berlin Wall came down and, suddenly, where was the urgency?"

The diesel-based candidate for the ASM common heavy-protection level chassis power pack is the XAP-1000, with the lead contractor, Cummins Engine Co., Inc., providing the V-12 engine, and the transmission from General Motors' Allison Transmission Division.

"The Soviet schedule started slipping," Mr. Wynbelt continued, "our schedule started slipping accordingly, and the urgency was suddenly gone. At one time, people at Department of the Army were willing to accept high risks, going from a test-bed approach right into full-scale development, bypassing the prototyping phase. Now came the school of thought, particularly within OSD [Office of the Secretary of Defense] that maybe we ought to do a little bit less risk—'the schedule is not quite as critical anymore, the threat has reduced, let's do it a little bit slower.' "

Consequently, when the ASM's proposed Block III main battle tank program went up for its Milestone I review last summer, the Defense Acquisition Board added a requirement for separate prototyping, which would mate the chassis with the turret, armament and electronics before moving into full-scale development. "OSD added the prototype phase to reduce risk," Mr. Wynbelt said. "That added cost, and it stretched the program by three years, but there wasn't a whole lot of concern." At some point, however, the Army's fighting vehicles are going to lose their demonstrated edge, while other ASM vehicles will allow the Army to catch up in areas where it has long been deficient, such as artillery and frontline combat engineer equipment. The Soviet armored force will remain a bench mark because it retains the largest related industrial base in the world and will likely continue to be the major source of armored equipment for militarily ambitious nations in the Third World.

"The other guys keep insisting on improving their armor," Mr. Wynbelt said, "which means you have to have bigger bullets, bigger guns, or at least more capable bullets. Our Abrams did extremely well in Iraq, but you have to keep in mind that it was going against an export version of the T-72. The T-72 has already been replaced in the Soviet Union by the T-80; several modifications have already occurred on the T-80.”

If ASM is continually delayed, the Army sees a number of battlefield deficiencies developing with the current generation of armored systems:

• Inability to defeat future Soviet armor improvements with direct-fire weapons.

• Inadequate artillery range and rate of fire.

• Inadequate target acquisition and fire control.

• Vehicles with varying and incompatible mobility, hampering combined arms operations.

• Product improvements to the M1-series Abrams tanks have pushed weight beyond levels that would have been unacceptable only a few years ago.

• Inadequate armor protection against future Soviet antiarmor munitions.

• Engineering equipment does not exist that can breach complex defensive obstacles in stride, a key requirement for the fluid battlefield of the evolving AirLand Battle-Future doctrine.

• A current and growing lack of commonality in system components, repair parts and maintenance tools.

• Increased requirements for items consumed in combat, mainly fuel and ammunition.

• Inadequate repair and resupply capabilities.

ASM has retained the AFV program's concept of commonality among major vehicle components and extended the idea of modularity, in which the profiles of individual vehicles may be altered according to operational circumstances and their components exchanged in service.

The Army expects that commonality will result in development and procurement savings through shared testing of prototypes and the flexibility and efficiency of a single production line operating at economic rates. The biggest savings, however, are expected in the life-cycle costs of ownership and operation—in the training of crews and mechanics, in the simplified repair of battlefield damage and in the reduction of spare and repair parts stockage requirements at all levels. Of the six current vehicles that the ASM designs would replace, there is commonality only between the M109-series 155-mm self-propelled howitzers and the accompanying M992 field artillery ammunition support vehicle (FAASV), which share the same chassis.

That means five different engines, five different transmissions, five different suspensions, six different tracks and six discrete electronics systems. In the ASM generation, the vehicle electronics (vetronics) architecture would be common to all vehicles and power packs and running gear would amount to two basic designs—the common heavy-protection chassis (CHC) and the common medium-protection chassis (CMC).

Modular armor—which could be built up or torn down to different levels—will also be a feature of the CHC vehicles, and all vehicles will have the same collective protection against NBC (nuclear-chemical-biological) threats. "There are constraints in how common the vehicles have to be," said Mr. Wynbelt. "You could have a common chassis where one vehicle could have the engine in the rear, the other have it front, as long as it's the same engine, the same transmission, same road wheels and track. The road wheel spacing may be different; even the number of road wheels may be different."

"All four [CHC] chassis must be producible on one production line, using flexible tooling," Mr. Wynbelt said. "That means they can't be too different. The major dif-ference will probably be in the hull weld-iing, but the hull structure is not a replaceable item; as long as the designs are close enough, where you can fabricate them on one production line, that is all that mat-ters. The important thing is that the items which require replacement in the vehicles, that those be common."

In each of the CHC designs, the Army has specified certain performance requirements and characteristics, which are discussed below, in alphabetical order:

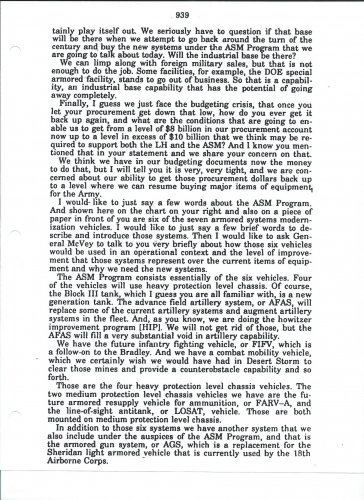

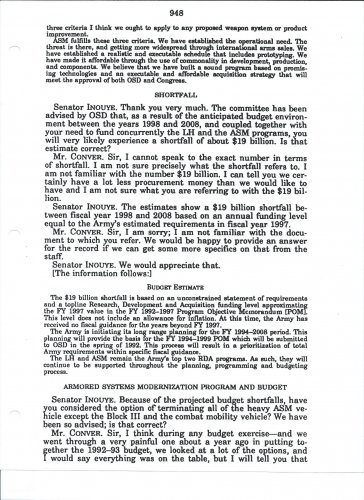

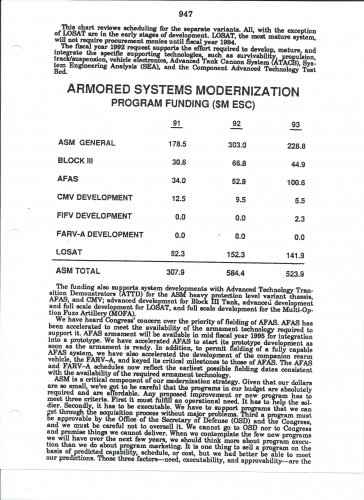

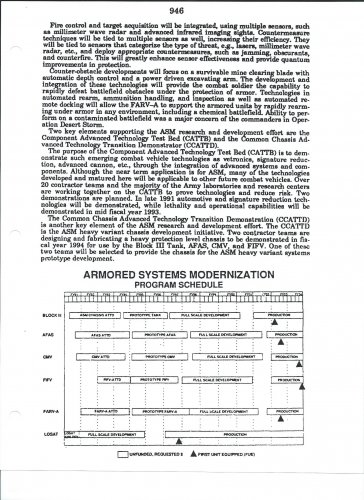

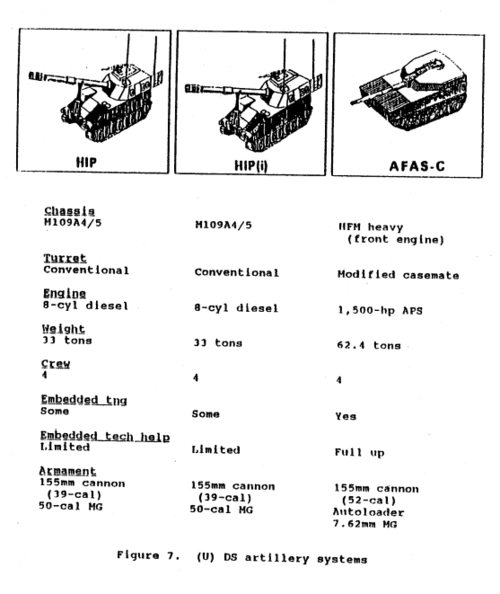

Advanced Field Artillery System (AFAS). This advanced self-propelled gun would begin appearing in the field in 2004, with an initial procurement objective of 824 to replace M109s—which, by that time, will have been converted to the M109A6 HIP (howitzer improvement program) configuration—in force package one, that is, forward-deployed units and U.S.-based contingency units.

AFAS has been a bone of contention be-tween the Army and interested parties in Congress who believe that the service has too long neglected its heavy-force artillery weapons, the basic M109 chassis having entered service in the early 1960s, with longer range ordnance added in the 1970s. Some critics have argued that AFAS should be placed on a faster track and removed from the CHC effort, believing that the service's desire for an optimum successor to the Abrams —where time is less critical—is inhibiting artillery modernization.

