Hi,

I don't see why a variable incidence wing couldn't be combined with high lift devices (slats, flaps) in order to further improve the lift coefficient for a given AoA. It definitely looks like F8U has flaps and slats.

I'd say we're largely in agreement

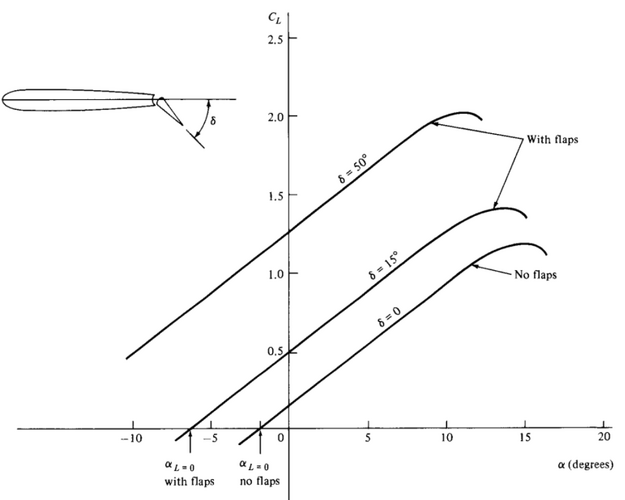

Thanks for posting the flap lift coefficient diagram, it is great for illustrating the concept ... assume we desire to land at Cl = 1.25 at a 0° angle to our line of reference (fuselage centreline, for example).

We can achieve this either by using 15° of flaps, which gives Cl = 1.25 at 10° angle of attack on the wing, so we need 10° of variable incidence to get our fuselage to the 0° alignment.

Or we can use 50° of flaps, which gives Cl = 1.25 at 0° angle of attack on the wing, which aligns with our centreline right away, and omit the variable incidence mechanism.

There's a sweet spot where simple flaps alone will not give the desired combination of Cl and landing attitude, and that's where a variable incidence wing might be the best solution, since the beefy structure you pointed out can be combined with simple and thus probably robust and low-maintenance flaps.

Once you desire a higher Cl, you might be forced to use complex flaps, and that's where my speculation comes into play: I suspect that once you go for complex flaps, the addition of a variable incidence mechanism is not the best solution as it's easier to tailor the complex flaps themselves to get to the desired Cl.

That's no hard law of course, just an arm-waving estimation of the trade-offs potentially considered by the aircraft designers facing this challenge during conceptual design of a new type for specific requirements.

Regards,

Henning (HoHun)