Early in 1943 the Rheinmetall-Borsig airborne weapons design team led by Dr. Lambrich created a Wasserrollbombe (bombing mine-bomb) capable of attacking stationary ships protected by anti-torpedo nets.

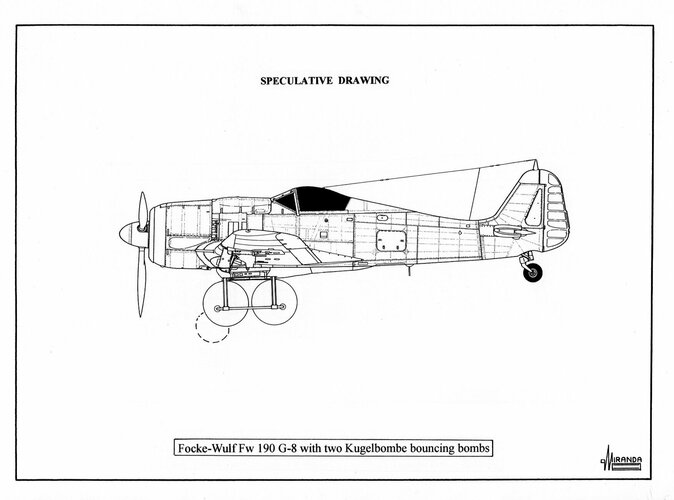

The Kugelbombe prototype was a sphere with 750-mm of diameter constructed of 12-mm thick ST-52R welded steel containing 300 kg of Hexanit explosive, one time fuse ZZ59 with 23-second delay and one hydrostatic fuse Krupp Wasserdruckzünder Type 44.

It was expected that when the 450 kg sphere was launched from an airplane flying at 700 km/h and at an altitude of 20 meters above the waves, it would behave like a skipping stone jumping a considerable distance (400 m) over a smooth surface before hit the target and sinks to 8 m for detonation.

Rough waters caused path deflections which could not be controlled.

In March 1942, during the Battle of the Bismarck Sea, B-25 aircraft managed to destroy several Japanese transports using skip bombs with a delayed-action fuse.

This strategy inspired Dr. Lambrich to design a perfected version of the Kugelbombe capable of attacking ships in the open sea.

The first step was to use a rocket motor to obtain a longer range disassembling the warhead from a Bordrakete RZ 100 air-to-air rocket to replace it with the Kugelbombe.

This rocket had 18 venturi nozzles inclined at an angle to provide spin stabilization.

Kugelbombe/RZ 100 assembly proved unsuitable because the sphere retained the rotational movement transverse to the flight path and when it hit the water it deviated to starboard, completely missing the target.

Rheinmetall engineers decided to eliminate rotation by modifying the angle of the venturis, a problem that had already been solved by the Luftwaffe when it converted the spin-stabilized artillery rocket W.Gr.28 into the fin-stabilized air-to-ground 14 WKBS Brandschrapnelrakete.

The W.Gr.28 base was replaced by another in which the venturis were drilled a zero-degrees pitch and four fins were fixed to the rocket engine.

