You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

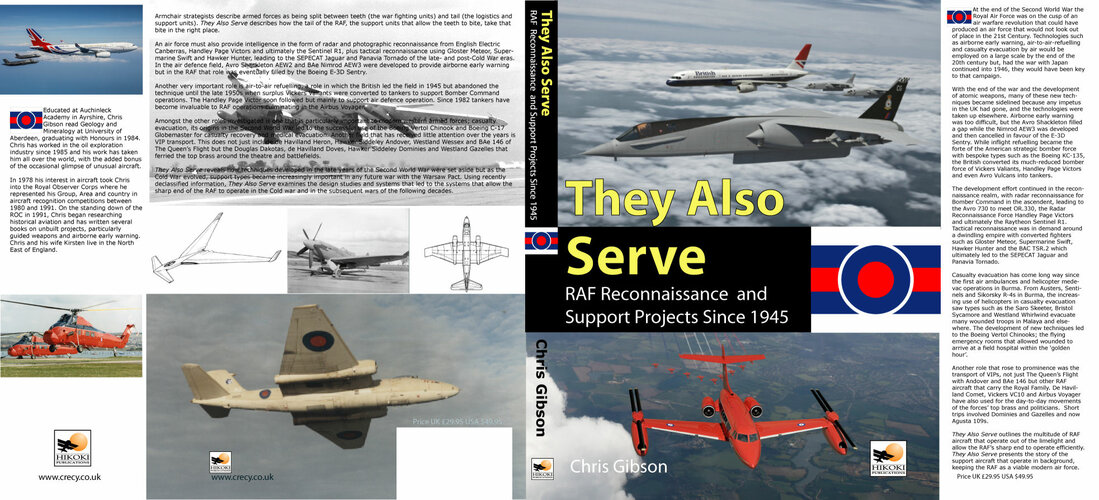

They Also Serve - RAF Reconnaissance and Support Projects Since 1945

- Thread starter boxkite

- Start date

-

- Tags

- air-sea rescue cold war cold war ii electronic warfare elint great britain nuclear battlefield post-cold war post-world war ii raf air support command raf bomber command raf germany raf search and rescue force raf strike command raf transport command royal air force royal air force marine branch sigint strategic reconnaissance world war ii

zebedee

ACCESS: Secret

HS125 with Circulation Control Rotors... I'm going to have make some space on the shelf I think...

Zeb

Zeb

- Joined

- 5 May 2007

- Messages

- 1,253

- Reaction score

- 2,307

I think it's what the kids call a 'soft launch'.

Not the kind used with ICBMs, I assume. Firing your books out of a tube with pressurised gas probably doesn't help sales.

Not the kind used with ICBMs, I assume. Firing your books out of a tube with pressurised gas probably doesn't help sales.

FighterJock

ACCESS: Top Secret

- Joined

- 29 October 2007

- Messages

- 4,942

- Reaction score

- 4,738

Same here uk 75, make it happen Chris. Would make a very nice Christmas or birthday present.

- Joined

- 6 September 2006

- Messages

- 4,596

- Reaction score

- 8,553

Cooler than using Amazon drones though.Not the kind used with ICBMs, I assume. Firing your books out of a tube with pressurised gas probably doesn't help sales.

I demand a book-delivering ICBM with multiple book scattering warheads delivering to ten postcodes at once.

- Joined

- 5 May 2007

- Messages

- 1,253

- Reaction score

- 2,307

It would knock next-day delivery out of the park. Automated warehouse-despatch-launch system for guaranteed delivery anywhere in the world in one hour!Cooler than using Amazon drones though.

I demand a book-delivering ICBM with multiple book scattering warheads delivering to ten postcodes at once.

- Joined

- 26 May 2011

- Messages

- 2,219

- Reaction score

- 3,138

Antonio noticed it a couple of weeks ago. Nice to see someone looks at my ramblings.

TAS is currently being ripped to bits by my editor and hopefully off for layout at the end of the month. I hope to

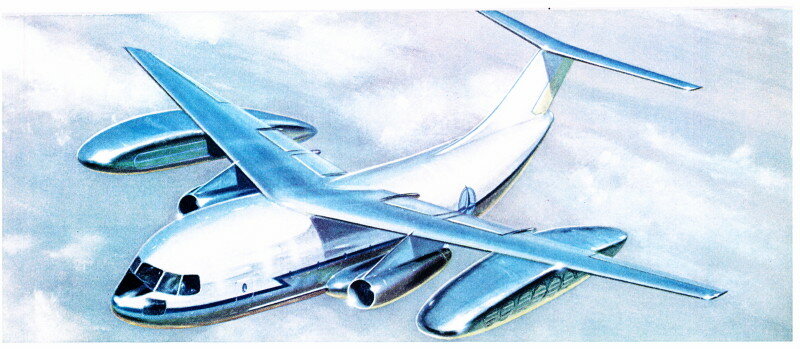

hand it over to Crecy in May. That nice Mr Yellowaster has been a great help in its writing as has TSRJoe. Citrus90 had to be coaxed into doing real aircraft, but has done a superb job of them and the unreal types. Attached is a DRAFT of what I hope will be the dustjacket. Final content to be confirmed as my editor might not like the beaten ginger stepchildren of British aviation such as balloons, airships and UAVs in Op Banner.