The Army naturally does not want to lose the advantages of commonality and the economics of production scale that AFAS represents in the CHC program (nearly 14 percent of the initial procurement objective), but counters that the advanced technologies planned for the new artillery piece will not permit faster development. The service has, however, advanced the schedule for AFAS so that it would follow the Block III tank into service by just three months. moving ahead of the combat mobility vehicle (CMV).

AFAS is facing a major decision later this year on whether the gun will use liquid propellant, which could provide continuous zoning, or a system known as uni-charge, in which discrete zoning is achieved by incremental blocks of solid propellant. Army requirements for AFAS include increased range up to 40 kilometers, a 300 percent increase in the rate of fire over the M109A6 and the ability to fire a time-on-target salvo of four rounds, in which the shells are launched at different elevations to arrive at the target simultaneously.

Armor would be improved over the current generation with particular attention to protection against top-attack munitions of the type that would be employed in enemy counterbattery fire. The crew spaces, fuel and ammunition will be compartmented from one another. Also, said Mr. Wynbelt, "it will have an autonomous capability and will not be dependent on a fire-control center somewhere else—it can pick its own targets."

"AFAS will have automated ammunition handling and must be able to fire at least 12 rounds a minute for five minutes; it is required to carry 60 rounds, so it can fire a total complement of ammunition in five minutes—that's a lot of rounds thrown out."

With the same basic chassis as the Block III tank, AFAS will have comparable mobility, with 300 percent more horsepower at the sprocket than the M109 series. Other design objectives include 30 percent less fuel consumption over a battlefield day, doubled track life and a two-thirds reduction in the time needed to replenish ammunition.

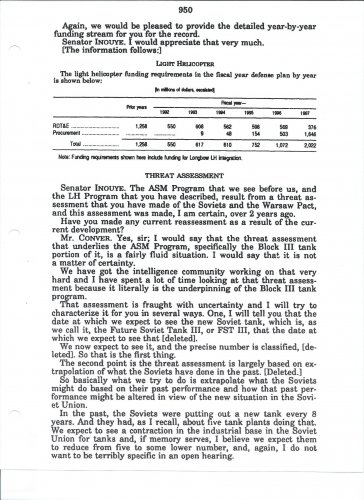

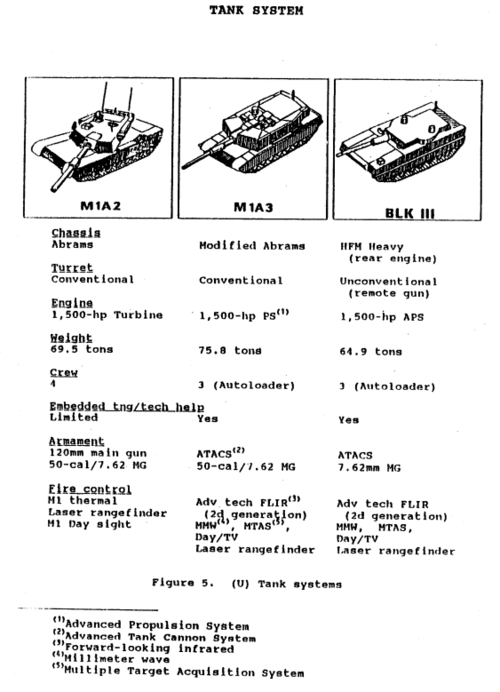

• Block III Main Battle Tank (MBT). The Army is looking for a 50 percent increase in kinetic-energy armor penetration in its future main battle tank, which would extend killing range by a third, plus a 75 percent greater rate of fire.

The ASM program executive office is confident this can be achieved with the advanced tank cannon (ATAC) system being developed by the Armament Research and Development Center, Picatinny Arsenal, N.J. ATAC combines the XM91 automatic loader with the XM291 high-velocity cannon, a 140-mm weapon with a tube length of about 61 calibers (around 28 feet, or 56 percent longer than the 46-caliber tube of the M256 120-mm cannon of the M1A1 and -A2 Abrams).

"If, at some time in the development cycle, ETC [electrothermal cannon] suddenly looks very good—if there is a breakthrough," said Mr. Wynbelt, "we could then utilize that technology. We are not ruling that out, even possible as a future improvement, but right now our studies show that it will not be there for our fielding dates," Radical breakthroughs are required in power generation, storage and conditioning, he added, before electrothermal or electromagnetic guns move out of the laboratory.

By reducing the crew from four to three (eliminating the M1's loader position); shrinking the size of the power pack by 40 percent; using external in-arm hydropneumatic suspension units (and thus saving about 17 cubic feet of space now occupied by torsion bars); and using modular armor with advanced composite materials, the ASM teams intend to significantly improve armor protection while cutting combat-loaded weight to five to ten tons below the M1A2, or a range of 57 to 62 tons.

The Block III MBT would have at least 35 percent greater protection from the frontal aspect and 48 percent more side protection. "We are going to have a type of modular armor," Mr. Wynbelt said. 'The M1 Armor is extremely good, very effective; however, it is difficult to implement change, because you are confined. What we are going to do is design a vehicle with an armored wall, and then you hang boxes of armor on there, which allows you to upgrade as armor technology improves—you either get your weight down or provide more capability. In the past, every vehicle has had to grow in armor protection because the threat grows; this allows you to do that with minimum impact on the vehicle."

The ASM program executive office has told the CHC developers to allow for a 50 percent growth potential in armor effectiveness, Mr. Wynbelt said. "In other words, you have to design the vehicle to accommodate a heavier weight sometime in the future; if the armor has to grow and the technology is not there to offset the protection growth with weight reduction, we still have to be able to upgrade."

The modular arrangement of the armor would permit some of it to be removed to facilitate air transport. "Or you could take it off," Mr. Wynbelt said, "if you go into, say, a low-intensity environment, where your biggest threat is not tank guns, but RPG [rocket-propelled grenade]-type weapons; you could put on the suite of armor that is optimized against that type of threat, and also allow you to lose several tons of weight. So it gives you tremendous flexibility."

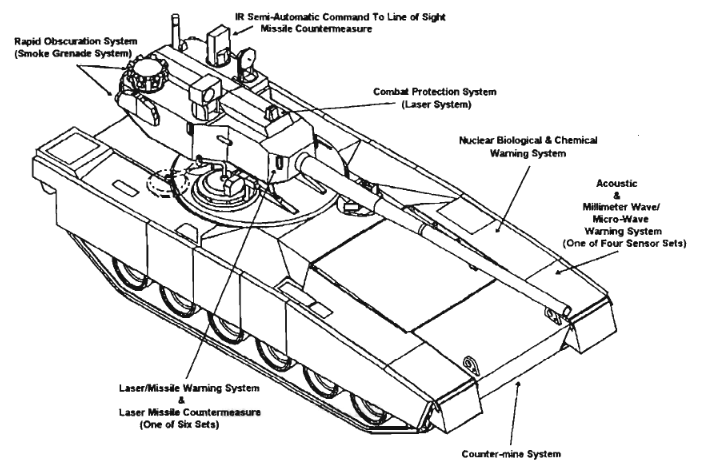

In survivability, there will also be a major effort to reduce visual, acoustic, magnetic, thermal and radar signatures, as well as a countermeasures suite of sensors, jammers and active defenses to foil guided munitions—the VIDS or vehicle integrated defense system. "You can no longer keep out every threat with passive armor alone, or even with reactive armor," said Mr. Wynbelt. "So we are looking more and more at countermeasures, where we use armor to defeat the dumb rounds and tank-fired projectiles—the ones that don't think—and countermeasures to offset the smart weapons and those that are guided to the target."

"Just as an example, if suddenly you have a warning you are being lased, then you can take action to mitigate the threat—flip the turret around and fire a round, or pop smoke and hide behind that. Those are the kinds of things we are looking at—automatic response or human-in-the-loop."

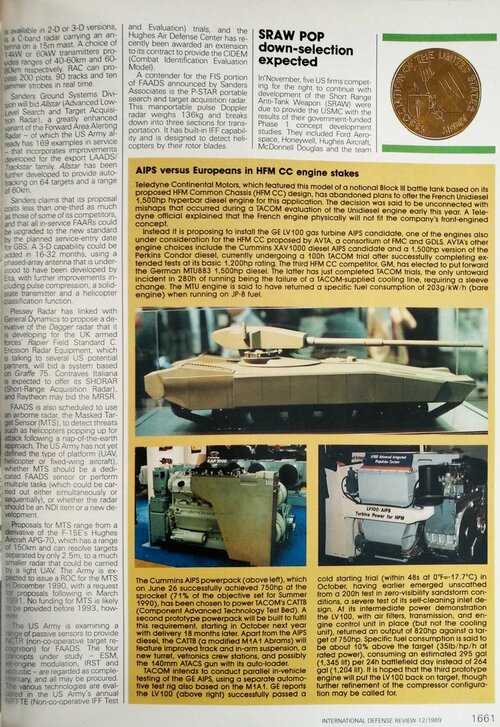

The mobility of the Block III and the other CHC vehicles is to equal or better the Abrams but do it with 50 percent less fuel consumption and a power pack 40 per-cent smaller. The technological basis for the desired level of performance is the Army Tank-Automotive Command's eight-year advanced integrated propulsion system (AIPS) program, whose second phase concluded last year with full-power demonstrations of two 1,500-horsepower power packs—a diesel-based design from Cummins Engine Co., Inc., with Allison Transmission Division of General Motors providing the transmission; and the other, a gas turbine from Textron Lycoming (the makers of the Abrams tank's AGT-1500 turbine) with the transmission designer, General Electrics Ordnance Systems Division, as the prime contractor.

