KJ_Lesnick

ACCESS: Top Secret

- Joined

- 13 February 2008

- Messages

- 1,042

- Reaction score

- 97

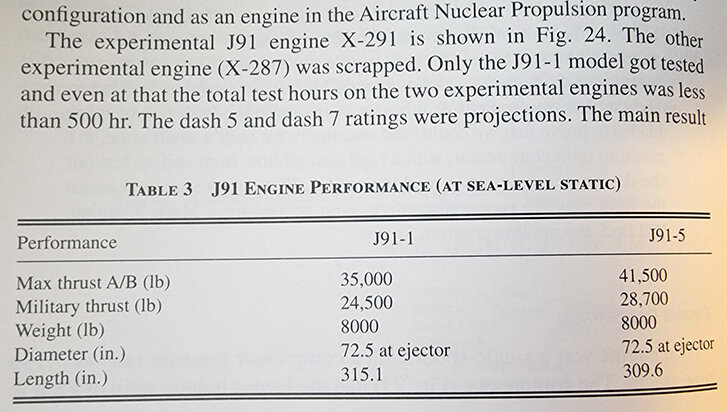

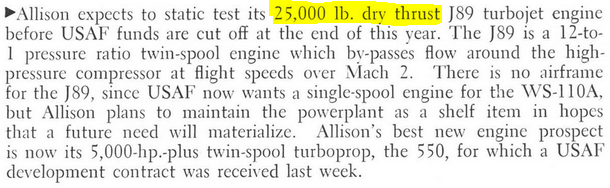

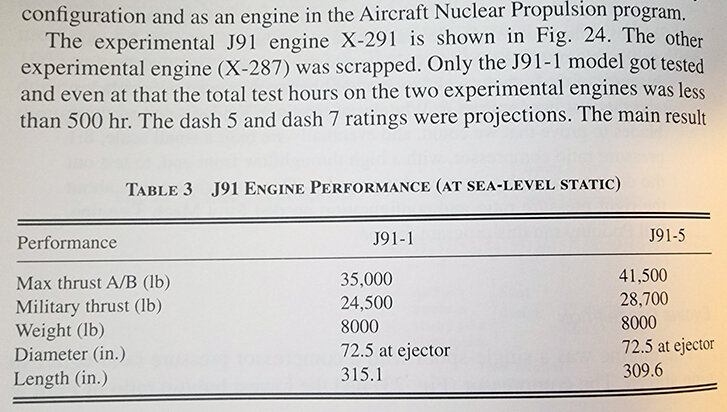

Normally, I would just look through my books but I don't have very much information about the J-91 other than it had a 9-stage compressor, a twin-stage turbine, a 7:1 pressure-ratio, a trans-sonic compressor, a 55-inch diameter, and that the J-58 was an 80% scaled down version with a higher pressure-ratio and a variable IGV to lower it's (the J-58's) pressure-ratio at high supersonic speeds, and that it had an afterburner that could burn either JP-4 or HEF-3 -- Plus I've heard conflicting data regarding the thrust output of the J-93's from 27,000 lbf to 31,500 lbf

I'm wondering the following questions...

1.) How the thrust levels of the J-91 using conventional fuel (JP-4 in combustor and afterburner) compared to the J-93 GE-1 using conventional fuel (JP-4 in combustor and afterburner)?

2.) How the thrust levels of the J-91 using conventional fuel (JP-4 in combustor and afterburner) compared to the J-93 GE-3 using conventional fuel (JP-4 in combustor and afterburner)?

3.) How the thrust levels of the J-91 using conventional fuel (JP-4 in combustor and afterburner) compared to the J-93 GE-3 using JP-6 (in both combustor and afterburner)?

4.) How the thrust levels of the J-91 using high-energy fuel in afterburner compared to the J-93 GE-1 using high energy fuel in the afterburner?

5.) How the thrust levels of the J-91 using high-energy fuel in afterburner compared to the J-93 GE-5 (GE-3 used only JP-4 or JP-6) using high-energy fuel in the afterburner?

KJ Lesnick

I'm wondering the following questions...

1.) How the thrust levels of the J-91 using conventional fuel (JP-4 in combustor and afterburner) compared to the J-93 GE-1 using conventional fuel (JP-4 in combustor and afterburner)?

2.) How the thrust levels of the J-91 using conventional fuel (JP-4 in combustor and afterburner) compared to the J-93 GE-3 using conventional fuel (JP-4 in combustor and afterburner)?

3.) How the thrust levels of the J-91 using conventional fuel (JP-4 in combustor and afterburner) compared to the J-93 GE-3 using JP-6 (in both combustor and afterburner)?

4.) How the thrust levels of the J-91 using high-energy fuel in afterburner compared to the J-93 GE-1 using high energy fuel in the afterburner?

5.) How the thrust levels of the J-91 using high-energy fuel in afterburner compared to the J-93 GE-5 (GE-3 used only JP-4 or JP-6) using high-energy fuel in the afterburner?

KJ Lesnick