Hope you like it. I learned a lot.

Chris

PS, for the record, I quite like the Hair Farce One scheme.

TAS is currently being ripped to bits by my editor and hopefully off for layout at the end of the month. I hope to

hand it over to Crecy in May. That nice Mr Yellowaster has been a great help in its writing as has TSRJoe. Citrus90 had to be coaxed into doing real aircraft, but has done a superb job of them and the unreal types. Attached is a DRAFT of what I hope will be the dustjacket. Final content to be confirmed as my editor might not like the beaten ginger stepchildren of British aviation such as balloons, airships and UAVs in Op Banner.

Hope you like it. I learned a lot.

Chris

PS, for the record, I quite like the Hair Farce One scheme.

Accidental Loggie

Converte et subvertere

- Joined

- 28 May 2022

- Messages

- 3

- Reaction score

- 3

- Joined

- 27 December 2005

- Messages

- 16,888

- Reaction score

- 21,589

The great truth of UK aviation publishing: stick a TSR2 on the cover and it sells.

Accidental Loggie

Converte et subvertere

- Joined

- 28 May 2022

- Messages

- 3

- Reaction score

- 3

I also like the plan view drawing of the Canberra on the back cover with the interesting wingtips!I can't take credit for the Skyflash-armed TSR.2 as it was Citrus90's inspired work.

Chris

- Joined

- 26 May 2011

- Messages

- 2,219

- Reaction score

- 3,138

- Joined

- 27 December 2005

- Messages

- 16,888

- Reaction score

- 21,589

Looking good Chris.

- Joined

- 26 May 2011

- Messages

- 2,219

- Reaction score

- 3,138

I also mention They Also Serve and some of its content in this podcast

aviation-xtended.co.uk

aviation-xtended.co.uk

hris

Ep.201 – three authors and a publication (aviation history roundtable)

Mick Oakey, Robert Forsyth and Chris Gibson come back to the History Round Table to answer listener questions. We discuss what books do not get written, what they would love to read, their proudest…

aviation-xtended.co.uk

aviation-xtended.co.uk

hris

Siberia

ACCESS: Confidential

- Joined

- 24 August 2012

- Messages

- 109

- Reaction score

- 97

Was already going to be buying a copy but helped reinforce that.I also mention They Also Serve and some of its content in this podcast.

Interesting mentions of the plans to sink the Argentine fleet and a low-level Victor run.

- Joined

- 26 May 2011

- Messages

- 2,219

- Reaction score

- 3,138

FighterJock

ACCESS: Top Secret

- Joined

- 29 October 2007

- Messages

- 4,942

- Reaction score

- 4,738

Excellent Chris looking forward to it. Got it pre-ordered already.

- Joined

- 26 May 2011

- Messages

- 2,219

- Reaction score

- 3,138

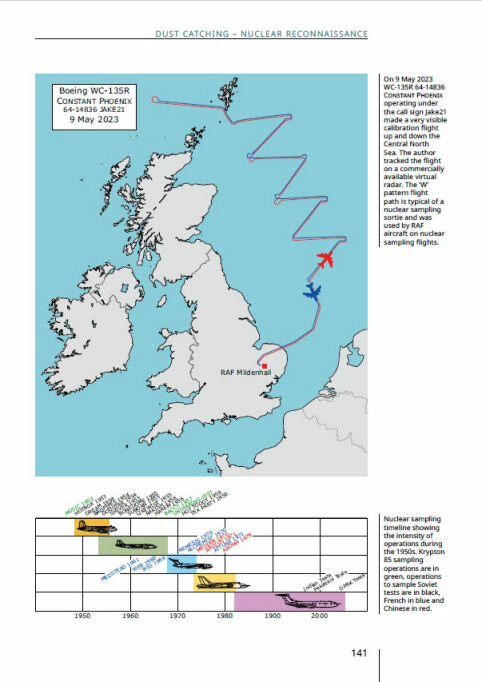

And here's an addendum for Chapter 7.

www.theguardian.com

www.theguardian.com

Chris

Starmer to end £40m helicopter contract in break from Sunak era

Former PM and ministers drew criticism for the VIP flights Labour says were ‘symbol of their government’

Chris

Alan Davies

ACCESS: Restricted

- Joined

- 9 October 2019

- Messages

- 11

- Reaction score

- 38

Crecy have confirmed that it has arrived in the warehouse and ready to ship. If you've pre-ordered, thank you, you'll see it before me as I'm away at the moment.