Each is composed of the engine, transmission, cooling system, air-handling system and final drive, all integrated into a compact package. The Cummins/Allison XAP-1000 is based on the advanced Cummins XAV-28 V-12 diesel, a low-heat rejection engine, which while not purely adiabatic, uses only oil coolant and has no water in the cooling system at all; it uses the energy of the higher temperature exhaust gasses to run an auxiliary power unit (APU). The General Electric/Textron Lycoming LV100 AIPS features self-cleaning inlet air filters, greatly reduced fuel consumption over the AGT-1500 and claims not to require a separate APU to power the vehicle's electrical system.

Both AIPS designs "have met the requirements," Mr. Wynbelt said, "and you can no longer say the turbine is a gas hog, because we have a high-technology turbine here that does essentially what a diesel can do." As for APUs, he added, "We put in a requirement for electrical loads, and it is then up to the contractor to decide whether he can handle that with his main engine or if he needs an APU."

The Cummins AIPS has been chosen to power the CHC design by Armored Vehicle Technology Associates (a consortium of General Dynamics Land Systems Division and FMC Corporation's Ground Systems Division), while the second CHC developer under contract, Teledyne Continental Motors, selected the General Electric unit.

For its CHC bid, the General Motors Military Vehicle Operation proposed the 1,475-horsepower MTU 883 V-12 diesel by Germany's Motoren und Turbinen Union (MTU) Friedrichshafen, coupled to a transmission by Zahnräderfabrik Renk A.G. The GM bid was rejected by the Army last December, but that decision is under formal protest, with the General Accounting Office expected to rule no later than next month. GM has a 25-year licensing agreement, signed in 1985, to market the MTU 883 for heavy military vehicles. At 79 inches long with the transmission installed, the engine is unusually compact, partly achieved by engineering the exhaust manifolds to fit within the space between the cylinder banks.

CHC suspension is likely to be based on hydropneumatic units, mounted on the outside of the hull.

"We are running some test-beds now," Mr. Wynbelt said, "loaded up to 70 tons to allow growth potential. There are at least two different systems being marketed in this country today, and there are some overseas as well. It is within the state of the art of technology; not only does it buy you internal space [compared to torsion bars], you can also lose over 1,000 pounds, easily."

As for an active suspension—in which electronic rate and angle sensors smooth out the action—Mr. Wynbelt said, "We are still not quite there yet, where you can sense the terrain ahead of you. That is in the technology base, but I don't think we will see it on this one." The suspension will include lock-out features for the AFAS and the CMV, automatic track tensioning and perhaps variable height, although this is an optional requirement.

Far from being determined at this point is the basic configuration of the Block III— a conventional turret, or an overhead gun, either pillar mounted or traversing with a vestigial low-profile turret. The latter options would greatly reduce the tank's profile, save a lot of weight and eliminate the mechanically, electrically and ballistically troublesome hull-turret junction; they would also place the crew's vantage point at the hull roof, leaving them entirely dependent on sensors and image-transfer devices for observation and sighting from the level of the gun.

One thing about the Block III layout seems almost inescapable: the power pack will probably have to be in the front of the vehicle if the long-barreled XM291 140-mm gun is to be the main armament. The gun muzzle cannot be extended too far beyond the front of the hull before it strikes the ground—even at maximum elevation—when the tank is operating at the maximum angle of attack permitted by the suspension geometry; obviously, tanks cannot approach combat with their guns to the rear (the Iraqi ruse at Khafji in January notwithstanding).

"The external dimensions are pretty much controlled by highway transportability," Mr. Wynbelt said, "which means you cannot go much wider than 144 inches [the hull width of the M1]."

The ideal steering ratio—the relationship between the length of the track on the ground and the side-to-side width of the tracks—is probably somewhere between 1.8:1 and 1.2:1. (The M1's ratio is about 1.33:1.) Longer vehicles become very difficult to steer, while those with a near-square planform lack directional stability. Even if the Block Ill's steering ratio were fixed at the upper end of the desirable range, and the length of the hull scaled accordingly, there would be only about 15 feet at most between the XM291's breech and the rear of the hull. Into that space (the M1's turret is well over 20 feet long) must fit the gun mount, an adequate supply of compart-mented ammunition, the autoloader and— depending on the resolution of the turreted/ turretless question—crew stations and access to all of these; it doesn't seem as if there will be room for the engine compartment, even at the reduced AIPS volume.

Ironically, many of the Block III tank features—automatic loader, advanced diesel engine (possibly), hydropneumatic suspension with (possibly) variable geometry— were present in the failed MBT-70/XM803 tank development of the late 1960s; they proved technologically immature then and, for the sake of simplicity, were eliminated from the "austere" successor M1 series, whose main innovation was advanced compound armor and the gas turbine engine (selected over a competing diesel prototype)

--------------

A Chip Off the Old Block III

In the mid-1980s, it was thought that the next discrete generation of main battle tanks might retain the Ml-series Abrams chassis while introducing new and differently arranged components, such as main armament, fire control, power pack and electronics. This possibility was referred to as Block III, or the third generation of preplanned Abrams product improvements, to be developed and introduced on the production line en bloc. Block 1 improvements resulted in the Ml Al version of the tank, while Block II became the M1A2, whose prototypes are now being tested.

Block III would have produced an M1A3, but this was not to be, as the decision was made to develop a completely new design. The name, however, has stuck. ASM-Future program officials concede that the nomenclature once created considerable confusion, not only in the Army at large, but even within the program office; they say the name will probably be changed at some point in the future, but for the moment, they are comfortable with it.

--------------

The Army's initial procurement objective for the Block III tank (force package one) is 1,946 vehicles, to begin reaching the field in 2004.

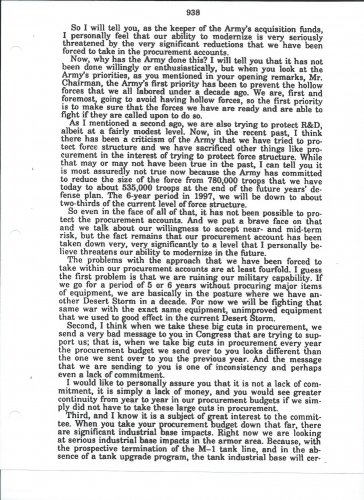

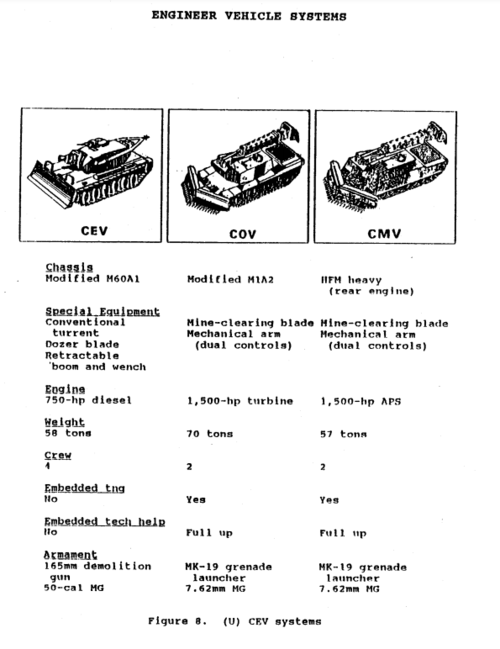

• Combat Mobility Vehicle (CMV). The CMV, which would begin appearing in the field in 2005, will provide the armored force a capability it has never had—the beaching of minefields and defensive obstacles at high speed. The initial procurement quantity of 258 vehicles would at least provide a start on replacing the elderly M728 combat engineer vehicle (CEV), based on the M60 chassis, which was type classified in 1963, began production in 1965 and entered the Army inventory in 1968.