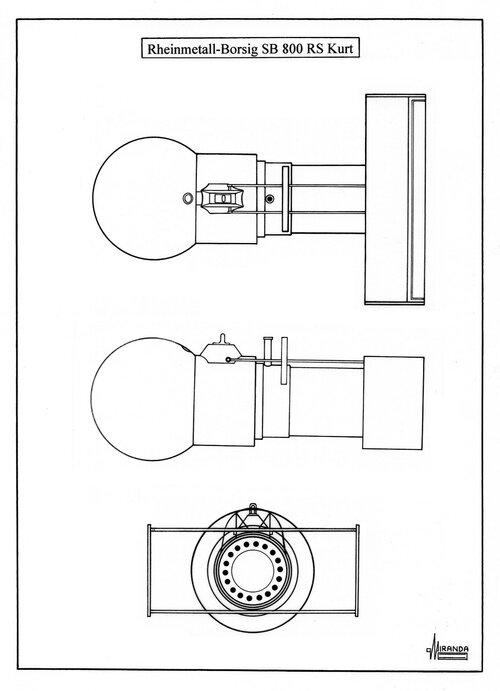

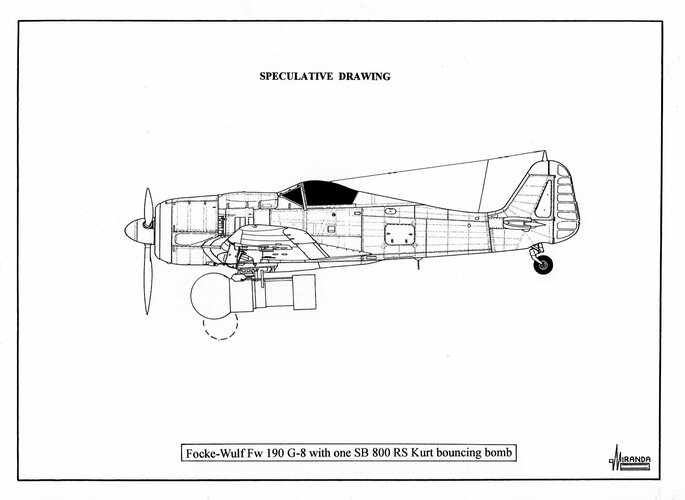

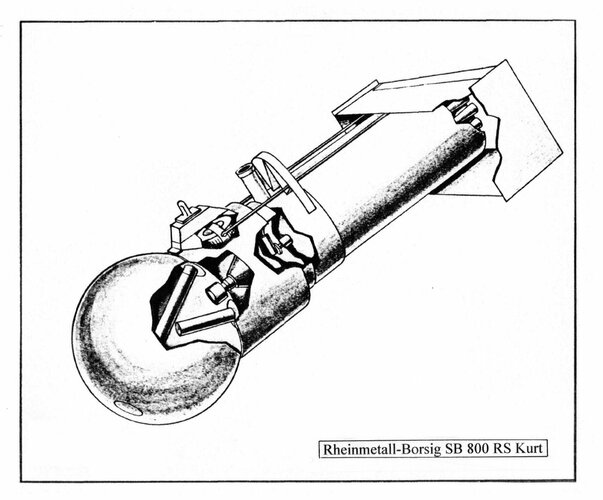

The new design, called the SB 800 RS Kurtbombe, was provided with a new 555-mm diameter cylindrical section located between the sphere and the rocket engine. This section contained a pneumatic operated gyroscope stabilizing unit (which would have been run up before the bomb was dropped) to give the missile directional stability and the explosive bolt which severs the warhead from the propulsion unit.

A box tailplane assembly was fitted around the nozzles section, to maintain the flight altitude, one elevator preset to an angle of 7-degrees was gyro-controlled.

Between autumn 1943 and summer 1944, a number of Kugelbombe and Kurt prototypes were flight tested at E-Stelle Travemünde and Waffenprüfplatz-Leba testing stations using Messerschmitt Me 410 B-5 and Focke-Wulf Fw 190 G-1 launch planes fitted with TSA2D bomb release computers.

The rocket engine ignited by an electric fuse 0.7 seconds after release and burned for 2.8 seconds and 0.5 seconds after the rocket impulse ceases, the explosive bolt severing the warhead from the after body. The rocket section drops and the sphere continues towards the target.

The flight range was 1,000-1,500 m.

The effective range released at 250 m/sec was 2,500 m, at 300 m/sec was 3,500 m and at 330 m/sec was 4,500 m.

A batch of 560 Kurt bombs were built by Rheinmetall-Borsig but the type never saw operational service.

When the OKL decided to cancel production of the heavy airborne rocket RZ 100 the Kurt project was closed down in November 1944.

Rheinmetall-Borsig SB 800 RS Kurtbombe technical data

Tailplane dimensions: 370 x 560 x 1,270 mm, overall length: 2,030 mm, max weight: 780 kg, max speed: 140 m/sec, effective range: 1,400 m, power plant: one RZ 100 rocket engine with 420-mm of diameter, 846-mm length and 85 kg of Diglycol propellant, rated at 7,000 kg peak thrust and 2.8 seconds life, warhead: 300 kg of Hexanit.

