- Joined

- 25 June 2009

- Messages

- 14,534

- Reaction score

- 5,476

I have adapted the following presentation from a recent Russian document from the ROSTekhnologiy ("ROSTech") company, which describes in detail their all-new project for a family of small/medium passenger transports to be developed with the technical assistance and expertise of Austria's Diamond Aircraft Industries. I've only translated the general presentation and technical characteristics, but the original document (see attachments) contains more information, notably on the business plan.

I have adapted the following presentation from a recent Russian document from the ROSTekhnologiy ("ROSTech") company, which describes in detail their all-new project for a family of small/medium passenger transports to be developed with the technical assistance and expertise of Austria's Diamond Aircraft Industries. I've only translated the general presentation and technical characteristics, but the original document (see attachments) contains more information, notably on the business plan.Of course, like all documents of its kind, it represents a company's prospects and hopes, and the language used is therefore sometimes emphatic and hopeful, lacking the objectivity that a journalist might have had reporting on the same project, but I chose to leave it "as is."

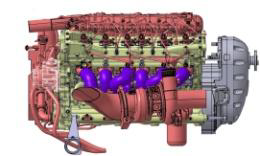

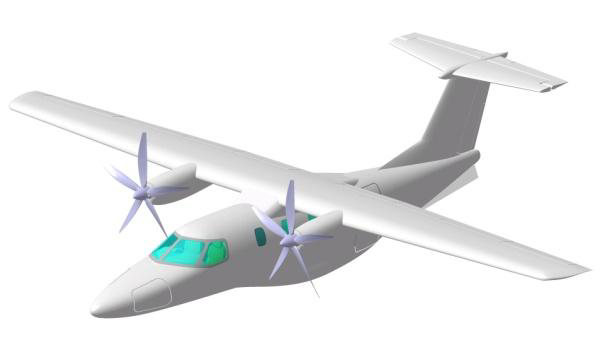

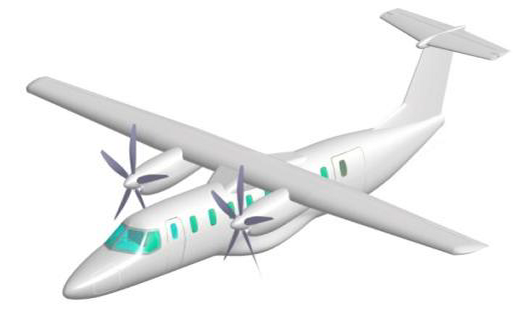

The basic project of State Corporation "Rostekhnologii" aims at eliminating problems in the segment of intraregional and local (passenger and freight) transportation, solving a wide range of problems in the interests of the economy and social sphere. The project consists in the development, mass production and mass launch of inexpensive, highly efficient, new generation multi-purpose light aircraft (initially in two categories): 9- and 19-seat capacity passenger aircraft made of composite materials, equipped with diesel engines in the 450-750 hp power range, providing fundamentally different prices, as well as better flight characteristics, economic and operational characteristics compared to all-metal or hybrid equivalents on the market.

This scheme involves comprehensive transfer in the shortest possible time to Russian Federation territory of the latest advanced technologies in terms of design, serial production, certification, approval of production by aviation authorities, and maintenance of a family of light all-composite multifunctional aircraft and diesel aircraft engines, from the world technological leader in this class: Diamond Aircraft Industries from Austria.

The goals of the program are as follows:

The main advantages would be low labor intensity, production costs and purchase prices, fundamentally better cost characteristics of operation, and high fuel efficiency.

- Strengthening the territorial integrity of the country and expanding the economic ties between the different economic entities of the Russian Federation;

- Developing socially significant passenger and cargo transportation and aviation operations in the interests of the economy and the social sphere;

- Increasing territorial labor mobility;

- Increasing transport accessibility and eliminating the gap in transport accessibility to high-quality living facilities in the country (region);

- Free movement across the territory of the Russian Federation as an element of improving the quality of life in the country;

- Overcoming the technological gap and industrial backwardness of the Russian Federation from leading aircraft manufacturing powers in the field of the latest aviation technologies;

- Creating, together with our partner Diamond Aircraft Industries, an aircraft manufacturing production of a fundamentally new type on the territory of the Russian Federation;

- Formation in the Russian Federation of a world-class technological competence center in the field of creating promising and mass-produced diesel-powered small aircraft made of composite materials, with with a passenger capacity of 1 to 20 seats including UAS and OPS derivative variants.

The products

The projected products consist of a unified family of light multifunctional aircraft (LMS in Russian) made of composite materials and diesel-powered:

- the LMS-9 nine-seater

- the LMS-19 nineteen-seater

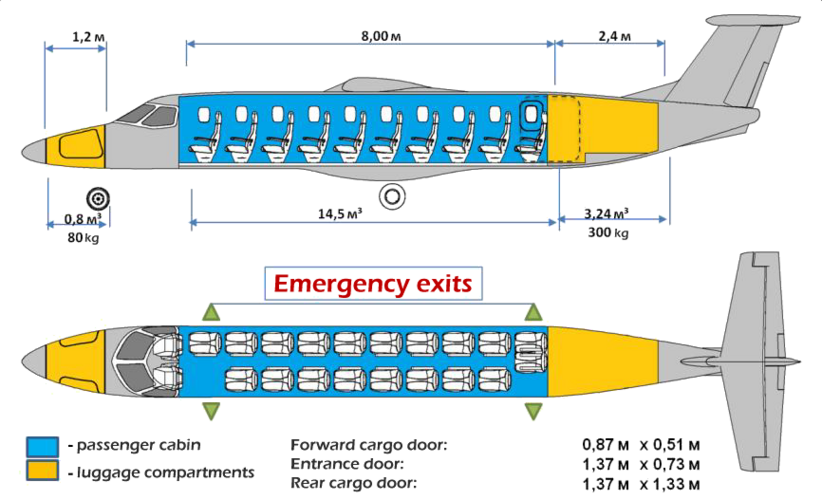

During project implementation, a low, competitive price for the aircraft will be offered in terms of labor intensity and cost of production: 120 million rubles for the 19-seat basic version with 2500 kg useful load, and 80 million rubles for the 9-seat basic version with 1400 kg useful load. The planned level of production costs provides reserves for price reduction.