The M728 is equipped with a 165-mm demolition gun, a lifting boom and winch and a scraper plow but is actually intended for slow-speed heavy engineering tasks of a quite different nature from those of the CMV, whose principal weapons will be an electronically controlled mine plow and a power-driven telescoping grappling and excavating arm with a bucket on the end.

The M728, Mr. Wynbelt explained, "cannot maintain pace with the M1, it is inadequately armored, and against complex ob-stacles, such as antitank ditches and dragon;s teeth, we can't do a whole lot." In AirLand Battle-Future, he said, "you have to quickly combine your forces at the critical point in the enemy lines, and if there are any obstacles, you have to have your obstacle-clearing capability with you—it must move as fast as you are moving. More than likely, the obstacles will be covered by fire, so the system has to be heavily armored. The emphasis is on time—you have to do it quickly, you have to have it right there."

The arm and bucket can clear obstacles by "grabbing them and throwing them out of the way, whether they be logs or abatis, or concrete obstacles," Mr. Wynbelt added, "If you have a ditch with a berm on the other side—which is a very difficult obstacle for a tank to cross—with the bucket and arm, you could reach across and just tear down that wall and fill the ditch. You can't do that with anything we have now."

The CMV's mine-clearing plow will be automatically controlled, Mr. Wynbelt said, "so that no matter what the attitude of the vehicle, it will keep the plow at a constant depth." Otherwise, "as the vehicle pitches, if you're not careful, the blade lifts clear and if there is a mine buried there, you lose your suspension, if not worse."

Both the bucket arm and the constant depth mine plow were extensively tested on the experimental counterobstacle vehicle of the mid-1980s, built on an M88A1 armored recovery vehicle chassis. Both tools will be blast resistant. The CMV is expected to provide a 175 percent increase in the pace of mine-clearing operations, when com-pared to the current force, which includes tank-mounted mine plows.

The CMV will carry only two crew members, compared to three in the M728, and will be about 13 percent lighter, at a combat weight of around 52 tons, yet the CMV will have 280 percent better frontal protection and side protection beefed up by 150 percent in terms of overall effectiveness. With a 1,500-horsepower engine, the CMV will be about two-thirds more powerful than the M728 but should use about 45 percent less fuel over a battlefield day.

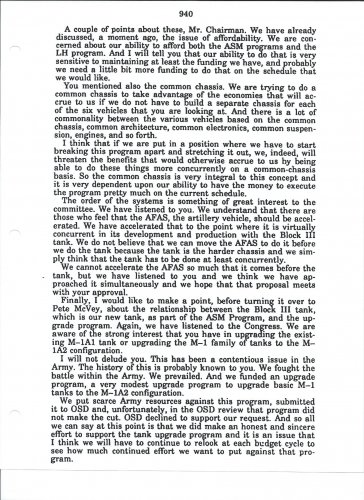

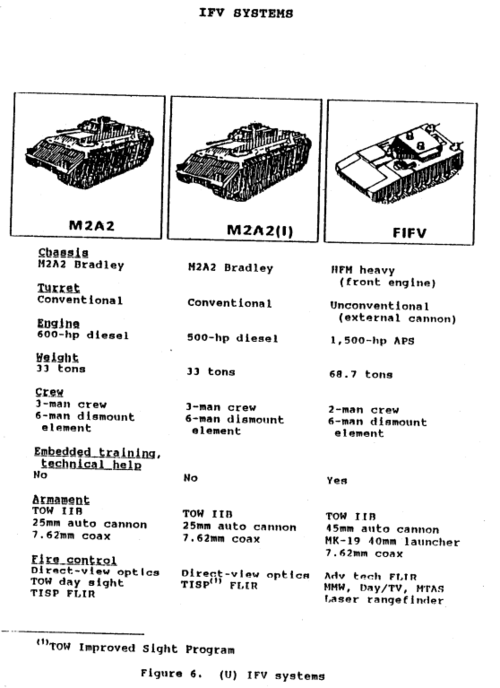

• Future Infantry Fighting Vehicle (FIFV)

The salient feature of the FIFV is that it will have the same armor protection as the Block III tank, thus ensuring that its pioneer infantrymen can go anywhere the tank goes. This is the kind of mechanized infantry vehicle the Army proposed in the early 1970s, before the Bradley's predecessor, the XM723 was developed, but could not sell to the Defense Department or Congress—it was deemed as heavy, complex and expensive as a tank and thus incapable of the required proliferation on the battlefield (roughly two infantry vehicles for every three tanks). All parties to this long-running debate, however, appear to have learned the lesson of the the Bradley and have accepted the necessity for an infantry vehicle that can advance in the face of the heaviest fire, without the need for compensating tactics. "With this vehicle, the infantry will be able to remain on board until they overrun target," Mr. Wynbelt said, "and then dis-embark, so that they will not have to fight toward an objective."

Compared to the Bradley, the FIFV will have more than 11 times the effective effective frontal protection and 200 percent greater protection from flank at-tacks, plus all of the VIDS passive and ac~ tive countermeasures of the Block III tank.

The FIFV will have missile armament with a degree of antiarmor capability as yet undetermined. The Army is looking for a 150 percent increase in effectiveness—including twice the armor penetration—from an automatic main gun in the 35-mm to 60-mm caliber range. There would also be a centrally controlled area suppression weapon system to deal with enemy infantry in the vincinity of the vehicle; this is expected to be 60 percent more effective than the individual port-firing weapons now operated by infantrymen mounted in the M2 Bradley.

With power and fuel capacity comparable to the main battle tank, the FIFV is expected to have 70 percent greater cruising range than the Bradley and cross-country speeds more than one-third higher. Vetronics and advanced fire control will allow the vehicle crew to be reduced from three men to two, but the size of the dismounted element is not yet certain.

"When we went from the M113 to the Bradley," Mr. Wynbelt said, "there was great controversy as to how big the squad should be. [It was fixed at nine, three of these being vehicle crew members. ] That controversy is happening all over again."

The first FIFV unit would begin equip-ping in the year 2005, and the initial pro-curement objective for force package one is 1,321 vehicles.

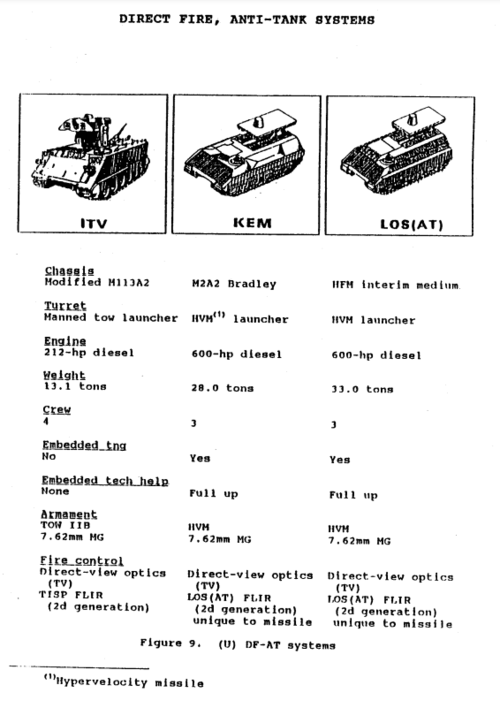

The remaining two ASM vehicles—the LOSAT (line-of-sight antitank) vehicle and the FARV-A (future armored rearm vehicle-artillery)—are based on the common medium-protection level chassis. The CMC will, in effect, be an improved version of the Bradley chassis, with the LOSAT built on the M2 chassis and the FARV-A using the Bradley-derived chassis of the multiple-launch rocket system (MLRS).

"The budget did not allow development of a new chassis for the medium systems," Mr. Wynbelt said. "The Bradley components are close to state of the art, they have been improved, the engine has growth potential, and we felt that there is a lot of utility in that chassis."

The required characteristics of the CMC vehicles are discussed below:

• LOSAT. This vehicle is urgently needed to replace the M901 ITV (improved TOW vehicle), and the Army wants to buy 907 of them for force packages one and two (the latter including reinforcing forces). LOSAT is leading all of the ASM vehicles and should begin appearing in the field in 1998.

LOSAT's armament is a laser-guided kinetic-energy missile (KEM) whose impact velocities approximate that of modern tank cannon, directed by a multiple target acquisition system. The KEM system and fire control are being developed by the Missiles Division of LTV Corporation's Missiles and Electronics Group, under a sole-source contract awarded last month by the Army Missile Command.

LOSAT will upgrade mobility and protection from M113 to Bradley levels, and the KEM system will range about 25 percent beyond the wire-guided TOW missile to around 5,000 meters. LOSAT will carry twice the number of missiles—24 as compared to 12 in the M901.

"ITV is a very capable system," Mr. Wynbelt said, "however, it is thinly armored, and it has M113 mobility, which will not maintain pace with a Bradley force or an Ml force, let alone the ASM force. The major drawback of the ITV is that it has a chemical-energy warhead type of weapon, the TOW II, which can be countered by reactive armor. It is also very slow—it requires up to 20 seconds or more to track the target. During that time, a lot can happen—the system can be knocked out, the enemy can toss up some kind of smoke you can't see through." LOSAT, he added, "will get you the same distance and farther in a matter of seconds—two or three seconds."

"With the ITV," Mr. Wynbelt continued, "you can only handle one target at a time; this can handle many more than that." Until recently, the guidance system had problems picking up the hyper-velocity missiles in tests. "The system had very great difficulty in tracking many targets," Mr. Wynbelt said, "but we made some changes, and it is doing extremely well now [eight out of nine successes in firings late last year]." LOSAT will be up for a Milestone II review late this year or early in 1992.

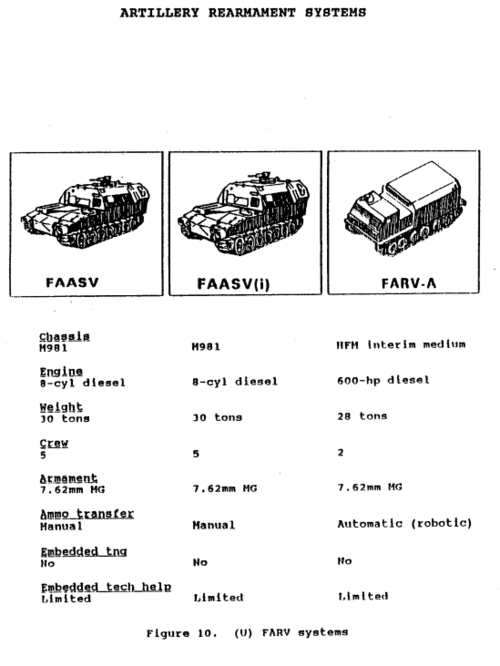

• FARV-A. This vehicle will be fielded in concert with AFAS in the year 2004, on the basis of one for each of the new self-propelled guns, or 824 in all for force package one. Indeed, FARV-A is essential to realize the dramatically greater rates of fire of AFAS.

FARV-A will carry out automated ammunition resupply through an armored, quick-disconnect port that protects the entire operation from artillery and small-caliber fire and NBC threats. The vehicle will have mobility comparable to AFAS, with cross-country speeds about 17 percent better than the M992 FAASV that resupplies the M109-series howitzers; cruising range will also be increased by about one-third.

Where FARV-A really differs in kind from current practice, however, is in its automated ammunition management system, based on information-bearing chips attached to each round. The chips will be automatically read when ammunition is hoisted aboard by the remotely operated materials handling equipment.

When ammunition is passed to the gun by a conveyor system, Mr. Wynbelt said, "the system will be able to read each chip and tell the AFAS what kind of round it is, the exact weight of the round, the ammo lot that it was produced in, and so forth. That all feeds into the AFAS computer, which takes that into consideration when it picks the round and fires it."

The final layout of FARV-A will depend on whether a unicharge propellant system is chosen for AFAS, or liquid propellant; if the latter, FARV-A would be fitted with conformal tanks to resupply propellant.

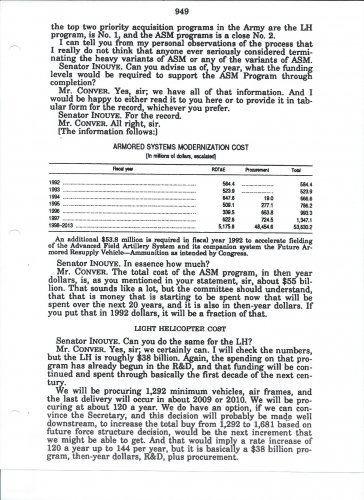

The number of ASM vehicles in the initial procurement objectives now being contemplated totals 6,080. What is it going to cost to develop, produce and field them? The program is too heavily weighted with imponderables at this point for there to be any definitive or even approximately good answer. Design-to-unit cost goals will be established for each vehicle, but this cannot be done "until you know what technologies you are going to be using," Mr. Wyn-belt said, which would normally be around the Milestone II review following the prototype fabrication and testing phase.

The program has produced some estimated unit costs, but Mr. Wynbelt cautioned that "they are somewhat soft." The estimated total cost is about $63 billion, which includes the cost of research, development, production, initial spare parts and fielding. Unit costs would thus be around $10 million on the same basis (which is not exactly the way the Army figures unit costs).

In the late 1960s and early 1970s, some members of Congress were incredulous that so prosaic a thing as a tank could cost as much as a million dollars. Before the outside critics begin calling for a prompt shut down of the "unaffordable" program, it is necessary to understand that about 60 per cent of the added cost over the current generation (around $2.4 million for an M1A1 and—because of the small numbers—perhaps twice that for an M1A2) is accounted for by inflation, which will accumulate to 50 percent or more over today's prices— at the very least—by the time the ASM vehicles are in production.

The other 40 percent of the increase is in capabilities, many of which have never been available to the Army's heavy force. Speaking of the Army's opponents in the Persian Gulf War and their equipment, Mr. Wynbelt said, "We could have had technology down to the level of theirs, and we could have saved a lot of money over the past ten or 20 years. Did we need smart weapons to defeat Iraq? No. Did we save a tremendous number of lives by having them? Absolutely."

Asked if the Army could afford to stand still for a time in armored vehicle technology, he said, "Well, you can—but it is not very wise."

--------

ARMY May 1991

Armor's Future: From One, Many

By Eric C, Ludvigsen

Associate Editor

Convinced of the advantages of commonality in the development, procurement and operation of the next generation of armored vehicles, the armored systems modernization program is performing a delicate balancing act between combat capability, schedules and costs.

Despite the sterling performance of its armored vehicles in the Persian Gulf War, the Army figures that, by the turn of the century, they will begin looking like exhausted designs, much as the M60-series tanks became a technological dead end in the 1970s. The Army's ASM. (armored systems modernization) program partly rests on the idea that, in order to maintain the advantage demonstrated in Kuwait and Iraq, the service must begin now. Even as it is, first units will not be fully equipped with the ASM vehicles until late in the first decade of the new century and, as Maj. Gen. Peter M. McVey, the ASM program executive officer, says in the accompanying interview, "That is a long time to be sitting on the technology we currently have in 1991."

When ASM's predecessor programs got under way in the mid-1980s, they were looking at the problem through the other end of the telescope—American armor/antiarmor technology was thought to be behind that of the long-time cold war adversary, the Soviet Union, with a widening gap in pros-pect. That was the conclusion of the De-fense Science Board's 1985 summer study, the first to suggest that the Army might be able to catch up, get ahead and stay ahead by developing a family of heavy vehicles, using common components and based on a new main battle tank (MBT) chassis.

The resulting effort, the two-year armored family of vehicles (AFV) task force study, posited as many as 30 different armored vehicles for 24 missions, based on 11 variants of heavy and medium common chassis.

"The original approach was to develop these systems concurrently and then field them by battalion sets," said Walter P. Wynbelt, technical director for future systems in the ASM program executive office. "That meant that each vehicle system had to be in development at the same time, into production at the same time. You can imagine the 'bow-wave' that would create—it was totally un-affordable." Indeed, the AFV's initial 1987 cost effectiveness evaluation estimated that the cost of developing and procuring a 34,000-vehicle fleet and supporting and operating it for a 20-year life cycle would be nearly $276 billion.

By that time, the trend was becoming evident that will reduce annual Army procurement budgets to less than 40 percent of their mid-1980s peak by fiscal 1995, so the Army rank ordered the AFV list and came up with six vehicles—four on a common heavy chassis and two on medium chassis —as an affordable program that would take maximum advantage of new technologies and also address long-neglected critical needs. "ASM was on a very short time line when it originally started," said Mr. Wynbelt of the period when the program was moving from AFV through a phase known as heavy forces modernization (HFM). "The Soviets were going to be fielding a new tank [FST-III —future Soviet tank III] before the end of the decade. The Abrams, even in its M1A2 configuration, would not be a match for that system, so there was an urgent need for a new tank. But then the Berlin Wall came down and, suddenly, where was the urgency?"

The diesel-based candidate for the ASM common heavy-protection level chassis power pack is the XAP-1000, with the lead contractor, Cummins Engine Co., Inc., providing the V-12 engine, and the transmission from General Motors' Allison Transmission Division.

"The Soviet schedule started slipping," Mr. Wynbelt continued, "our schedule started slipping accordingly, and the urgency was suddenly gone. At one time, people at Department of the Army were willing to accept high risks, going from a test-bed approach right into full-scale development, bypassing the prototyping phase. Now came the school of thought, particularly within OSD [Office of the Secretary of Defense] that maybe we ought to do a little bit less risk—'the schedule is not quite as critical anymore, the threat has reduced, let's do it a little bit slower.' "

Consequently, when the ASM's proposed Block III main battle tank program went up for its Milestone I review last summer, the Defense Acquisition Board added a requirement for separate prototyping, which would mate the chassis with the turret, armament and electronics before moving into full-scale development. "OSD added the prototype phase to reduce risk," Mr. Wynbelt said. "That added cost, and it stretched the program by three years, but there wasn't a whole lot of concern." At some point, however, the Army's fighting vehicles are going to lose their demonstrated edge, while other ASM vehicles will allow the Army to catch up in areas where it has long been deficient, such as artillery and frontline combat engineer equipment. The Soviet armored force will remain a bench mark because it retains the largest related industrial base in the world and will likely continue to be the major source of armored equipment for militarily ambitious nations in the Third World.

"The other guys keep insisting on improving their armor," Mr. Wynbelt said, "which means you have to have bigger bullets, bigger guns, or at least more capable bullets. Our Abrams did extremely well in Iraq, but you have to keep in mind that it was going against an export version of the T-72. The T-72 has already been replaced in the Soviet Union by the T-80; several modifications have already occurred on the T-80.”

If ASM is continually delayed, the Army sees a number of battlefield deficiencies developing with the current generation of armored systems:

• Inability to defeat future Soviet armor improvements with direct-fire weapons.

• Inadequate artillery range and rate of fire.

• Inadequate target acquisition and fire control.

• Vehicles with varying and incompatible mobility, hampering combined arms operations.

• Product improvements to the M1-series Abrams tanks have pushed weight beyond levels that would have been unacceptable only a few years ago.

• Inadequate armor protection against future Soviet antiarmor munitions.

• Engineering equipment does not exist that can breach complex defensive obstacles in stride, a key requirement for the fluid battlefield of the evolving AirLand Battle-Future doctrine.

• A current and growing lack of commonality in system components, repair parts and maintenance tools.

• Increased requirements for items consumed in combat, mainly fuel and ammunition.

• Inadequate repair and resupply capabilities.

ASM has retained the AFV program's concept of commonality among major vehicle components and extended the idea of modularity, in which the profiles of individual vehicles may be altered according to operational circumstances and their components exchanged in service.

The Army expects that commonality will result in development and procurement savings through shared testing of prototypes and the flexibility and efficiency of a single production line operating at economic rates. The biggest savings, however, are expected in the life-cycle costs of ownership and operation—in the training of crews and mechanics, in the simplified repair of battlefield damage and in the reduction of spare and repair parts stockage requirements at all levels. Of the six current vehicles that the ASM designs would replace, there is commonality only between the M109-series 155-mm self-propelled howitzers and the accompanying M992 field artillery ammunition support vehicle (FAASV), which share the same chassis.

That means five different engines, five different transmissions, five different suspensions, six different tracks and six discrete electronics systems. In the ASM generation, the vehicle electronics (vetronics) architecture would be common to all vehicles and power packs and running gear would amount to two basic designs—the common heavy-protection chassis (CHC) and the common medium-protection chassis (CMC).

Modular armor—which could be built up or torn down to different levels—will also be a feature of the CHC vehicles, and all vehicles will have the same collective protection against NBC (nuclear-chemical-biological) threats. "There are constraints in how common the vehicles have to be," said Mr. Wynbelt. "You could have a common chassis where one vehicle could have the engine in the rear, the other have it front, as long as it's the same engine, the same transmission, same road wheels and track. The road wheel spacing may be different; even the number of road wheels may be different."

"All four [CHC] chassis must be producible on one production line, using flexible tooling," Mr. Wynbelt said. "That means they can't be too different. The major dif-ference will probably be in the hull weld-iing, but the hull structure is not a replaceable item; as long as the designs are close enough, where you can fabricate them on one production line, that is all that mat-ters. The important thing is that the items which require replacement in the vehicles, that those be common."

In each of the CHC designs, the Army has specified certain performance requirements and characteristics, which are discussed below, in alphabetical order:

Advanced Field Artillery System (AFAS). This advanced self-propelled gun would begin appearing in the field in 2004, with an initial procurement objective of 824 to replace M109s—which, by that time, will have been converted to the M109A6 HIP (howitzer improvement program) configuration—in force package one, that is, forward-deployed units and U.S.-based contingency units.

AFAS has been a bone of contention be-tween the Army and interested parties in Congress who believe that the service has too long neglected its heavy-force artillery weapons, the basic M109 chassis having entered service in the early 1960s, with longer range ordnance added in the 1970s. Some critics have argued that AFAS should be placed on a faster track and removed from the CHC effort, believing that the service's desire for an optimum successor to the Abrams —where time is less critical—is inhibiting artillery modernization.

The Army naturally does not want to lose the advantages of commonality and the economics of production scale that AFAS represents in the CHC program (nearly 14 percent of the initial procurement objective), but counters that the advanced technologies planned for the new artillery piece will not permit faster development. The service has, however, advanced the schedule for AFAS so that it would follow the Block III tank into service by just three months. moving ahead of the combat mobility vehicle (CMV).

AFAS is facing a major decision later this year on whether the gun will use liquid propellant, which could provide continuous zoning, or a system known as uni-charge, in which discrete zoning is achieved by incremental blocks of solid propellant. Army requirements for AFAS include increased range up to 40 kilometers, a 300 percent increase in the rate of fire over the M109A6 and the ability to fire a time-on-target salvo of four rounds, in which the shells are launched at different elevations to arrive at the target simultaneously.

Armor would be improved over the current generation with particular attention to protection against top-attack munitions of the type that would be employed in enemy counterbattery fire. The crew spaces, fuel and ammunition will be compartmented from one another. Also, said Mr. Wynbelt, "it will have an autonomous capability and will not be dependent on a fire-control center somewhere else—it can pick its own targets."

"AFAS will have automated ammunition handling and must be able to fire at least 12 rounds a minute for five minutes; it is required to carry 60 rounds, so it can fire a total complement of ammunition in five minutes—that's a lot of rounds thrown out."

With the same basic chassis as the Block III tank, AFAS will have comparable mobility, with 300 percent more horsepower at the sprocket than the M109 series. Other design objectives include 30 percent less fuel consumption over a battlefield day, doubled track life and a two-thirds reduction in the time needed to replenish ammunition.

• Block III Main Battle Tank (MBT). The Army is looking for a 50 percent increase in kinetic-energy armor penetration in its future main battle tank, which would extend killing range by a third, plus a 75 percent greater rate of fire.

The ASM program executive office is confident this can be achieved with the advanced tank cannon (ATAC) system being developed by the Armament Research and Development Center, Picatinny Arsenal, N.J. ATAC combines the XM91 automatic loader with the XM291 high-velocity cannon, a 140-mm weapon with a tube length of about 61 calibers (around 28 feet, or 56 percent longer than the 46-caliber tube of the M256 120-mm cannon of the M1A1 and -A2 Abrams).

"If, at some time in the development cycle, ETC [electrothermal cannon] suddenly looks very good—if there is a breakthrough," said Mr. Wynbelt, "we could then utilize that technology. We are not ruling that out, even possible as a future improvement, but right now our studies show that it will not be there for our fielding dates," Radical breakthroughs are required in power generation, storage and conditioning, he added, before electrothermal or electromagnetic guns move out of the laboratory.

By reducing the crew from four to three (eliminating the M1's loader position); shrinking the size of the power pack by 40 percent; using external in-arm hydropneumatic suspension units (and thus saving about 17 cubic feet of space now occupied by torsion bars); and using modular armor with advanced composite materials, the ASM teams intend to significantly improve armor protection while cutting combat-loaded weight to five to ten tons below the M1A2, or a range of 57 to 62 tons.

The Block III MBT would have at least 35 percent greater protection from the frontal aspect and 48 percent more side protection. "We are going to have a type of modular armor," Mr. Wynbelt said. 'The M1 Armor is extremely good, very effective; however, it is difficult to implement change, because you are confined. What we are going to do is design a vehicle with an armored wall, and then you hang boxes of armor on there, which allows you to upgrade as armor technology improves—you either get your weight down or provide more capability. In the past, every vehicle has had to grow in armor protection because the threat grows; this allows you to do that with minimum impact on the vehicle."

The ASM program executive office has told the CHC developers to allow for a 50 percent growth potential in armor effectiveness, Mr. Wynbelt said. "In other words, you have to design the vehicle to accommodate a heavier weight sometime in the future; if the armor has to grow and the technology is not there to offset the protection growth with weight reduction, we still have to be able to upgrade."