Flight tests of the Kurtbombe showed that the drag generated by the tailplane limited the speed of the Fw 190 G to less than 500 km/h and the effective range to only 1,400 m.

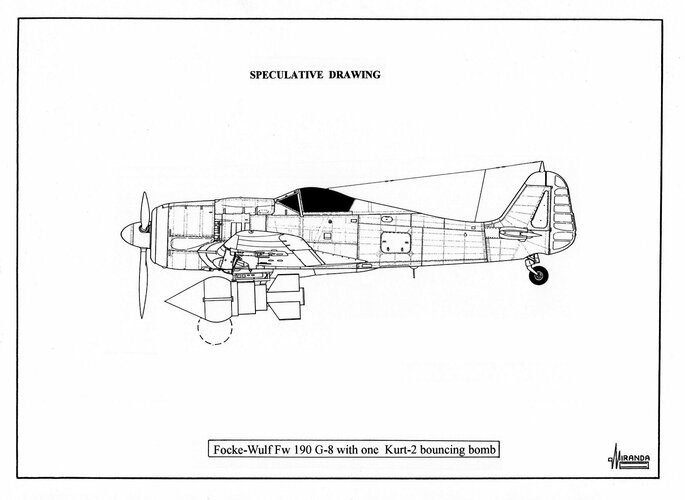

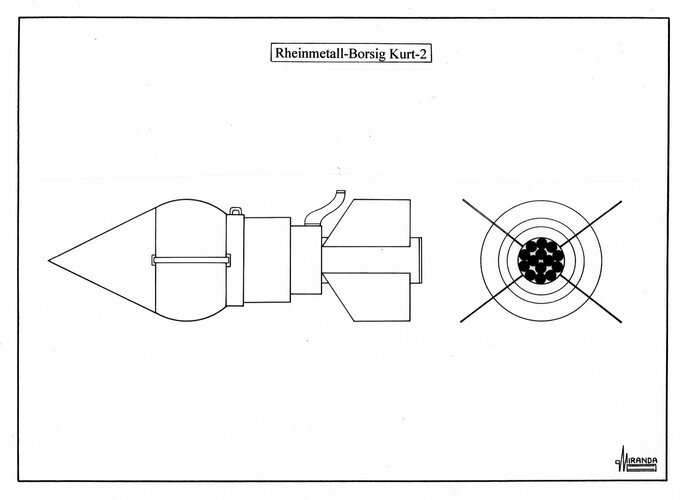

The design for the Kurt-2 prepared by the Dr. Lambrich team

The new design included significant aerodynamic modifications to reduce drag: the box tailplane assembly was replaced by four tailfins made of 7.5-mm thick plywood and a detachable nose cone was added.

A warhead separation system was also installed consisting of springs compressed to 1,000 kg that were released by means of an explosive bolt.

The RZ 100 rocket engine was replaced by a steel cylinder with a length of 600-mm and a diameter of 300-mm containing the engines of fourteen R4M air-to-air rockets each rated at 245 kg peak thrust.

The wind tunnel trials carried in the spring of 1944 showed that the Kurt-2 dropped from an Arado Ar 234 C-5 jet bomber flying at 800 km/h could reach a speed of 330 m/sec.

Rheinmetall-Borsig Kurt-2 technical data

Tailfin span: 1,315-mm, length: 2,265-mm, height: 750-mm.

The Kugelbombe prototype was a sphere with 750-mm of diameter constructed of 12-mm thick ST-52R welded steel containing 300 kg of Hexanit explosive, one time fuse ZZ59 with 23-second delay and one hydrostatic fuse Krupp Wasserdruckzünder Type 44.

It was expected that when the 450 kg sphere was launched from an airplane flying at 700 km/h and at an altitude of 20 meters above the waves, it would behave like a skipping stone jumping a considerable distance (400 m) over a smooth surface before hit the target and sinks to 8 m for detonation.

Rough waters caused path deflections which could not be controlled.

In March 1942, during the Battle of the Bismarck Sea, B-25 aircraft managed to destroy several Japanese transports using skip bombs with a delayed-action fuse.

This strategy inspired Dr. Lambrich to design a perfected version of the Kugelbombe capable of attacking ships in the open sea.

The first step was to use a rocket motor to obtain a longer range disassembling the warhead from a Bordrakete RZ 100 air-to-air rocket to replace it with the Kugelbombe.

This rocket had 18 venturi nozzles inclined at an angle to provide spin stabilization.

Kugelbombe/RZ 100 assembly proved unsuitable because the sphere retained the rotational movement transverse to the flight path and when it hit the water it deviated to starboard, completely missing the target.

Rheinmetall engineers decided to eliminate rotation by modifying the angle of the venturis, a problem that had already been solved by the Luftwaffe when it converted the spin-stabilized artillery rocket W.Gr.28 into the fin-stabilized air-to-ground 14 WKBS Brandschrapnelrakete.

The W.Gr.28 base was replaced by another in which the venturis were drilled a zero-degrees pitch and four fins were fixed to the rocket engine.

The new design, called the SB 800 RS Kurtbombe, was provided with a new 555-mm diameter cylindrical section located between the sphere and the rocket engine. This section contained a pneumatic operated gyroscope stabilizing unit (which would have been run up before the bomb was dropped) to give the missile directional stability and the explosive bolt which severs the warhead from the propulsion unit.

A box tailplane assembly was fitted around the nozzles section, to maintain the flight altitude, one elevator preset to an angle of 7-degrees was gyro-controlled.

Between autumn 1943 and summer 1944, a number of Kugelbombe and Kurt prototypes were flight tested at E-Stelle Travemünde and Waffenprüfplatz-Leba testing stations using Messerschmitt Me 410 B-5 and Focke-Wulf Fw 190 G-1 launch planes fitted with TSA2D bomb release computers.

The rocket engine ignited by an electric fuse 0.7 seconds after release and burned for 2.8 seconds and 0.5 seconds after the rocket impulse ceases, the explosive bolt severing the warhead from the after body. The rocket section drops and the sphere continues towards the target.

The flight range was 1,000-1,500 m.

The effective range released at 250 m/sec was 2,500 m, at 300 m/sec was 3,500 m and at 330 m/sec was 4,500 m.

A batch of 560 Kurt bombs were built by Rheinmetall-Borsig but the type never saw operational service.

When the OKL decided to cancel production of the heavy airborne rocket RZ 100 the Kurt project was closed down in November 1944.

Rheinmetall-Borsig SB 800 RS Kurtbombe technical data

Tailplane dimensions: 370 x 560 x 1,270 mm, overall length: 2,030 mm, max weight: 780 kg, max speed: 140 m/sec, effective range: 1,400 m, power plant: one RZ 100 rocket engine with 420-mm of diameter, 846-mm length and 85 kg of Diglycol propellant, rated at 7,000 kg peak thrust and 2.8 seconds life, warhead: 300 kg of Hexanit.

Flight tests of the Kurtbombe showed that the drag generated by the tailplane limited the speed of the Fw 190 G to less than 500 km/h and the effective range to only 1,400 m.

The design for the Kurt-2 prepared by the Dr. Lambrich team

The new design included significant aerodynamic modifications to reduce drag: the box tailplane assembly was replaced by four tailfins made of 7.5-mm thick plywood and a detachable nose cone was added.

A warhead separation system was also installed consisting of springs compressed to 1,000 kg that were released by means of an explosive bolt.

The RZ 100 rocket engine was replaced by a steel cylinder with a length of 600-mm and a diameter of 300-mm containing the engines of fourteen R4M air-to-air rockets each rated at 245 kg peak thrust.

The wind tunnel trials carried in the spring of 1944 showed that the Kurt-2 dropped from an Arado Ar 234 C-5 jet bomber flying at 800 km/h could reach a speed of 330 m/sec.

Rheinmetall-Borsig Kurt-2 technical data

Tailfin span: 1,315-mm, length: 2,265-mm, height: 750-mm.