Hi I received my copy today. Excellent book as I expected, very detailed and well illustrated. What I wasn't expecting was how big it is compared to the others in the series, I hope my Billy bookcase can take the weight!Anyone got their paws on this yet?

When I picked the parcel up off my doorstep I thought I'd ordered two books by mistake as it was so heavy

Really great book and well worth the wait.

Looking forward to Tuesday when I have a day off work and have a proper read of it.

Pirate Pete

ACCESS: Secret

- Joined

- 25 July 2007

- Messages

- 321

- Reaction score

- 487

My copy arrived today, courtesy of Amaze-on...

Have to say it is indeed an excellent tome. have just flicked through it so far and am very much looking forward to reading it thoroughly.

Have to say it is indeed an excellent tome. have just flicked through it so far and am very much looking forward to reading it thoroughly.

Last edited:

- Joined

- 27 September 2006

- Messages

- 6,052

- Reaction score

- 6,153

My copy is in my paws. For those older members it is like a Salamander book on steroids. Each page is densely packed with info and good stuff.. Many hours of happy reading ahead.

Some extras from me:

The cameras and recce pod on the 1127RAF/Harrier GR1 were the same as those intended for P1154. I am sure I have a drawing somewhere. Will try and find.

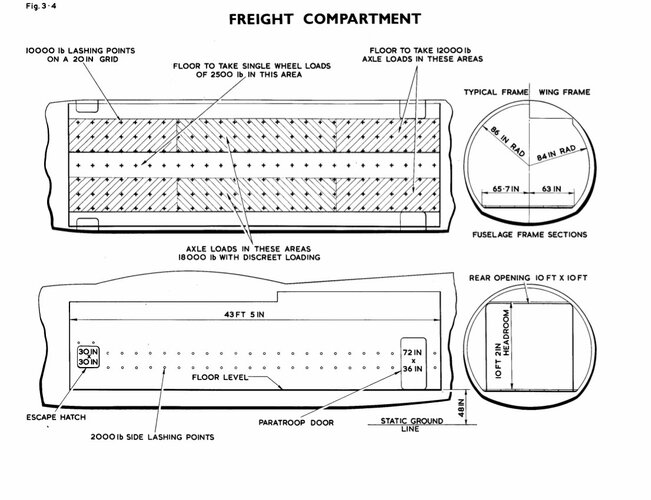

The AW681 casualty config appears in a PDF posted somewhere here. Closest I can find is the cargo config, attached below.

Although 748 Andover and a Blackburn design for a small jet lifter feature I couldnt find the DH/HS129 so here is a link and a couple of pictures.

Some extras from me:

The cameras and recce pod on the 1127RAF/Harrier GR1 were the same as those intended for P1154. I am sure I have a drawing somewhere. Will try and find.

The AW681 casualty config appears in a PDF posted somewhere here. Closest I can find is the cargo config, attached below.

Although 748 Andover and a Blackburn design for a small jet lifter feature I couldnt find the DH/HS129 so here is a link and a couple of pictures.

Attachments

Last edited:

- Joined

- 29 August 2010

- Messages

- 588

- Reaction score

- 281

I wish that someone would do an American equivalent to this book (and others like it).

ChrisHope you like it. I became quite intrigued by the Allies thinking about when the war in Europe would be done and dusted and how Tiger Force would operate.

Chris

Just how much info is in the book about Tiger Force? Always curious about its intended operations.

TIA

Ewen

- Joined

- 26 May 2011

- Messages

- 2,219

- Reaction score

- 3,138

Out in the world there isn't an awful lot published about Tiger force as in reality it didn't really exist for very long and never got stood up as a force per se. There's a bit in Kew but what I examine is how the Air Staff planned to put Lancasters and Lincolns over Tokyo through the use of in-flight refuelling and/or Habbakuks. Basing is interesting and the policies for refuelling make fascinating reading as does why use Lancasters rather than acquire B-29s (or B-32s).

As I mention above, the Allies expected the European war to be over by Christmas, freeing up Bomber Command for the Far East. Of interest is how that thinking changed post-Overlord.

Chris

As I mention above, the Allies expected the European war to be over by Christmas, freeing up Bomber Command for the Far East. Of interest is how that thinking changed post-Overlord.

Chris

- Joined

- 27 September 2006

- Messages

- 6,052

- Reaction score

- 6,153

Only trying to add some info to your excellent book.You've lost me here, not sure what you mean.

Chris

Which bits of my "extras" are confusing?

- Joined

- 22 January 2006

- Messages

- 4,101

- Reaction score

- 1,663

A big mystery because a lot more could be published about American unbuilt aircraft projects.I wish that someone would do an American equivalent to this book (and others like it).