The modular arrangement of the armor would permit some of it to be removed to facilitate air transport. "Or you could take it off," Mr. Wynbelt said, "if you go into, say, a low-intensity environment, where your biggest threat is not tank guns, but RPG [rocket-propelled grenade]-type weapons; you could put on the suite of armor that is optimized against that type of threat, and also allow you to lose several tons of weight. So it gives you tremendous flexibility."

In survivability, there will also be a major effort to reduce visual, acoustic, magnetic, thermal and radar signatures, as well as a countermeasures suite of sensors, jammers and active defenses to foil guided munitions—the VIDS or vehicle integrated defense system. "You can no longer keep out every threat with passive armor alone, or even with reactive armor," said Mr. Wynbelt. "So we are looking more and more at countermeasures, where we use armor to defeat the dumb rounds and tank-fired projectiles—the ones that don't think—and countermeasures to offset the smart weapons and those that are guided to the target."

"Just as an example, if suddenly you have a warning you are being lased, then you can take action to mitigate the threat—flip the turret around and fire a round, or pop smoke and hide behind that. Those are the kinds of things we are looking at—automatic response or human-in-the-loop."

The mobility of the Block III and the other CHC vehicles is to equal or better the Abrams but do it with 50 percent less fuel consumption and a power pack 40 per-cent smaller. The technological basis for the desired level of performance is the Army Tank-Automotive Command's eight-year advanced integrated propulsion system (AIPS) program, whose second phase concluded last year with full-power demonstrations of two 1,500-horsepower power packs—a diesel-based design from Cummins Engine Co., Inc., with Allison Transmission Division of General Motors providing the transmission; and the other, a gas turbine from Textron Lycoming (the makers of the Abrams tank's AGT-1500 turbine) with the transmission designer, General Electrics Ordnance Systems Division, as the prime contractor.

Each is composed of the engine, transmission, cooling system, air-handling system and final drive, all integrated into a compact package. The Cummins/Allison XAP-1000 is based on the advanced Cummins XAV-28 V-12 diesel, a low-heat rejection engine, which while not purely adiabatic, uses only oil coolant and has no water in the cooling system at all; it uses the energy of the higher temperature exhaust gasses to run an auxiliary power unit (APU). The General Electric/Textron Lycoming LV100 AIPS features self-cleaning inlet air filters, greatly reduced fuel consumption over the AGT-1500 and claims not to require a separate APU to power the vehicle's electrical system.

Both AIPS designs "have met the requirements," Mr. Wynbelt said, "and you can no longer say the turbine is a gas hog, because we have a high-technology turbine here that does essentially what a diesel can do." As for APUs, he added, "We put in a requirement for electrical loads, and it is then up to the contractor to decide whether he can handle that with his main engine or if he needs an APU."

The Cummins AIPS has been chosen to power the CHC design by Armored Vehicle Technology Associates (a consortium of General Dynamics Land Systems Division and FMC Corporation's Ground Systems Division), while the second CHC developer under contract, Teledyne Continental Motors, selected the General Electric unit.

For its CHC bid, the General Motors Military Vehicle Operation proposed the 1,475-horsepower MTU 883 V-12 diesel by Germany's Motoren und Turbinen Union (MTU) Friedrichshafen, coupled to a transmission by Zahnräderfabrik Renk A.G. The GM bid was rejected by the Army last December, but that decision is under formal protest, with the General Accounting Office expected to rule no later than next month. GM has a 25-year licensing agreement, signed in 1985, to market the MTU 883 for heavy military vehicles. At 79 inches long with the transmission installed, the engine is unusually compact, partly achieved by engineering the exhaust manifolds to fit within the space between the cylinder banks.

CHC suspension is likely to be based on hydropneumatic units, mounted on the outside of the hull.

"We are running some test-beds now," Mr. Wynbelt said, "loaded up to 70 tons to allow growth potential. There are at least two different systems being marketed in this country today, and there are some overseas as well. It is within the state of the art of technology; not only does it buy you internal space [compared to torsion bars], you can also lose over 1,000 pounds, easily."

As for an active suspension—in which electronic rate and angle sensors smooth out the action—Mr. Wynbelt said, "We are still not quite there yet, where you can sense the terrain ahead of you. That is in the technology base, but I don't think we will see it on this one." The suspension will include lock-out features for the AFAS and the CMV, automatic track tensioning and perhaps variable height, although this is an optional requirement.

Far from being determined at this point is the basic configuration of the Block III— a conventional turret, or an overhead gun, either pillar mounted or traversing with a vestigial low-profile turret. The latter options would greatly reduce the tank's profile, save a lot of weight and eliminate the mechanically, electrically and ballistically troublesome hull-turret junction; they would also place the crew's vantage point at the hull roof, leaving them entirely dependent on sensors and image-transfer devices for observation and sighting from the level of the gun.

One thing about the Block III layout seems almost inescapable: the power pack will probably have to be in the front of the vehicle if the long-barreled XM291 140-mm gun is to be the main armament. The gun muzzle cannot be extended too far beyond the front of the hull before it strikes the ground—even at maximum elevation—when the tank is operating at the maximum angle of attack permitted by the suspension geometry; obviously, tanks cannot approach combat with their guns to the rear (the Iraqi ruse at Khafji in January notwithstanding).

"The external dimensions are pretty much controlled by highway transportability," Mr. Wynbelt said, "which means you cannot go much wider than 144 inches [the hull width of the M1]."

The ideal steering ratio—the relationship between the length of the track on the ground and the side-to-side width of the tracks—is probably somewhere between 1.8:1 and 1.2:1. (The M1's ratio is about 1.33:1.) Longer vehicles become very difficult to steer, while those with a near-square planform lack directional stability. Even if the Block Ill's steering ratio were fixed at the upper end of the desirable range, and the length of the hull scaled accordingly, there would be only about 15 feet at most between the XM291's breech and the rear of the hull. Into that space (the M1's turret is well over 20 feet long) must fit the gun mount, an adequate supply of compart-mented ammunition, the autoloader and— depending on the resolution of the turreted/ turretless question—crew stations and access to all of these; it doesn't seem as if there will be room for the engine compartment, even at the reduced AIPS volume.

Ironically, many of the Block III tank features—automatic loader, advanced diesel engine (possibly), hydropneumatic suspension with (possibly) variable geometry— were present in the failed MBT-70/XM803 tank development of the late 1960s; they proved technologically immature then and, for the sake of simplicity, were eliminated from the "austere" successor M1 series, whose main innovation was advanced compound armor and the gas turbine engine (selected over a competing diesel prototype)

--------------

A Chip Off the Old Block III

In the mid-1980s, it was thought that the next discrete generation of main battle tanks might retain the Ml-series Abrams chassis while introducing new and differently arranged components, such as main armament, fire control, power pack and electronics. This possibility was referred to as Block III, or the third generation of preplanned Abrams product improvements, to be developed and introduced on the production line en bloc. Block 1 improvements resulted in the Ml Al version of the tank, while Block II became the M1A2, whose prototypes are now being tested.

Block III would have produced an M1A3, but this was not to be, as the decision was made to develop a completely new design. The name, however, has stuck. ASM-Future program officials concede that the nomenclature once created considerable confusion, not only in the Army at large, but even within the program office; they say the name will probably be changed at some point in the future, but for the moment, they are comfortable with it.

--------------

The Army's initial procurement objective for the Block III tank (force package one) is 1,946 vehicles, to begin reaching the field in 2004.

• Combat Mobility Vehicle (CMV). The CMV, which would begin appearing in the field in 2005, will provide the armored force a capability it has never had—the beaching of minefields and defensive obstacles at high speed. The initial procurement quantity of 258 vehicles would at least provide a start on replacing the elderly M728 combat engineer vehicle (CEV), based on the M60 chassis, which was type classified in 1963, began production in 1965 and entered the Army inventory in 1968.

The M728 is equipped with a 165-mm demolition gun, a lifting boom and winch and a scraper plow but is actually intended for slow-speed heavy engineering tasks of a quite different nature from those of the CMV, whose principal weapons will be an electronically controlled mine plow and a power-driven telescoping grappling and excavating arm with a bucket on the end.

The M728, Mr. Wynbelt explained, "cannot maintain pace with the M1, it is inadequately armored, and against complex ob-stacles, such as antitank ditches and dragon;s teeth, we can't do a whole lot." In AirLand Battle-Future, he said, "you have to quickly combine your forces at the critical point in the enemy lines, and if there are any obstacles, you have to have your obstacle-clearing capability with you—it must move as fast as you are moving. More than likely, the obstacles will be covered by fire, so the system has to be heavily armored. The emphasis is on time—you have to do it quickly, you have to have it right there."