The technical requirements for the aircraft include high fuel efficiency, a radical reduction in operating costs and the ability to be used in severe climatic conditions (including the Arctic and Antarctic) and in conditions where there is no ground infrastructure:

Required aircraft characteristics LMS-19 LMS-9 Flight performance characteristics Takeoff run/Takeoff distance (short takeoff) 350/540 meters 305/470 meters Landing run/Landing distance (from 15 meters) 340/675 meters 295/560 meters Aerodynamic quality at cruising speed at least 20 at least 20 Maximum cruising speed 440 kms/h 440 kms/h Life cycle (hours/flight cycles) at least 100,000 at least 100,000 Cost of 1 l/hour of operation throughout the entire life cycle not more than 10 million rubles not more than 10 million rubles Minimum fuel consumption at cruising speed not more than 140 kg per hour not more than 90 kg per hour Specific fuel consumption (maximum load) in passenger versions, g/passenger x km not more than 19.0 not more than 23.0 Mass characteristics Maximum takeoff weight 6,400 kg 3,500 kg Empty weight 3,900 kg 2,100 kg Maximum useful load 2,500 kg 1,400 kg Transport capabilities and high technology in operation Flight range with maximum passenger load (baggage 30/20 kg), km at least 1300/1600 at least 1500/2000 Maximum flight range, km more than 2500 more than 2500

Operation Operation according to technical condition throughout the entire life cycle Takeoff and landing on unpaved, snow, ice areas and water surfaces (optional) Taxiing, takeoff and landing on unpaved (soil strength 4.5 kg/cm sq.) areas (optional) Operation in all Russian conditions, in the Arctic and Antarctic Flight performance and operation at temperatures:minus 55 degrees Celsius; plus 40 degrees Celsius Flights and operations in high latitudes up to 75 degrees north Approach and landing according to the minimum of ICAO Category III (special option) Maintenance and storage of aircraft in open parking areas without the use of hangars

Low and affordable price of LMS for any operator - Low operating costs of LMS

Polymer composite airframe

- Low dead weight and reduced fuel consumption

- Significant increase in speed and range compared to turboprop counterparts

Family of diesel aircraft engines

Increase in fuel efficiency of LMS by 40-60% compared to turboprop analogues

- 450 hp

- 750 hp

Universal equipment of the LMS included in the project: floats, skis, enlarged pneumatics

- Takeoff/landing on ice, snow, water, short unpaved strips provides the possibility of operation in all regions of the Russian Federation without restrictions

- Multi-purpose nature of use

- Reduction of costs for maintenance of ground infrastructure

Highest commonality level

Commonality between the 19 and 9 models (up to 80%)

ensures a significant reduction in manufacturing costs and maintenance expenses

Use of resource-saving production technologies

The use of low-temperature molding technologies for composite structures through the "vacuum infusion"

method significantly improves quality, reduces energy consumption and the cost of the LMS aircraft.

Significant reduction in labor intensity of assembly operations

At least a tenfold reduction in the number of assembly units,

2.5-3 times reduces the labor intensity of assembly

and reduces the cost of the product several times

A set of modern design and technological solutions will make the LMS family affordable and efficient in operation. As a result of the project implementation, prerequisites will be created for the mass use of the aircraft in the segment of air transport support for local and intraregional air transportation, solving a wide range of problems in the interests of the economy and the social sphere, and other “special” problems, and a powerful impetus will be given to the development of general aviation.

Key competencies and acquired superiority developed during the project's implementation

The combination of the Diamond Aircraft Industries company's technologies and the achievements of Russian participants in the project implementation will allow to bring the characteristics of the created LMS-19/-9 to a qualitatively new level, so as to ensure superiority over the best foreign analogues, while creating the necessary conditions for converting potential demand into real transportation volumes, making them both wide-scaled and accessible.

Design:

- digital technologies for designing and calculating the strength of thin reinforced PCM shells => high weight efficiency of structures

- Engines:

- technologies for designing and manufacturing high-power diesel aircraft engines (unique competence of Diamond Aircraft Industries)

- Modern technologies for manufacturing CM structures:

- Vacuum infusion

- ability to manufacture large-sized elements => fewer assembly units => lower specific labor intensity of airframe production

- energy efficiency

- high product quality (accuracy, low porosity, surface cleanliness)

- relatively high automation of technology

- long service life of technological equipment

- Automated mechanical processing of CM

- high productivity, equipment versatility

- Technologies for assembling CM products (technologies for equally strong connection of CM elements)— know-how

Modern technologies for maintenance and repair:

- operation “as is” => without an assigned service life, multiple increase in the life cycle of the airframe

- use of an onboard diagnostic system, including monitoring the condition of the airframe structure made of composite materials (has no analogues)

- Achieved advantages:

- Superiority of LMS-19-9 over its analogues in terms of purchase price, operating economy, and service life

- Availability of aircraft for consumers due to price reduction due to the relatively low cost of serial production

- Possibility of scaling production and organizing mass serial production of any aircraft for any customer

The use of new technologies and composite structural materials in the development and production of the "Rostec" State Corporation's LMS project is a basic condition for the creation of competitive, inexpensive, highly efficient aircraft for solving any problems.

Attachments

Last edited: