- Joined

- 25 July 2007

- Messages

- 4,283

- Reaction score

- 4,126

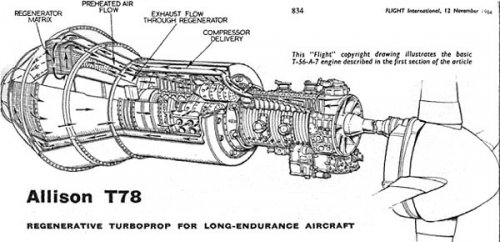

The 12 Nov 1964 edition of Flight describes the 4000shp Allison T78-A-2 regenerative turboprop.

http://www.flightglobal.com/pdfarchive/view/1964/1964%20-%202849.html

Around the same time, Curtiss-Wright were working on a similar concept and, in 1966, GE mentions regenerative turboprops in a patent application.

Some snippets and images from the Flight article follow. Does anyone know if there was later (or current) work done on regenerative turboprops?

--------------------

From Flight

"Allison Division of General Motors is currently working on a $60m US Navy contract for the design and development of a regenerative turboprop, in which a proportion of the waste heat in the exhaust is recovered through a heat exchanger. The application of this cycle is to be to the next generation of ASW and early-warning aircraft, where this type of engine's ability to develop its peak thermal efficiency when throttled to 50 to 80 per cent power gives a low s.f.c. (specific fuel consumption) for long-endurance patrolling. Designated the Allison Model 545 (military, T78), the new engine will be rated at 4,000 s.h.p."

A test rig was created using a modified T56-A-7. An over-sized test regenerator was developed by AiResearch. The weight of this test regenerator was 320 lbs (for "400 lbs/hr fuel savings").

"The T78 resembles the T56 in being a single-shaft engine incorporating a 14-stage axial compressor and a four-stage turbine, and in having a cannular combustion chamber with six flame tubes. as in the earlier engine, the propellor reduction gear is carried remotely with a triagulated tubular brace, and driven through an extension shaft ...

... The hot gases from the turbine flow into a tailpipe, in inner wall of which is a tapered cone and the outer wall the tube block of the heat exchanger, which when closed diverts the exhaust gases into the regenerator and when open gives the greater part of the gases free passage. The T78 is thus a dual-purpose engine; it may be used either for maximum economy at reduced, but regenerated, cruising powers, or it can be opened up for high output at take-off, or attack, or for high-altitude operation where s.f.c. is normally better in any case."

-----------------

Curtiss-Wright Abstract

THE EVALUATION OF A LIQUID METAL REGENERATOR FOR A 3750 HP TURBOPROP ENGINE, 15 MAY 1963

Abstract : The feasibility of a liquid metal heat exchange system as a versatile, high reliability component meeting the compactness and high performance characteristics required for the Navy's regenerative turboprop engine has been demonstrated.

http://stinet.dtic.mil/oai/oai?verb=getRecord&metadataPrefix=html&identifier=AD0407471

-----------------

http://www.flightglobal.com/pdfarchive/view/1964/1964%20-%202849.html

Around the same time, Curtiss-Wright were working on a similar concept and, in 1966, GE mentions regenerative turboprops in a patent application.

Some snippets and images from the Flight article follow. Does anyone know if there was later (or current) work done on regenerative turboprops?

--------------------

From Flight

"Allison Division of General Motors is currently working on a $60m US Navy contract for the design and development of a regenerative turboprop, in which a proportion of the waste heat in the exhaust is recovered through a heat exchanger. The application of this cycle is to be to the next generation of ASW and early-warning aircraft, where this type of engine's ability to develop its peak thermal efficiency when throttled to 50 to 80 per cent power gives a low s.f.c. (specific fuel consumption) for long-endurance patrolling. Designated the Allison Model 545 (military, T78), the new engine will be rated at 4,000 s.h.p."

A test rig was created using a modified T56-A-7. An over-sized test regenerator was developed by AiResearch. The weight of this test regenerator was 320 lbs (for "400 lbs/hr fuel savings").

"The T78 resembles the T56 in being a single-shaft engine incorporating a 14-stage axial compressor and a four-stage turbine, and in having a cannular combustion chamber with six flame tubes. as in the earlier engine, the propellor reduction gear is carried remotely with a triagulated tubular brace, and driven through an extension shaft ...

... The hot gases from the turbine flow into a tailpipe, in inner wall of which is a tapered cone and the outer wall the tube block of the heat exchanger, which when closed diverts the exhaust gases into the regenerator and when open gives the greater part of the gases free passage. The T78 is thus a dual-purpose engine; it may be used either for maximum economy at reduced, but regenerated, cruising powers, or it can be opened up for high output at take-off, or attack, or for high-altitude operation where s.f.c. is normally better in any case."

-----------------

Curtiss-Wright Abstract

THE EVALUATION OF A LIQUID METAL REGENERATOR FOR A 3750 HP TURBOPROP ENGINE, 15 MAY 1963

Abstract : The feasibility of a liquid metal heat exchange system as a versatile, high reliability component meeting the compactness and high performance characteristics required for the Navy's regenerative turboprop engine has been demonstrated.

http://stinet.dtic.mil/oai/oai?verb=getRecord&metadataPrefix=html&identifier=AD0407471

-----------------