The arm and bucket can clear obstacles by "grabbing them and throwing them out of the way, whether they be logs or abatis, or concrete obstacles," Mr. Wynbelt added, "If you have a ditch with a berm on the other side—which is a very difficult obstacle for a tank to cross—with the bucket and arm, you could reach across and just tear down that wall and fill the ditch. You can't do that with anything we have now."

The CMV's mine-clearing plow will be automatically controlled, Mr. Wynbelt said, "so that no matter what the attitude of the vehicle, it will keep the plow at a constant depth." Otherwise, "as the vehicle pitches, if you're not careful, the blade lifts clear and if there is a mine buried there, you lose your suspension, if not worse."

Both the bucket arm and the constant depth mine plow were extensively tested on the experimental counterobstacle vehicle of the mid-1980s, built on an M88A1 armored recovery vehicle chassis. Both tools will be blast resistant. The CMV is expected to provide a 175 percent increase in the pace of mine-clearing operations, when com-pared to the current force, which includes tank-mounted mine plows.

The CMV will carry only two crew members, compared to three in the M728, and will be about 13 percent lighter, at a combat weight of around 52 tons, yet the CMV will have 280 percent better frontal protection and side protection beefed up by 150 percent in terms of overall effectiveness. With a 1,500-horsepower engine, the CMV will be about two-thirds more powerful than the M728 but should use about 45 percent less fuel over a battlefield day.

• Future Infantry Fighting Vehicle (FIFV)

The salient feature of the FIFV is that it will have the same armor protection as the Block III tank, thus ensuring that its pioneer infantrymen can go anywhere the tank goes. This is the kind of mechanized infantry vehicle the Army proposed in the early 1970s, before the Bradley's predecessor, the XM723 was developed, but could not sell to the Defense Department or Congress—it was deemed as heavy, complex and expensive as a tank and thus incapable of the required proliferation on the battlefield (roughly two infantry vehicles for every three tanks). All parties to this long-running debate, however, appear to have learned the lesson of the the Bradley and have accepted the necessity for an infantry vehicle that can advance in the face of the heaviest fire, without the need for compensating tactics. "With this vehicle, the infantry will be able to remain on board until they overrun target," Mr. Wynbelt said, "and then dis-embark, so that they will not have to fight toward an objective."

Compared to the Bradley, the FIFV will have more than 11 times the effective effective frontal protection and 200 percent greater protection from flank at-tacks, plus all of the VIDS passive and ac~ tive countermeasures of the Block III tank.

The FIFV will have missile armament with a degree of antiarmor capability as yet undetermined. The Army is looking for a 150 percent increase in effectiveness—including twice the armor penetration—from an automatic main gun in the 35-mm to 60-mm caliber range. There would also be a centrally controlled area suppression weapon system to deal with enemy infantry in the vincinity of the vehicle; this is expected to be 60 percent more effective than the individual port-firing weapons now operated by infantrymen mounted in the M2 Bradley.

With power and fuel capacity comparable to the main battle tank, the FIFV is expected to have 70 percent greater cruising range than the Bradley and cross-country speeds more than one-third higher. Vetronics and advanced fire control will allow the vehicle crew to be reduced from three men to two, but the size of the dismounted element is not yet certain.

"When we went from the M113 to the Bradley," Mr. Wynbelt said, "there was great controversy as to how big the squad should be. [It was fixed at nine, three of these being vehicle crew members. ] That controversy is happening all over again."

The first FIFV unit would begin equip-ping in the year 2005, and the initial pro-curement objective for force package one is 1,321 vehicles.

The remaining two ASM vehicles—the LOSAT (line-of-sight antitank) vehicle and the FARV-A (future armored rearm vehicle-artillery)—are based on the common medium-protection level chassis. The CMC will, in effect, be an improved version of the Bradley chassis, with the LOSAT built on the M2 chassis and the FARV-A using the Bradley-derived chassis of the multiple-launch rocket system (MLRS).

"The budget did not allow development of a new chassis for the medium systems," Mr. Wynbelt said. "The Bradley components are close to state of the art, they have been improved, the engine has growth potential, and we felt that there is a lot of utility in that chassis."

The required characteristics of the CMC vehicles are discussed below:

• LOSAT. This vehicle is urgently needed to replace the M901 ITV (improved TOW vehicle), and the Army wants to buy 907 of them for force packages one and two (the latter including reinforcing forces). LOSAT is leading all of the ASM vehicles and should begin appearing in the field in 1998.

LOSAT's armament is a laser-guided kinetic-energy missile (KEM) whose impact velocities approximate that of modern tank cannon, directed by a multiple target acquisition system. The KEM system and fire control are being developed by the Missiles Division of LTV Corporation's Missiles and Electronics Group, under a sole-source contract awarded last month by the Army Missile Command.

LOSAT will upgrade mobility and protection from M113 to Bradley levels, and the KEM system will range about 25 percent beyond the wire-guided TOW missile to around 5,000 meters. LOSAT will carry twice the number of missiles—24 as compared to 12 in the M901.

"ITV is a very capable system," Mr. Wynbelt said, "however, it is thinly armored, and it has M113 mobility, which will not maintain pace with a Bradley force or an Ml force, let alone the ASM force. The major drawback of the ITV is that it has a chemical-energy warhead type of weapon, the TOW II, which can be countered by reactive armor. It is also very slow—it requires up to 20 seconds or more to track the target. During that time, a lot can happen—the system can be knocked out, the enemy can toss up some kind of smoke you can't see through." LOSAT, he added, "will get you the same distance and farther in a matter of seconds—two or three seconds."

"With the ITV," Mr. Wynbelt continued, "you can only handle one target at a time; this can handle many more than that." Until recently, the guidance system had problems picking up the hyper-velocity missiles in tests. "The system had very great difficulty in tracking many targets," Mr. Wynbelt said, "but we made some changes, and it is doing extremely well now [eight out of nine successes in firings late last year]." LOSAT will be up for a Milestone II review late this year or early in 1992.

• FARV-A. This vehicle will be fielded in concert with AFAS in the year 2004, on the basis of one for each of the new self-propelled guns, or 824 in all for force package one. Indeed, FARV-A is essential to realize the dramatically greater rates of fire of AFAS.

FARV-A will carry out automated ammunition resupply through an armored, quick-disconnect port that protects the entire operation from artillery and small-caliber fire and NBC threats. The vehicle will have mobility comparable to AFAS, with cross-country speeds about 17 percent better than the M992 FAASV that resupplies the M109-series howitzers; cruising range will also be increased by about one-third.

Where FARV-A really differs in kind from current practice, however, is in its automated ammunition management system, based on information-bearing chips attached to each round. The chips will be automatically read when ammunition is hoisted aboard by the remotely operated materials handling equipment.

When ammunition is passed to the gun by a conveyor system, Mr. Wynbelt said, "the system will be able to read each chip and tell the AFAS what kind of round it is, the exact weight of the round, the ammo lot that it was produced in, and so forth. That all feeds into the AFAS computer, which takes that into consideration when it picks the round and fires it."

The final layout of FARV-A will depend on whether a unicharge propellant system is chosen for AFAS, or liquid propellant; if the latter, FARV-A would be fitted with conformal tanks to resupply propellant.

The number of ASM vehicles in the initial procurement objectives now being contemplated totals 6,080. What is it going to cost to develop, produce and field them? The program is too heavily weighted with imponderables at this point for there to be any definitive or even approximately good answer. Design-to-unit cost goals will be established for each vehicle, but this cannot be done "until you know what technologies you are going to be using," Mr. Wyn-belt said, which would normally be around the Milestone II review following the prototype fabrication and testing phase.

The program has produced some estimated unit costs, but Mr. Wynbelt cautioned that "they are somewhat soft." The estimated total cost is about $63 billion, which includes the cost of research, development, production, initial spare parts and fielding. Unit costs would thus be around $10 million on the same basis (which is not exactly the way the Army figures unit costs).

In the late 1960s and early 1970s, some members of Congress were incredulous that so prosaic a thing as a tank could cost as much as a million dollars. Before the outside critics begin calling for a prompt shut down of the "unaffordable" program, it is necessary to understand that about 60 per cent of the added cost over the current generation (around $2.4 million for an M1A1 and—because of the small numbers—perhaps twice that for an M1A2) is accounted for by inflation, which will accumulate to 50 percent or more over today's prices— at the very least—by the time the ASM vehicles are in production.

The other 40 percent of the increase is in capabilities, many of which have never been available to the Army's heavy force. Speaking of the Army's opponents in the Persian Gulf War and their equipment, Mr. Wynbelt said, "We could have had technology down to the level of theirs, and we could have saved a lot of money over the past ten or 20 years. Did we need smart weapons to defeat Iraq? No. Did we save a tremendous number of lives by having them? Absolutely."

Asked if the Army could afford to stand still for a time in armored vehicle technology, he said, "Well, you can—but it is not very wise."