- Joined

- 27 September 2006

- Messages

- 6,052

- Reaction score

- 6,153

Books in the UK do not get charged tax. I think they do in the EU?The P&P for EU is simply abusive. I see that the book cost at Crecy is 36 GBP (42 €) while I've payed 56€. Ordered on Sept the 8th and will be delivered between Oct the 9th and 14th.

- Joined

- 26 May 2011

- Messages

- 2,219

- Reaction score

- 3,138

The P&P for EU is simply abusive. I see that the book cost at Crecy is 36 GBP (42 €) while I've payed 56€. Ordered on Sept the 8th and will be delivered between Oct the 9th and 14th.

What I have noticed is that postage to/from Europe, US and Canada went through the roof in 2019. It has basically shut down sending books overseas as the costs are usually more than the book.

Chris

Last edited:

- Joined

- 26 May 2011

- Messages

- 2,219

- Reaction score

- 3,138

Blame m'learned friends.A big mystery because a lot more could be published about American unbuilt aircraft projects.

Chris

- Joined

- 20 January 2007

- Messages

- 923

- Reaction score

- 1,030

First comments on Serve. What were they popping when they doodled 3-fuselages...some schemes are comic-book, as impractical as those 10-engine VTOLs. UK designers 1950/60s were not expected to be able to spell Maintainability, Reliability - that was for erks, but really...

So...why did they waste their time. Did they have nothing better to do?

Well...no.

No writer has picked up this point:

UK Aero was, is, military-driven for the same reason Billy the Kid robbed banks: that's where the money is. So they employed hefty Design Offices/Experimental Depts., believed R&D to be a business end-in-itself, and resisted licences-IN, all because their prime Buyer, MoS/MoA, put Independence above Interdependence. So he was willing to accept the Military element of a DO into overhead in calculating contract prices.

In 50/60s most production contracts were priced after an early batch had been built cost-plus, so actuals were known. The Men from the Ministry then simply arrived at a learning curve that reduced unit direct labour content (man-hours) over quantity, so £X p.m.hr, x Y m.hrs., then put overhead on that number (some learning was also applied to material scrap rates). The overhead rate (X% - some 00s) on direct labour m.hr was to include that proportion of the cost of the DO that had UK military potential. That is why I babble that PV was rare-to-non-existent in UK Aero.

MoS did not argue against the existence of a DO (indeed it was a qualification to Tender), nor against its size - a matter for Owners. They tried to exclude costs irrelevant to Ministers: DO effort wholly civil. But they did not dismiss comic-book schemes, because innovation is what a DO is for. So: make-work doodles, hoarding skilled labour waiting for the next Big Thing, would be a cost-for-Owners if the scheme was manifestly civil, but (partly, even muchly) for MoS if it could be linked to something which might interest RAF Director of Operational Reqts.

So...why did they waste their time. Did they have nothing better to do?

Well...no.

No writer has picked up this point:

UK Aero was, is, military-driven for the same reason Billy the Kid robbed banks: that's where the money is. So they employed hefty Design Offices/Experimental Depts., believed R&D to be a business end-in-itself, and resisted licences-IN, all because their prime Buyer, MoS/MoA, put Independence above Interdependence. So he was willing to accept the Military element of a DO into overhead in calculating contract prices.

In 50/60s most production contracts were priced after an early batch had been built cost-plus, so actuals were known. The Men from the Ministry then simply arrived at a learning curve that reduced unit direct labour content (man-hours) over quantity, so £X p.m.hr, x Y m.hrs., then put overhead on that number (some learning was also applied to material scrap rates). The overhead rate (X% - some 00s) on direct labour m.hr was to include that proportion of the cost of the DO that had UK military potential. That is why I babble that PV was rare-to-non-existent in UK Aero.

MoS did not argue against the existence of a DO (indeed it was a qualification to Tender), nor against its size - a matter for Owners. They tried to exclude costs irrelevant to Ministers: DO effort wholly civil. But they did not dismiss comic-book schemes, because innovation is what a DO is for. So: make-work doodles, hoarding skilled labour waiting for the next Big Thing, would be a cost-for-Owners if the scheme was manifestly civil, but (partly, even muchly) for MoS if it could be linked to something which might interest RAF Director of Operational Reqts.

Last edited:

Similar threads

-

On Atlas' Shoulders: RAF Transport Aircraft Projects Since 1945

- Started by phil gollin

- Replies: 86

-

Strategic Air Command in the UK - Robert S. Hopkins III

- Started by CJGibson

- Replies: 2

-

Spyflights & Overflights : Cold War Aerial Reconnaissance

- Started by overscan (PaulMM)

- Replies: 23

-

Battle Flight: RAF Air Defence Projects and Weapons Since 1945 by Chris Gibson

- Started by overscan (PaulMM)

- Replies: 46

-